RASOR FP861/A1 Mounting instructions

Other RASOR Cutter manuals

RASOR

RASOR GRT12SM Mounting instructions

RASOR

RASOR DD120L User manual

RASOR

RASOR FP120M User manual

RASOR

RASOR FP861V2 Mounting instructions

RASOR

RASOR DS503MT Mounting instructions

RASOR

RASOR SW12SM Mounting instructions

RASOR

RASOR GRT10L Mounting instructions

RASOR

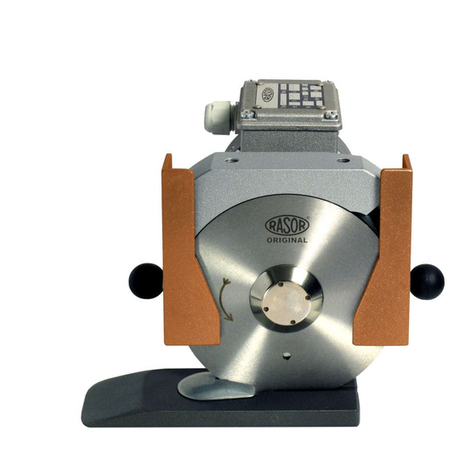

RASOR DD120R User manual

RASOR

RASOR SW12SSX User manual

RASOR

RASOR GRT-MINI Mounting instructions

RASOR

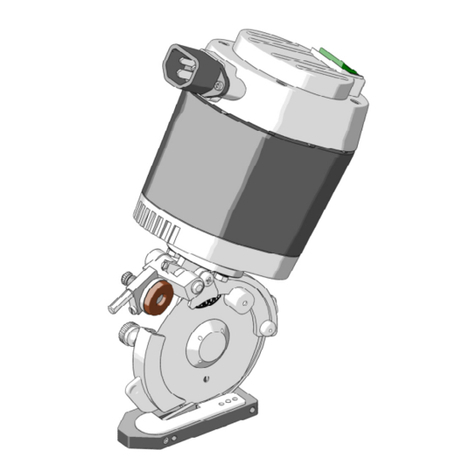

RASOR FP861V User manual

RASOR

RASOR SW100 Mounting instructions

RASOR

RASOR FP503 Mounting instructions

RASOR

RASOR FP100L User manual

RASOR

RASOR DD120DT User manual

RASOR

RASOR FORZA Operation instructions

RASOR

RASOR DS503 Mounting instructions

RASOR

RASOR SW100S Mounting instructions

RASOR

RASOR SW12M Mounting instructions

RASOR

RASOR FP862MT Mounting instructions

Popular Cutter manuals by other brands

Bosch

Bosch POF 1400 ACE Original instructions

SignWarehouse.com

SignWarehouse.com Bobcat BA-60 user manual

Makita

Makita 4112HS instruction manual

GEISMAR STUMEC

GEISMAR STUMEC MTZ 350S manual

Hitachi

Hitachi CM 4SB2 Safety instructions and instruction manual

Dexter Laundry

Dexter Laundry 800ETC1-20030.1 instruction manual