10

Application

Flush-mount letterbox housing made

of1.0mmhot-dipgalvanizedsteel

toaccommodateBKM611-4/4-…/

AFM611-4/4-…,withxturefacility

for suitable combination frame,

plaster compensation 15 mm.

Prepared for mounting in a row of

severalBGU611-4/4-…unitsside

bysideoroneabovetheother.With

connecting screws for mounting in

a row.

Combination possible with

GU611-4/1-…,toaccommodate

function modules.

BGU 611-4/4-… mounting

without function strip

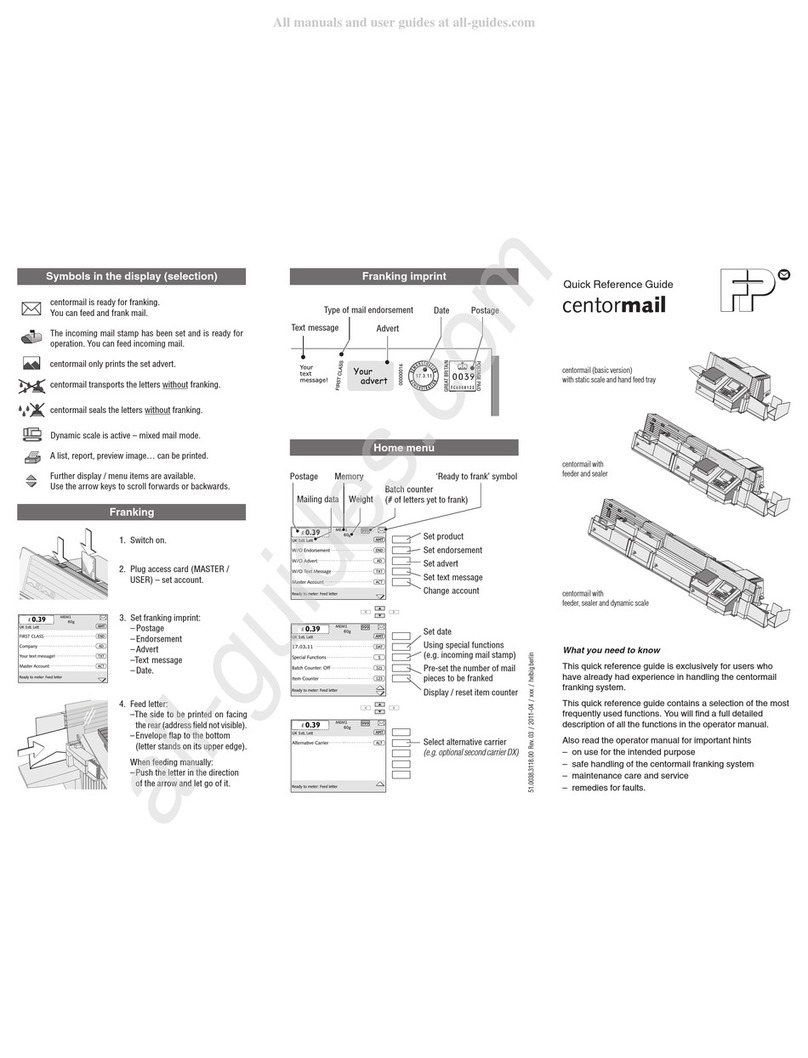

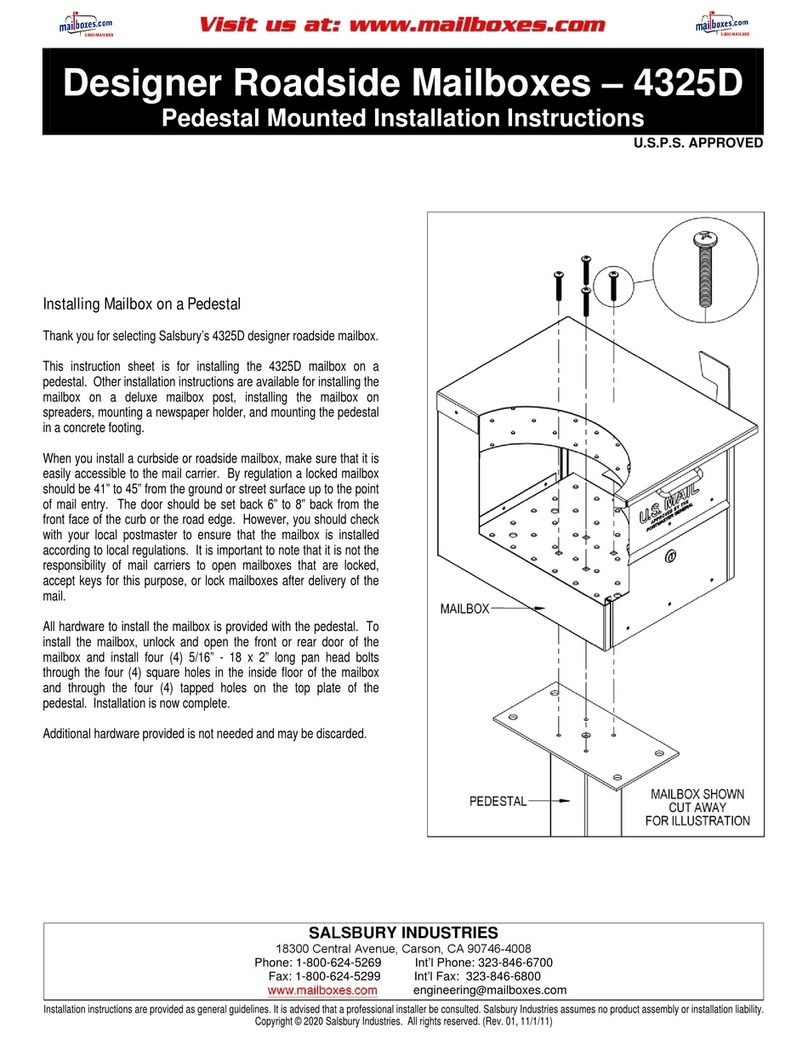

1 Where applicable, connect the

BGU611-4/4-… units to each other

using the enclosed screws, and

mount either ush with the level

of the prepared plaster, or up to

15 mm deeper.

2 In the case of in-row mounted

units, the intermediate wall of the

housing must be broken out at the

corners.

3 Align the xing plates in the

BGU611-4/4-…

4 Mount the combination frame:

Insert the KR611-… in such a way

that the sealing prole of the combi-

nation frame is open at the bottom.

5 Suspend the supplied long fas-

tening bracket at the combination

frame and screw rmly to the xing

plates of the BGU611-4/4-…

6 The intermediate webs of

combination frames from size

800x800mm form a cross. An

adjusting screw is recessed into this

cross which enables adjustment of

the combination frame. If required,

adjust this screw in order to align

and straighten the intermediate

webs of the combination frame and

to provide support for them against

the ush-mount letterbox frame.

Inserting the mounting modules

7 Slot BKM611-4/4-… or

AFM611-4/4-… into the

BGU611-4/4-… from the front.

8 There are lateral orientation tabs

positioned at the side of the BKM/

English

AFM611-4/4-… which must engage

in the guides provided in the support

edge. The BKM/AFM611-4/4-… is

then positioned in the surrounding

frame aligned ush with the front of

the frame.

9 Using the two torx screws on the

left and right-hand edge, tighten

the BKM/AFM611-4/4-… with the

plastic claws behind the shoulders

of the combination frame. The torx

screwdriver is provided with the

mounting module.

Mounting the BGU 611-4/4-…

with function modules

10 Punch through the screw holes

in the GU611-4/1-… and screw to a

BGU611-4/4-… If required, connect

several BGU611-4/4-… units using

the provided screws, insert

the connecting cables in the

GU 611-4/1-… and mount either

ush with the prepared plaster or

up to 15mm deeper. Max. plaster

compensation 15mm.

11 For in-row mounted housing

units, break out the prepunched

corners in the intermediate wall

(see Fig. 2 and 10).

12 Align the xing plates

BGU611-4/4-… (see Fig. 3).

13 Mount the combination frame.

Insert the KR611-… so that the

sealing prole of the combination

frame is open at the bottom

(see Fig. 4).

14 Suspend the supplied long fas-

tening brackets at the combination

frame and screw rmly to the xing

plates of the BGU611-4/4-…

(see Fig. 5).

15 The intermediate webs of

combination frames from size

600x500mm form a cross. An

adjusting screw is recessed into this

cross which enables adjustment of

the combination frame. If required,

adjust this screw in order to align

and straighten the intermediate

webs of the combination frame and

to provide support for them against

the ush-mount letterbox frame

(see Fig.6).

16 Remove combination terminal

strip from the module packaging,

centre it turned around 45° to the

left on the retaining plate and latch

into position by rotating it around

a quarter turn in the clockwise

direction so that the terminal desig-

nations can be read vertically posi-

tioned one above the other.

17 Strip the connecting cables, press

onto the housing oor, x using

the cable clamps and connect the

system to the combination terminal

strip in accordance with the relevant

circuit diagram.

18 (no illustration) Insert the

mounting frame. Insert the

MR611-… in such a way that the

sealing lm is positioned at the

upper edge of the mounting frame.

If several MR611-… units are used,

they must always be inserted from

bottom to top that the sealing lm

of the lower mounting frame is posi-

tioned underneath the lm of the

upper one in sh scale formation.

19 Screw the MR611-… using the

provided quick-release screws into

the ush-mount housing

GU611-4/1-…, rotating a quarter

turn to the right (until they reach

their stop position).

Inserting the modules

20 (no illustration) Connect the plug

of the ribbon cable to the combina-

tion terminal strip.

21 Applying a light pressure,

underpin the module in the module

slot of the MR611-… opposite the

movable locking bolt. Exerting a

slightly higher degree of pressure,

clip into place on the other side.

22 Slot BKM611-4/4-… or

AFM611-4/4-… into the

BGU611-4/4-… from the front

(see Fig. 7/8).

23 There are lateral orientation tabs

positioned at the side of the

BKM/AFM611-4/4-… which must

engage in the guides provided in the

support edge.

The BKM/AFM611-4/4-… is then

positioned in the surrounding frame

aligned ush with the front of the

frame (see Fig. 7/8).