2

6. Loosely mount outer ends of each pivot shaft to

mounting brackets on underside of bed with a pivot

shaft keeper, (2) 1/4–20 x 1/2” lg. capscrews,

lockwashers and flat washers (Fig. 2).

7. Rotate shafts so curved latches hold tailgate closed.

While holding latches firmly against tailgate, tighten

capscrews securing shaft keeper brackets to underside

of bed.

8. With a 5/16–18 x 1–1/4” lg. capscrew, flat washer and

locknut, mount pivot lever to bent bracket on underside

of bed. Shorter, (2 1/2”) end of lever to be positioned

upward, towards bed (Fig. 2). Do not over tighten

capscrew. Lever must pivot freely.

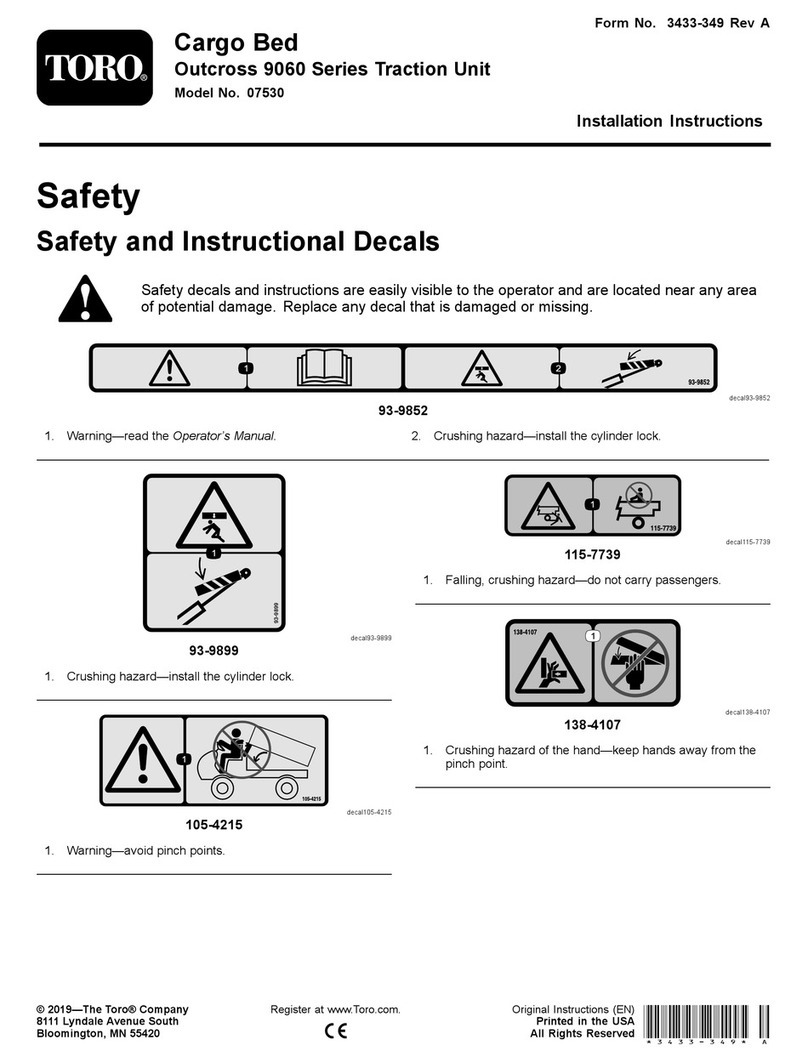

9. Mount curved end of pivot link rod assembly to bottom

hole in pivot lever with a washer and cotter pin (Fig. 3).

Figure 3

1. Pivot link rod

2. Pivot lever

1

3. Rod fitting

4. Tailgate shaft bracket

2

3

4

10.Mount rod fitting to tailgate shaft bracket with a flat

washer and cotter pin (Fig. 3).

CAUTION: Spring on pivot link rod assembly is

tensioned at the factory. Remove nut carefully if

disassembly is required.

11. Secure rear dump link to top hole in pivot lever with a

washer and cotter pin (Fig. 4).

Figure 4

1. Rear dump link

2. Pivot lever

1

2

12.Determine which position bed is mounted in, forward or

rearward. For next step, use short front dump link if bed

is mounted in forward (full bed) position and long link

if mounted in rearward (2/3 bed) position. Retain other

front dump link in case bed position in changed.

13.Using appropriate front dump link, insert shaft end

through slot in bed cross tube. Remove lynch pin

securing inside end of upper cylinder clevis pin to bed.

Insert washer end of dump link onto end of clevis pin

and re–secure with lynch pin.

14.Loosely secure front dump link to rear dump link with

(2) clamps, positioning as shown in figure 5.

15.With curved latches holding tailgate securely closed and

the bed lift cylinders fully retracted, in the down

position, adjust the dump link assembly length until

there is 1/8” gap between the front of the cylinder pin

and the front of the cylinder rod slot (Fig. 5, inset).

Figure 5

1. Front dump link

2. Slot in cross tube

3. Cylinder

4. Rear dump link

5. Cylinder pin

1

2

3

4

5

1/8”

16.To adjust the tailgate latch, loosen clamps and shorten

or lengthen dump link assembly. If tailgate rattles,

lengthen dump link assembly. If dump link assembly is

too long, linkage could bend when bed is completely

lowered.