VeEX VePAL TX300M User manual

Other VeEX Test Equipment manuals

VeEX

VeEX TX300s User manual

VeEX

VeEX FX30 User manual

VeEX

VeEX MX100 Series Guide

VeEX

VeEX CX100 Series User manual

VeEX

VeEX WiFi Air Expert Series User manual

VeEX

VeEX MPX100 User manual

VeEX

VeEX V-SAM VePAL V300 User manual

VeEX

VeEX DS3 BERT User manual

VeEX

VeEX VePAL BX100A Series Guide

VeEX

VeEX VePAL TX320s User manual

VeEX

VeEX RTU-300 User manual

VeEX

VeEX Fiber Scope Inspector User manual

VeEX

VeEX VePAL TX300 User manual

VeEX

VeEX VePAL TX300 User manual

VeEX

VeEX UX400 User manual

VeEX

VeEX CX380C User manual

VeEX

VeEX VePAL TX300 User manual

VeEX

VeEX MTTplus User manual

VeEX

VeEX VePAL TX300 User manual

VeEX

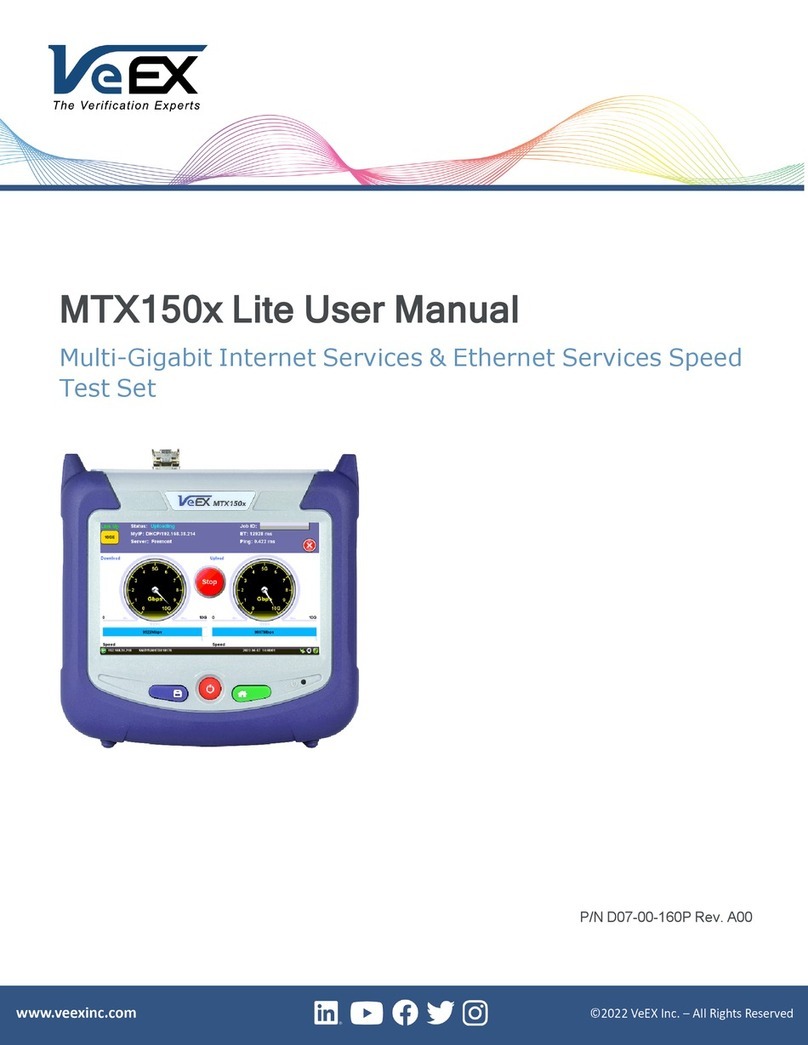

VeEX MTX150x Lite User manual