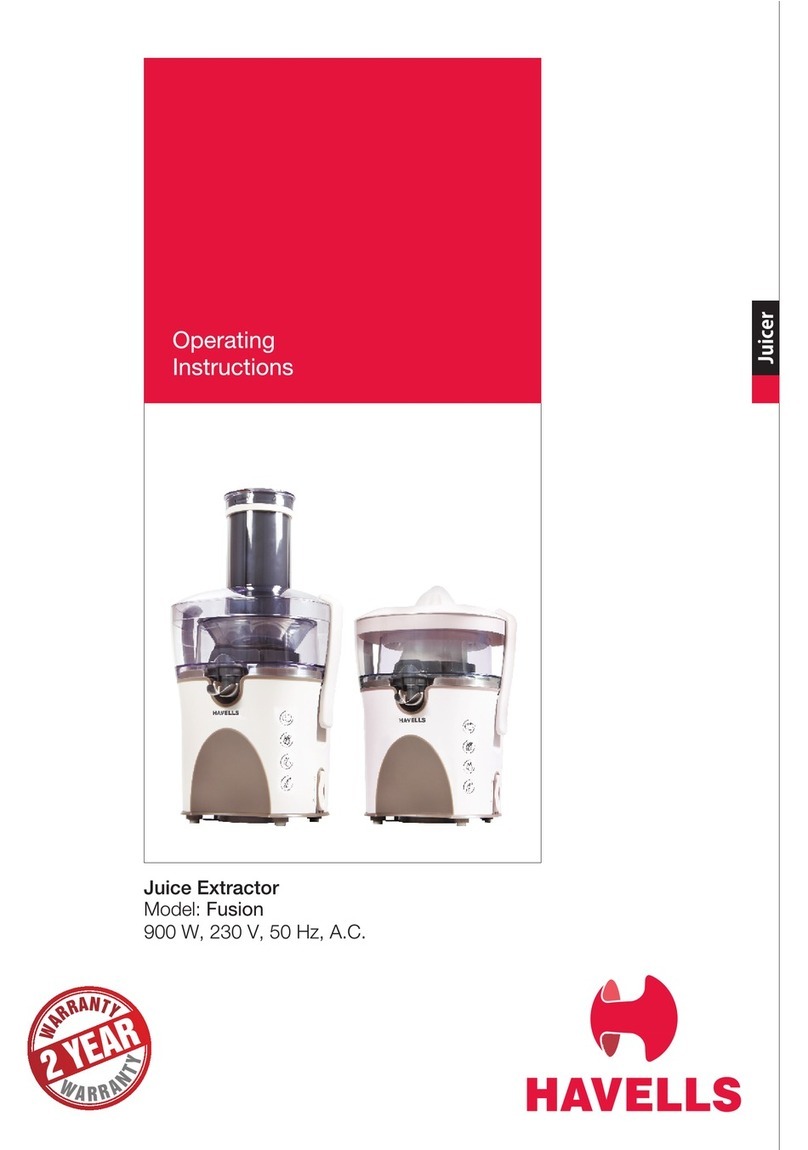

3INSTALLATION

•ATTENTION! The machine weighs 56Kg. When moving the machine, we suggest that this

be accomplished by two persons. The best way to handle a machine is to use one hand to

get a grip underneath the rear and the other placed beneath the squeezing tray. (Fig. 4)

•Place the machine on a sufficiently sturdy and stable base.

•Ensure that the machine’s voltage and frequency match the values of your electrical

installation. See the identification plate. (Fig. 5)

•Use an electrical outlet that is equipped with an effective earth connection. This outlet

should be used exclusively by the juice extraction machine. Do not plug other appliances

into the outlet.

•Before turning on the machine, it is recommended that the pieces that will be in contact with

juice be cleaned first (Cups, Balls, Blade, Juice Tray, Filter and Front Cover).

•Turn on the power switch. (Fig. 6) If no message appears on the display (Fig. 7), this

means that there is a lack of voltage; in this case, make sure that you have plugged the

machine into a live line and that the power switch is turned on. Once this problem has been

taken care of, one of the following three messages will appear: StoP, a number , C

•If the StoP message appears on the display, the machine cannot be operated because the

safety system prevents it. In this case, check the following:

a The Front Cover is properly in place, with its clasps properly fitted inside the slots.

(Fig. 8 & 9)

b The Juice Tray and the Blade are properly in place and Fastening Nuts tightened.

(Fig. 10)

•If a number or the letter Cappears on the Programmer display, the machine is ready for

normal operation.

4OPERATING THE JUICER

•Once the machine is turned on, the display will show a number between 1 and 50 or the

letter C. The number indicates the quantity of oranges to be squeezed and the letter C

means that oranges will be squeezed without interruption for approximately 30 minutes.

•Depending on the number of oranges that you want to squeeze, keep pressing the SELECT

button and the number on the display will increase from 1 to 50, and then the letter Cwill

appear (1,2,3,..........48,49,50,C,1,2,3.....). If you keep the SELECT button depressed for

more than 3 seconds, the number will decrease.

•Perform this operation until the wanted number is shown on the display.

•Once a quantity is selected and an operation is performed, the Programmer will store this

information (even if it afterwards is switched off) until a new number selection is made.

•When the ON button on the panel is pressed, the machine will squeeze the number of

oranges shown on the Programmer display. During the process, the number of oranges

that remain to squeeze will be shown on the display. If you want to repeat the operation,

simply press the ON button. To stop the process, press the STOP button.

5STOP

With the machine switched on, press the StoP button. On the display a number 0will appear

and the machine will stop at the time the Cups reach the vertical position. Afterwards, the

Programmer display will show the number of the previous selection.