1 689 975 140 2013-07-01|Robert Bosch GmbH

Symbols used | EPS 807 / 815 | 3 en

1. Symbols used

1.1 In the documentation

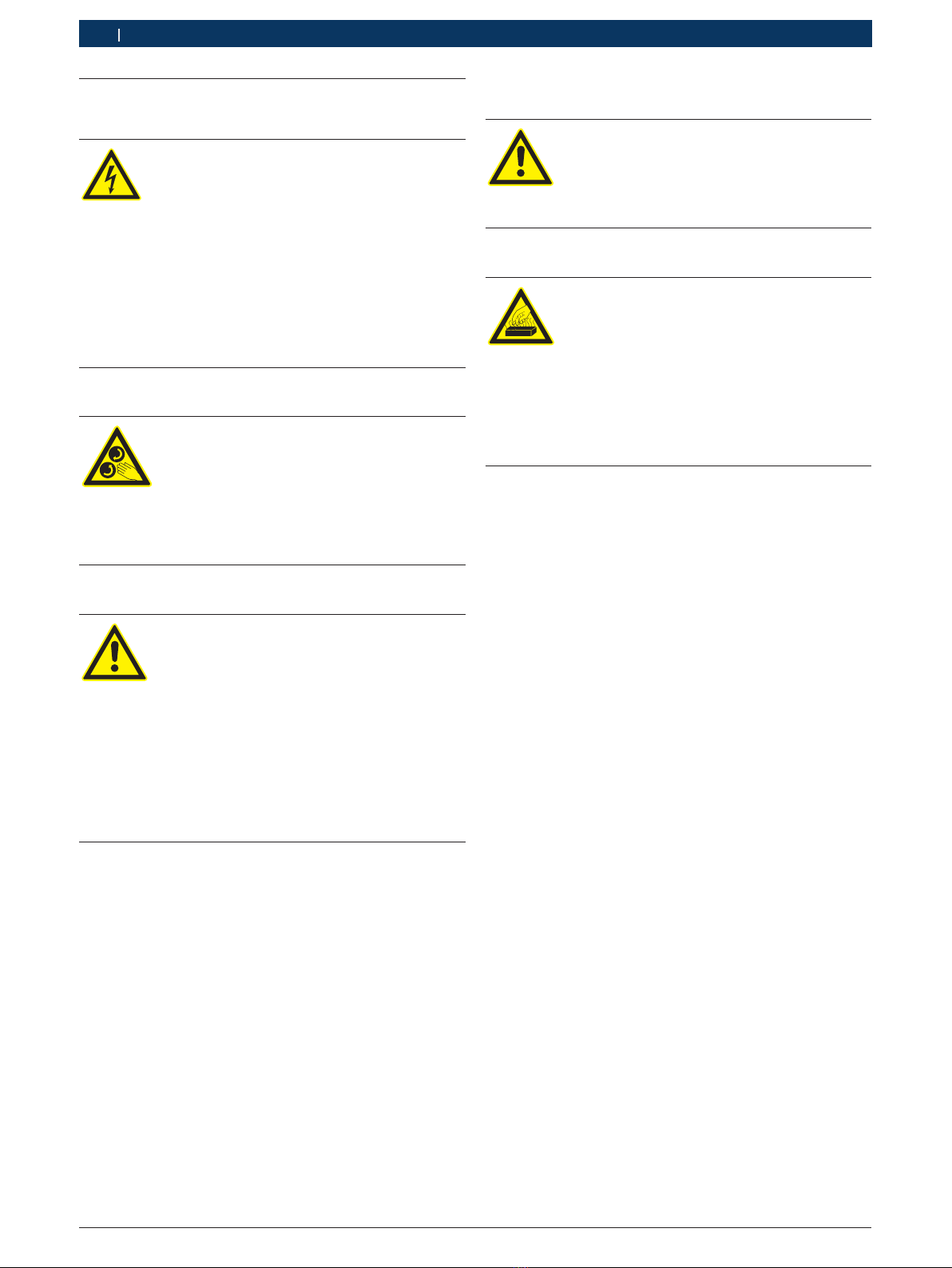

1.1.1 Warning notices - Structure and meaning

Warning notices warn of dangers to the user or people in

the vicinity. Warning notices also indicate the consequenc-

es of the hazard as well as preventive action. Warning no-

tices have the following structure:

Warning

symbol

KEY WORD – Nature and source of hazard!

Consequences of hazard in the event of fail-

ure to observe action and information given.

¶Hazard prevention action and information.

The key word indicates the likelihood of occurrence and

the severity of the hazard in the event of non-observance:

Key word Probability of

occurrence

Severity of danger if in-

structions not observed

DANGER Immediate impend-

ing danger

Death or severe injury

WARNING Possible impending

danger

Death or severe injury

CAUTION Possible dangerous

situation

Minor injury

1.1.2 Symbols in this documentation

Symbol Designation Explanation

!Attention Warns about possible property damage.

iInformation Practical hints and other

useful information.

1.

2.

Multi-step

operation

Instruction consisting of several steps.

eOne-step

operation

Instruction consisting of one step.

Intermediate

result

An instruction produces a visible inter-

mediate result.

"Final result There is a visible final result on com-

pletion of the instruction.

1.2 On the product

!Observe all warning notices on products and ensure

they remain legible.

1.3 Important notes

Installation and/or repair work may only be performed

by trained and instructed Service personnel at Robert

Bosch GmbH or by organizations appointed to do such

work by Robert Bosch GmbH. If the devices are opened

or modified by unauthorized persons, then all warranty

claims will be rendered null and void.

Electrical systems and resources may only be put into

operation when in proper operating condition (for more

information, refer to Inspection and testing information

0108_084). This requirement is deemed to have been

fulfilled if after modification or repair (initial test) it has

been ascertained that requirements as specified by the

electrotechnical rules have been adhered to. To this

end, tests as under the type and scope of the measures

defined by the electrotechnical rules (e. in Germany BGV

A2) are to be conducted. The type and scope of tests are

specified in VDE 0701/0702 Section 1 within Germany.

The relevant national specifications are to be adhered to.

!Observe ESD handling instructions when working on

the device when it is open. The instructions are avail-

able in EDIS at 'Bosch Test Equipment\Inspection &

Testing A-Z\General notes\Safety'.