011302/01 9

10.- SETTING THE CUP STOPPING POSITION.

•Only if the cups fail to stop in the vertical position.

•Start up the motor, stop it with Stop and check if the cups stop before or after

reaching the vertical position.

•If they stop before reaching the vertical position, they probably need cleaning

and greasing. This can be checked by following the steps in Point 1.

•If they stop after the vertical position, this can be corrected in several ways:

oIf the machine registration number is 4376 onwards, it can be corrected

electronically. he process to follow in order to modify the stopping point from

the electronic circuit board is the following:

¾Switch off the machine using the switch at the rear.

¾Switch on again while pressing STOP. Four numbers will be displayed

on the screen.

¾With four numbers on the screen (they only appear for 3 seconds)

press the ON button. A number from 0 to 9 will be displayed on the left-

hand side of the screen. The number displayed corresponds to the

tenths of a second delay in stopping the machine, thus if the machine

needs to be stopped sooner, a number lower than that displayed on the

screen needs to be selected. To change this number, press ON (when

the screen is displaying the number on the left-hand side) and the

number will change. For the electronics to store this number in memory,

wait 5 seconds (the screen will then display a number in the central

position, corresponding to the number of oranges selected).

¾Check that the stopping point is correct. If this is not the case, repeat

the process with another delay value.

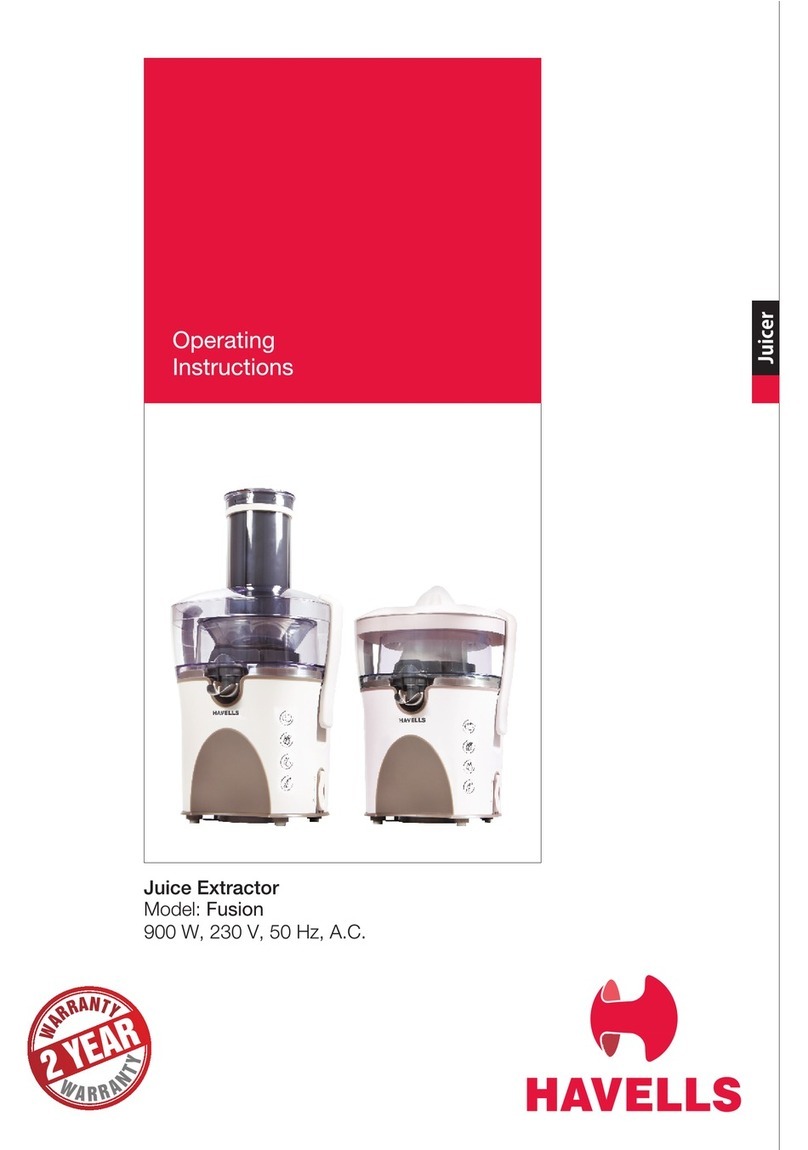

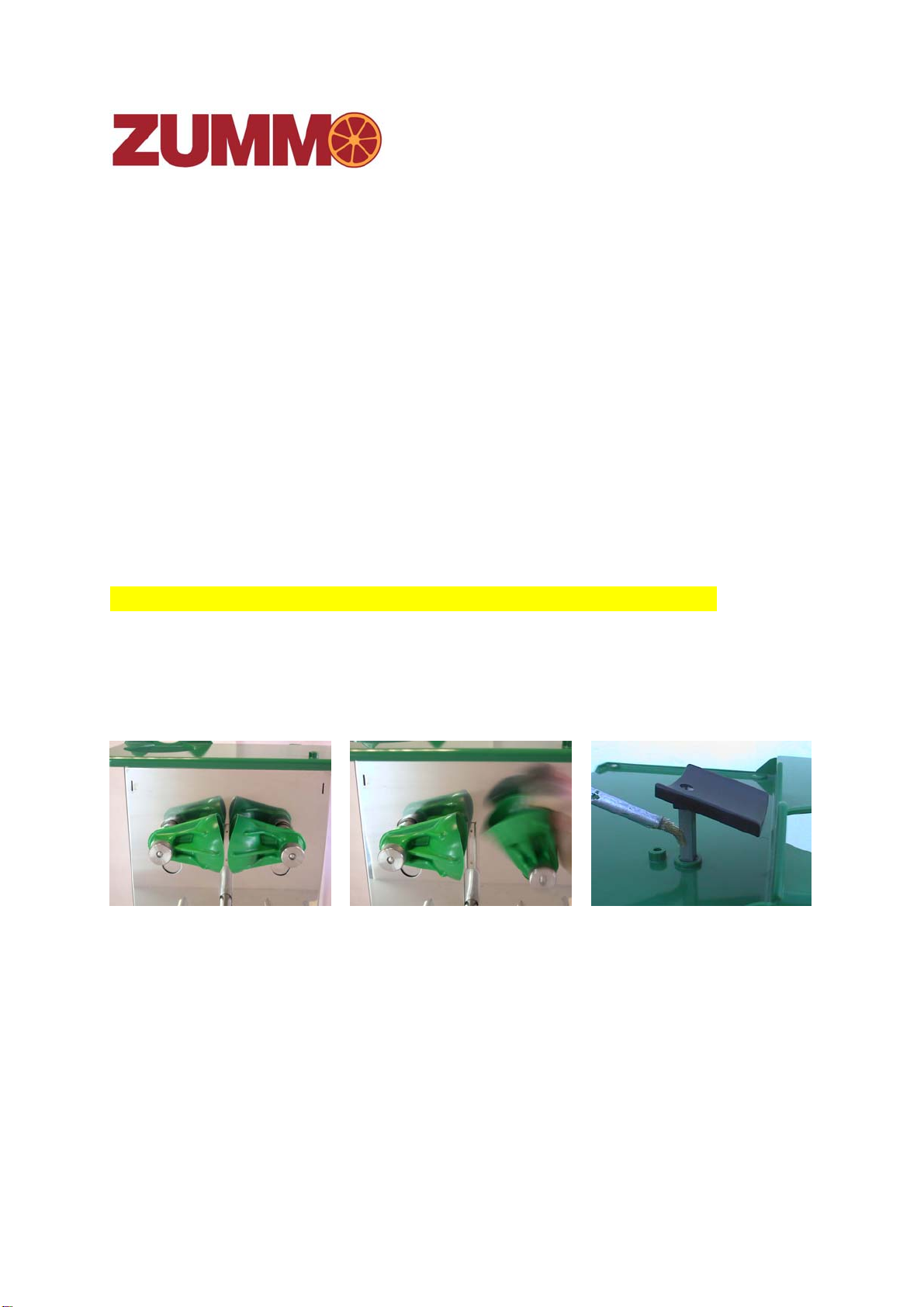

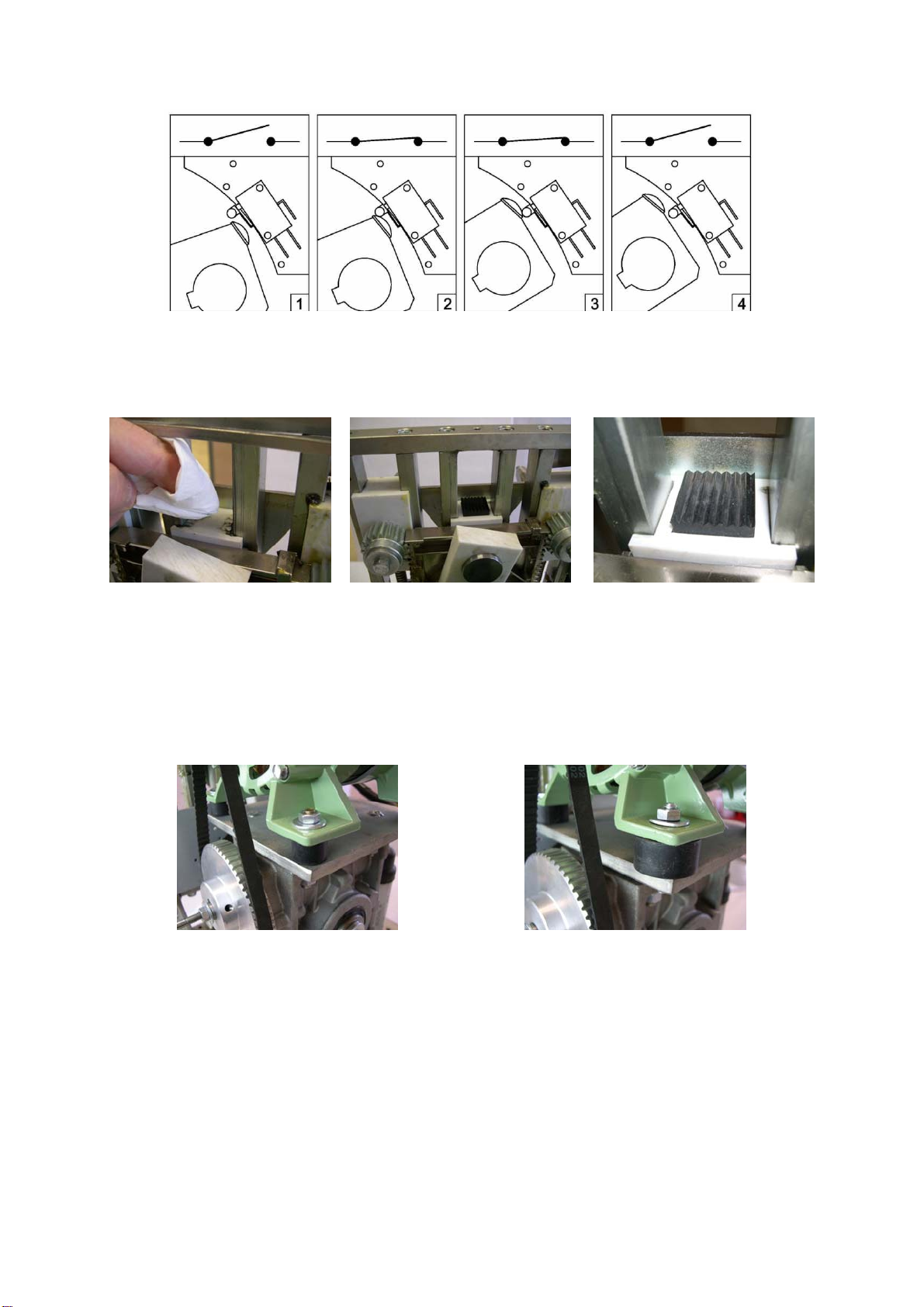

oIf the machine has a registration number earlier than 4376 or if it cannot be

corrected electronically, the position of the micro meter can be altered (Figs.

10a and 10b), and it can be advanced or retarded as necessary.

10a 10b

When the micro meter is refitted, it should be adjusted so that there is contact

for almost the whole time the cam is passing, approximately as shown in

Steps 2 and 3 in the following illustration.