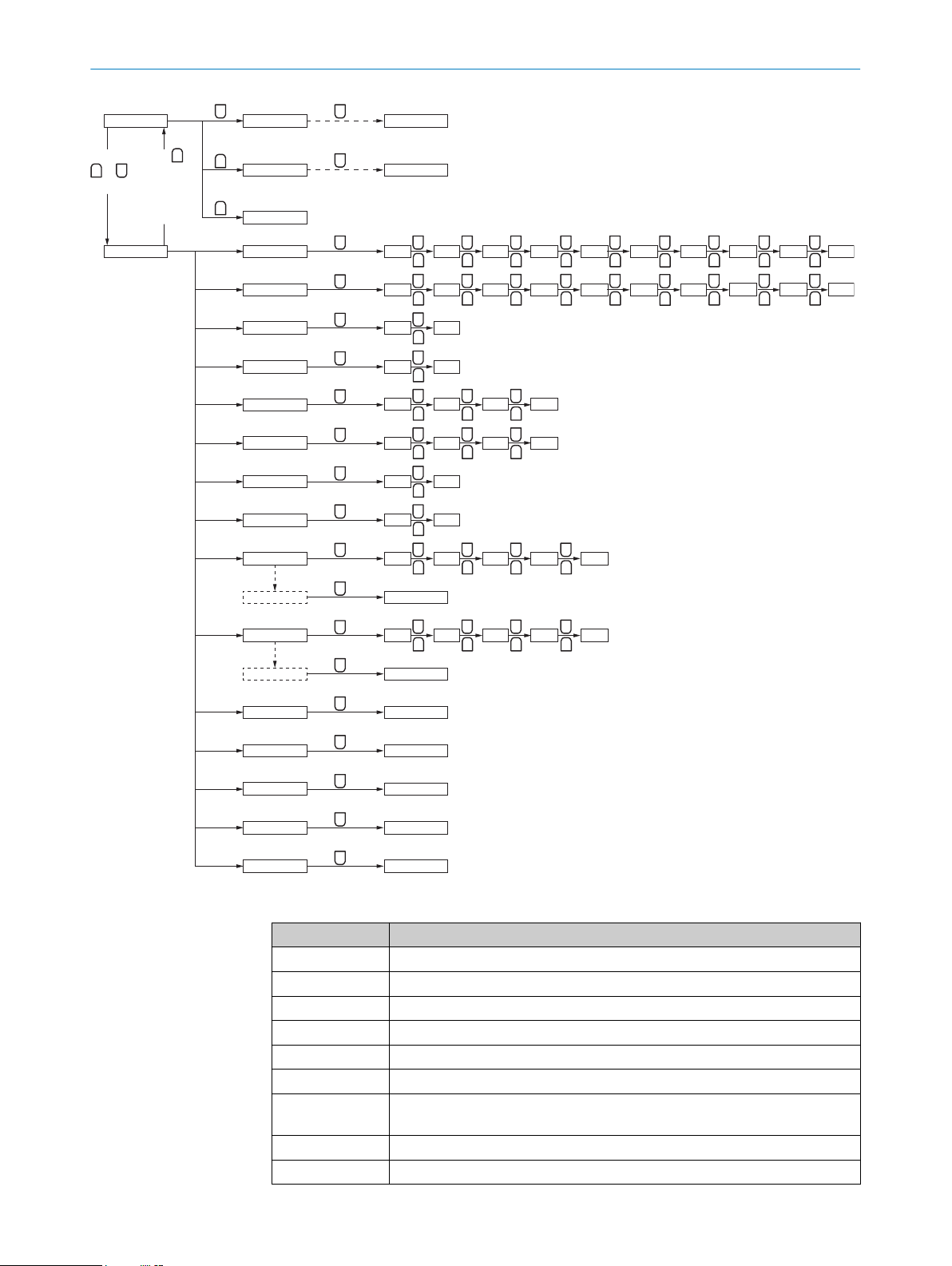

Menu item Function

“IL1” Sets the inversion of signal output QL1 for the Smart Task

“IL2” Sets the inversion of signal output QL2 for the Smart Task

“tL1” Sets the delay function of output QL1

Time 1 setup Sets the delay time for output QL1. Can only be used when the delay

function is not deactivated. Note: In the case of a value that can only be

adjusted via IO-Link, the display shows “---”

“tl2” Sets the delay function of output QL2

Time 2 setup Sets the delay time for output QL2. Can only be used when the delay

function is not deactivated. Note: In the case of a value that can only be

adjusted via IO-Link, the display shows “---”

“oFs” Sets the offset value for the taught-in switching threshold (in mm). Note: In

the case of a value that can only be adjusted via IO-Link, the display shows

“---”

“qF1” Sets switching threshold SP1 for Qint.1 (in cm)

“qn1” Sets switching threshold SP2 for Qint.1 (in cm). Only available when the

“Window” / “two point” switching mode has been selected.

“qF2” Sets switching threshold SP1 for Qint.2 (in cm)

“qn2” Sets switching threshold SP2 for Qint.2 (in cm). Only available when the

“Window” / “two point” switching mode has been selected

If the switching outputs are to be set via the menu, adjust the Q_X entries.

Press the Run button to leave the menu.

4.4 Pushbutton lock

Pushbutton lock on: Press the (Run) button for > 1 s

Pushbutton lock off: Press the (Run) button again for > 1 s

5 Troubleshooting

5.1 Troubleshooting

The Troubleshooting table indicates measures to be taken if the sensor stops working.

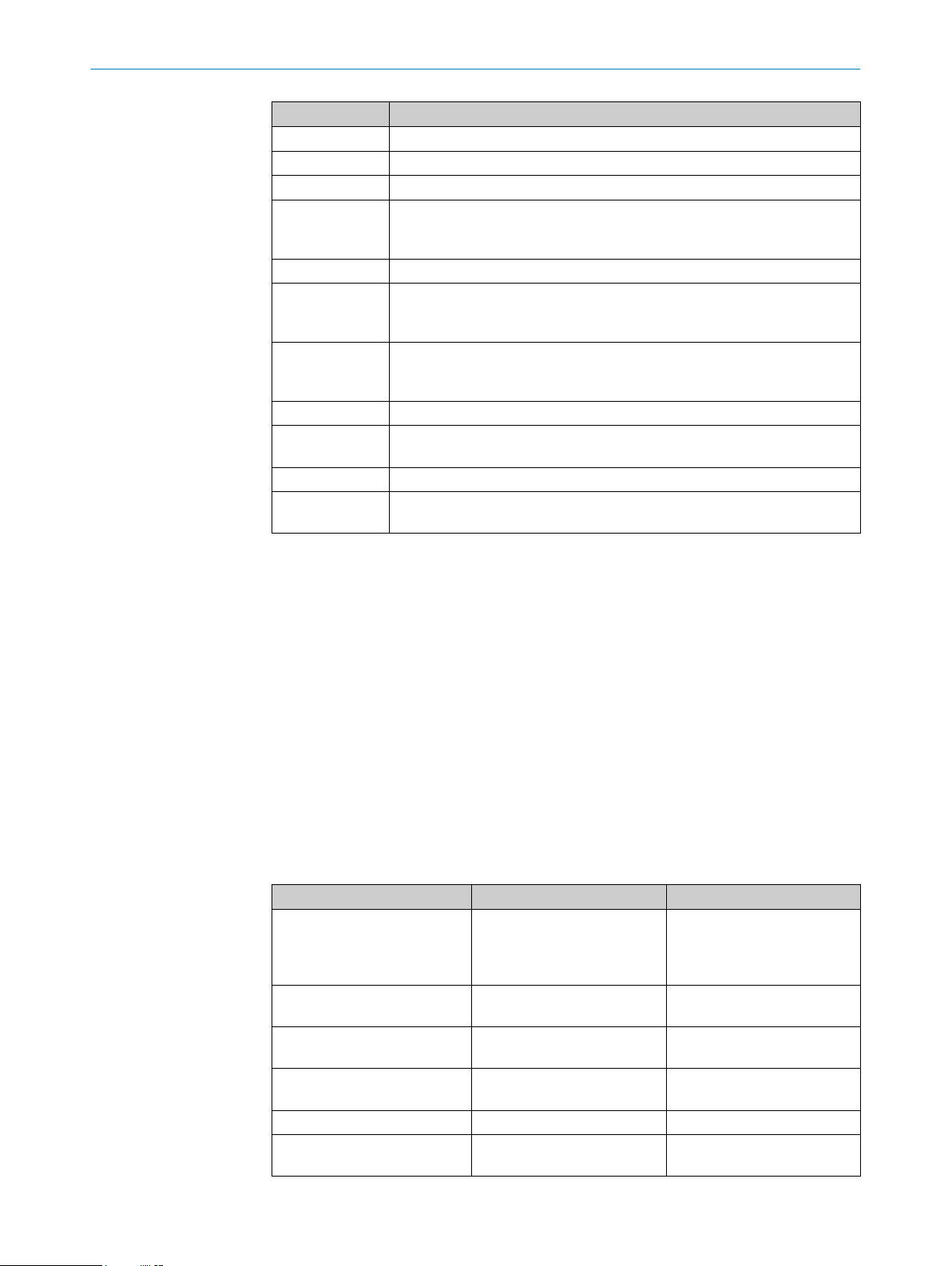

5.2 Table: Fault diagnosis

LED indicator/fault pattern Cause Measures

Green LED does not light up No voltage or voltage below

the limit values

Check the power supply,

check all electrical connec‐

tions (cables and plug connec‐

tions)

Green LED does not light up Voltage interruptions Ensure there is a stable power

supply without interruptions

Green LED does not light up Sensor is faulty If the power supply is OK,

replace the sensor

Green LED lights up, no output

signal when object is detected

Test input (Test) is not con‐

nected properly

See the note on connecting

the TI

Green LED flashes IO-Link communication -

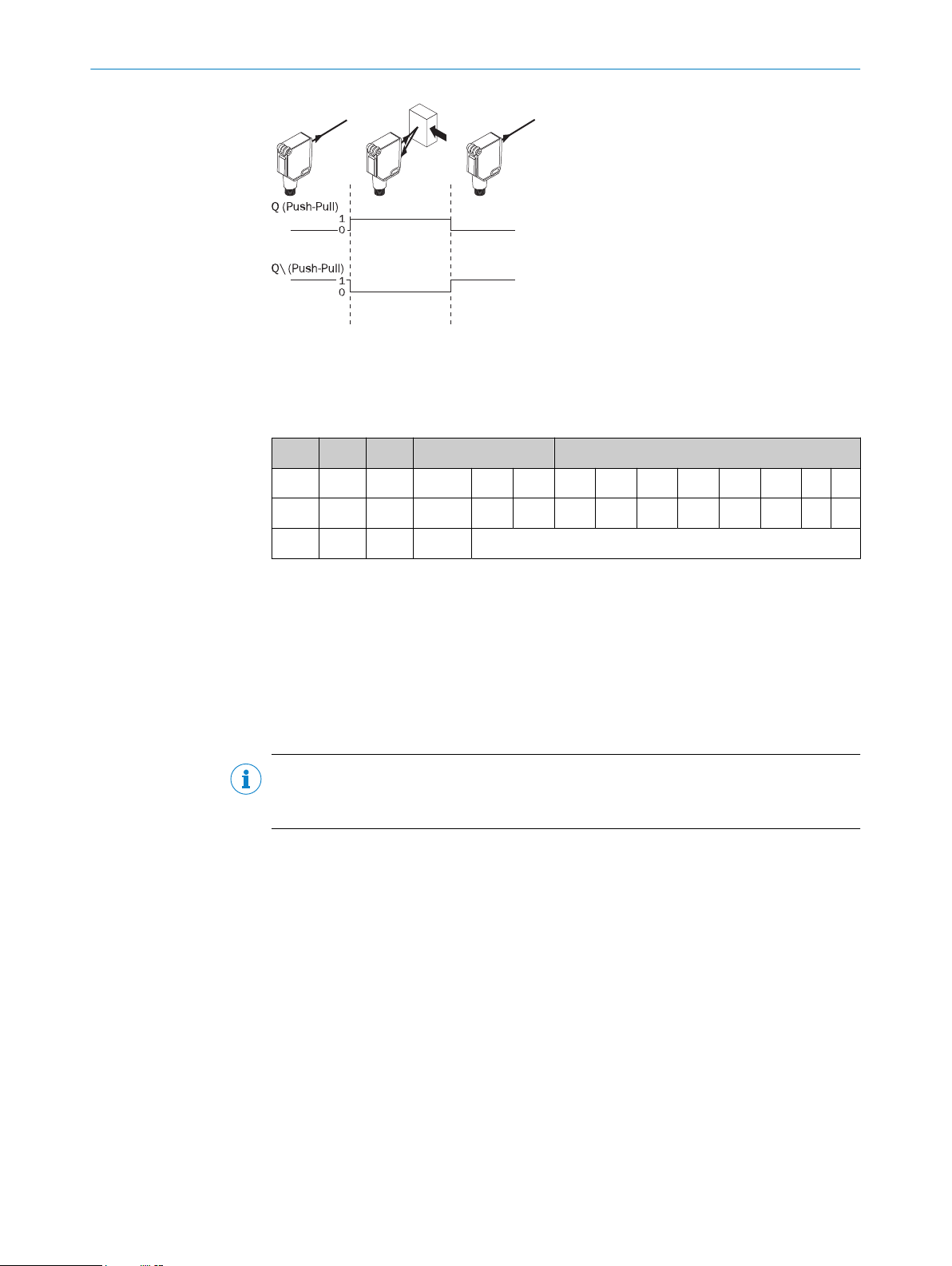

Switching outputs not accord‐

ing to graphic F

IO-Link communication -

CONFIGURATION 4

8024108.17AH / 04.02.2021 | SICK

Subject to change without notice 9