14

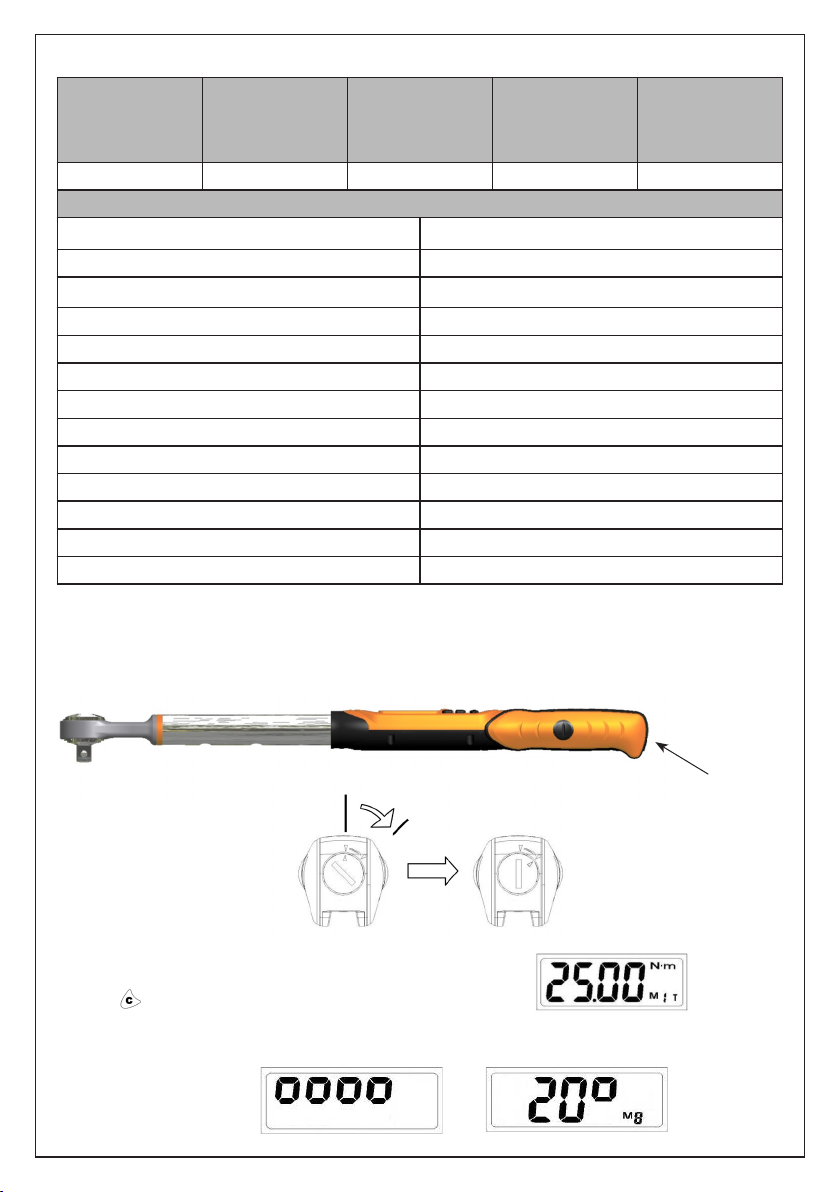

Model

N°.

Operation

Range

(N-m)

Square

Drive

(inches)

Alarm

Setting

Range

(N-m)

Lenght

(mm)

599 DGT-A/20 40-200 1/2” 10-200 519

Beta 599 DGT-A/20

Accuracy CW: ±2% CCW: ±2%

Operation Mode Peak Hold / Track

Unit Selection N-m, ft-lb, in-lb, kg-cm “ ° “

Head Type Reversible ratchet

Gear Teeth 72

Buttons 5

Bright LED 12 LEDs / 4 red + 8 green

Battery AA (R6) x 2

Battery Life (Continuous Operation) ~ 110 hours

Battery Life (Standby) ~ 1 year

Operating Temperature -10°C / 60°C

Storage Temperature -20°C / 70°C

Humidity Up to 90% non-condensingone

SPECIFICATIONS

+

_

Battery and cover

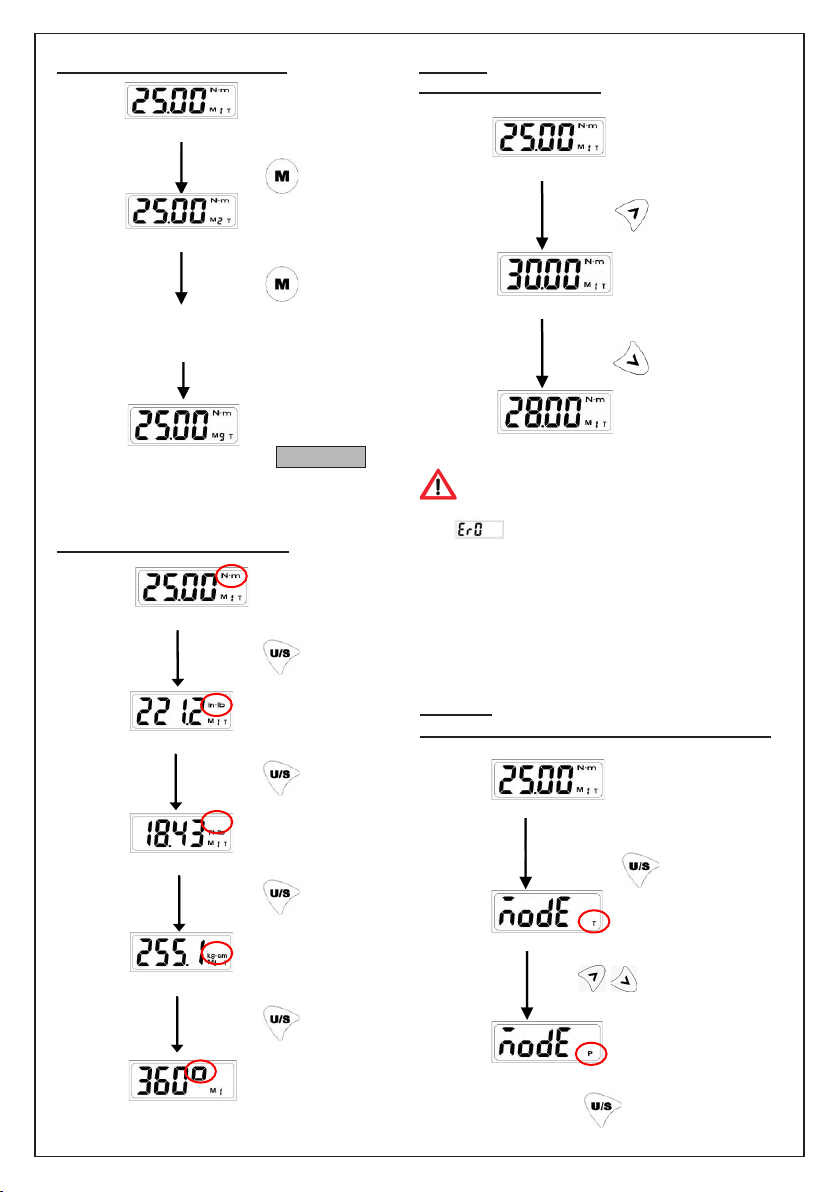

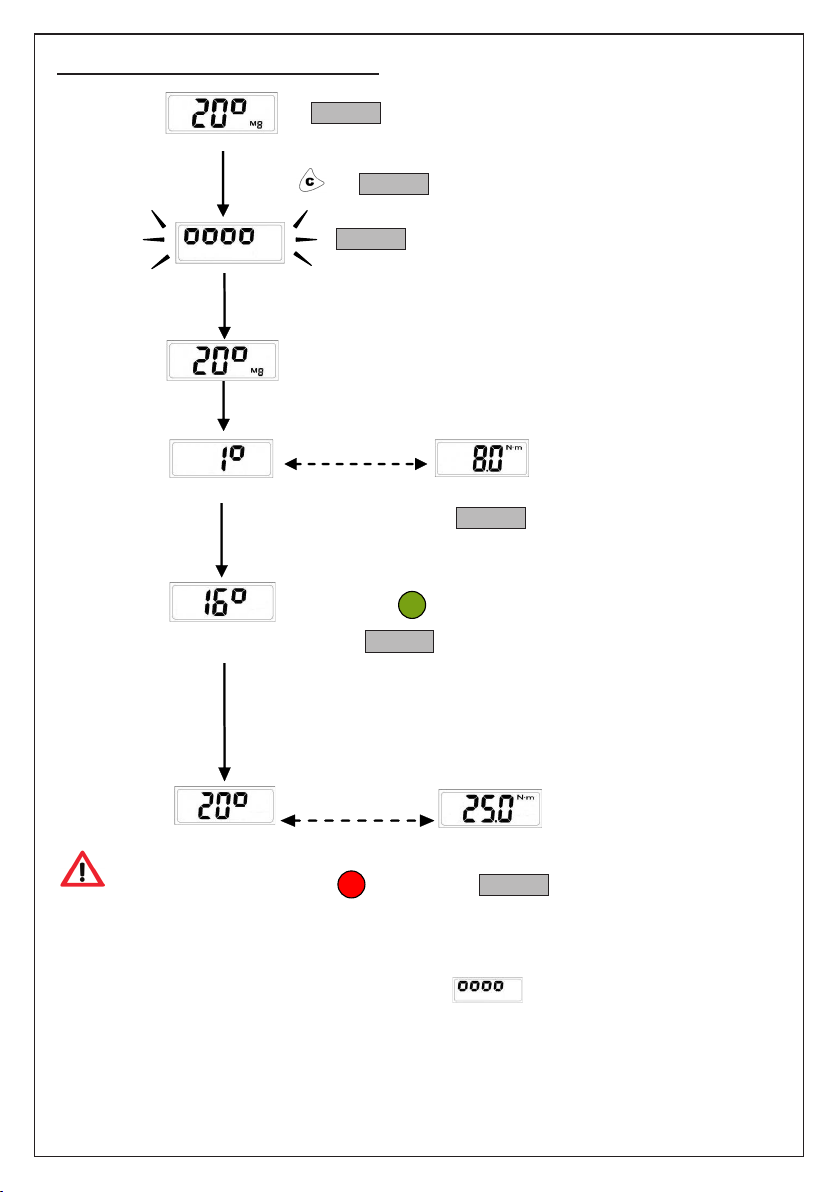

POWER ON AND RESETTINGWRENCH

– Press to power on the digital torque wrench.

– In the “torque” mode, the screen will display a preset value.

– In the “angle” mode, the screen will display rst a “zero” value, and then a preset angle value.

BATTERY INSTALLATION

– Remove the battery cover.

– Insert two R6/AA batteries matching the -/+ polarities of the battery to the battery compartment.

– Put on the battery cover and rotate it tightly according to the following figures.