[5] OPERATIONAL DESCRIPTION

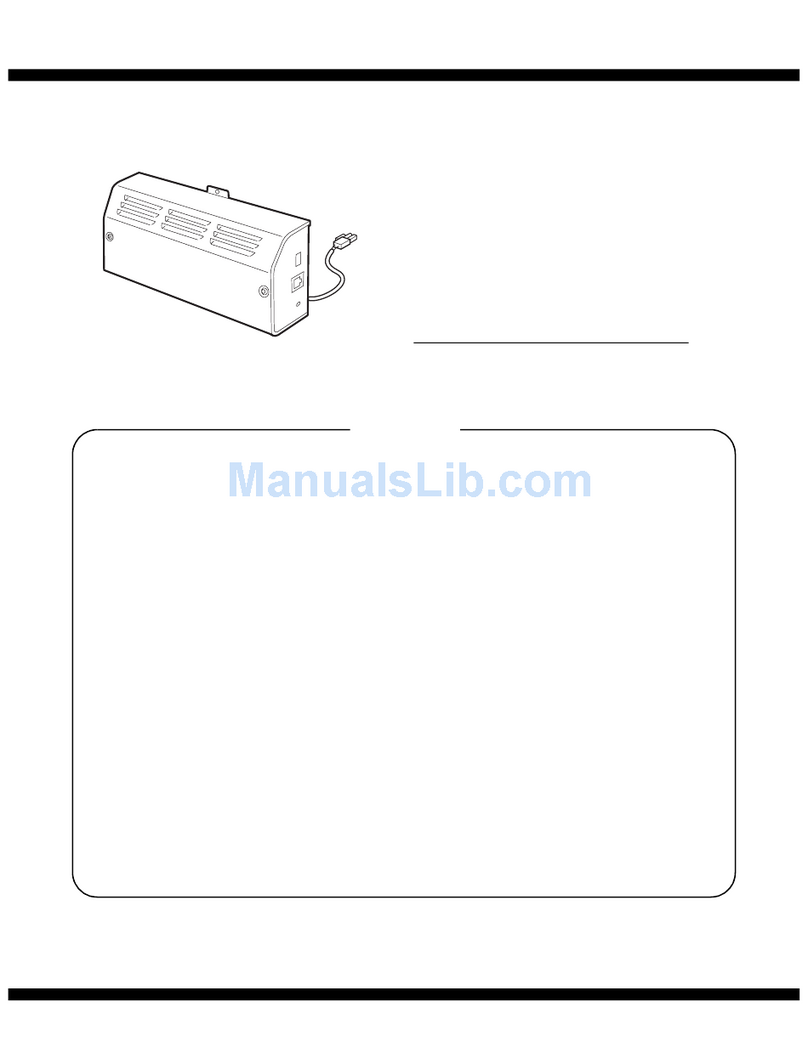

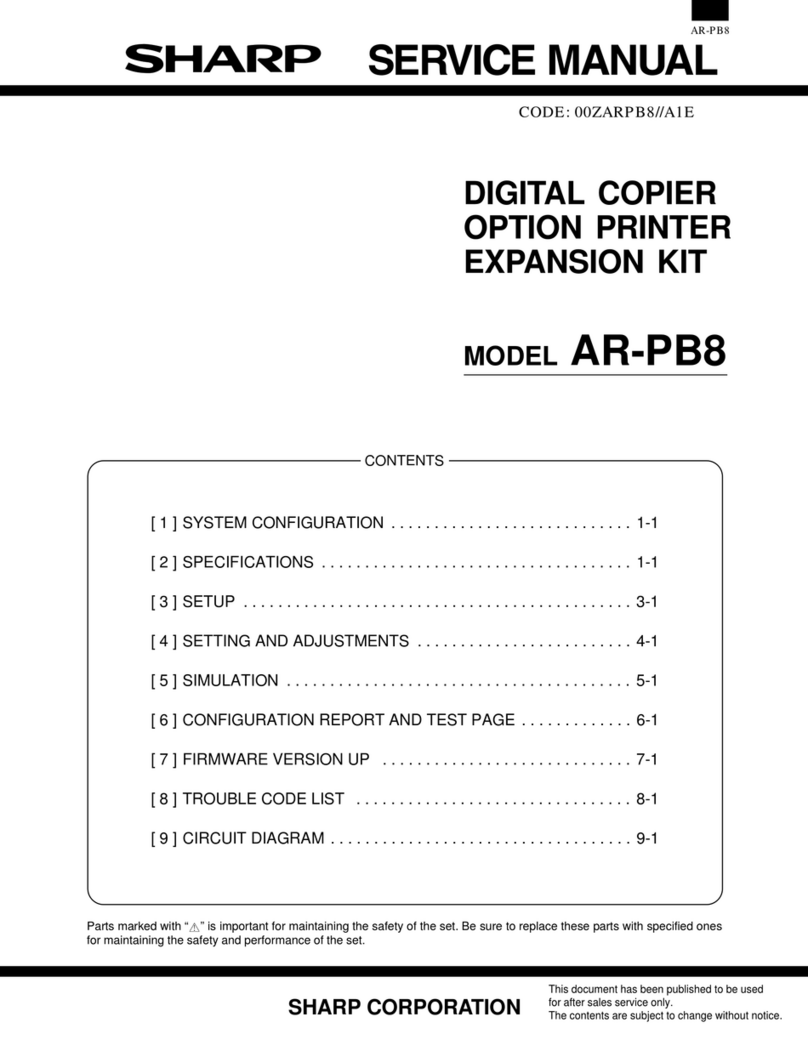

1. Paper feed section major parts

No. Part name Operation

1 Document length

sensor (L2) Detects the document length on

the tray.

2 Document length

sensor (L1) Detects the document length on

the tray.

3 Document length

sensor (W0) Detects the presence of

document.

4 Document width sensor

(W1, W2, W3) Detects the document width.

5 Pickup roller Picks up the document.

6 Paper feed roller Feed and transport the

document.

7 Paper entry sensor

(PAPER) Detects the document transport.

8 PS roller Makes synchronization between

the document lead edge and the

image lead edge.

9 PS follower roller Makes synchronization between

the document lead edge and the

image lead edge.

10 Transport roller Transports the document.

11 Transport follower roller Transports the document.

12 Paper exit follower roller Discharges the document.

13 Paper exit roller Discharges the document.

2. Brief descriptions of operations

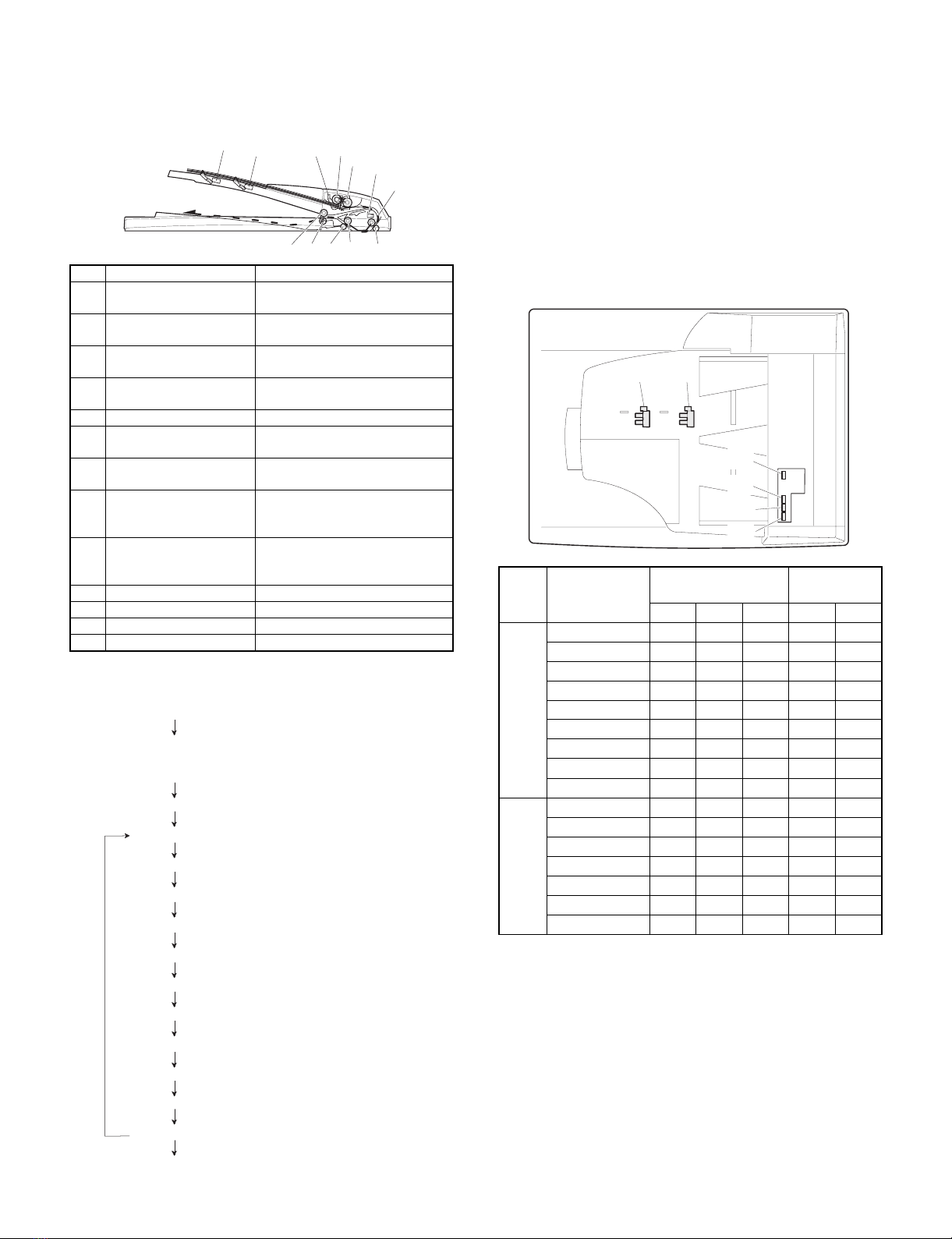

3. Document size detection

Document size detection by document set tray

When a document is set on the document set tray in the auto mode of

paper/copy magnification ratio selection, the document size is

detected to perform the auto selection function of paper and the copy

magnification ratio according to the detected document size.

When documents of different sizes are mixed and set on the tray, the

max. size is detected. The document width is detected by the docu-

ment width sensors (W1, W2, W3), and the document length is

detected by the document length sensors (L1, L2) to determine the

document size.

The document size judgment is made after a certain time from when

the document set sensor (W0) detects the document.

Document size

and set direction

Document width

sensor Document

length sensor

W1 W2 W3 L1 L2

AB

series

A5 FDDDD

B5 FFDDD

A5R DDDDD

A4 FFFDD

B5R DDDFD

A4R FDDFD

8.5" ×13" FDDFF

B4 FDDFF

A3 FFFFF

Inch

series

8.5" ×5.5" FDDDD

8.5" ×5.5"R DDDDD

11" ×8.5" FFFDD

11" ×8.5"R FDDFD

8.5" ×13" FDDFF

8.5" ×14" FDDFF

11" ×17" FFFFF

[Note] Sensor ON: FOFF: D

123,4 56

8

9

1011

12

13

7

1) Document set (Document set sensor ON)

3) Copy start (Machine)

4) SPF motor ON

5) Pickup solenoid ON

6) Pickup roller rotation

7) Paper feed roller rotation

8) Paper entry sensor detects paper presence.

9) PS roller rotation

10) Copy operation (Machine)

11) Transport roller rotation

12) Paper exit roller rotation

13) Document exit

YES

14) Next document

NO

2) Document size detection (The document width is detected

with document width sensors W1, W2, and W3, and the

document length is detected with document length sensors

L1 and L2.)

15) SPF motor OFF

L2 L1

W1

W0

W2

W3

– 5 –