2

SUMMARY

1. Introducon...................................................................................... 3

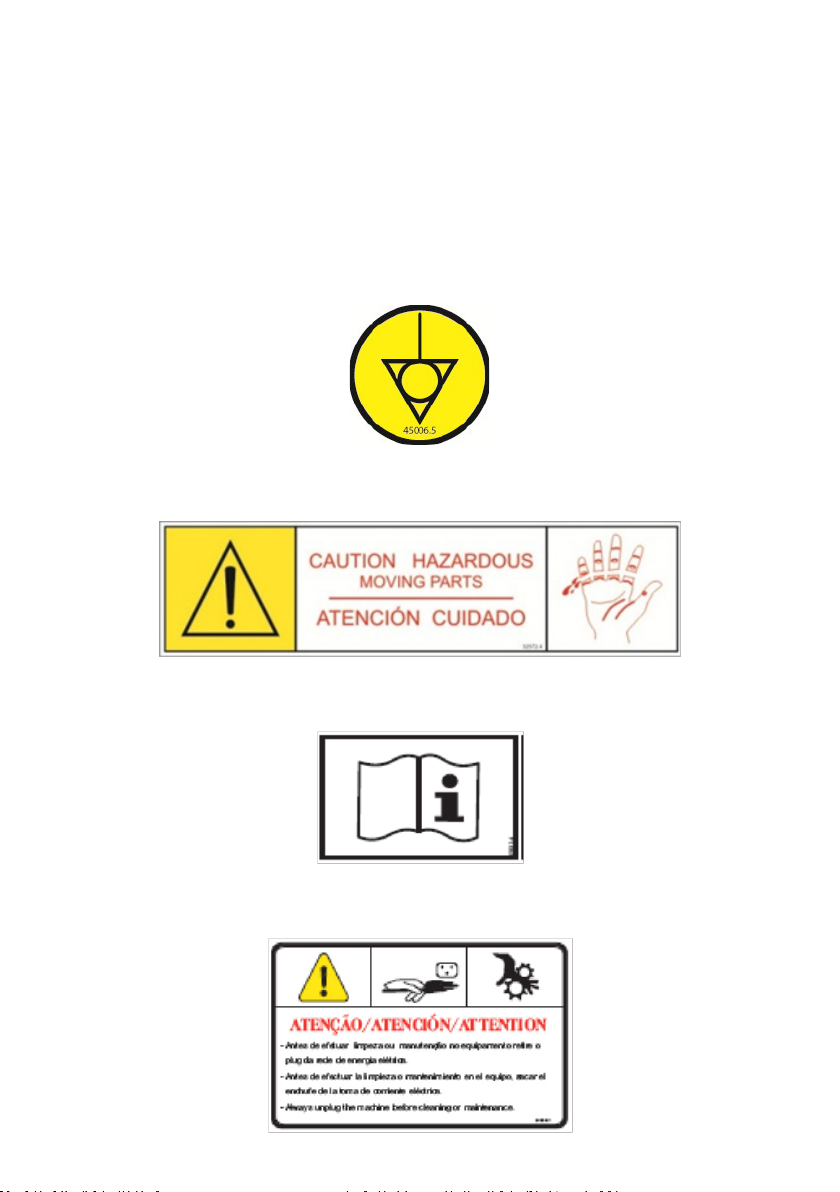

1.1 Main Safety Precauons ..................................................................................... 3

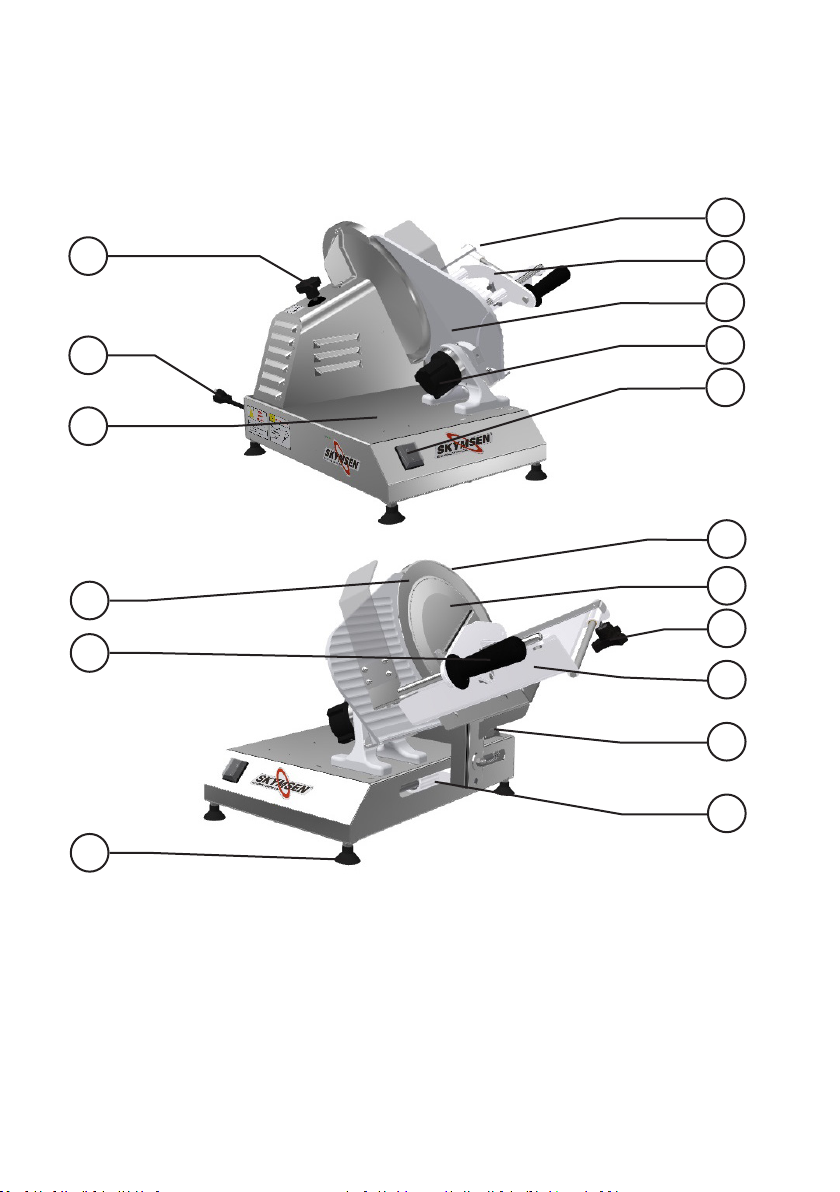

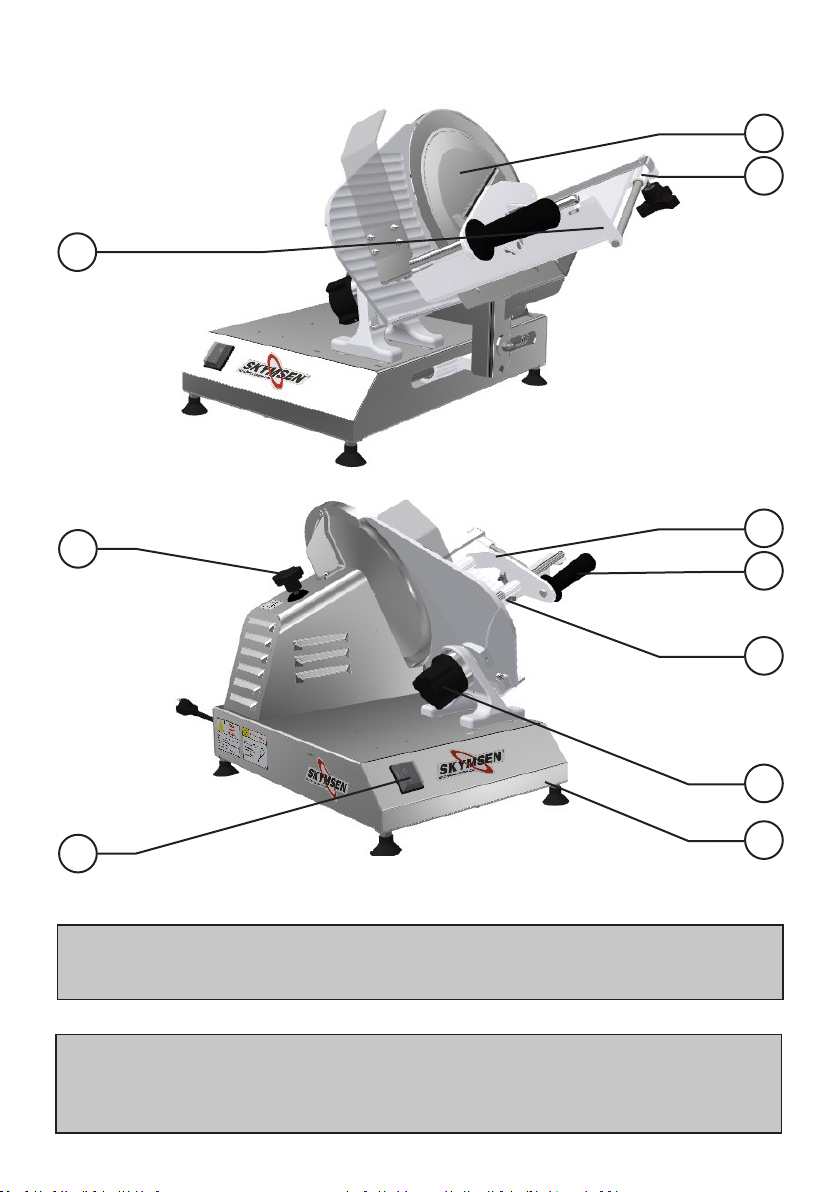

1.2 Main Components ................................................................................................ 6

1.3 Technical Characteriscs ........................................................................................ 7

2 . Installaon and Pre Operaon .......................................................... 7

2.1 Installaon............................................................................................................ 7

2.2 Pre Operaon ...................................................................................................... 8

3 Operaon ........................................................................................... 8

3.1 Starng.................................................................................................................. 8

3.2 Operaon Process.................................................................................................. 9

3.3 Safety Sysrem .......................................................................................................11

3.4 Cleaning and Sanizaon......................................................................................11

3.5 Knife Sharpening Procedure..................................................................................12

3.6 Cauons with Stainless Steel................................................................................13

4. General Safety Pracces .................................................................. 15

4.1 Basic Operaon Pracces......................................................................................15

4.2 Safety Procedures and Notes before Switching the Machine ON ...........................16

4.3 Roune Inspecon................................................................................................17

4.4 Operaon .............................................................................................................17

4.5 Aer Finishing The Work.......................................................................................17

4.6 Maintenance ........................................................................................................18

4.7 Warning................................................................................................................18

5. Analysis and Problem Solving ......................................................... 19

5.1 Problems Causes and Soluons ...........................................................................19

6 . Applicable Norms ........................................................................... 21

7. Electric Diagram............................................................................... 22