ANNA-B112 - System integration manual

UBX-18009821 - R09 Contents Page 4 of 66

C1-Public

2.2.4 Arm Mbed OS ....................................................................................................................................24

2.2.5 Wirepas Mesh....................................................................................................................................28

2.2.6 Saving Bluetooth MAC address and other production data....................................................28

Flashing ANNA-B112 ...............................................................................................................................29

2.3.1 Flashing over UART..........................................................................................................................30

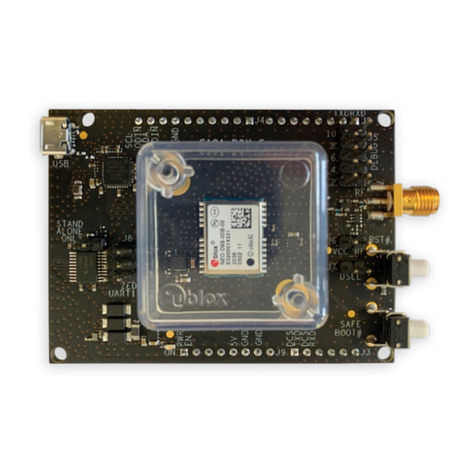

2.3.2 Flashing over the SWD interface...................................................................................................36

3Design-in............................................................................................................................................. 39

Overview......................................................................................................................................................39

Antenna interface.....................................................................................................................................39

3.2.1 ANNA-B112 Internal antenna design...........................................................................................39

3.2.2 ANNA-B112 External antenna design..........................................................................................40

3.2.3 General antenna design guidelines...............................................................................................40

Supply interfaces ......................................................................................................................................44

3.3.1 Module supply design ......................................................................................................................44

Data communication interfaces ............................................................................................................44

3.4.1 Asynchronous serial interface (UART) design............................................................................44

3.4.2 Serial peripheral interface (SPI).....................................................................................................45

3.4.3 I2C interface.......................................................................................................................................45

NFC interface.............................................................................................................................................45

3.5.1 Battery protection ............................................................................................................................45

General High Speed layout guidelines ..................................................................................................46

3.6.1 General considerations for schematic design and PCB floor-planning.................................46

3.6.2 Module placement ............................................................................................................................46

3.6.3 Layout and manufacturing.............................................................................................................46

Module footprint and paste mask .........................................................................................................47

Thermal guidelines ...................................................................................................................................47

ESD guidelines ...........................................................................................................................................47

4Handling and soldering................................................................................................................... 49

Packaging, shipping, storage, and moisture preconditioning.........................................................49

Handling......................................................................................................................................................49

Soldering .....................................................................................................................................................49

4.3.1 Reflow soldering process ................................................................................................................49

4.3.2 Cleaning ..............................................................................................................................................51

4.3.3 Potting ................................................................................................................................................51

4.3.4 Other remarks ...................................................................................................................................51

5Qualifications and approvals ........................................................................................................ 52

6Product testing................................................................................................................................. 52

u-blox in-series production test .............................................................................................................52

OEM manufacturer production test .....................................................................................................53

6.2.1 “Go/No go” tests for integrated devices ......................................................................................53

Appendix .................................................................................................................................................... 54

AGlossary .............................................................................................................................................. 54

BAntenna reference designs ........................................................................................................... 55

B.1 Internal antenna reference design with module at PCB corner.......................................................55

B.2 Internal antenna reference design with module along PCB edge ...................................................57