FASTLINK™ ANCHOR STRAP

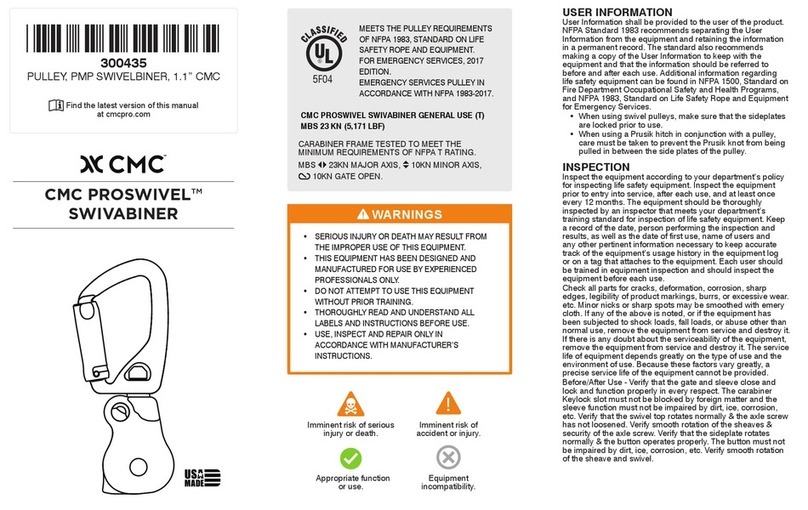

USER INFORMATION

User Information shall be provided to the user of the product. NFPA 2500 recommends separating

the User Information from the equipment and retaining the information in a permanent record. The

standard also recommends making a copy of the User Information to keep with the equipment and

that the information should be referred to before and after each use.

Additional information regarding life safety equipment can be found in NFPA 1500, Standard on Fire

Department Occupational Safety, Health, and Wellness Program, and NFPA 1858 and NFPA 1983,

incorporated into the 2022 Edition of NFPA 2500, Standard for Operations and Training for Technical

Search and Rescue Incidents and Life Safety Rope and Equipment for Emergency Services.

INSPECTION

Inspect the equipment according to your department’s policy for inspecting life safety equipment.

Inspect the equipment prior to entry into service, before and after each use, and at least once

every 12 months. The equipment should be thoroughly inspected by an inspector that meets your

department’s training standard for inspection of life safety equipment. Keep a record of the date,

person performing the inspection, results, date of rst use, name of users, and any other pertinent

information necessary to accurately track the equipment’s usage history in the equipment log or on a

tag that attaches to the equipment. Each user should be trained in equipment inspection and should

inspect the equipment before each use.

When inspecting equipment, check for cuts, worn or frayed areas, broken bers, soft or hard spots,

discoloration, or melted bers. Check the stitching for pulled threads, abrasion, or breaks. Check the

hardware for damage, sharp edges, and signs of improper operation. If any of the above is noted,

or if the equipment has been subjected to shock loads, fall loads, or abuse other than normal use,

remove the equipment from service and destroy it. If there is any doubt about the serviceability of the

equipment, remove the equipment from service and destroy it.

This equipment has a lifespan of 10 years from the date of manufacture shown on the product label.

Retiring equipment from service is also a function of the operating conditions, level of use, and

environmental conditions. Any concerns about its safe use is cause for retirement.

INSTRUCTIONS FOR USE

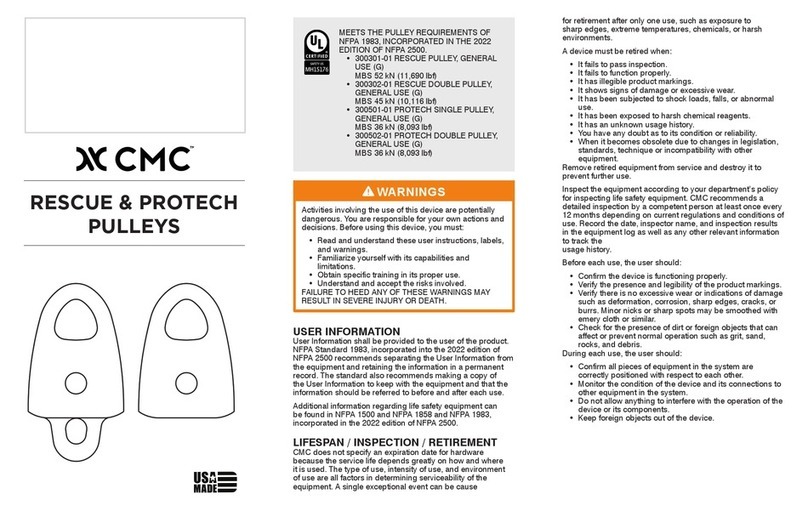

CMC Anchor Straps include Single Layer and Double Layer models. Single Layer Anchor Straps

are polyester while Double Layer Anchor Straps are nylon and offer an integrated web keeper for

compact stowage.

CMC Anchor Straps are designed for securing the system to an anchorage. Each anchor strap is

classied to NFPA standards for specic congurations. When installing anchor straps, care should

be taken to place the strap over surfaces free of burrs or sharp objects. Consider using CMC Anchor

Strap Sleeves for added protection.

It is the responsibility of the user to determine the structural integrity of the anchorage. Refer to

departmental policies and technical guidance when selecting the appropriate anchor strap length

for the given anchorage. Check to make sure there are no twists in the anchor straps. Conrm that

all connecting elements are locked and secured prior to loading the system. Continue to monitor the

anchorage and anchor straps for the duration of technical operations.

Anchor Strap

The Anchor Strap connects two proof-loaded steel D-Rings. This model is classied to NFPA

standards for Basket (U), Choker (Girth Hitch), and End-to-End congurations.

Basket (U)

• Place the strap around the anchorage in a doubled U-shape.

• Bring the two D-rings together side-by-side to form a single connection point.

• When attaching to these D-rings, a Delta Quick-Link is recommended to avoid tri-axial loading

on the connector. If a carabiner is used, it may rotate, cross-loading the gate.

• This conguration offers the highest classied strength rating for CMC Anchor Straps.

WARNING: When using a carabiner to connect both D-rings in Basket conguration, the

carabiner may rotate so that the load is on the gate. Monitor the carabiner and, if necessary,

adjust the strap and carabiner to avoid tri-axial or cross loading of the carabiner.

Choker (Girth Hitch)

• Place the strap around the anchorage.

• Pass the small D-ring through the large D-ring.

• Pull the free end with the small D-ring to tighten the strap around the anchorage.

• As the strap tightens down, orient the free end in the direction of anticipated load.

• Once the strap is girth hitched around the anchorage, the small D-ring functions as a single

connection point.

• Compared to the Basket (U) conguration, the Choker has lower risk of tri-axial or cross loading

a connecting carabiner, however, it has a lower strength rating.

End-to-End

• Connect the D-ring on one end of the anchor strap to a designated anchor point.

• Use the D-ring on the opposing free end as a single connection point.

• Compared to the Basket (U) conguration, End-to-End has lower risk of tri-axial or cross-loading

a connecting carabiner, however, it has a lower strength rating.

VARIABLE ANCHOR STRAP

The Variable Anchor Straps are designed for use in the same manner as the Anchor Strap. They are

subject to the same warnings as the Anchor Strap, including risk of tri-axial loading if a carabiner is

used to connect the two D-rings. The Variable Anchor Straps have an additional section of webbing

that runs through an adjuster buckle, allowing the strap length to be set within a desired range of 3 ft

(91 cm) to 7 ft (213 cm). They are classied to NFPA standards for Basket (U), Choker (Girth Hitch),

and End-to-End.

To achieve the specied MBS for the Double Layer Variable Anchor Straps, the user must tie an

overhand knot in the excess webbing downstream of the adjuster buckle. For the Single Layer

Variable Anchor Strap, an overhand knot is not required for achieving the MBS, however, users

should follow the recommendations set forth by their authority having jurisdiction (AHJ) for managing

excess tail at the anchor.

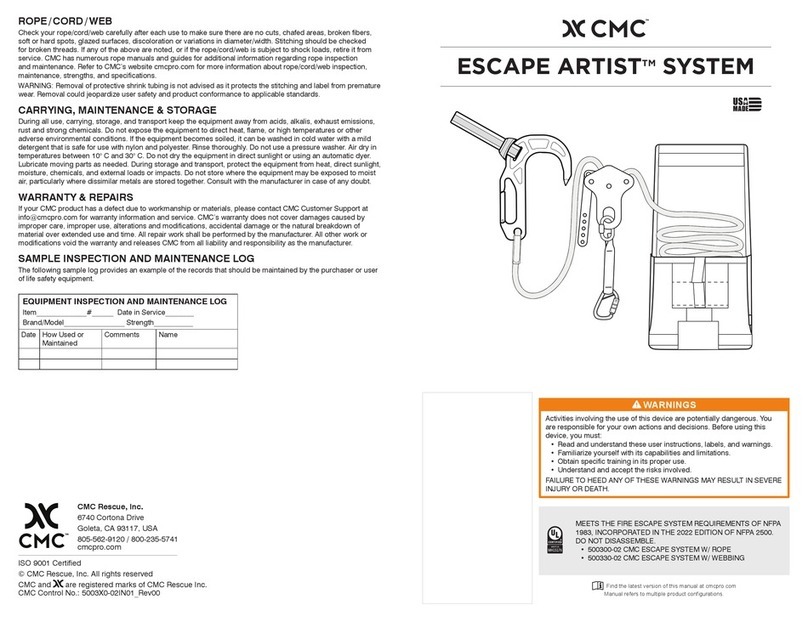

FASTLINK™ ANCHOR STRAP

The FastLink Anchor Strap connects a 12 mm Delta Quick Link and a ProTech™ Auto-Lock Carabiner

with keeper. This strap is secured by connecting the carabiner directly to the Quick Link. The Quick

Link remains screwed shut and serves as a focal attachment point that mitigates risk of tri-axial or

cross loading. Conrm that the carabiner and Quick Link are locked and secured prior to loading the

system. This model is classied to NFPA standards for Basket (U) and End-to-End congurations.

WARNING: The FastLink™ Anchor Strap should not be used in a Choker conguration as this may

put a side load on the carabiner.

Basket (U)

• Pass the strap around the anchorage in a doubled U-shape.

• Connect the carabiner to the Quick Link. The Quick Link becomes a focal attachment point that

mitigates the risk of tri-axial or cross loading. Do not use the carabiner as the focal attachment

point.

• This conguration offers the highest classied strength rating for CMC Anchor Straps.

End-To-End

• Connect one end of the anchor strap to a designated anchor point.

• Use the opposing free end as a single connection point.

• Consider orienting the strap so the carabiner is used for connecting single elements and the

Quick Link is used for connecting multiple elements.

• Compared to the Basket (U) conguration, End-to-End has a lower strength rating.

CARRYING, MAINTENANCE & STORAGE

During use, carrying, and storage, keep the equipment away from acids, alkalis, exhaust emissions,

rust, and strong chemicals. Carry the equipment where it will be protected as the equipment could

melt or burn and fail if exposed to ame or high temperatures. Store in a cool, dry location. Do not

store where the equipment may be exposed to moist air, particularly where dissimilar metals are

stored together.

Carrying, Maintenance, Storage & Transport

GENERAL DESCRIPTION

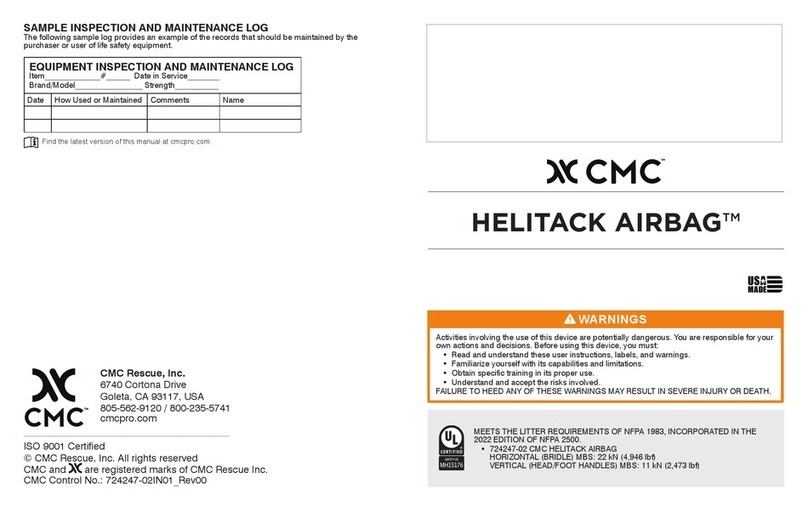

(VARIOUS SIZES) BASKET (U)

CHOKER

(GIRTH HITCH) END-TO-END

SINGLE LAYER

SL STRAP, ANCHOR, RED, CMC 69.7 kN

(15,669 lbf)

33.9 kN

(7,621 lbf)

33.1 kN

(7,441 lbf)

SL STRAP, VARIABLE ANCHOR, RED, CMC 61 Kn

(13,713 lbf)

31.2 kN

(7,014 lbf)

22.5 kN

(5,058 lbf)

SL STRAP, FASTLINK ANCHOR, RED, CMC 45.8 kN

(10,296 lbf)

24.8 kN

(5,575 lbf)

MEETS THE MULTIPLE CONFIGURATION STRAP REQUIREMENTS OF NFPA 1983, INCORPORATED IN

THE 2022 EDITION OF NFPA 2500. RATED FOR GENERAL USE (G)

DOUBLE LAYER

DL STRAP, ANCHOR, BLU, CMC 85 kN

(19,109 lbf)

48 kN

(10,791 lbf)

46 kN

(10,341 lbf)

DL STRAP, VARIABLE ANCHOR, BLU, CMC 69 kN

(15,512 lbf)

41 kN

(9,217 lbf)

18 kN

(4,047 lbf)

DL STRAP, VARIABLE ANCHOR, BLK, CMC 53 kN

(11,915 lbf)

21 kN

(4,721 lbf)

26 kN

(5,845 lbf)

DL STRAP, FASTLINK ANCHOR, BLU, CMC 45 kN

(10,116 lbf)

25 kN

(5,620 lbf)

MEETS THE MULTIPLE CONFIGURATION STRAP REQUIREMENTS OF NFPA 1983, STANDARD ON LIFE

SAFETY ROPE AND EQUIPMENT FOR EMERGENCY SERVICES, 2017 EDITION.

WARNING: The FastLink Anchor Strap should not be used in a Choker conguration as this may put a side load on

the carabiner.

MAX 30˚CMILD

MAX 30˚C