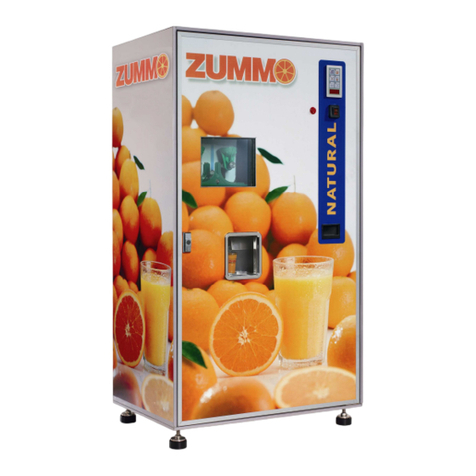

Zummo Z1 Nature User manual

Other Zummo Juicer manuals

Zummo

Zummo Z40 User manual

Zummo

Zummo Z1 Nature User manual

Zummo

Zummo ZO8A User manual

Zummo

Zummo Z40 Owner's manual

Zummo

Zummo Z10 User manual

Zummo

Zummo Z1 Nature Technical specifications

Zummo

Zummo Z14 Nature Technical specifications

Zummo

Zummo Viva Z25-BL, Viva Z25-BR, Viva Z25-GR User manual

Zummo

Zummo NATURE ONE Z40 User manual

Zummo

Zummo Z40E User manual