Type 2000

Contents

3

CONTENTS

1 About these instructions ............................................................................................................................5

1.1 Symbols............................................................................................................................................ 5

1.2 Definition of terms ............................................................................................................................ 6

2 Intended use ...............................................................................................................................................7

3 Basic safety instructions............................................................................................................................8

4 General information..................................................................................................................................10

4.1 Contact address ............................................................................................................................. 10

4.2 Warranty ......................................................................................................................................... 10

4.3 Information on the Internet ............................................................................................................. 10

5 Product description..................................................................................................................................11

5.1 Features.......................................................................................................................................... 11

5.2 Structure and function.................................................................................................................... 11

5.2.1 Flow direction below seat ..................................................................................................13

5.2.2 Flow direction above the seat............................................................................................13

5.3 Device options................................................................................................................................ 14

5.4 Variants........................................................................................................................................... 14

6 Technical data ..........................................................................................................................................15

6.1 Conformity ...................................................................................................................................... 15

6.2 Standards ....................................................................................................................................... 15

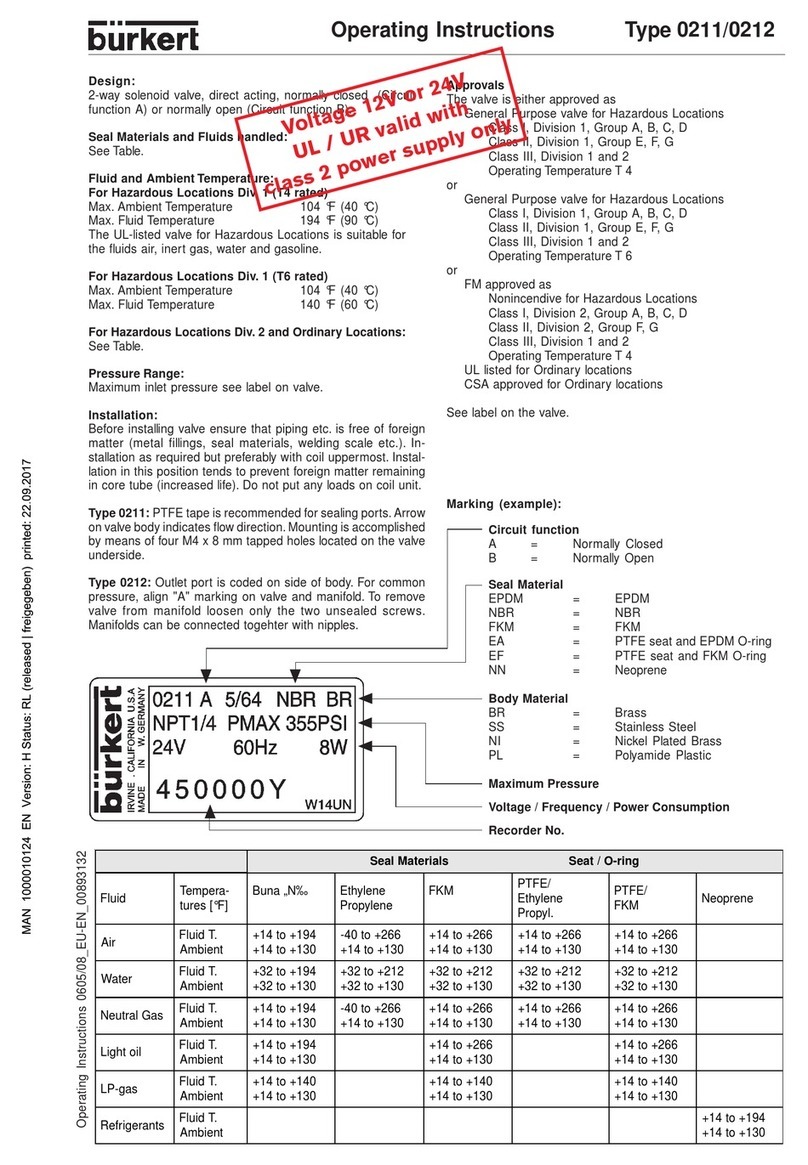

6.3 Type label ....................................................................................................................................... 15

6.3.1 Designation of the actuator size ........................................................................................15

6.4 Operating conditions ...................................................................................................................... 15

6.4.1 Temperature ranges...........................................................................................................16

6.4.2 Pressure ranges .................................................................................................................18

6.4.3 Minimum pilot pressure values ..........................................................................................18

6.5 Mechanical data ............................................................................................................................. 22

7 Installation ................................................................................................................................................23

7.1 Safety instructions installation........................................................................................................ 23

7.2 Preparatory work ............................................................................................................................ 24

7.2.1 Attach dirt trap ...................................................................................................................24

7.3 Installing valve body ....................................................................................................................... 24

7.4 Installing devices with welded connection ..................................................................................... 24

7.4.1 Removing actuator from the valve body for devices without control unit .........................24

7.4.2 Removing actuator from the valve body for devices with installed control unit ................25

7.4.3 Installing actuator on valve body .......................................................................................25

7.5 Installing control unit ...................................................................................................................... 26

7.6 Turning actuator ............................................................................................................................. 26

7.6.1 Turning the actuator, devices with hexagon nut................................................................26

7.7 Connecting device pneumatically .................................................................................................. 27

7.7.1 Connecting control medium ..............................................................................................27