Reison 10-380-KL User manual

Other Reison Medical Equipment manuals

Reison

Reison 10-383 User manual

Reison

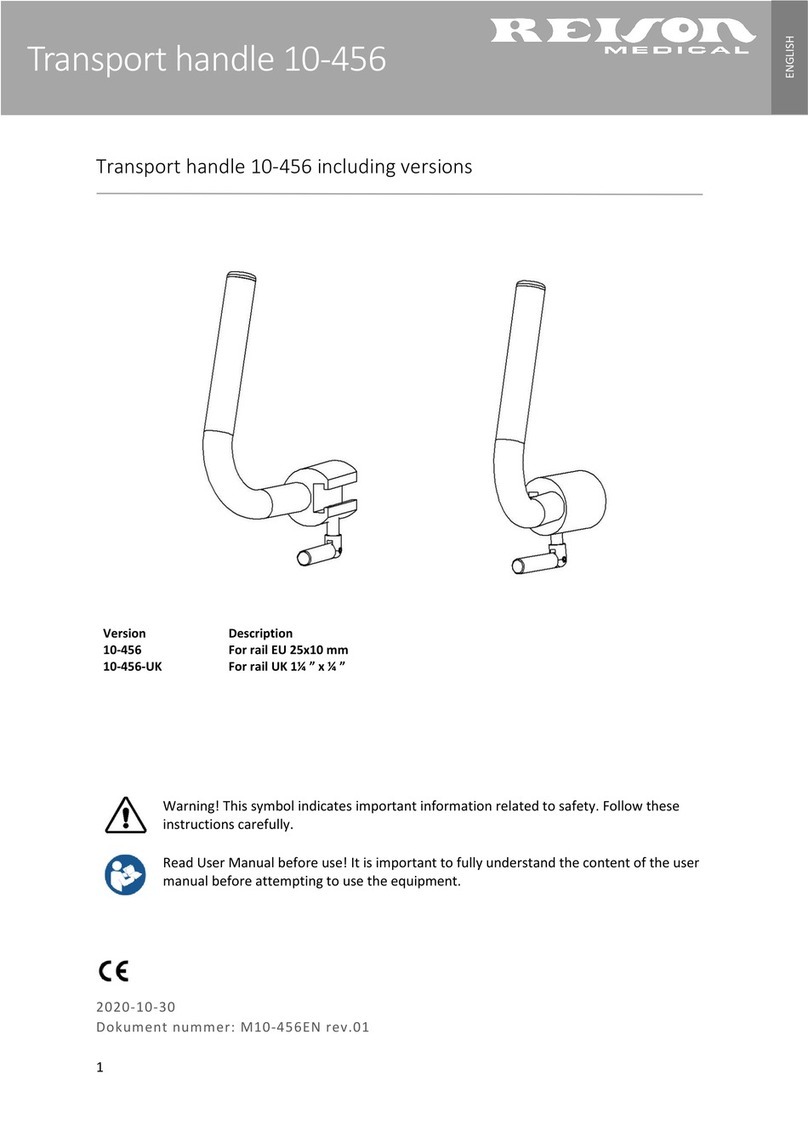

Reison 10-456 User manual

Reison

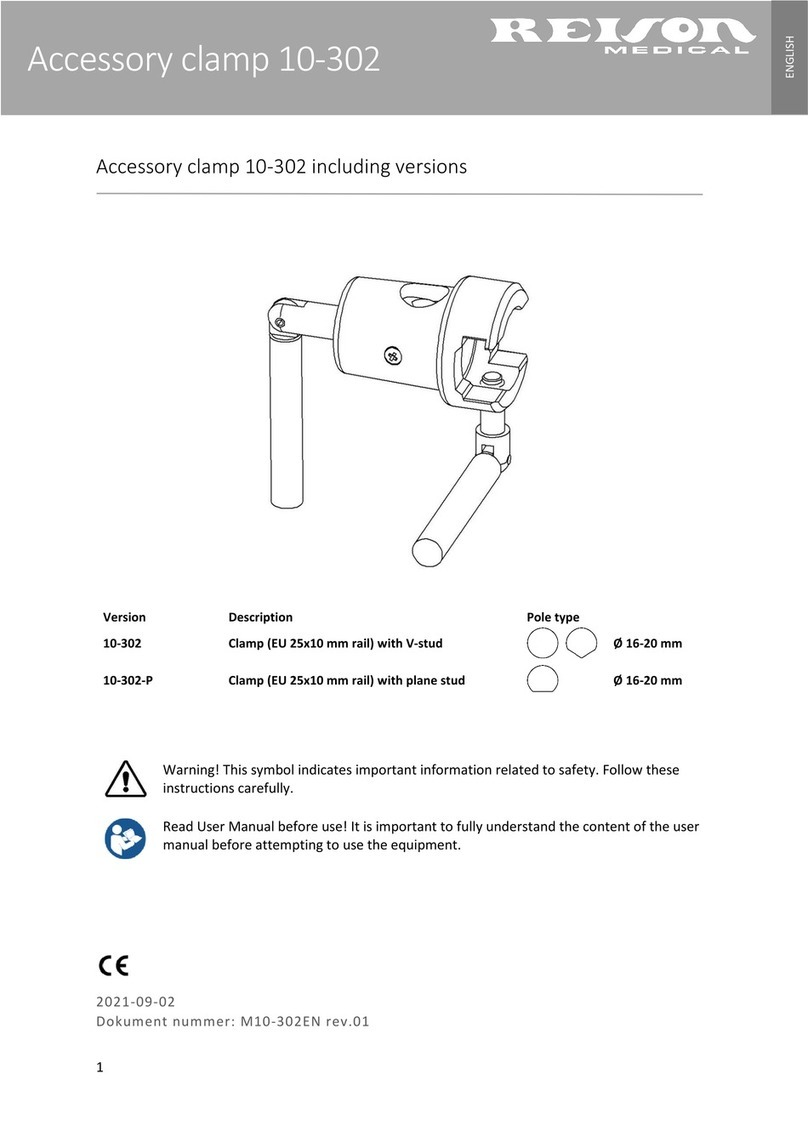

Reison 10-302 User manual

Reison

Reison 10-305 User manual

Reison

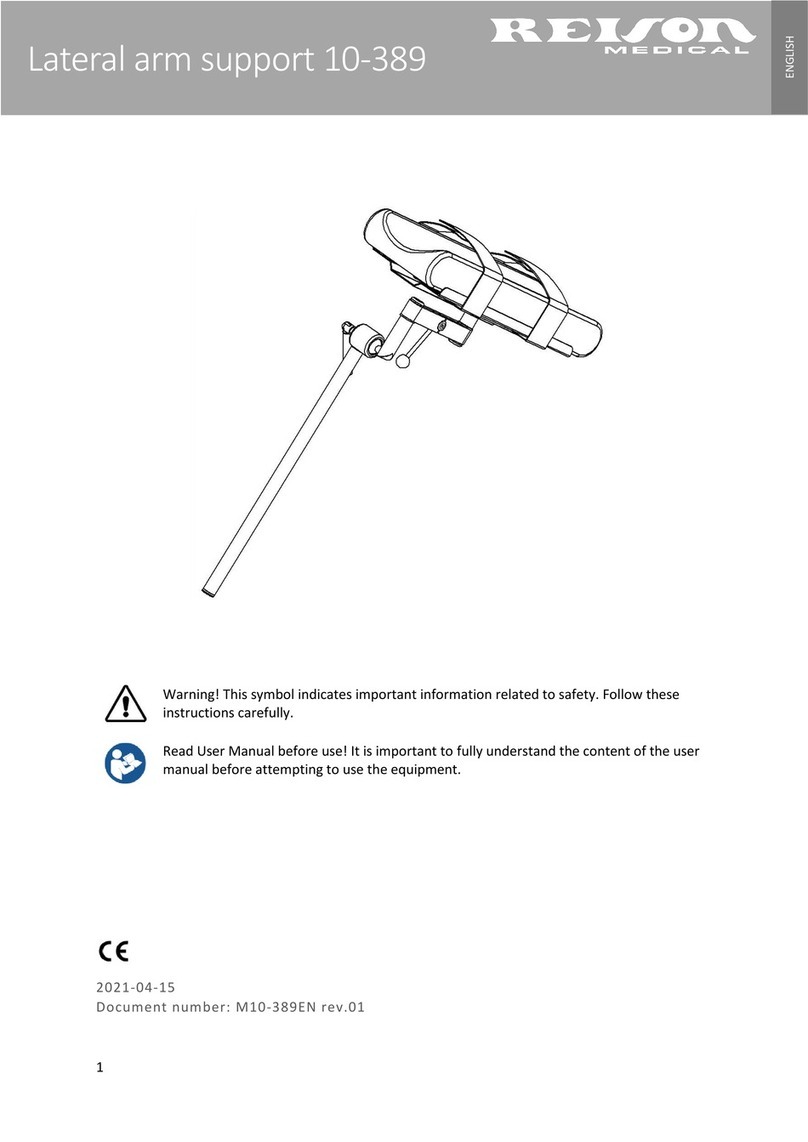

Reison 10-389 User manual

Reison

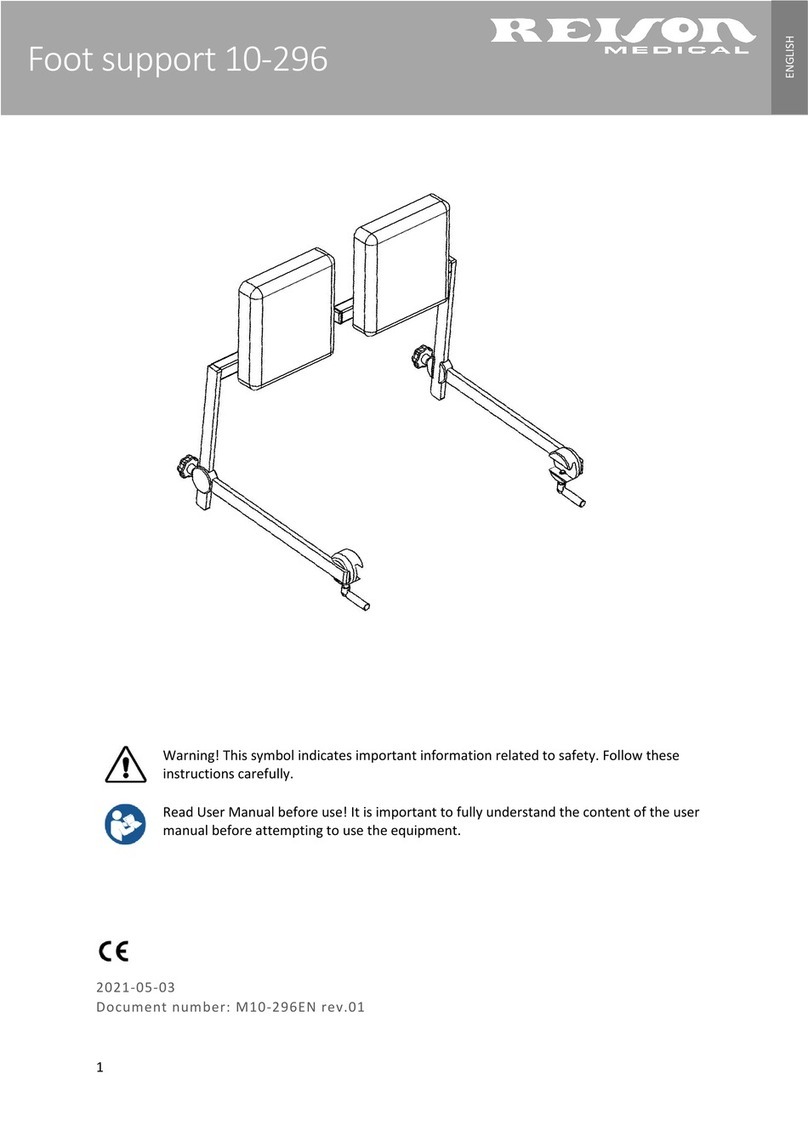

Reison 10-296 Installation instructions

Reison

Reison 10-393 User manual

Reison

Reison 10-380-K User manual

Reison

Reison Nordiska 10-380 User manual

Reison

Reison 10-390-K User manual

Reison

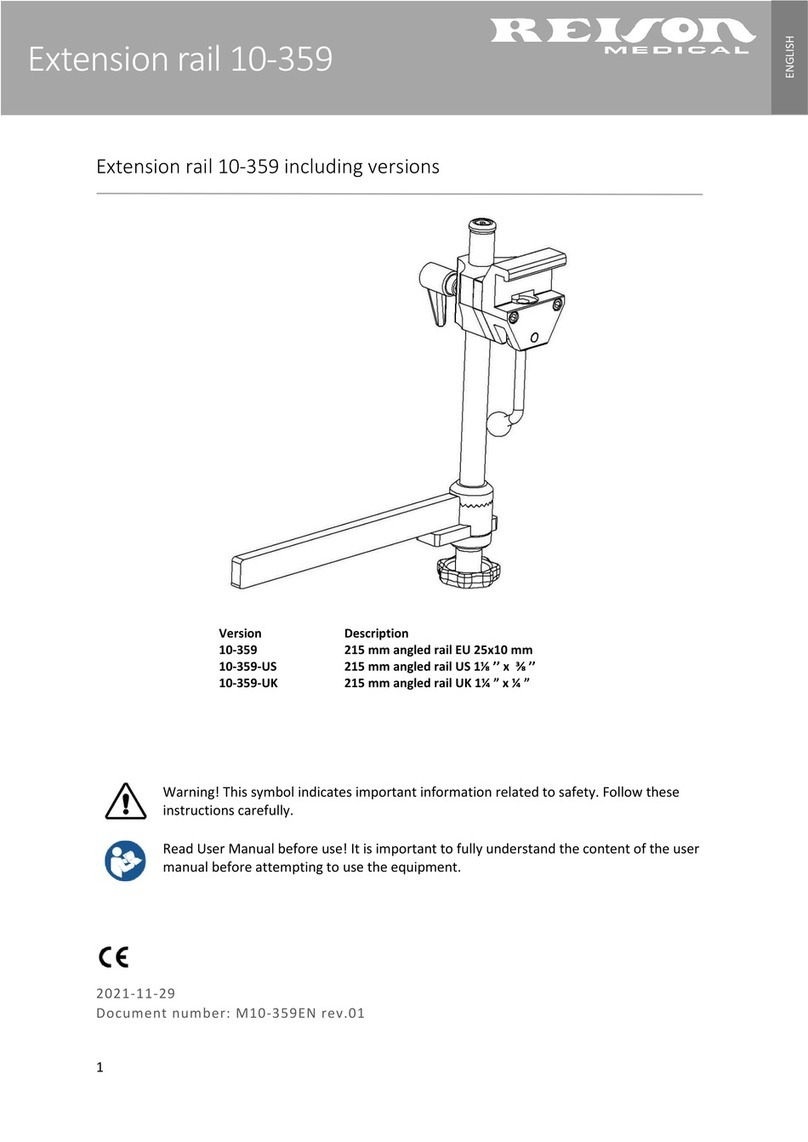

Reison 10-359 User manual

Reison

Reison Nordiska 10-389 User manual

Reison

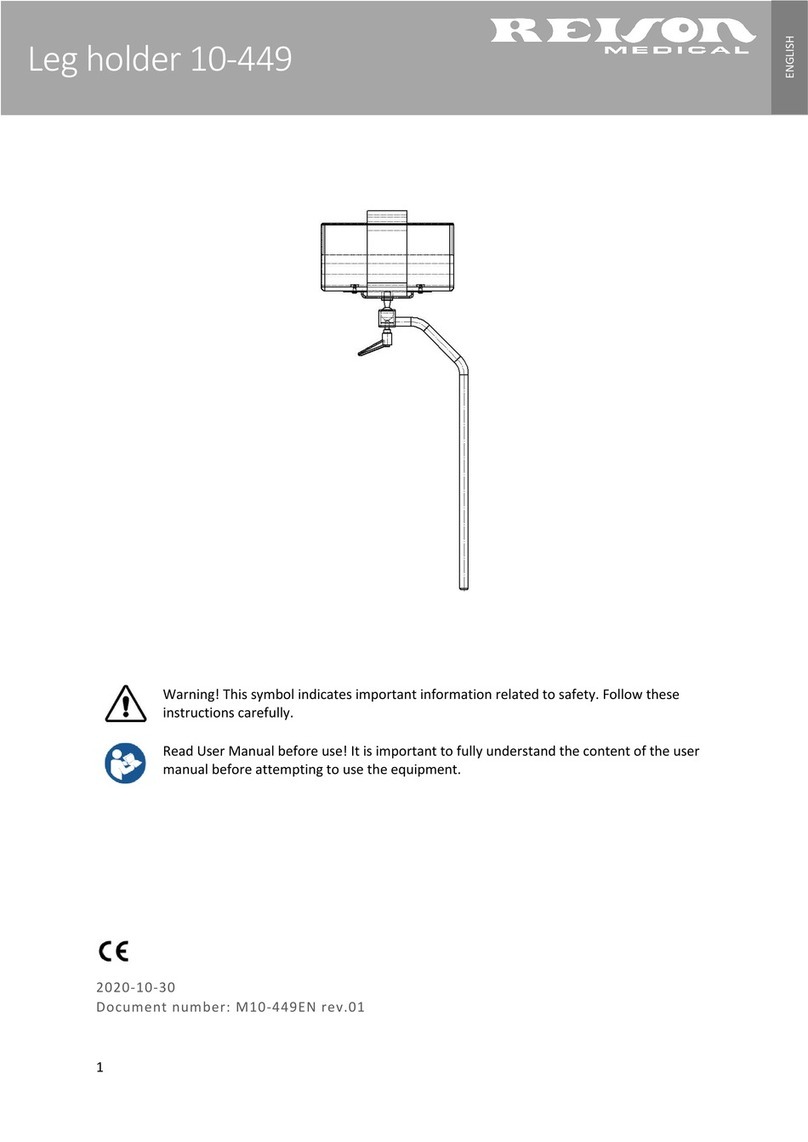

Reison 10-449 User manual

Reison

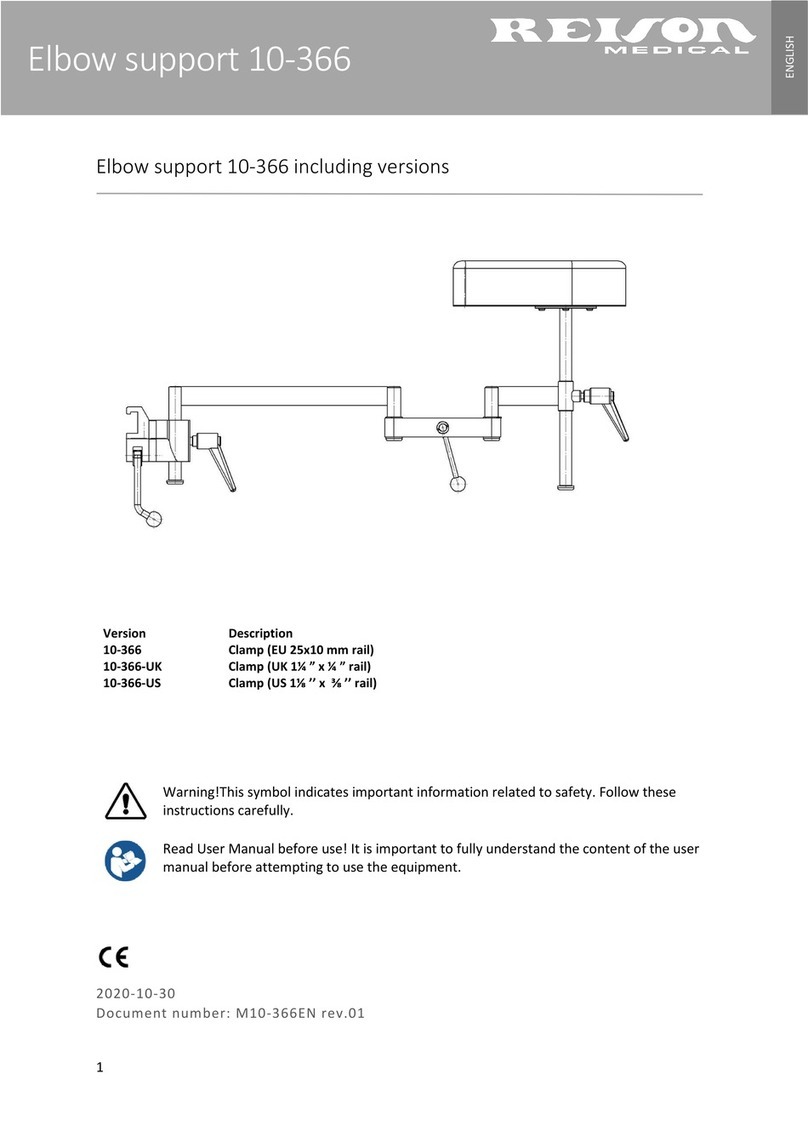

Reison 10-366 User manual

Reison

Reison 10-359 User manual

Reison

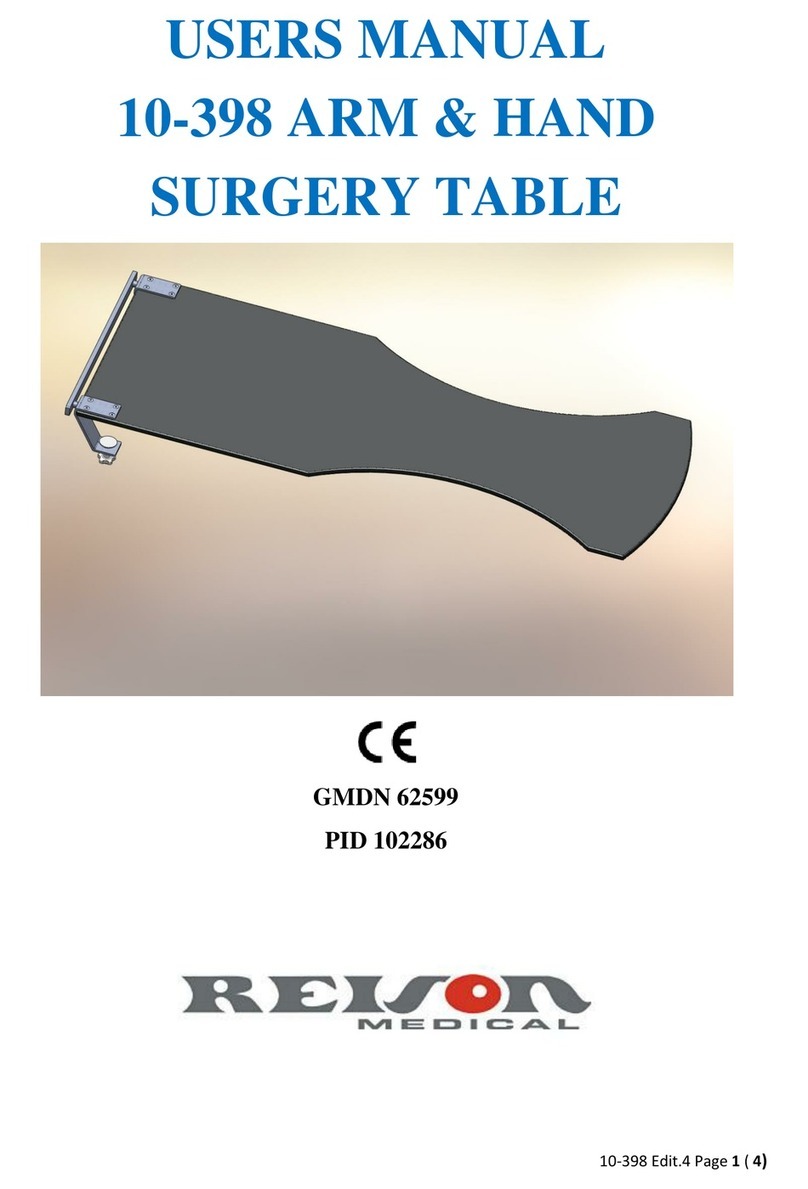

Reison 10-398 User manual

Reison

Reison 10-302 User manual

Reison

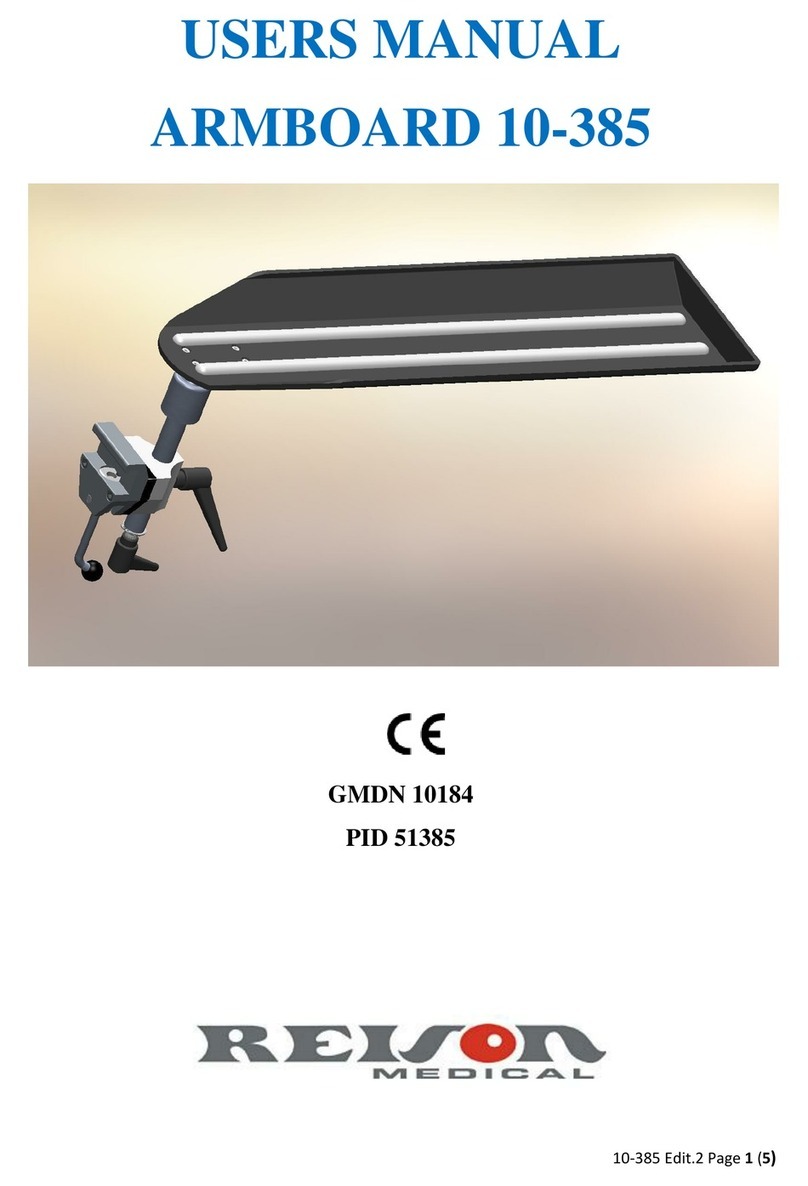

Reison ARMBOARD 10-385 User manual

Reison

Reison MEDICAL 10-304 User manual

Reison

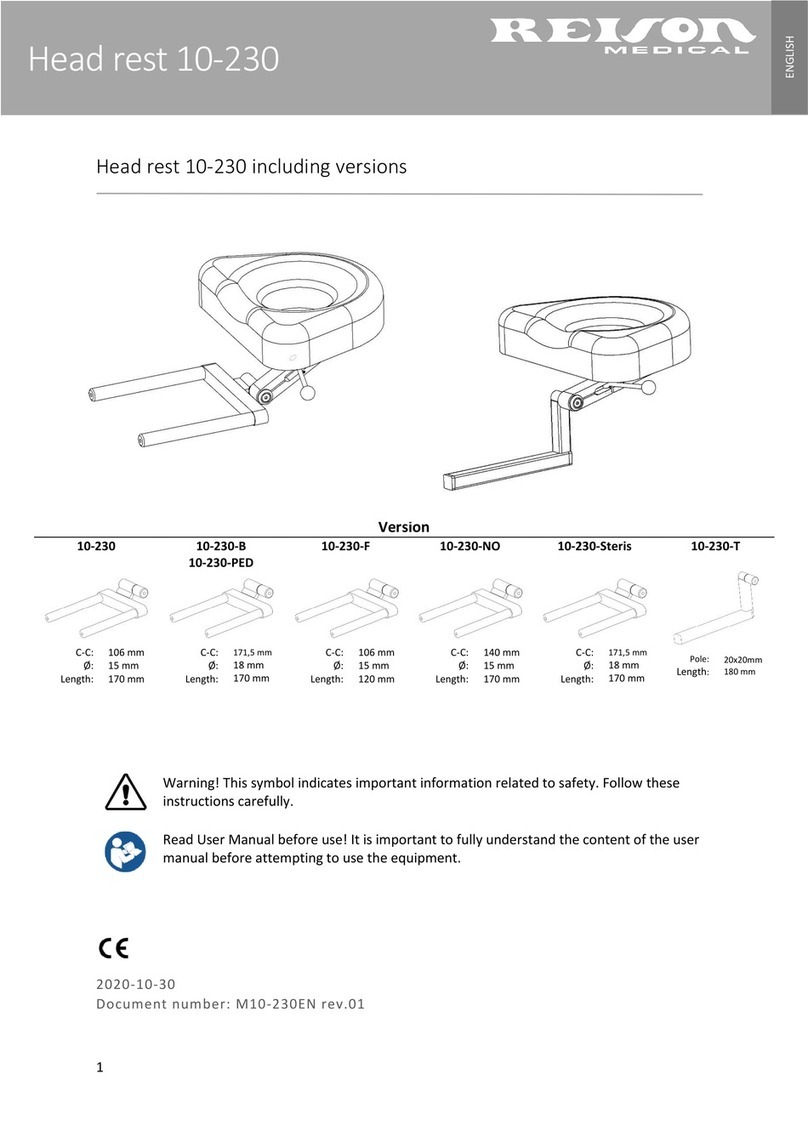

Reison 10-230 Installation instructions

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual