tau DC18 User manual

INSTALLATION GUIDE

GUIDA ALL’INSTALLAZIONE

NOTICE D’INSTALLATION

IT - Istruzioni originali

DC18

DC18-M

1 2 3 4

DC18-P

D-MNL0DC18 08-05-2023 - Rev.08

2

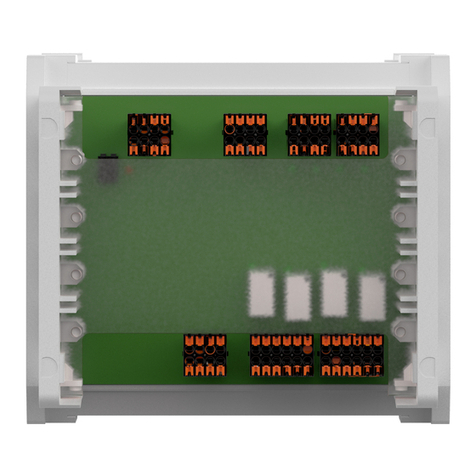

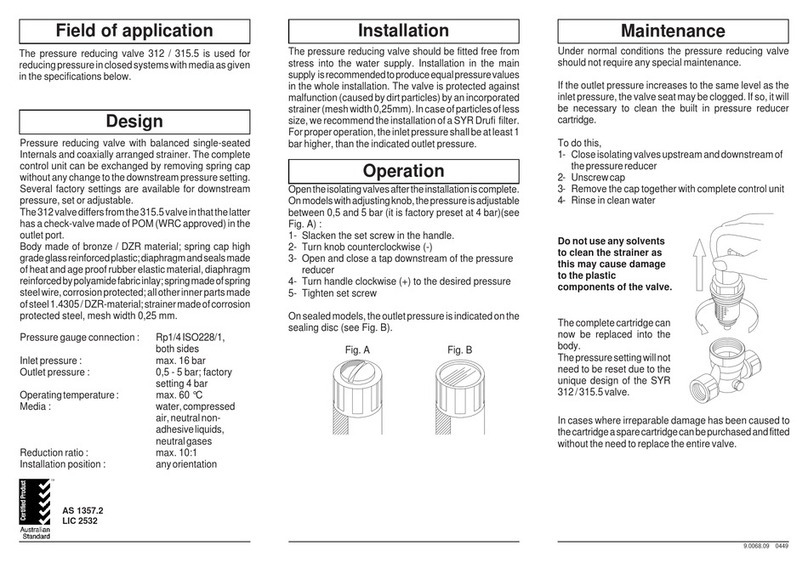

DC18 WIRING DIAGRAM WITH ACTIVATION

AND SAFETY SENSORS

DC18-M

8

1

ON 2 3 4

910

11

12

1314

15

16

17

18

1920

21

22

23

24

25

26

27

J4

J9

J10

J11

J12 J13 J14

J15

J16

ENCODER

ENCODER

-

+

A

B

SEL.

B2

SEL.

B1

SEL. B0

COMMON (green and blue)

COMMON

-

TEST SENSOR (brown)

NOT USED

-

GND (black)

EMERGENCY

EMERGENCY

START

20

18

START

20

19

123 4 567

DOORSS340/1023T

123 4 567

DOORSS340/1023T

123 4 123 4

+TEST SENSOR (grey)

+ 24Vcc (red)

RADAR OUT. N.A. (white)

SECURITY OP. N.C.

SECURITY CL. N.C. (yellow)

RADAR IN. N.A.

SENSOR OPEN SIDE

SENSOR CLOSED SIDE

SENSOR OPEN SIDE

SENSOR CLOSED SIDE

DOORRADM DOORRADMU

1234

BA-+

DL 1

LED3

LED2

ENGLISH

3

DC18-P

1

2

67

J1

J2

J3

J4

J5 J6 J7

J8

3

FASE

NEUTRO

SCHEDA CARICA BATTERIE

BATTERIASERR.ELET.MOTORE

SECONDARIO TF PRIMARIO TF

F1

3,15 A

F2

6,3 A

F3

2 A

LED4

LED5

TERRA

230V ac

SEZIONATORE

ALIMENTAZIONE DI RETE

MOTOR (+)

MOTOR (-)

ELECTROLOCK

+

-

BATTERY

+

BATTERY

* su richiesta

115 Vac

+/-10%, 60Hz

ENGLISH

4

DC18-M

8

1

ON 2 3 4

910

11

12

1314

15

16

17

18

1920

21

22

23

24

25

26

27

J4

J9

J10

J11

J12 J13 J14

J15

J16

ENCODER

ENCODER

-

+

A

B

SEL.

B2

SEL.

B1

SEL. B0

COMMON

COMMON

-

TEST SENSOR

NOT USED

-

GND

EMERGENCY

EMERGENCY

START

20

18

START

20

19

123 4 567

DOORSS340/1023T

123 4 567

DOORSS340/1023T

+TEST SENSOR

+ 24Vcc

RADAR OUT. N.A.

SECURITY OP. N.C.

SECURITY CL. N.C.

RADAR IN. N.A.

SENSOR OPEN SIDE

SENSOR CLOSED SIDE

1234

BA-+

DL 1

LED3

LED2

+-

OUTSIDE SENSOR

S-10DOORRAD2

TEST

+-

POWER

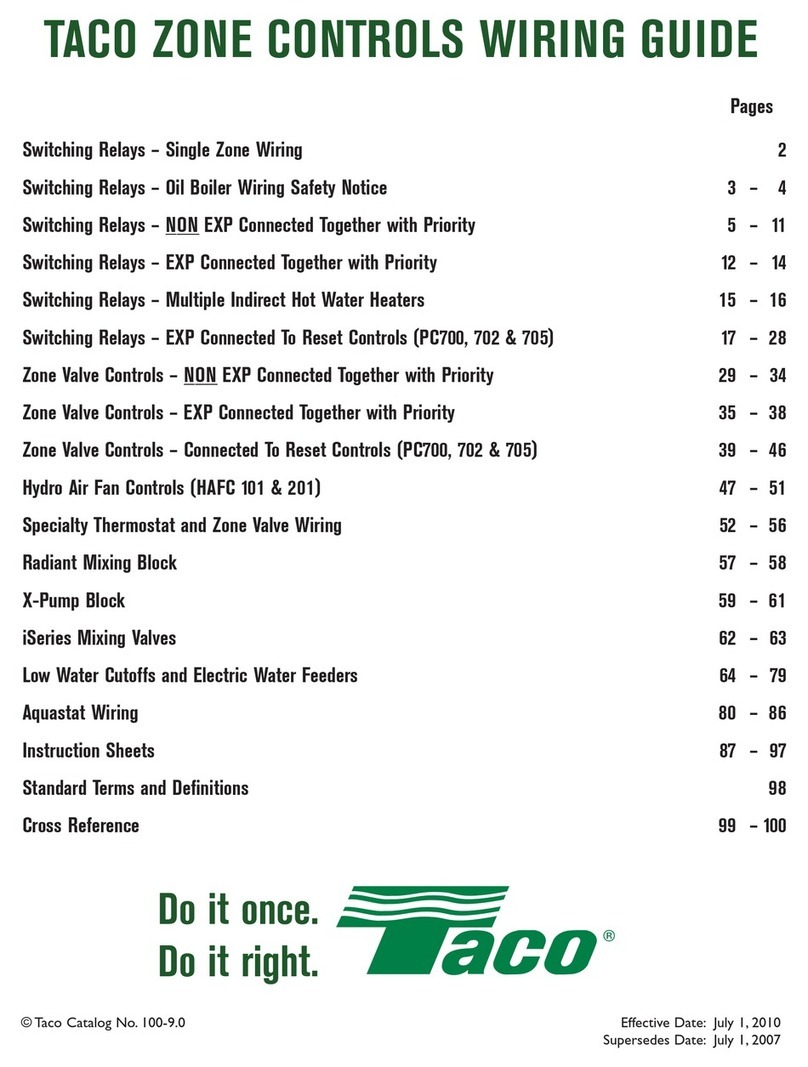

DC18 WIRING DIAGRAM WITH ACTIVATION

AND SAFETY SENSORS DOORRAD2 AND

DOORSS340/1023T

ENGLISH

5

DC18-P

1

2

67

J1

J2

J3

J4

J5 J6 J7

J8

3

FASE

NEUTRO

SCHEDA CARICA BATTERIE

BATTERIASERR.ELET.MOTORE

SECONDARIO TF PRIMARIO TF

F1

3,15 A

F2

6,3 A

F3

2 A

LED4

LED5

TERRA

230V ac

SEZIONATORE

ALIMENTAZIONE DI RETE

MOTOR (+)

MOTOR (-)

ELECTROLOCK

+

-

BATTERY

+BATTERY

+-

OUTSIDE SENSOR

S-10DOORRAD2

TEST

+-

POWER

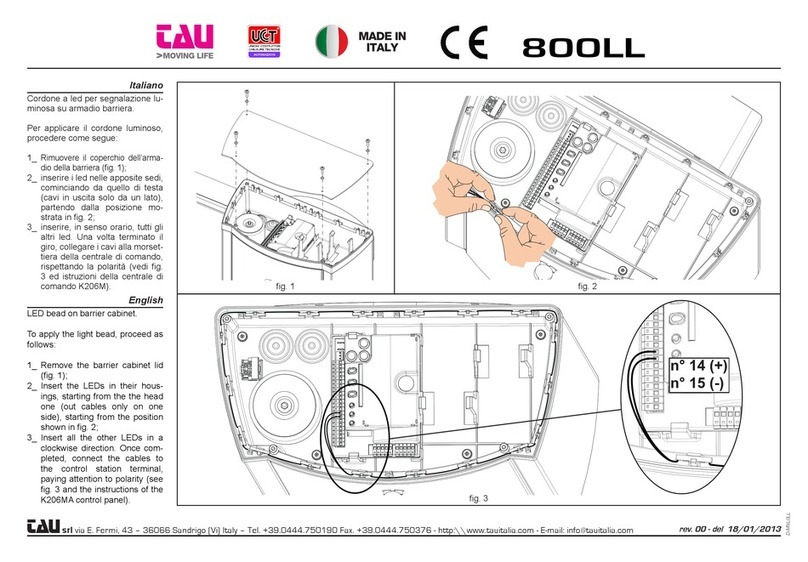

Mors. 10 - Brown

Mors. 8 - Grey

Mors. 15 - Yellow

Mors. 11 - Green

Mors. 11 - Blue

Mors. 13 - White

Mors. 17 - Black

Mors. 16 - Red

* su richiesta

115 Vac

+/-10%, 60Hz

ENGLISH

6

WARNINGS

This manual has been especially written for use by qualied installers. No information given in

this manual can be considered as being of interest to end users. This manual is enclosed with

control unit DC18 and may therefore not be used for dierent products!

Important information:

Disconnect the panel from the power supply before opening it.

The DC18 control unit has been designed to control an electromechanical gear motor for auto-

mating gates and doors of all kinds.

Any other use is considered improper and is consequently forbidden by current laws.

Please note that the automation system you are going to install is classied as “machine con-

struction” and therefore is included in the application of European directive 2006/42/EC (Machi-

nery Directive). This directive includes the following prescriptions:

- Only trained and qualied personnel should install the equipment;

- the installer must rst make a “risk analysis” of the machine;

- the equipment must be installed in a correct and workmanlike manner in compliance with all

the standards concerned;

- after installation, the machine owner must be given the “declaration of conformity”.

This product may only be installed and serviced by qualied personnel in compliance with cur-

rent, laws, regulations and directives.

When designing its products, TAU observes all applicable standards (please see the attached

decla- ration of conformity) but it is of paramount importance that installers strictly observe the

same stand- ards when installing the system.

Unqualied personnel or those who are unaware of the standards applicable to the “automatic

gates and doors” category may not install systems under any circumstances.

Whoever ignores such standards shall be held responsible for any damage caused by the

system!

Do not install the unit before you have read all the instructions.

INSTALLATION

Before proceeding, make sure the mechanical components work correctly. Also check

that the gear motor assembly has been installed according to the instructions. Then

make sure that the power consumption of the gear motor is not greater than 3A

(otherwise the control panel may not work properly).

THE EQUIPMENT MUST BE INSTALLED “EXPERTLY” BY QUALIFIED PERSONNEL AS REQUIRED

BY LAW.

Note: it is compulsory to earth the system and to observe the safety regulations that are

in force in each country.

IF THESE ABOVE INSTRUCTIONS ARE NOT FOLLOWED IT COULD PREJUDICE THE PROPER

WORKING ORDER OF THE EQUIPMENT AND CREATE HAZARDOUS SITUATIONS FOR PEO-

PLE. FOR THIS REASON THE “MANUFACTURER” DECLINES ALL RESPONSIBILITY FOR ANY

MALFUNCTIONING AND DAMAGES THUS RESULTING.

ENGLISH

7

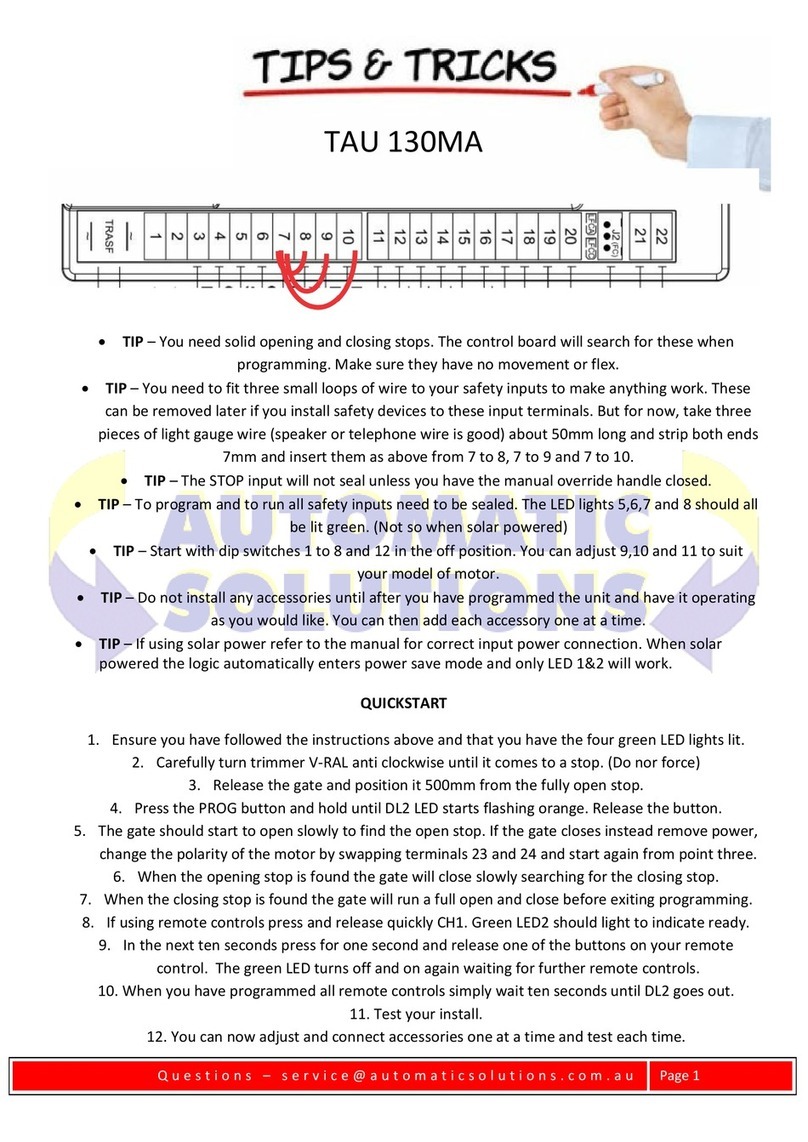

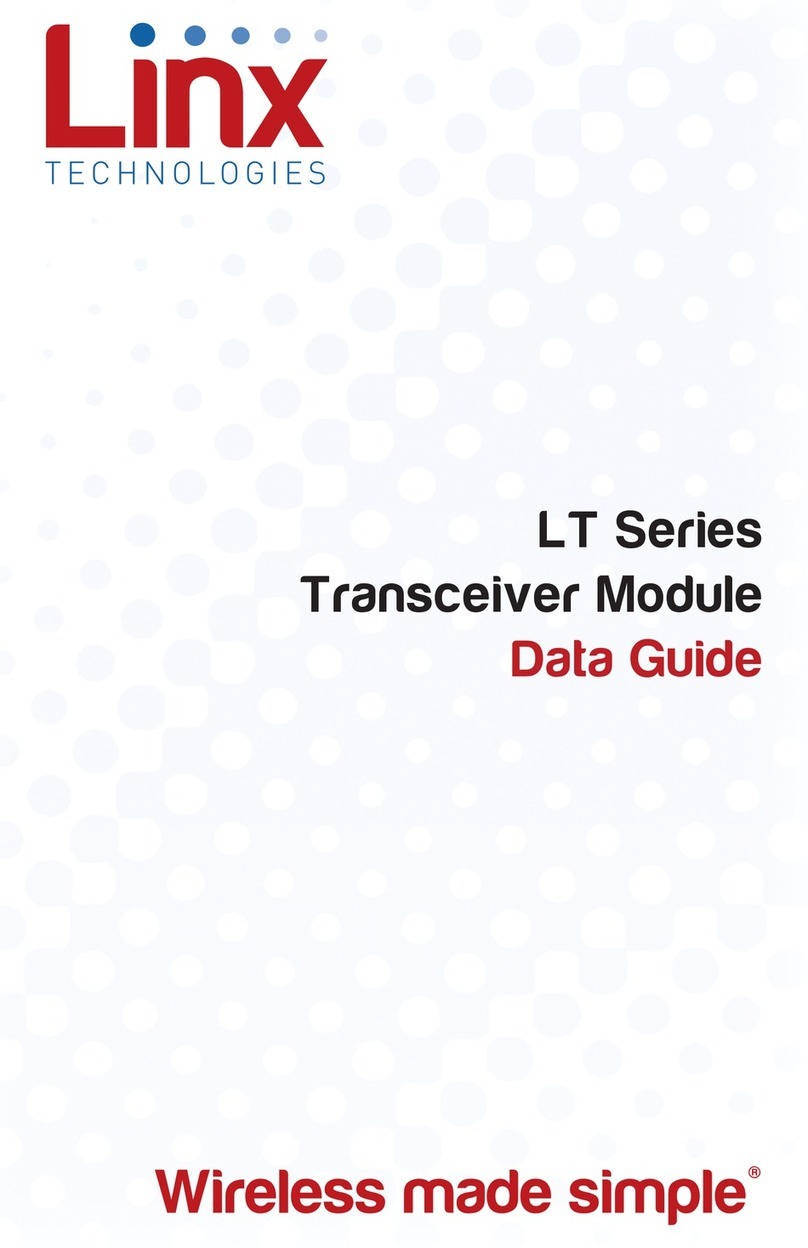

1. ELECTRIC ARRANGEMENTS

NOTE:

The grey part indicates

the survey zone of radar

and sensors.

The number of cables

and the relevant section

in mm is indicated for

every device.

1

3

4

8

9

6

5

27

1) EXTERNAL RADAR (4x0,5mm)

2) INTERNAL RADAR (4x0,5mm)

3) OPENING CONTROL (2x0,5mm)

4) PROGRAM SELECTOR (4x0,5mm)

5) SAFETY SENSOR FOR CLOSING (6x0,5mm)

6) SAFETY SENSOR FOR OPENING(6x0,5mm)

7) BRINK OPERATOR (mains power supply 3x1,5mm)

8) ELECTRIC LOCK (2x1mm)

9) FLOOR STOP

• The power supply line must be protected against short circuit and dispersion to

ground.

• On the power supply mains, provide for an omni-polar switch/selector with

contact opening distance of at least of 3 mm.

• Use self-extinguishing cables for electric connections.

• Separate the mains power supply line from the very-low voltage line relative to

control and safety accessories.

• On the plastic side panels of the Brink operator there are the holes that must be

broken open, through which the electric cables must be inserted. The installer

must made the power supply cable stable inside the operator and, particularly,

limit the peeling of cable primary sheath so that the air and surface distances

are not reduced if a connector detaches from the terminal.

• If operator is installed on a door leaf, perform electric connection by a bran-

ching box with suitable exible unions and pipes, available on the market.

ENGLISH

8

CONTROL PANEL FOR AUTOMATIC SWING DOOR

• MICROPROCESSOR-BASED CONTROLLER

• ENCODER SENSOR FOR SELF-LEARNING OF TRAVEL

• CONNECTOR FOR BATTERY

• DIAGNOSTICS LEDS

ATTENTION:

- do not use single cables (with one single wire), ex. telephone cables, in order to avoid

breakdowns of the line and false contacts;

- do not re-use old pre-existing cables;

TESTING

Once the connection is completed:

TECHNICAL CHARACTERISTICS

Board power supply 230 V AC - 50 Hz*

Fast acting fuse entrance 230V AC (F5 - 5x20) 3.15A

Fast acting fuse for protection of auxiliary circuits 24 V CC

(F1 - 5x20) 2 A

Fast acting fuse for motor protection 40Vcc (F2 - 5x20) 6,3 A

Motor power supply circuits voltage 40 V DC

Auxiliary device circuits supply voltage 24 V DC

Logic circuits supply voltages 5 V DC

Operating temperature -20 °C ÷ +55 °C

* On request 115 Vac +/- 10%, 60Hz

WORKING PROGRAMS

Six dierent working programs can be selected (can be set by mechanical selector or by

T-SIDETD programmer):

• “ENTRAMBI I SENSI” (AUTO)

• “SOLO USCITA” (EXIT ONLY)

• “SEMPRE CHIUSA” (HOLD CLOSE)

• “MANUALE” (

• “SEMPRE APERTA” (HOLD OPEN)

• “SOLO ENTRATA” (ENTRY ONLY)

Program Description Active inputs Remarks

“ENTRAMBI I SENSI”

(AUTO) Two-Way Trac

Outside Radar

Inside Radar

Start / PP

Emergency

ENGLISH

9

“SOLO USCITA”

(EXIT ONLY) Exiting Trac

Inside Radar

Start / PP

Emergency

“SEMPRE CHIUSA”

(HOLD CLOSE)

Door always closed

(time to exit 10 sec.) Emergency

“MANUAL”

To move the door

manually without

controlling the motor

“SEMPRE APERTA”

(HOLD OPEN)

Door remains always

open

“SOLO ENTRATA”

(ENTRY ONLY) Entering Trac

Outside Radar

Start / PP

Emergency

CONNECTIONS TO TERMINAL BOARD

CONNETTORE J1 - power input connection 230V 50hz:

Terminals

Input/Output Description

1PHASE 230V AC

2GROUND

3NEUTRAL 230V AC

* On request 115 Vac +/- 10%, 60Hz

CONNETTORE J2 - transformer primary connector.

CONNETTORE J3 - transformer secondary connector.

CONNETTORE J4 - connector to link the two electronic boards

CONNETTORE J5 - motor connection.

CONNETTORE J6 - terminal used to command an electric lock; to be combined with a relay

in order to activate the lock.

Terminals Function Description

6 - 7 ELECTRIC LOCK 6= + 24V DC

7 = - GND

CONNETTORE J14 - connection for safety sensors test:

Terminals Function Description

8-10 TEST SENSOR 8 = + 24V DC

10 = - GND

9 NOT USED

ENGLISH

10

CONNETTORE J13 - sensor connection:

Terminals Function Description

11 - 12 INTERNAL SENSOR

(N.O. contact)

Opens in “EXIT ONLY” and “AUTO”.

Door won’t close until sensor is released.

11 - 13 EXTERNAL SENSOR

(N.O. contact)

Opens in “ENTANCE ONLY” and “AUTO”.

Door won’t close until sensor is released.

11 - 14 OPENING SAFETY SENSOR

(N.C. contact)

Stops the door if it detects an obstacle/person

during the opening phase, and it resumes opening

when the obstacle/person is removed.

11 - 15 CLOSING SAFETY SENSOR

(N.C. contact)

Stops the door if it detects an obstacle/person during

the closing phase and it reopens.

16 - 17 SENSORS POWER SUPPLY 16= + 24V DC

17 = - GND

CONNETTORE J7 - battery connector.

CONNETTORE J8 - battery charger board connector.

CONNETTORE J9 - connector for T-WIFI.

CONNETTORE J11 - connector for lid button.

CONNETTORE J12 - connection for T-LINESELF and EMERGENCY button:

18 - 20

EMERGENCY

(N.C.)

(20= commun)

Closed

Opens in any program, except in “LOCKED”.

When dip # 1 on SW1 is set on ON opens also in

“LOCKED”.

Opening None.

Closing Reverts motion and opens.

Open Door won’t close until input is released.

In pause None.

19 - 20

OPEN/START

(N.O.)

(20= commun)

Closed Open.

Opening None.

Closing Reverts motion and opens.

Open None.

In pause None.

20 - 21

22 - 23

MECHANICAL

SWITCH

20= Commun

21= Switch B0

22= Switch B1

23= Switch B2

Connections:

Selector Control Panel

120

2 21

3 22

4 23

WARNING: In case neither the mechanical selector it is necessary to jumper

wire terminals 20 - 22.

ENGLISH

11

SM

0419

M1 M2

1 2 3 4

SHOLD OPEN = Keeps door fully open.

AUTO = All Opening Inputs enabled

EXIT ONLY = Disables Outside Radar.

MANUAL = To move the door manually with-

out controlling the motor.

LOCK = Keeps door closed, allowing

opening only with EMERGENCY

Input (with Dip #1 on SW1 on

ON).

CONNETTORE J10 - connection to T-SIDETD (see its manual).

Terminals Function Description

24 POSITIVE T-SIDETD POWER + 5 V DC

25 A T-SIDETD SIGNAL signals the communication between T-SIDETD

and DC20

26 B T-SIDETD SIGNAL signals the communication between T-SIDETD

and DC20

27 NEGATIVE T-SIDETD POWER - 5 V DC

CONNETTORE J16 - encoder connection.

STROKE SETUP

To carry out the STROKE SETUP it is necessary to use the T-SIDETD digital keyboard

Before proceeding with the SETUP of the stroke, use the dipswitch to select the type of au-

tomatic swing door and its characteristics:

1AUTOMATION TYPE ON T-SIDE-S gearmotor with closing spring

OFF T-SIDE gearmotor without closing spring

2WEIGHT OF THE DOOR ON Heavy door max 110 Kg

OFF Light door up to 80 Kg

3MASTER/SLAVE ON To activate the MASTER/SLAVE mode for double swing

leaf automations

OFF For automations with single swing leaf

4MASTER/SLAVE ON To dene the SLAVE status

OFF To dene the MASTER status

IMPORTANT: during the initialization procedure no obstacles must be placed in the

doorway and in the radar detection eld, otherwise the procedure fails and must be

repeated. Furthermore, the door must not be manually assisted and other parame-

ters must not be changed with the digital keyboard.

At the rst installation, power up the control unit and once the digital keyboard is connected,

ENGLISH

12

it will propose the SETUP procedure automatically. To start the procedure, press the P1 key.

To start the SETUP of the stroke, press the P1 key, the DL1 LED will start to ash yellow and,

subsequently, the door will start a slow opening and closing maneuver to nd the opening

and closing limit switches. At the end, the door will perform a complete opening and closing

maneuver at standard speed. Once the setup is done, the door must be closed and the DL1

LED must ash green.

The automation will therefore work with the standard factory settings. In case an interven-

tion is required to change the operating parameters, the digital keyboard must be used by

accessing the various menus

SENSOR TEST SETTING

• Use only sensors which feature testing wires, connecting these to the wire terminals 8

and 10 of the controller DC18;

• Set DIP #15 and #16 on to ON in order to enable the test;

• Test will be performed at the beginning of each cycle (except when reversing motion).

BATTERY CHARGER KEY

Key: LED steady on; LED ashing;

GREEN LED – battery charger

status

o battery charger o;

ashing every 2 seconds initial slow charge;

continuous ashing under fast charge;

ashing every 4 seconds in backup;

steadily lit battery charged;

RED LED – fault diagnostics

o everything OK;

steadily lit FAULTY battery (cell voltage < than the minimum

or …..)

continuous ashing short circuit

ashing every 2 seconds battery not connected

AUTOMATIC OPERATION RESETTING - REALIGNMENT

When the board is powered or if the status of the inputs is unknown, the software must

realign the automation to determine the initial position.

The direction of the realignment depends on the program selected and the command given.

ATTENTION: if there are any “motor” alarms, the automatic reset timer is inhibited.

ENGLISH

13

DIAGNOSTICS LEDs AND BUZZER

DL1 DIAGNOSTIC

DL2 POWER SUPPLY 12 V

DL3 POWER SUPPLY 5 V

DL4 AUX POWER SUPPLY 24 V DC

DL5 Red LED for signaling MOTOR POWER SUPPLY 40V DC

DL1 LED ERRORS

Key: LED steady on; LED ashing;

Automation warnings:

green - ashing every 4 seconds automation closed – everything OK;

green - continuous ashing automation moving (opening/closing);

green – quick ashing automation pausing;

green – steadily lit automation open;

/ alternating green/red - warning setup to be performed

yellow – QUICK ashing setup in progress

/ green/yellow – QUICK ashing Parameter recalculation in progress / program

change

Allarmi automazione:

red - 1 error photocell test failed

red - 2 error obstacle present

red - 3 error no voltage

red - 4 error automation in unknown status

red - 5 error automation timeout

red - 6 error incorrect communication MASTER/SLAVE

red - 7 error wrong parameters (generic error)

red - 8 error incorrect winter stroke parameters

Motor alarms:

yellow - 1 error encoder faulty or disconnected motor 1

yellow - 2 error motor 1 faulty or disconnected

yellow - 3 error motor 1 absorption exceeding the limits

yellow - 4 error obstacle detected by encoder 1

yellow - 5 error encoder faulty or disconnected motor 2

yellow - 6 error motor 2 faulty or disconnected

yellow - 7 error motor 2 absorption exceeding the limits

yellow - 8 error obstacle detected by encoder 2

ENGLISH

14

TROUBLESHOOTING

MALFUNCTION POSSIBLE CAUSE ACTION

DL1 ashes green/

red alternately. LEARNING Missing. Perform LEARNING as described in

LEARNING section.

During LEARNING

motor won’t move.

Safety or Command Inputs

are not correctly connect-

ed.

Check connections on wire terminals.

Safety or Command Inputs

are in use.

Remove obstacle from Sensor or Photo-

cells detection range.

With Mechanical

Switch connected,

door can’t complete

LEARNING process.

Mechanical Switch is set

on “SOLO ENTRATA” (EN-

TRY ONLY).

Set Mechanical Switch either on “EN-

TRAMBI I SENSI” (AUTO) or “BLOCCATA

CHIUSA” (LOCKED).

Door opens but not

closes.

Sensor or Photocell detect

an obstacle.

Remove obstacle from Sensor or Photo-

cells detection range; check eciency of

detection devices.

Dip # 3 on SW1 is set on

OFF and battery is not

connected, faulty or low.

Check connection and eciency of the

battery operated anti-panic device.

Doors stops and re-

vert operation. The

following cycle is per-

formed at reduced

speed.

The door found an ob-

stacle. Remove the obstacle.

The following cycle is per-

formed at reduced speed.

The door has excessive friction which

is seen as an obstacle Check the door

movement, if necessary adjust trimmers

TR3 and TR4 (force).

Door opens a little

bit, then closes at

reduced speed.

Encoder is damaged or

not properly connected.

Check the encoder 4-pole connector is

inserted.

DL1 1 yellow ashes Encoder not working Check the encoder cable or replace the

encoder as required.

Door won’t open in

“BLOCCATA CHIUSA”

(LOCKED) program

with EMERGENCY

input.

Controller is set on “BLOC-

CATA CHIUSA” (LOCK) pro-

gram and DIP # 1 on SW1

is set on OFF.

Select a dierent program, or set the

DIP # 1 on SW1 to ON to enable EMER-

GENCY input.

Battery is connected,

but door won’t open

in case of power

failure.

DIP # 3 on SW1 is set on

OFF.

Set DIP # 3 on SW1 on ON to enable

automatic opening in case of power

failure.

DOUBLE LEAF SWING DOOR

To manage the functioning of a double leaf swing door, two operators are needed: one cong-

ured as Master and the other one congured as Slave.

In the case of overlapping leaves, congure as Master the operator applied to the swing leaf

(the one that opens rst).

ENGLISH

15

In the case of a swing door with two overlapping closing leaves and installed on

emergency exits, the installer must measure the force required to open both leaves

of the door by manually pushing the Slave leaf in the direction of escape (most un-

favorable).

The force required to open the door manually must not exceed 150N and must be

measured on the main edge, right angle to the leaf, at a height of 1000±10mm.

If the measured force should exceed the limit of 150N, apply the emergency break-

out symbol only on the main leaf (Master) of the door.

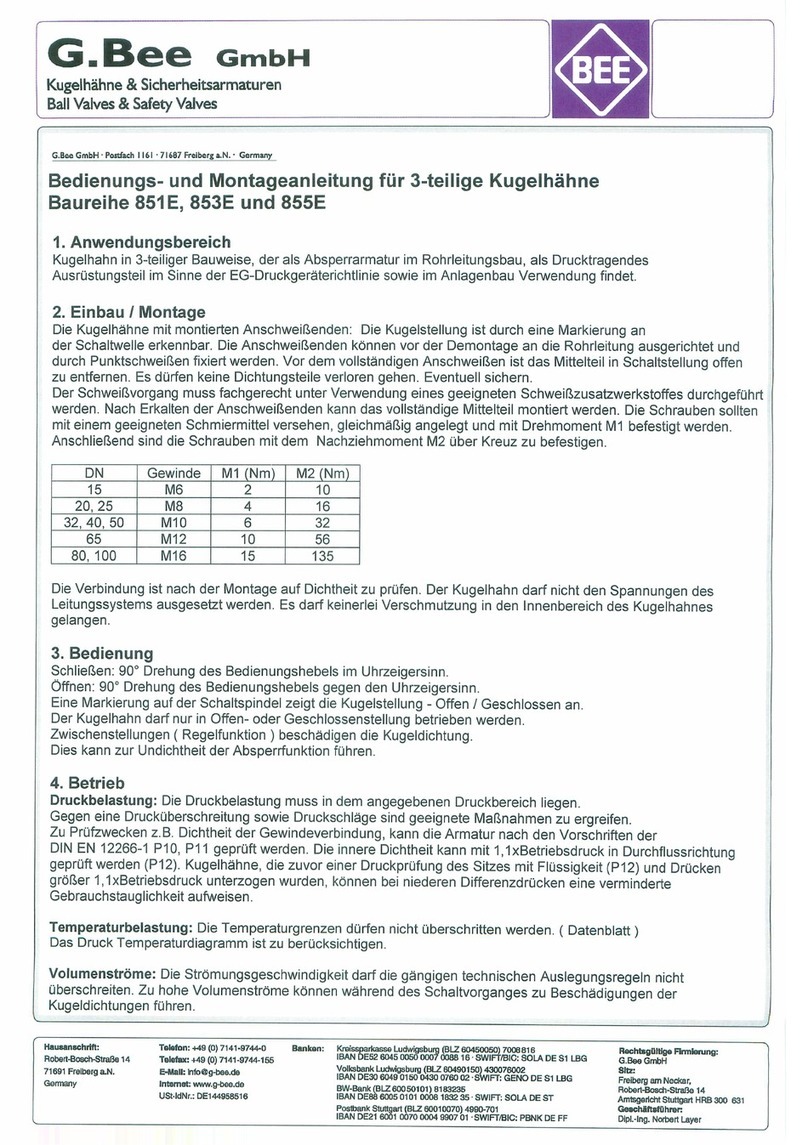

ELECTRICAL CONNECTIONS FOR DOUBLE LEAF DOOR

Make the electrical connections to the operators (see paragraph “Electrical connections”), con-

sidering that the command actuators for door opening, the program selector and the electric

lock must be connected to the Master operator.

The safety sensors installed on the master leaf must be connected to the Master operator, the

safety sensors installed on the slave leaf must be connected to the Slave operator.

If the door has a double electric lock to block each leaf individually, connect the electric lock

that blocks the slave leaf to the Slave operator..

ALIMENTAZIONE

DI RETE 230 V ac *

TASTIERA

DIGITALE

SENSORE

DI APERTURA

COMANDO

OPEN

OPERATORE MASTER

CABLAGGIO

M/S

OPERATORE SLAVE

SENSORI DI

SICUREZZA

PILOTAGGIO

ELETTROSERRATURA

MASTER

PILOTAGGIO

ELETTROSERRATURA

SLAVE

ANTA 1 (MASTER) ANTA 2 (SLAVE)

SENSORI DI

SICUREZZA

MASTER

The Master and Slave operators must be connected to each other as shown in the

gure

Connect to the Master operator with the T-SIDETD digital keyboard

ENGLISH

16

DC18-M SLAVE

8

910

11

12

1314

15

16

17

18

1920

21

22

23

24

25

26

27

J4

J10

J12 J13 J14

-

A

B

DC18-M MASTER

8

910

11

12

1314

15

16

17

18

1920

21

22

23

24

25

26

27

J4

J10

J12 J13 J14

-

+

A

B

BA-+

ENGLISH

17

ENGLISH

18

19

Via Enrico Fermi, 43 - 36066 Sandrigo (VI) - Italy

Tel +39 0444 750190 - Fax +39 0444 750376

[email protected] - www.tauitalia.com

Foglietto illustrativo

CARTA - Raccolta dierenziata. Segui le indicazioni del tuo comune. (N.B.: togliere i punti metallici)

Instruction leaet

PAPER - Waste separation. Follow the instructions of your city hall. (Note: remove the staples)

22

PAP

This manual suits for next models

2

Table of contents

Other tau Control Unit manuals

Popular Control Unit manuals by other brands

bee

bee 851E Operating and assembly instruction

Quectel

Quectel QuecOpen AG525R-GL Hardware design

olympia electronics

olympia electronics i-OLEG LumiGate GR-7610/V2 manual

Luna

Luna T-Ray 5000 user manual

Agilent Technologies

Agilent Technologies N5532A User's and service guide

GGM

GGM GUS Series Operation manual