i

TABLE OF CONTENT

1. FUNDAMENTAL OF THE SYSTEM ..........................................................................2

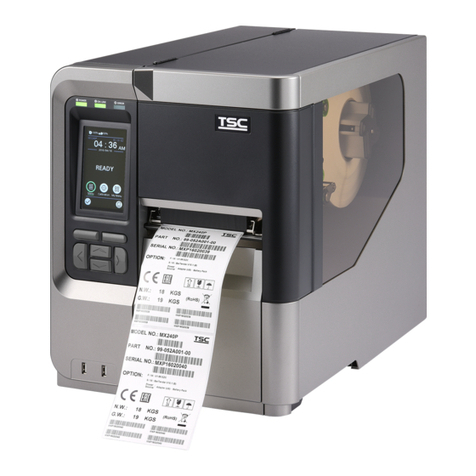

1.1. Overview.................................................................................................................2

2. ELECTRONICS..........................................................................................................7

2.1 Summary of Board Connectors.............................................................................7

2.2 Interface Pin Configuration..................................................................................11

3. MECHANISM...........................................................................................................13

3.1 Remove Covers and the Lower Front Panel ..............................................13

3.2 Replacing the LCD Panel Module for MU series ................................................15

3.3 Replacing the Touch Panel Module for MT series..............................................16

3.3 Replacing the Power Supply Unit........................................................................18

3.4 Replacing Multi-interface Board..........................................................................19

3.5 Replacing the Main Board....................................................................................20

3.6 Replacing the Platen Roller Assembly................................................................21

3.7 Replacing the Stepping Motor.............................................................................22

3.8 Replacing the Print head ASS’Y ..........................................................................23

3.9 Replacing the Gap/Black Mark Sensor Module..................................................25

3.10 Replacing the Ribbon Rewind Spindle .............................................................27

3.11 Cutter Module Installation (Option) ...................................................................28

3.12 Peel-off Kit Installation (Option)........................................................................29

3.13 Internal Rewinding Kit Installation (Option) .....................................................34

3.14 Replacing the Cutter Driver IC Board (Option).................................................37

4. TROUBLESHOOTING............................................................................................. 39

4.1 Common Problems...............................................................................................39

4.2 Mechanism Fine Adjustment to Avoid Ribbon Wrinkles ...................................43

4.3 Adjustment Knob..................................................................................................45

4.3.1 Print head Pressure Adjustment Knob ................................................................45

4.3.2 Print Head Burn Line Adjustment Knob...............................................................46

5. MAINTENANCE.......................................................................................................47

UPDATE HISTORY......................................................................................................49