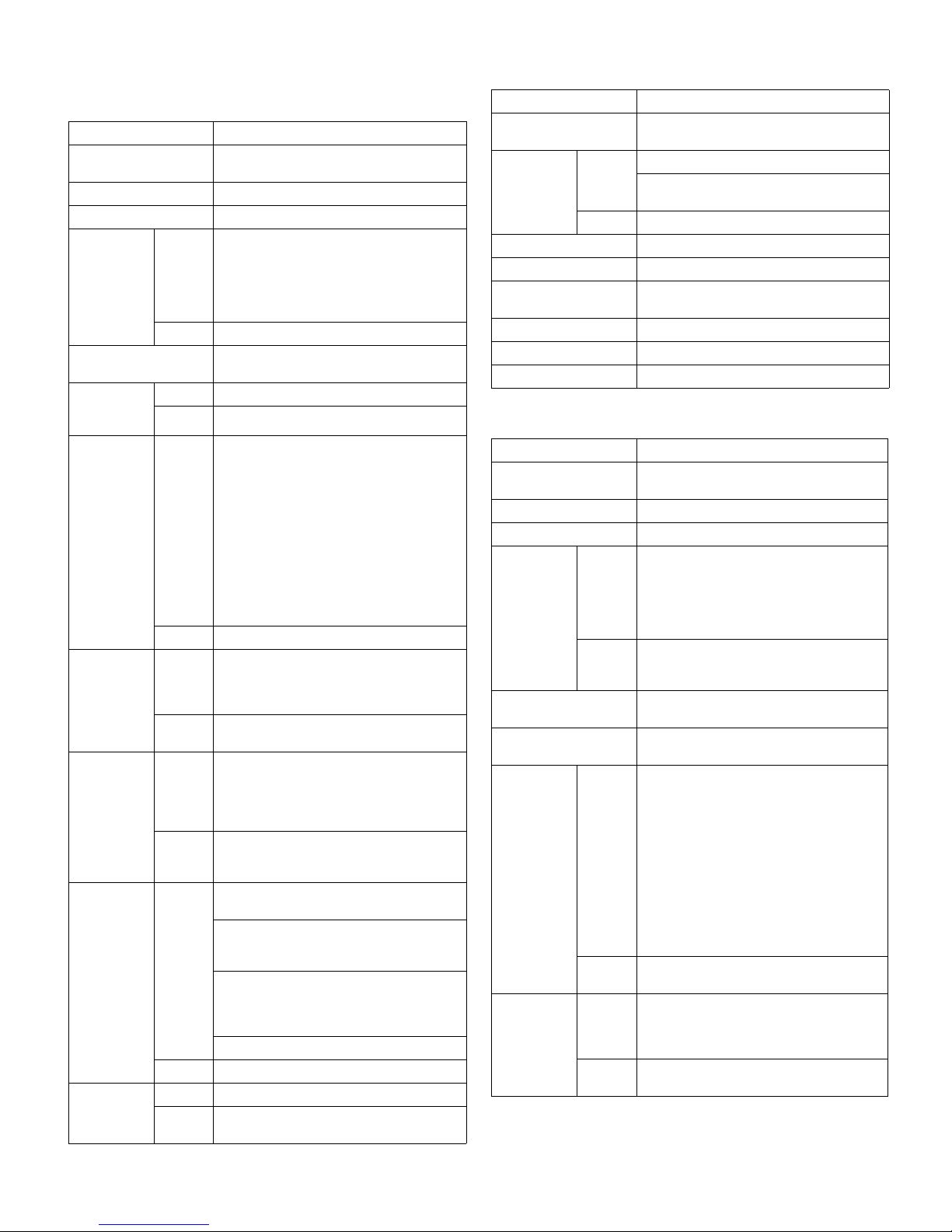

AR-D28/D27/MU2 SPECIFICATIONS

3 – 1

[3] SPECIFICATIONS

1. AR-D28

2. AR-D27

AR-D28

Type Stand MPD&2000 Sheet Paper Drawer

(large capacity tray + multi purpose drawer)

Transport speed To support 35-45 sheet/minute

Transport alignment Center alignment

Paper size 1 Tray A3, B4, A4, A4R, B5, B5R, A5R

11"x17", 8.5"x14", 8.5"x13", 8.5"x11",

8.5"x11"R, 5.5"x8.5"R

Executive, Japanese p/c, Monarch(envelope)

Com-10(envelope), DL(envelope),

C5(envelope), ISO B5(envelope)

2 Tray A4, 8.5" x 11"

How to change

the paper size Guide adjustment by user/

Software setting by user

Factory

default paper

size setting

1 Tray 8.5" x 11"

2 Tray The size guide plate is packed together.

Media avail-

able for paper

feeding

1 Tray Plain paper : 60-128g/m² / 16-34lbs

Index paper : 176g/m² / 47lbs

Cover paper : 200-205g/m² / 54-55lbs

Envelope : 75-90g/m², 20-24lbs

Transparency film

*Media heavier than 105g/m² should be

A4/8.5x11" or smaller. Media heavier than

128g/m² should be fed from shorter edge.

*Only single paper feed is enabled for over-

lay copy or copy on back-side of printed

paper.

2 Tray Plain 60-105g/m² / 16-28lbs

Paper capacity

1 Tray Standard: 500sheets(80g/m²)

Post card: 40sheets

Envelope: 40sheets

Transparency film: 40sheets

2 Tray 880+1,320sheets (64g/m²) /

800+1,200sheets (80g/m²)

Paper type 1 Tray Plain, recycled, pre-printed, pre-punched,

color, letter head, labels, heavy, transpar-

ency, Japanese p/c, envelope

(User can set bi-type for each of the above

paper type.)

2 Tray Plain, recycled, pre-printed, pre-punched,

color, letter head (User can set bi-type for

each of the above paper type.)

Sizes to be

detected 1 Tray Auto detection-AB:

A3, B4, A4, A4R, B5, B5R, 8.5"x13", A5R

Auto detection-Inch:

11"x17", 8.5"x14", 8.5"x11", 8.5"x11"R,

7.25"x10.5"R, 5.5" x 8.5R

Manual (input detection):

postal card, Monarch(envelope),

Com-10(envelope), DL(envelope),

C5(envelope), ISO B5(envelope)

Ignore detection selectable:

2 Tray Size setting by the serviceman

Paper bal-

ance detec-

tion

1 Tray Provided (paper empty and 3 steps)

2 Tray Enable (Paper empty and

6 steps (3 steps + 3 steps))

Paper loading system To be loaded from the upper side with

front loading system

Tray ascent/

descent time Ascent Within 12 seconds

At paper empty, required time from

tray insert to the empty detection

Descent Own weight descent

Dehumidification heater Not provided

Power consumption 32.2W or lower

Power source Supplied from main unit

(DC24V 1.3A / DC5V 0.2A)

External dimensions 589 x 630 x 404 (mm)

Occupied dimensions 963 x 665 (mm)

Weight Approx. 34kg

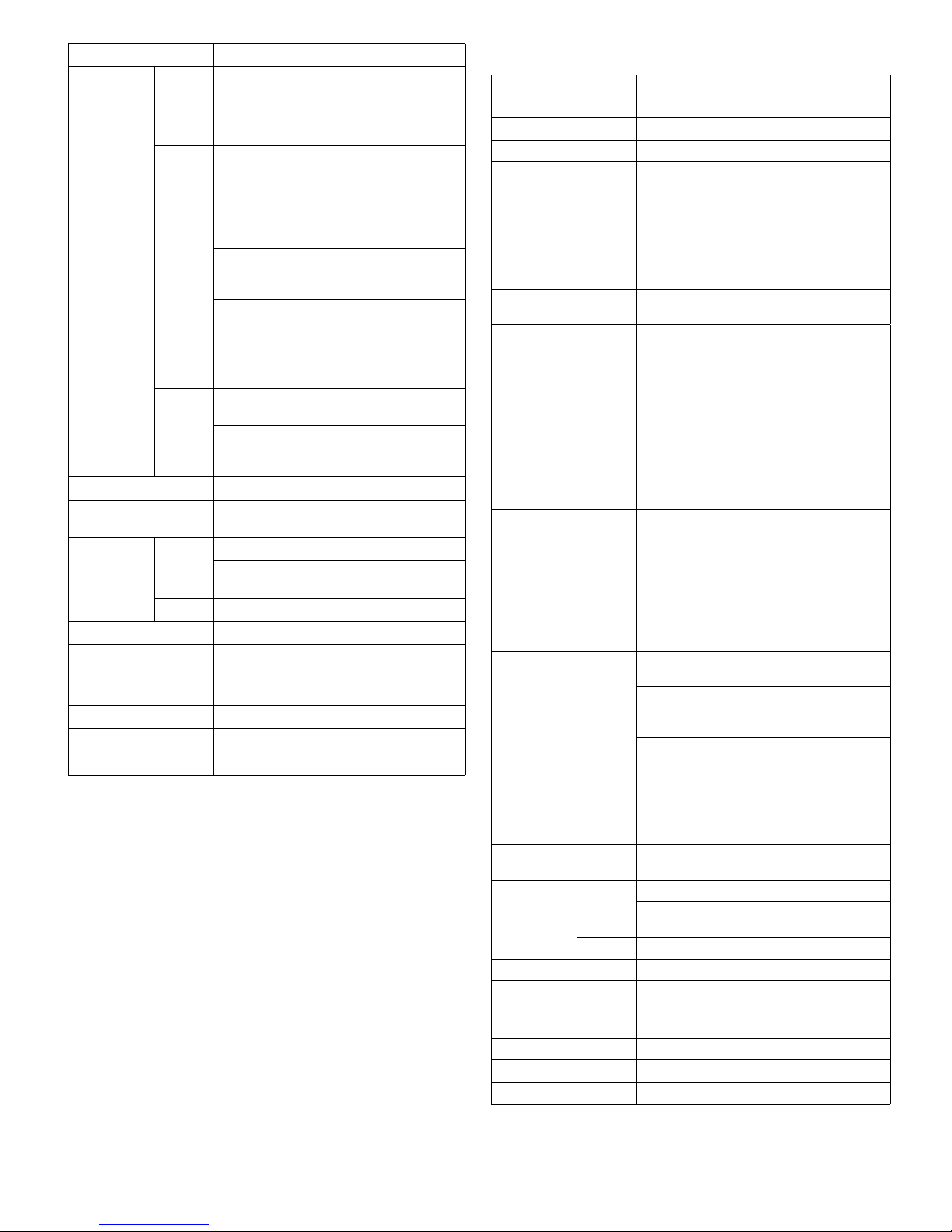

AR-D27

Type Stand /3x500 Sheet Paper Drawer

(2 paper trays + 1 multi purpose drawer)

Transport speed To support 35-45 sheet/minute

Transport alignment Center alignment

Paper size 1 Tray A3, B4, A4, A4R, B5, B5R, A5R

11"x17", 8.5"x14", 8.5"x13", 8.5"x11",

8.5"x11"R, 5.5"x8.5"R

Executive, Japanese p/c,Monarch(envelope)

Com-10 (envelope), DL (envelope),

C5 (envelope), ISO B5 (envelope)

2 or 3

Tray A3, B4, A4, A4R, B5, B5R

11"x17", 8.5"x14", 8.5"x13", 8.5"x11",

8.5"x11"R, 7.25"x10.5"R

How to change the

paper size Unit is delivered with paper guide set at max.

position in width. (Both of two cassettes.)

Factory default paper

size setting To be set to maximum paper guide width at

factory default status (for both trays)

Media avail-

able for paper

feeding

1 Tray Plain paper : 60-128g/m² / 16-34lbs

Index paper : 176g/m² / 47lbs

Cover paper : 200-205g/m² / 54-55lbs

Envelope : 75-90g/m², 20-24lbs

Transparency film

*Media heavier than 105g/m² should be

A4/8.5x11" or smaller.

Media heavier than 128g/m² should be

fed from shorter edge.

*Only single paper feed is enabled for

overlay copy or copy on back-side of

printed paper.

2 or 3

Tray Plain 60-105g/m²/16-28lbs

Paper capacity

1 Tray Standard:500sheets(80g/m²)

Post card:40sheets

Envelope:40sheets

Transparency film:40sheets

2 or 3

Tray Standard paper:500sheets x 2 (64g/m²)

AR-D28