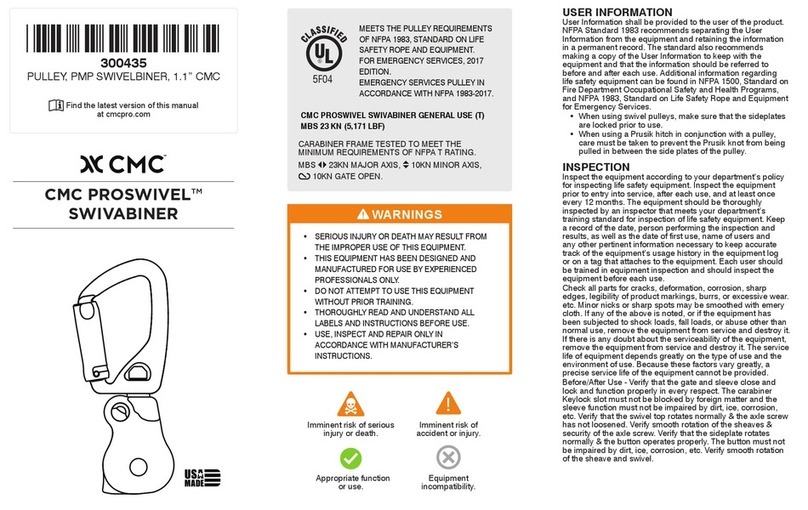

USER INFORMATION

User Information shall be provided to the user of the product. NFPA Standard 1983 recommends separating

the User Information from the equipment and retaining the information in a permanent record. The standard

also recommends making a copy of the User Information to keep with the equipment and that the information

should be referred to before and after each use. Additional information regarding life safety equipment can be

found in NFPA 1500, Standard on Fire Department Occupational Safety, Health, and Wellness Program and

NFPA 1983, Standard on Life Safety Rope and Equipment for Emergency Services.

INSPECTION

Inspect the equipment according to your department’s policy for inspecting life safety equipment. Inspect

the equipment prior to entry into service, after each use, and at least once every 12 months. The equipment

should be thoroughly inspected by an inspector that meets your department’s training standard for inspection

of life safety equipment. Keep a record of the date, person performing the inspection and results, as well as

the date of rst use, name of users and any other pertinent information necessary to keep accurate track of

the equipment’s usage history in the equipment log or on a tag that attaches to the equipment. Each user

should be trained in equipment inspection and should inspect the equipment before each use. When inspecting

the equipment, check the webbing and rope for cuts, worn or frayed areas, broken bers, soft or hard spots,

discoloration, or melted bers. Check the stitching for pulled threads, abrasion, or breaks. Check the hardware

for damage, sharp edges, and improper operation. If any of the above is noted, or if the equipment has been

subjected to shock loads, fall loads, or abuse other than normal use, remove the equipment from service

and destroy it. If there is any doubt about the serviceability of the equipment, remove the equipment from

service and destroy it. The equipment has a lifespan of 10 years from the date of manufacture shown on the

product label. Retiring equipment from service is also a function of the operating conditions, level of use, and

environmental conditions. Any concerns about its safe use is cause for retirement.

USE

The AZTEK ProSeries®System LT is a versatile mini-system that can be used anywhere a quick mechanical

advantage is needed. The AZTEK System LT is pre-rigged and provides either a 5:1 or a 4:1 mechanical

advantage system that extends up to 6 feet. Fully extended, the AZTEK System LT has a minimum breaking

strength of 36 kN (8,093 lbf). The AZTEK System LT is ideal for a variety of applications, including: positioning

for a litter tender, rappel pick-off, and lowering or raising system knot pass.

CERTIFICATION

TO BE COMPLIANT WITH NFPA 1983, THE FOLLOWING ADDITIONAL COMPONENTS MUST BE USED IN

CONJUNCTION WITH THE AZTEK OMNI PULLEYS (30032X):

• 8 mm Aztek ProSeries®Cord with CMC sewn termination (293021)

• 6 mm Prusik (using 3-over-2 wraps) (29500X)

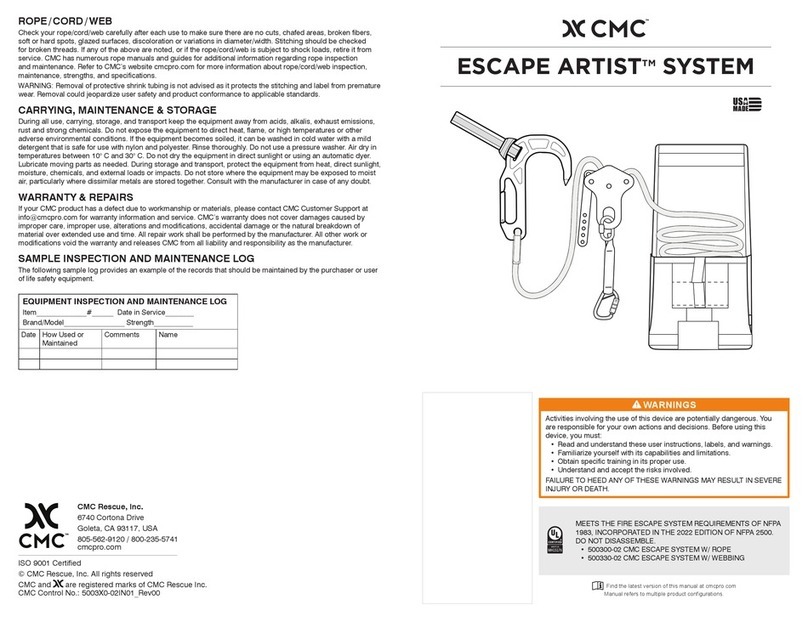

CARRYING, MAINTENANCE & STORAGE

Clean and dry this equipment after each use to remove any dust, debris and moisture. During use, carrying

and storage keep the equipment away from acids, alkalis, rust and strong chemicals. Do not expose the

equipment to ame or high temperatures. Store in a cool, dry location. Do not store where the equipment may

be exposed to moist air, particularly where dissimilar metals are stored together.

WARRANTY & REPAIRS

If your CMC product has a defect due to workmanship or materials, please contact CMC Customer Support

at

[email protected] for

warranty

information

and

ser

vice.

CMC’s

war

ranty

does

not

cover

damages

caused

by improper care, improper use, alterations and modications, accidental damage or the natural breakdown of

material over extended use and time. All repair work shall be performed by the manufacturer. All other work or

modications void the warranty and releases CMC from all liability and responsibility as the manufacturer.