tau D760M User manual

1

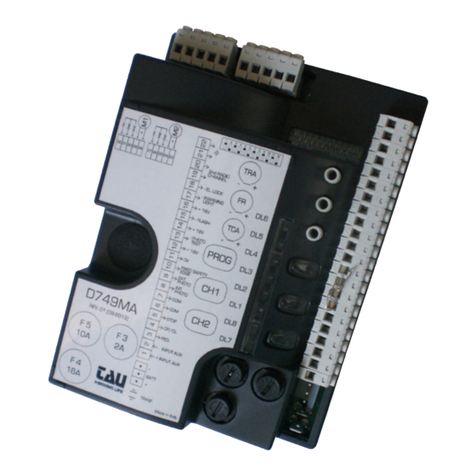

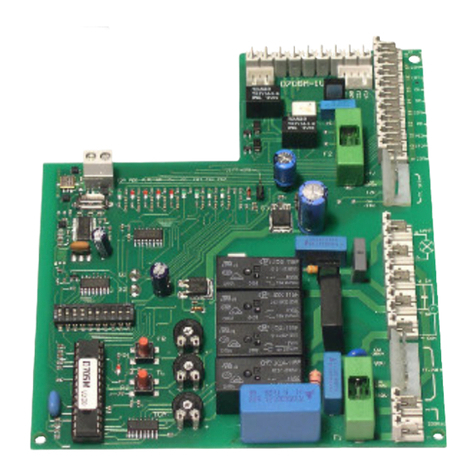

D760M

GUIDA ALL’INSTALLAZIONE

INSTALLATION GUIDE

INSTALLATIONSANLEITUNG

NOTICE D’INSTALLATION

GUÍA PARA LA INSTALACIÓN

GUIA DE INSTALAÇÃO

D760M

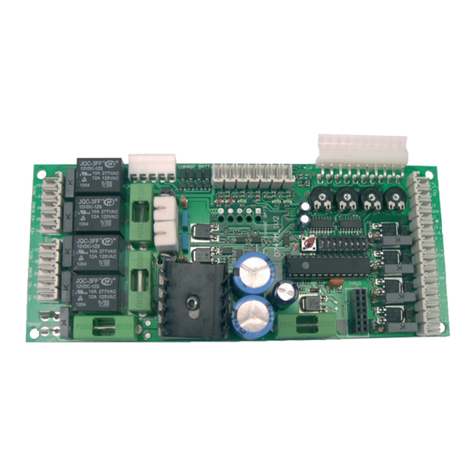

Quadro di comando per due motori monofase 230V AC

Control panel for two single-phase motors 230V AC

Steuerplatine für zwei einphasige 230V AC Motoren

Logique de commande pour

deux moteurs monophasés 230V AC

Panel de mandos para dos motores monofásicos 230V AC

Placa electrónica para dois motores monofásicos 230V AC

Via Enrico Fermi, 43 - 36066 Sandrigo (VI) Italia

Tel +39 0444 750190 - Fax +39 0444 750376

info@tauitalia.com - www.tauitalia.com

IT - Istruzioni originali

D-MNL0D760M 14-02-2018 - Rev.11

300

230

124

2

D760M

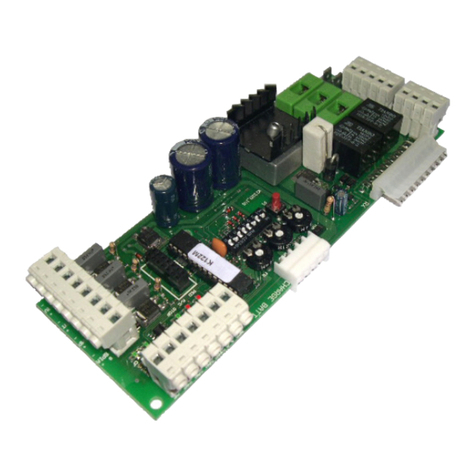

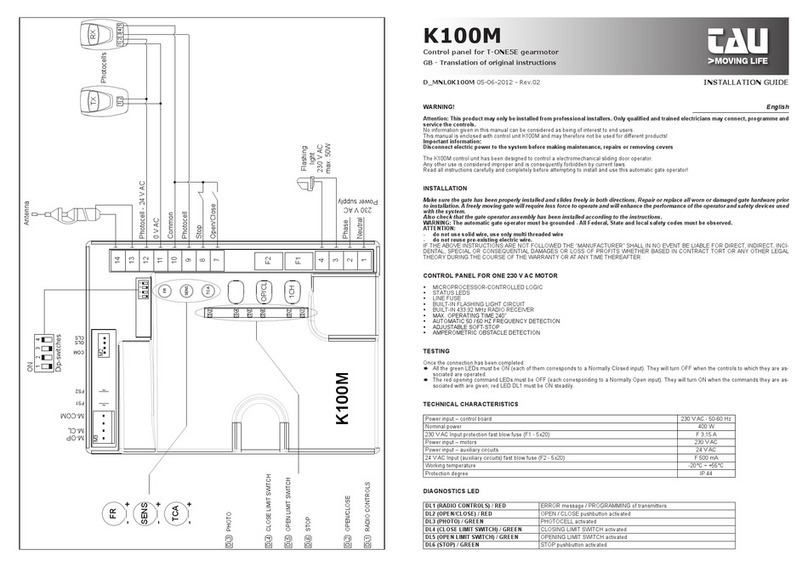

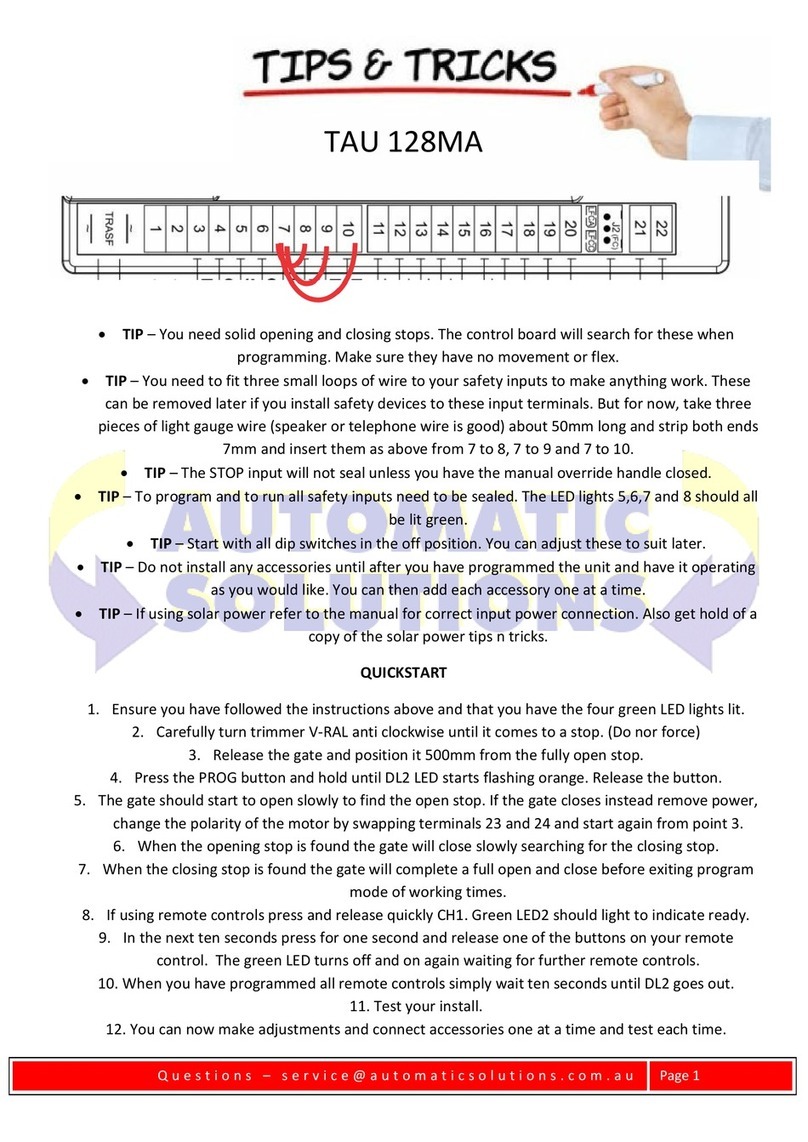

SCHEMA CABLAGGIO D760M / D760M WIRING DIAGRAM / SCHALTPLAN DER D760M

I O

12

12

3 4 5 6 7 8 9 10

3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 25 26 2722 23 2419 20 21

11 12 13 14 15 16 17 18 25 26 2722 23 2419 20 21

F1

P1 P2

J1

F2

28

28 29

29

R.ANTA FR. M1 CH.AUTO

FR. M2

DL7

J1

DL7

3

D760M

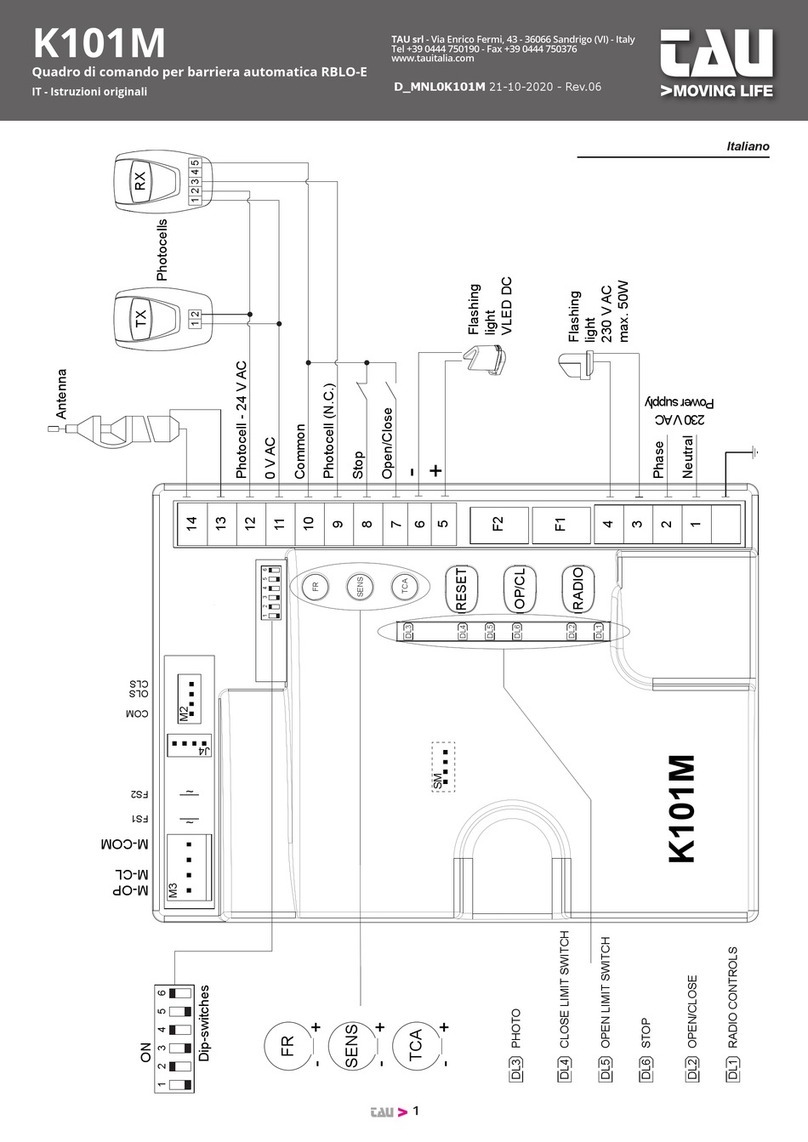

SCHÉMA CÂBLAGE D760M / ESQUEMA DEL CABLEADO D760M / ESQUEMA ELÉCTRICO D760M

O/C =Open/Close

Ped = Pedestrian

Cap = Capacitor

TX = Transmitter

RX = Receiver

E.L. = Electric lock

M = Motor

SPIA

AP2

230Vac

M3

1

23 4 5 6 7 8 9 10

CH1COM1 AP1CH2COM2 FOTI

11 12 13 14 15 16

COMAP/CH PED STOP CF COM

17 18

FOTE 24FOT

25

0VAC

26 2722 23 2419 20 21

24VAC

LAMP M2 M1

E.SERR 2 CH

230 Vac

Power supply

Flashing

light

230 Vac

max. 50W

Close

Common

Open

Close

Common

Open

Cap Cap

TX

1 2

RX

12345

Common

Sensitive edge

Internal photocell (N.C)

External photocell (N.C.)

Common

O/C

Ped

Stop

E.L.

12V 15W

2nd radio

channel

Gate open

warning light

max. 3W

Ext.

photoc.

Int.

photoc.

RX

12345

TX

1 2

Antenna

13

D760M

MANUFACTURER’S DECLARATION OF INCORPORATION

(in accordance with European Directive 2006/42/EC App. II.B)

Manufacturer: TAU S.r.l.

Address: Via E. Fermi, 43

36066 Sandrigo (Vi)

ITALY

Declares under its sole responsibility, that the product: Electronic control unit

designed for automatic movement of: Swing Gates

for use in a: Residential / Communities

complete with: Radioreceiver

Model: D760M

Type: D760M

Serial number: see silver label

Control panel for two single-phase motors

230V AC

Has been produced for incorporation on an access point (swing gate) of for assembly with other devices used to

Also declares

- 2014/35/EU Low Voltage Directive

- 2014/30/EU Electromagnetic Compatibility Directive

and, where required, with the Directive:

- 2014/53/EU Radio equipment and telecommunications terminal equipment

Also declares that it is not permitted to start up the machine until the machine in which it is incorporated or of

pertinent to the quasi-machinery.

Legal Representative

_________________________________________

Loris Virgilio Danieli

Name and address of person authorised to draw up all pertinent technical documentation:

Loris Virgilio Danieli - via E. Fermi, 43 - 36066 Sandrigo (Vi) Italy

ENGLISH

14

D760M

WARNINGS

D760M and may therefore not be used for different products!

Important information:

Disconnect the panel from the power supply before opening it.

The D760M control unit has been designed to control an electromechanical gear motor for automating

gates and doors of all kinds.

When designing its products, TAU observes all applicable standards (please see the attached decla-

ration of conformity) but it is of paramount importance that installers strictly observe the same stand-

and doors” category may not install systems under any circumstances.

Whoever ignores such standards shall be held responsible for any damage caused by the

system!

Do not install the unit before you have read all the instructions.

INSTALLATION

Before proceeding, make sure the mechanical components work correctly. Also check that the

gear motor assembly has been installed according to the instructions. Then make sure that

the power consumption of the gear motor is not greater than 3A (otherwise the control panel

may not work properly).

-

Note: it is compulsory to earth the system and to observe the safety regulations that are in

force in each country.

-

ENGLISH

15

D760M

ENGLISH

CONTROL CARD FOR TWO SINGLE-PHASE MOTORS 230V AC

-

ATTENTION:

- do not use single cables (with one single wire), ex. telephone cables, in order to avoid

breakdowns of the line and false contacts;

- do not re-use old pre-existing cables.

TESTING

When all connections have been made:

safeties

-

nostics Led”)

TECHNICAL CHARACTERISTICS

600 W ca.

F 3,15 A

Input voltage of motor circuits

Input voltage of auxiliary circuits

F 500 mA

Logic circuit input voltage

Working temperature

IP43

TERMINAL BOARD CONNECTIONS

Key:

-

Terminals Function Description

1 - 2 POWER

SUPPLY

3 - 4 FLASHING

LIGHT

modulated for direct use. Flashing frequency is double

5 - 6 - 7 MOTOR M1

Notice: connect the capacitor between terminals 5 and 7;

16

D760M

8 - 9 - 10 MOTOR M2

MOTOR M2 power output, 230 Vac, max. 300 W.

8=CLOSE, 9=COMMON., 10=OPEN.

Notice:

11 - 12 OPEN/CLOSE OPEN/CLOSE button input (contact normally open); for operating

information see dip-switches 2 and 3 functions. (COMMON=11);

11 - 13 PEDESTRIAN

N.O. PEDESTRIAN button contact input – commands total opening

and closing of motor 1 – governed by dip-switches 2 and 3.

(COMMON=11);

11 - 14 STOP

STOP button input (normally closed contact); this stops the automatic

system. At the next command, the opposite operation to the previous

one is performed (COMMON=9). Bridge the connectors if not used;

15 - 18 SENSITIVE

EDGE

SENSITIVE EDGE input (potential free contact N.C., dip 10 OFF) or

It works during both the opening and closing phases, causing the

temporary stop of the automation and its partial movement reversal

for 20cm, therefore freeing any obstacle (18=COMMON) Note: short-

circuit if not used.

16 - 18 INTERNAL

PHOTOCELLS

PHOTOCELL OR SAFETY DEVICE input INSIDE the automation

(Normally Closed contact); COMMON=18.

When these devices trigger during the opening phase, they tem-

porarily stop the automation until the obstacle has been removed;

during the closing phase they stop the automation and then totally

open it again. Bridge the connectors if not used.

17 - 18 EXTERNAL

PHOTOCELLS

PHOTOCELL OR SAFETY DEVICE input OUTSIDE the automation

(Normally Closed contact); COMMON=18.

Then these devices trigger during the closing phase, they stop the auto-

mation and then totally open it again. Bridge the connectors if not used.

-

19 - 20 ELECTRIC LOCK ELECTRIC LOCK power output 12 Vac max. 15 W;

21 - 22 2nd RADIO CH

2nd RADIO CHANNEL output; the output mode can be selected

through Dip Switches 7 - 8;

23 - 24 GATE OPEN

WARNING LIGHT

GATE OPEN WARNING LIGHT output; 24 V ac, max 3W; the light

entire opening and closing manoeuvre and remains on if the gate is

open and off when the gate has closed;

25 - 27 PHOTOCELL TX

24 Vac external transmitting photocell power supply output for safe-

ty device control (connect the external TX photocell only) max. of 2

photocell transmitters;

26 - 27 AUX 24Vac output, 10W for the power supply of photocells, external re-

ceivers, etc.

28 - 29 AERIAL AERIAL input (EARTH=28, SIGNAL=29);

ENGLISH

17

D760M

LOGIC ADJUSTMENTS

TRIMMER

R. ANTA

second motor delay adjustment: during closing cycle from approx. 0 to 30 sec. (on top

of the time that the card calculates automatically during the SETUP procedure)during

opening from approx. 0 to 6 sec (on top of the time that the card calculates automati-

cally during the SETUP procedure).

FR. M1

-

FR. M2

-

CH.AUTO Automatic closing time adjustment from

Notice: turn the TRIMMER clockwise to increase adjustments; turn it anticlockwise to

decrease.

PROGRAMMING INSTRUCTIONS (SETUP)

DOUBLE SWING GATE - DIP SWITCH # 4 in ON (Soft-Stop function enabled):

-

-

SINGLE SWING GATE - DIP SWITCH # 4 in ON ( Soft-Stop function enabled):

GATE 2 WINGS - DIP SWITCH # 4 in OFF (Soft-Stop function disabled):

ENGLISH

18

D760M

-

-

GATE 1 WINGS - DIP SWITCH # 4 in OFF (Soft-Stop function disabled):

Notice:

- during the SETUP procedure the safety devices are disabled.

- STOP input will stop the programming at any time. The programming mode remains active

and can be re-started from point 1

- while DL7 blinks, press and hold down for at least 5 seconds P1 and P2 buttons to kill exit

programming mode

- set a working time slightly longer than necessary (a couple of seconds) to allow complete

opening/closing of the leaves.

DIP SWITCH

1AUTOMATIC

CLOSING

On

Off

22 / 4 STROKE

On

-

3

Off in the same conditions, the same command sequence causes the

3NO REVERSE On NO RE-

VERSE)

Off

4DECELERATION On the deceleration function is on -

TIONS”)

Off

5PRE-FLASHING On

Off

6FOTOTEST

On

Off

ENGLISH

19

D760M

7MAN MODE On

Off Normal function

WARNING: with dip 7 ON the input OPEN / CLOSE (terminals 11-12) switches OPEN, the

PEDESTRIAN input (terminals 11-13) switches CLOSE.

In MAN mode, it is not necessary to run the race setup, and the dip-switches 1, 2, 3 and

4 are not used.

82nd RADIO CH

On

is activated and remains activated until the next pressure.

Off

9OPENING

RAM BLOW

On

of the electric lock (to be used only in the presence of an electric

Off

10 SENSITIVE EDGE

SELECTION

On

Off

Note: if not used, keep the DIP in the OFF position.

JUMPER J1

closes automatically after 5 seconds.

IMPORTANT:

ensure the proper operation of the board.

-

433.92 MHz BUILT-IN RADIO RECEIVER

The radio receiver can learn up to a maximum of 30SLIM-RP, T-

4RP

4_ LED DL7 turns on again to indicate that the code has been memorised (if this does not happen,

5_ to memorise codes to other radio control devices, repeat the procedure from point 1 up to a maxi-

mum of 30

Notice: if the maximum number of radio control devices (30

rapidly for about 3 seconds without memorising the code.

ENGLISH

20

D760M

-

ming buttons.

-

-

4_ LED DL7 turns off for approx. 3 seconds and then remains steady to indicate that the code has

DIAGNOSTICS LED

DL1 - Red

DL2 - Red PEDESTRIAN button red LED signal

DL3 - Green STOP button green LED signal

DL4 - Green

DL5 - Green

DL6 - Green

DL7 - Red and ERRORS red LED signal

Regular operation

Photo-cell Test Error

Missing Programming Error

Programming Mode Active

MALFUNCTIONS: POSSIBLE CAUSES AND SOLUTION

The automation does not start

The radio control has very little range

The gate opens the wrong way

GUARANTEE: GENERAL CONDITIONS

sales document, receipt or invoice).

-

ENGLISH

21

D760M

manship or materials.

for travelling expenses and labour costs.

The guarantee does not cover the following cases:

provided by the company inside the product pack.

improper repairs, incorrect installation, or other reasons that do not depend on TAU.

-

ing to the instructions provided by the company inside the product pack.

The repair or replacement of pieces under guarantee does not extend the guarantee period.

ENGLISH

Other manuals for D760M

1

Table of contents

Other tau Control Panel manuals

Popular Control Panel manuals by other brands

Honeywell Home

Honeywell Home TrueZONE HZ322 Professional installation guide

Zonefirst

Zonefirst BPE Installation and operating instructions

DSC

DSC Power Series PC1616 quick guide

CAME

CAME TS4.3 user manual

Autonics

Autonics LP-A Series product manual

PEDROLLO

PEDROLLO EVOLUTION Series operating instructions