2

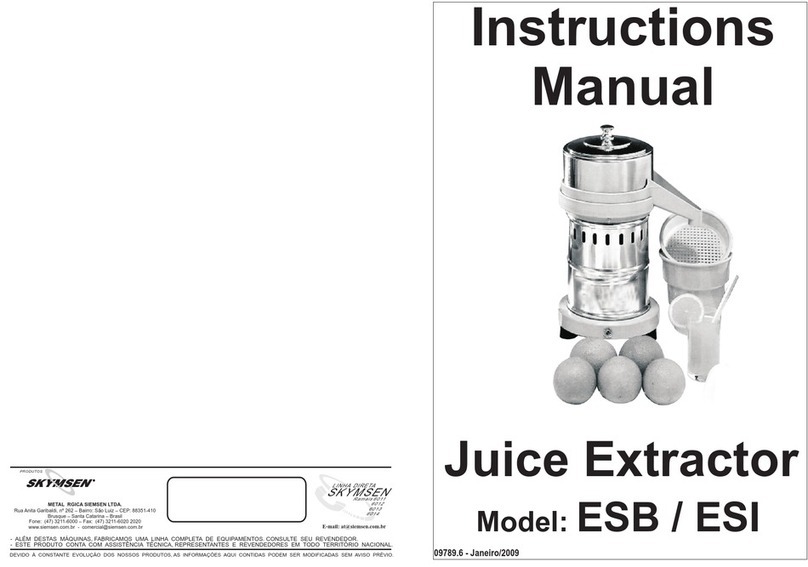

SUMMARY

1. Introducon ......................................................................................3

1.1 Safety .................................................................................................................... 3

1.2 Main Components ................................................................................................. 5

1.3 Technical Characteristcs ......................................................................................... 6

2. Instalaon and Pre-Operaon............................................................ 6

2.1 Installaon ............................................................................................................ 6

2.1 Pre- Operaon ....................................................................................................... 7

3. Operaon .......................................................................................... 7

3.1 Starng.................................................................................................................. 7

3.2 Operang Procedures ............................................................................................ 7

3.3 Cleaning................................................................................................................. 8

3.4 Cauons with Stainless Steel: ................................................................................ 9

4. General Safety Pracces .................................................................. 10

4.1 Basic Operaon Pracces......................................................................................10

4.2 Safety Procedures and Notes before Switching the Machine ON ...........................11

4.3 Roune Inspecon................................................................................................11

4.7 Warning................................................................................................................12

4.4 Operaon .............................................................................................................12

4.5 Aer Finishing The Work.......................................................................................12

4.6 Maintenance ........................................................................................................12

5. Analysis and Problems Solving.........................................................13

5.1 Problem, causes and soluons..............................................................................13

6. Applicable Norms ............................................................................ 15

7. Electric Diagram............................................................................... 16

19

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________

___________________________________________________________