MX-LCX5 SPECIFICATIONS 1 – 1

MX-LCX5 Service Manual

[1] SPECIFICATIONS

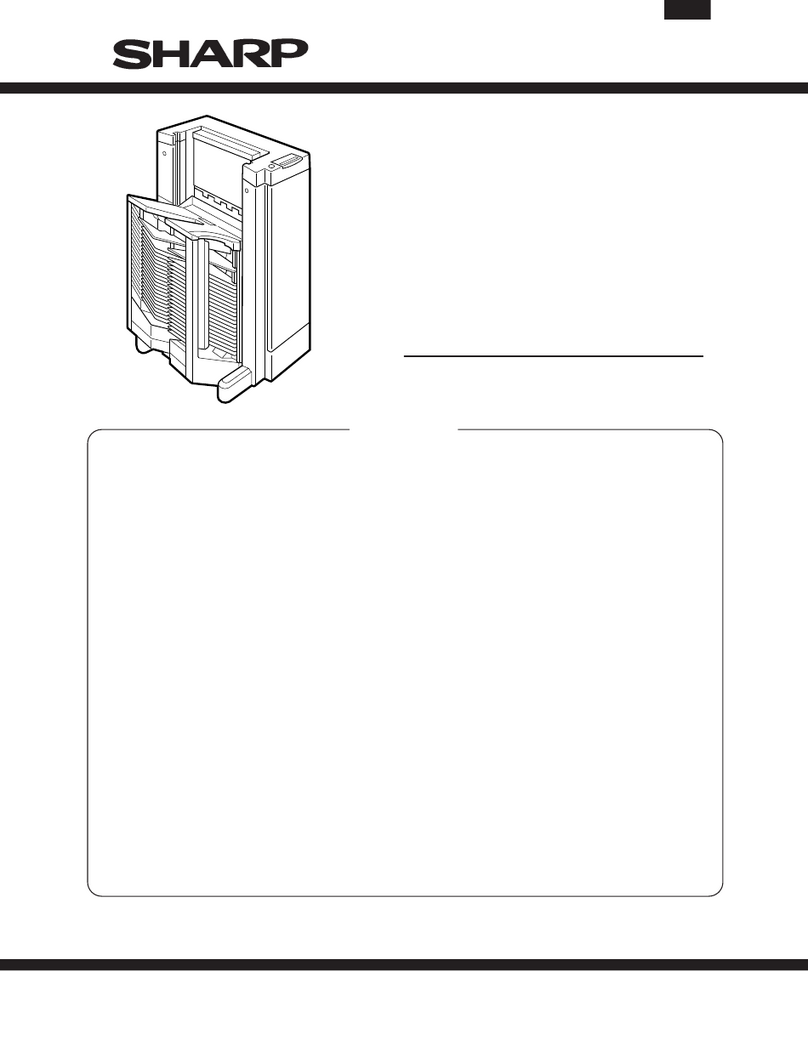

Form Large Capacity Trays (3 Trays)

Transport speed 85 – 110 sheets/minute to be supported

Transport standard Center alignment

Paper size Auto-AB: A3W, A4W, A3, B4, A4, A4R*, B5, B5R, A5R, 8.5 x 13*

Auto-Inch: 12 x 18, 11 x 17, 9 x 12, 8.5 x 14*, 8.5 x 13.4*, 8.5 x 11, 8.5 x 11R*, 7.25 x 10.5R, 5.5 x 8.5R

Manual: 318 x 469.5 mm, 318 x 234.75 mm, 312.5 x 440 mm, 312.5 x 220 mm

SRA3 (320 x 450 mm), SRA4 (320 x 225 mm) 8K, 16K, 16KR, Postcard

Custom Size: Main scanning: 100 – 320 mm (4.0 – 12.5)

Sub scanning: 140 – 470 mm (5.5 – 18.5)

*: As automatic detection, 8.5 x 11R/8.5 x 14/8.5 x 13.4 and A4R/8.5 x 13/8.5 x 13.4 is exclusion. Refer to the attached table.

Paper size label Available

Paper size setting Upper tray: User settings

Middle tray: User settings

Lower tray: User settings

Paper size setting for shipment Inch: 11 x 17

AB: A3

Feedable paper size/weight Upper tray: 52 – 205 g/m2/ 16 lbs Bond – 110 lbs Index

Middle tray: 52 – 300 g/m2/ 16 lbs Bond – 170 lbs Index

Lower tray: 52 – 205 g/m2/ 16 lbs Bond – 110 lbs Index

Paper type Plain paper, Heavy paper, Recycled paper, Thin paper, Pre-printed paper, Letter head, Punched paper, Transparency paper,

Colored paper, Tab paper, Label paper (Available only for the Offset tray)

Paper capacity Standard Paper

Upper tray / Lower tray: 1,000 sheets

Middle tray: 2,000 sheets

(80 g/m2)

Detection of remaining paper Available level detection (5 levels)

Upper tray / Lower tray: 100%, 75%, 50%, 25%, Empty

Middle tray: 100%, 75%, 50%, 25%, Empty

* Detection error 3%

Paper supply Paper supply from the upper section by the front loading method

Tray rising/falling time Rising Upper tray / Lower tray: 9 seconds or less

Middle tray: 24 seconds or less

Time required from tray insertion to empty detection without paper

Falling Self-weight falling

Reliability MCBJ in compliance with the main unit

MCBF

Life 5 years or 24,000K

Power consumption 150W or less

Power source DC24V Supplied by the main unit

Dimensions W 878 x D 729 x H 980 mm

Occupied dimension W 880 x D 730

Weight Approximately 175 kg

Installation/Maintenance By service person

Heater AC 18W x 2 36W (By service parts: 0PQC4180431//)