04 05

Check if the Juice Extractor is firm in its position. Before using it,

wash partsin contact with the food with neutral soap and water.

3. Operation

3.1 Starting

IMPORTANT

Always wait until the motor complete stop before changing the

crown.

Make sure the Crown is properly fitted.

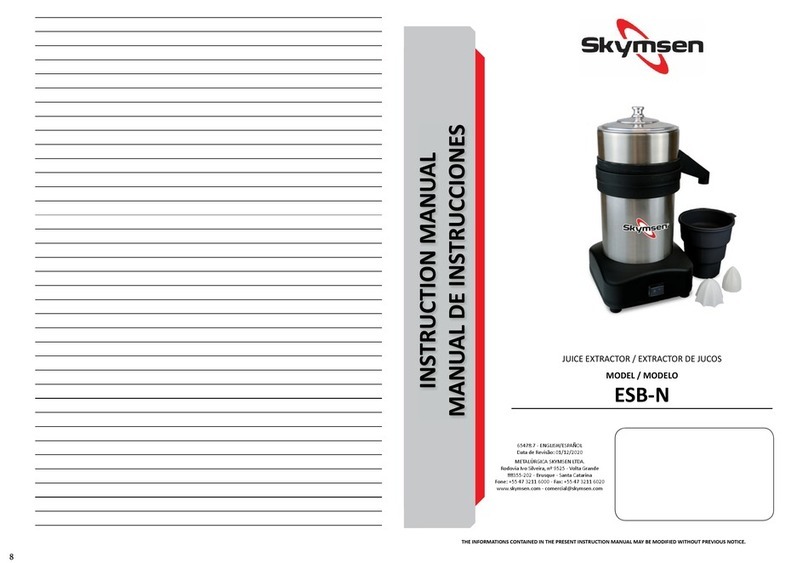

To start operating turn ON the ON/OFF switch Nº05 (Pic-1) located on the

Base Nº 06 (Pic-01).

3.2 Feeding Procedures

Juice Extractors work with high speed. First, cut the oranges or the

lemons in two halves.

T urn the machine on, hold half of the fruit and press it down firmly

against the crown Nº09 or Nº10 (Pic-01) and the juice will run into the cup

Nº08 (Pic-1) going first through the Sieve Nº07 (Pic-01).

3.3 Cleaning

IMPORTANT

Never clean the machine when it is connected to a power point,

always unplug the machine before cleaning. Before taking out the

crown, be sure the motor has come to a complete stop.

All removable parts must be removed and washed.

Follow the below instructions for washing removable parts:

3.3.1 Turn off the machine and unplug it.

3.3.2 Remove the Lid Nº01 (Pic-01), the Crown Nº 09 or N° 10

(Pic-01) and then the Juice Chamber Nº 02 (Pic-01)

3.3.3 Wash all removable parts with running water and neutral

soap and dry them.

3.3.4 To reinstall them, follow the above order inversely.

3.3.1 Cautions with Stainless Steel:

The Stainless Steel may present rust signs, which ARE ALWAYS CAUSED

BY EXTERNAL AGENTS, especially when the cleaning or sanitization is not

constant and appropriate.

The Stainless Steel resistance towards corrosion is mainly due to the

presence of chrome, which in contact with oxygen allows the formation of a very

thin protective coat. This protective coat is formed through the whole surface of the

steel, blocking the action of external corrosive agents.

When the protective coat is broken, the corrosion process begins, being

possible to avoid it by means of constant and adequate cleaning.

Cleaning must always be done immediately after using the equipment. For

such end, use water, neutral soap or detergent, and clean the equipment with a soft

cloth or a nylon sponge. Then rinse it with plain running water, and dry immediately

with a soft cloth, this way avoiding humidity on surfaces and especially on gaps.

The rinsing and drying processes are extremely important to prevent stains

and corrosion from arising.

IMPORTANT

Acid solutions, salty solutions, disinfectants and some sterilizing solutions

(hypochlorites, tetravalent ammonia salts, iodine compounds, nitric acid

and others), must be AVOIDED, once it cannot remain for long in contact

with the stainless steel:

These substances attack the stainless steel due to the CHLORINE on its

composition, causing corrosion spots (pitting).

Even detergents used in domestic cleaning must not remain in contact with

the stainless steel longer than the necessary, being mandatory to remove it with plain

water and then dry the surface completely.

Use of abrasives:

Sponges or steel wool and carbon steel brushes, besides scratching the

surface and compromising the stainless steel protection, leave particles that rust and

react contaminating the stainless steel. That is why such products must not be used

for cleaning and sanitization. Scrapings made with sharp instruments or similar must

also be avoided.

Main substances that cause stainless steel corrosion:

Dust, grease, acid solutions such as vinegar, fruit juices, etc., saltern

solutions (brine), blood, detergents (except for the neutral ones), common steel

particles, residue of sponges or common steel wool, and also other abrasives.