4 INT-KNX-2 SATEL

4. If the module is to supervise the enclosure tamper contact, connect the wires of tamper

contact to the TMP and COM terminals. If the module is not to supervise the enclosure

tamper contact, connect the TMP terminal to the module COM terminal.

5. Connect the module to the KNX bus.

6. Connect the power leads to the +12 V and COM terminals. If the distance to the control

panel is less than 300 meters, the module can be supplied directly from the control panel.

If the distance to the control panel is higher, the module must be supplied from another

power source, which is located at a closer distance (a power supply unit or an expander

with power supply).

6 Module identification

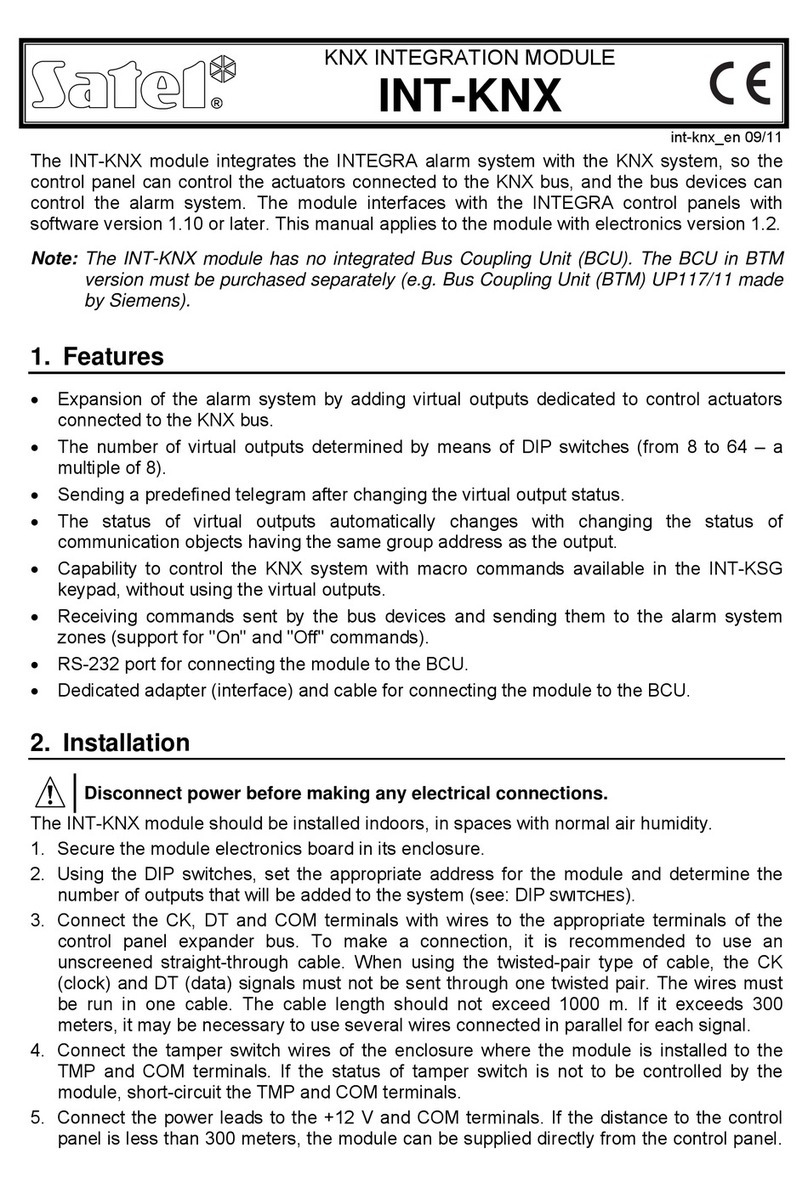

The control panel does not support the modules which have not been identified, therefore

you must run the identification function after completion of the installation and power-up of

the alarm system. You can do it by means of:

LCD keypad: SERVICE MODE STRUCTURE HARDWARE IDENTIFICATION EXPANDERS ID.,

D

LOADX program: “Structure” window “Hardware” tab “Expansion modules” branch

“Exp. modules identification” button.

During the identification procedure, a number of outputs in the system, determined by means

of DIP switches, is assigned to the module, and additional addresses are allocated if the

number of outputs is greater than 8.

The control panel monitors presence of the identified modules. If the module is disconnected

from communication bus, position of DIP-switches is changed, or the device is replaced with

another one with DIP-switches set in the same way, a tamper alarm will be triggered.

7 Configuring the module

You can configure the module by means of the DLOADX program (version 1.13.008 or newer):

“Structure” window “Hardware” tab “Expansion modules” branch [module name].

Some of the parameters and options are stored in the control panel memory, and some of

them in the module memory. After clicking on the button in the main menu, the data

are only read from the control panel. Before you proceed to programming, the data must also

be read from the module. After clicking on the module name, the program may prompt you to

read these data. Otherwise, click on the “Read” button (see Fig. 3).

After programming is completed, click on the “Write” button to write the data to the module,

and on the button to write the data to the control panel.

7.1 Description of parameters and options

Name – individual name of the device (up to 16 characters).

Physical address – address of the INT-KNX-2 module.

KNX comm. delay after reset – the time that must elapse after starting the module, before

the module begins sending KNX telegrams.

Two level address – if the option is enabled, the address has a two-level structure. If the

option is disabled, the address structure is three-level.

Trouble if KNX bus disconnected – if the option is enabled, the module will report a trouble

after loss of communication with the KNX bus.