1. Legal framework

Checking that respirators with tight fitting face pieces seal adequately to the wearer’s face

has long been considered best practice as part of a Respiratory Protective Equipment

(RPE) programme. With the introduction of the new Control of Substances Hazardous

to Health Regulations (COSHH) and the supportingApproved Codes of Practice (ACOPs),

fit testing is now a mandatory requirement. RPE is only deemed suitable if it is suitable for

the job, the environment, the level of exposure and the wearer. One type and size of

respirator will not fit everybody, so fit testing has been introduced to find the most suitable

respirator for each individual.

2. What type of respirators require face fit testing?

The type of respirators that require a fit test are those which employ a tight fitting facepiece

such as disposable respirators, half masks and full face masks, including those that form

part of a powered or airfed respirator.

3. Who should be fit tested?

Fit testing should be carried out on:

(i) All existing wearers of these types of respirator if it has not already been done

(ii) People who are about to start wearing RPE in order to ensure that incorrectly fitting

respirators are not selected for use.

4. How often should people be fit tested?

Currently, fit testing should be repeated at regular intervals or at appropriate times such as:

(i) If the RPE wearer significantly loses or gains weight, has major dental work or

sustains a major facial injury.

(ii) If a different size or model of RPE is specified

HSE is currently consulting industry on the time frame of fit testing.

5. Who should conduct fit testing?

According to HSE guidelines, fit testing should be conducted by a ‘competent person’.

There is currently no recognised certification for a competent fit tester, therefore a certain

skill set is suggested such as adequate knowledge in the selection of suitable RPE, ability

to correctly fit the selected RPE and follow manufacturers guidelines, ability to recognise

a poorly fitting facepiece, ability to identify poorly maintained facepieces, etc. For full

details of suggested competencies, please refer to the HSE Document 282/28 which can be

downloaded from www.hse.gov.uk (search for document 282/28).

The decision on who is a competent person to carry out fit testing is the responsibility of

the employer. An industry fit tester qualification/accreditation scheme is currently being

worked on.

1514

Appendix 1:

Further information on Face Fit Testing

6. Fit test methods – Quantitative and Qualitative

Two main methods of fit testing are available, Qualitative and Quantitative fit testing

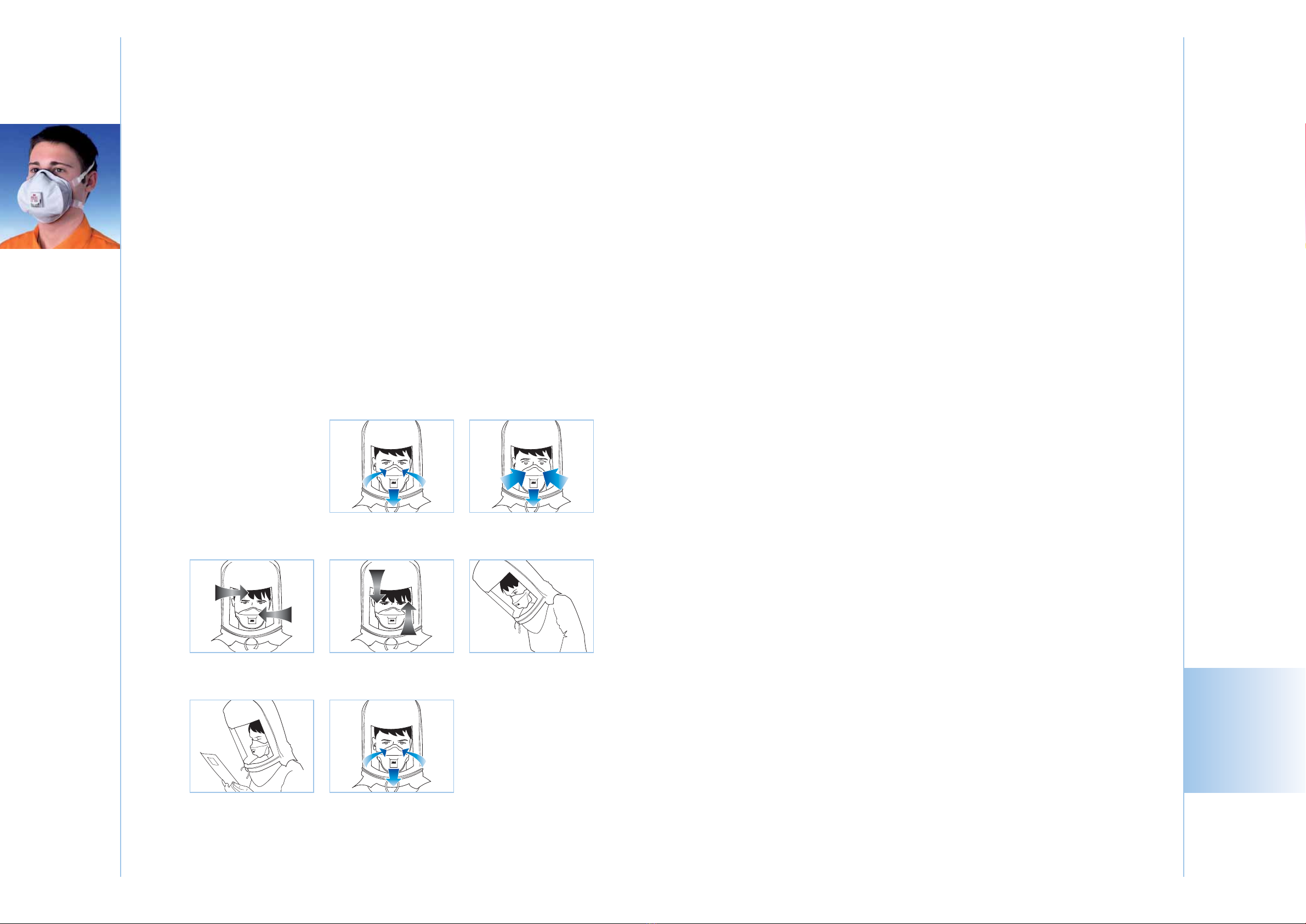

6.1 Qualitative fit testing:

Qualitative fit testing provides a pass or fail result based on the wearer detecting a

test agent. It provides a subjective measure of the quality of the seal of the facepiece

to the wearers face. These tests are suitable for disposable respirators and half masks.

The test agent can either be detected by taste or by smell.

The 3M Qualitative Test uses ‘taste’to detect face seal leakage. A controlled

concentration of aerosol is introduced into a hood fitted over the wearer. This test is

suitable for all disposable respirators and half masks fitted with particulate or

combination gas/vapour and particulate filters. 3M offer two test kits in this category,

one using a sweet tasting substance (saccharin) and the others which uses a bitter

tasting solution.

The 3M Kit can not be used with Full Face Mask respirators.

3M products that can be used with the 3M QLFT are:

•All 3M Disposable respirators (e.g 3M 8000 Series & 3M 9300 Series)

• 3M 4000 Series Respirators

• 3M 6000 Half Masks

• 3M 7500 Half Masks

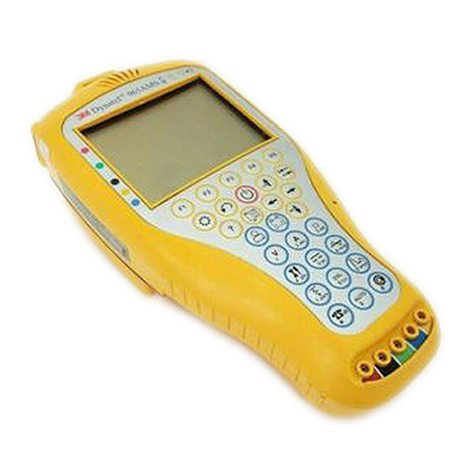

6.2 Quantitative fit testing:

Quantitative fit tests give an objective measure of the quality of the seal between the

wearer’s face and the facepiece. A fit factor number is produced which indicates the

quality of the face seal and leads to a Pass/Fail result. There are 3 main methods

available on the market today. (1) Test Chamber, (2) Particle Counting Device (such as

the TSI PortaCount) and (3) Controlled Negative Pressure Device.

This guide deals only with the 3M Qualitative Fit testing method.

3M 9300 Series 3M 8835 Series 3M 4000 Series

3M 7500 Series