Page 2

EN

Operating instructions

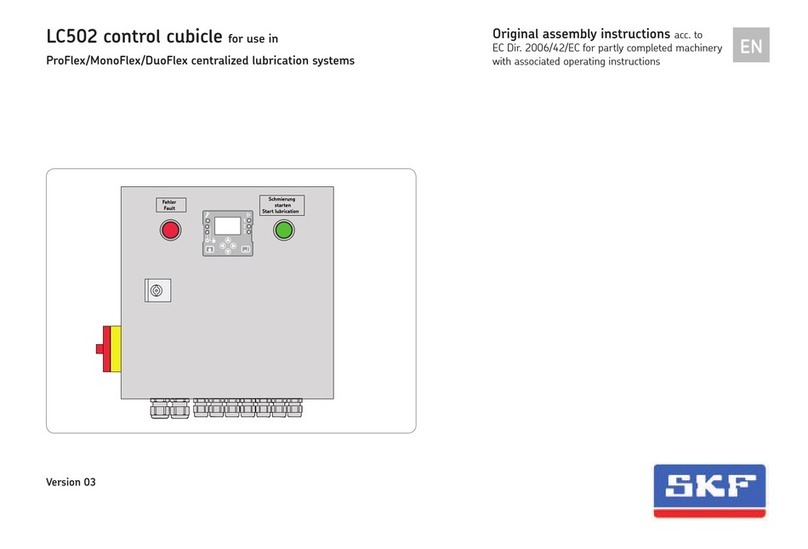

1. Display and control elements of

control screen 3

1.1 LC502 control screen 3

2. Display and operating menu 5

2.1 Base menu 5

2.1.1 Main menu 5

2.2 Info - Information mode... 6

3. Menu structure 10

3.1 Menu structure of Info 10

- View 11

- Edit 12

3.4 Menu structure of Status 13

4. LC502 Factory settings on a single-line

centralized lubrication system 14

lubrication system 14

inputs 20

4.3.1 Control inputs 20

outputs 23

8. Basic settings 44

9. Control ports 47

9.1 KFGL 47

plate, 24 VDC 47

9.1.2 KFGL pump for industrial applications,

12 VDC, 24 VDC 49

9.1.4 KFGL pump for industrial applications

230 VAC 50

10. Operational and pump faults 51

10.1 Operational malfunctions 51

10.2 System errors 51

10.3 Display errors 51

10.5 Error types 52

11. LC502 menu displays 55

12. Technical data for LC502 control unit 61

4.5.1 Control outputs 23

5. Options for customer adjustment 24

and dwell times... 24

pressure build-up and release 26

rotations 30

6. Options for customer adjustment of a

centralized lubrication system with two

main lines 34

7. Status display 35

7.1 Status - Display of current device

status 35

inputs and outputs 41

7.6 IO Conn. - read connection states of

inputs and outputs 42

control unit 43