5

1.0 General Function and Description

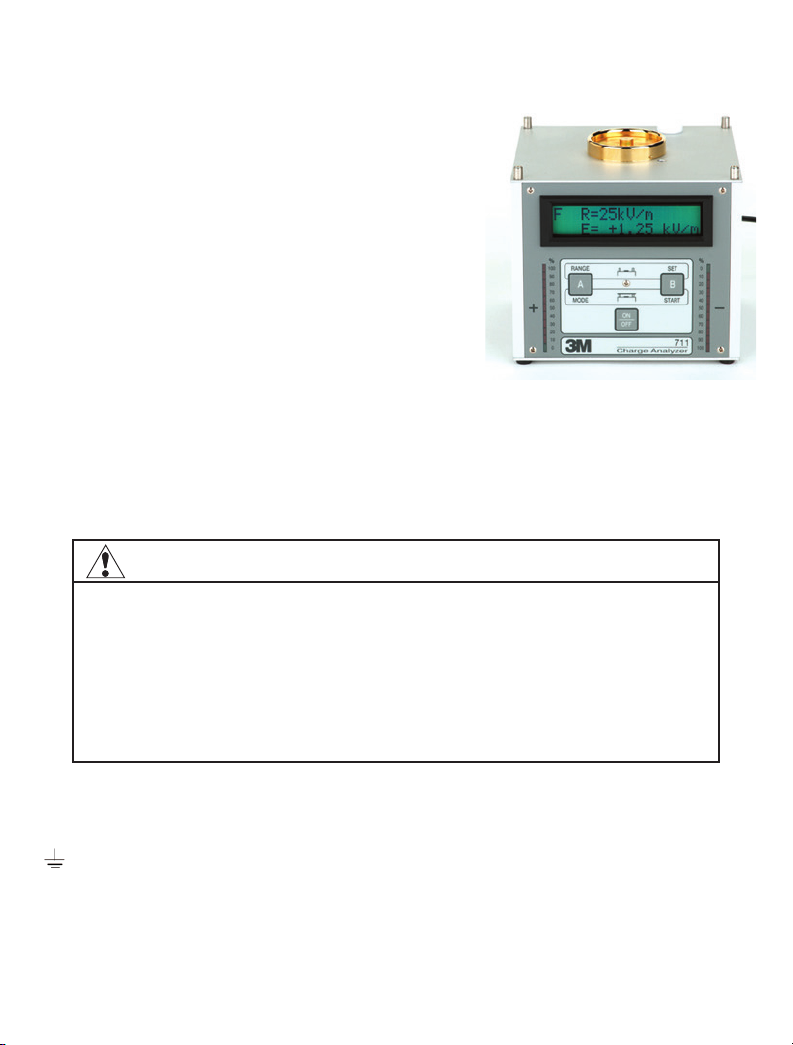

The 3M™Charge Analyzer 711 is an electronic test

instrument designed for ease of use. The lightweight

and compact construction offers great versatility

in the workplace. It can be used as a laboratory

analytical tool, evaluating the performance of ionizing

equipment, static-protective packaging, worksurfaces

and personnel grounding systems. It is also very

effective for use as a demonstration tool in employee

static awareness training programs.

All parameter settings are controlled via a built-

in EEPROM. These parameters are defaulted to when the Charge Analyzer

711 is switched on again. In case of a malfunction, the unit will display a

corresponding message and then automatically switch off.

The Charge Analyzer 711 operation works according to the fieldmill-principle.

The fieldmeter is a parametric amplifier. An electrostatic field induces a charge

on the sensor electrode, generating an AC current that is proportional to the field

strength. An amplifier measures this current without reducing the energy of the

electrostatic field in average time.

The Charge Analyzer 711 is powered by built-in

rechargeable NiMH-batteries or an AC wall plug-

in adaptor. When the unit is powered from the

rechargeable batteries, the LCD-display will not be

back illuminated to extend battery life. This power

saving feature will initiate within 60 seconds after

the last measurement or button depression. Also

during battery operation, the continuous LED-bar

indication changes to a single (momentary) action.

In case of a low battery power condition, the Charge Analyzer 711 automatically

switches off, first displaying LOW BATTERY then SWITCHING OFF UNIT. If

this occurs, continued operation of the Charge Analyzer 711 can be maintained

through the AC adaptor. Recharge time is approximately 14 hours with unit off,

when batteries are fully discharged.

Two vertical LED bars indicating 0 - 100% charge level and polarity are located

on the left and right sides of the front panel. The alphanumeric LCD-display

is the information center of the Charge Analyzer 711 and allows the user to

observe the principles of static protection. The unit’s high accuracy makes it well

suited for product performance analysis.

Note: To obtain the

maximum understanding

and use of this instrument,

it is recommended that the

User’s Guide be thoroughly

reviewed. Follow Setup and

Use procedures, observing

all safety messages and

important notes listed

in each of the operating

functions.

IMPORTANT NOTE

Avoid extreme discharge of the

rechargeable batteries. If the

batteries require charging, do

not allow the unit to sit idle for a

period of time without first fully

charging the batteries.