USER INFORMATION

User Information shall be provided to the user of the product. NFPA Standard 1983, incorporated into the 2022

edition of NFPA 2500 recommends separating the User Information from the equipment and retaining the

information in a permanent record. The standard also recommends making a copy of the User Information to keep

with the equipment and that the information should be referred to before and after each use.

Additional information regarding life safety equipment can be found in NFPA 1500 and NFPA 1858 and NFPA 1983,

incorporated in the 2022 edition of NFPA 2500.

LIFESPAN / INSPECTION / RETIREMENT

The service life of equipment depends greatly on the type of use, intensity of use, and the environment of use. CMC

does not specify an expiration date for hardware because the service life depends greatly on how and where it is

used. For softgoods including Fire Escape Web and escape line, CMC has set a lifespan of 10 years from the date

of manufacture shown on the product label.

A single exceptional event can be cause for retirement after only one use, such as exposure to sharp edges,

extreme temperatures, chemicals, or harsh environments. Any concerns about its safe use is cause for retirement.

Remove retired equipment from service and destroy it to prevent further use.

A device must be retired when:

• It fails to pass inspection.

• It fails to function properly.

• It has illegible product labels or markings.

• It shows signs of damage or excessive wear.

• It has been subjected to shock loads, falls, or abnormal use.

• It has been exposed to harsh chemical reagents.

• It has an unknown usage history.

• You have any doubt as to its condition or reliability.

• When it becomes obsolete due to changes in legislation, standards, technique or incompatibility with other

equipment.

Inspect the equipment according to your department’s policy for inspecting life safety equipment. CMC

recommends a detailed inspection by a competent person at least once every 12 months depending on current

regulations and conditions of use. Record the date, inspector name, and inspection results in the equipment log as

well as any other relevant information to track the usage history.

When inspecting the system, follow the manufacturer’s recommendations for inspection provided with each of the

Escape Artist System components. If the system is used in actual fire ground emergency escape, or if there is any

doubt about the serviceability of the system,remove the system from service and destroy it.

Before each use, the user should:

• Confirm the equipment is functioning properly.

• Verify the presence and legibility of the product labels and markings.

• Check soft components for cuts, worn or frayed areas, broken fibers, soft or hard spots, discoloration, or

melted fibers. Check the stitching for pulled threads, abrasion, or breaks.

• Check hard components for excessive wear or indications of damage such as deformation, corrosion, sharp

edges, cracks, or burrs. Minor nicks or sharp spots may be smoothed with emery cloth or similar.

• Check for the presence of dirt or foreign objects that can affect or prevent normal operation such as grit, sand,

rocks, and debris.

During Each Use, the user should:

• Confirm all pieces of equipment in the system are correctly positioned with respect to each other.

• Monitor the condition of the equipment and its connections to other equipment in the system.

• Do not allow anything to interfere with the operation of the equipment or its components.

• Prevent foreign objects from interfering with moving parts.

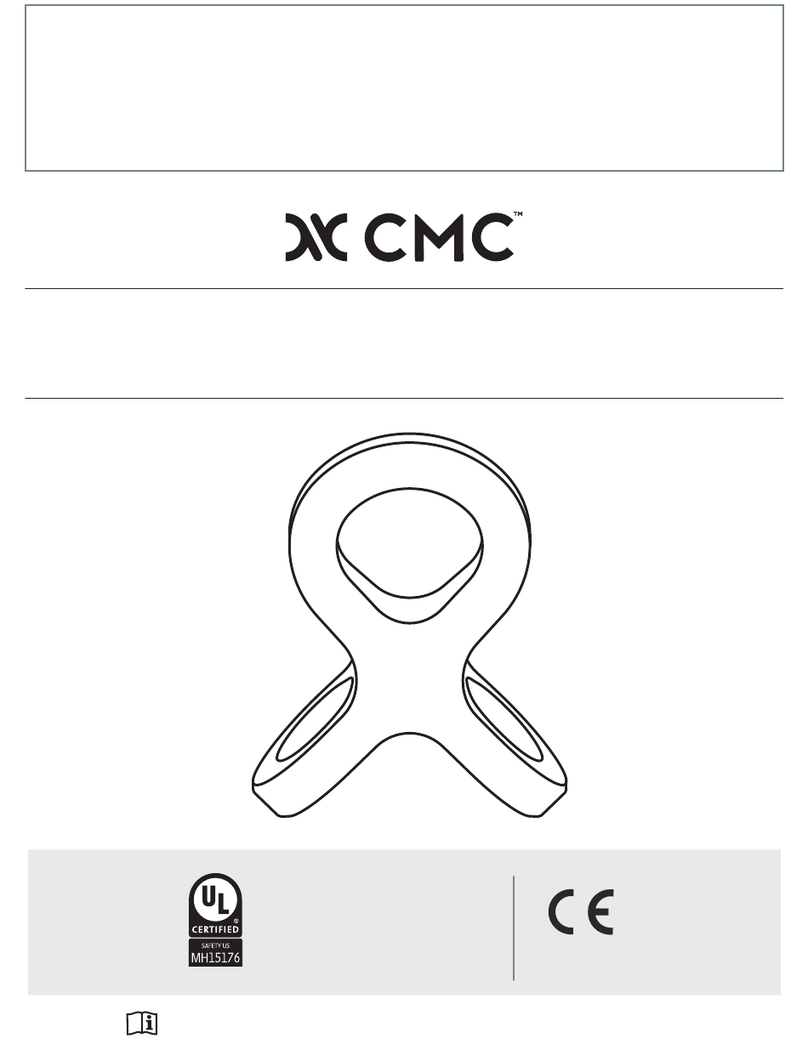

ESCAPE ARTIST

MEETS THE DESCENT CONTROL DEVICE REQUIREMENTS OF NFPA 1983, INCORPORATED

IN THE 2022 EDITION OF NFPA 2500.

• 300913-01 CMC ESCAPE ARTIST, RATED FOR ESCAPE USE (E), Ø 7.5 MM

THIS DESCENT CONTROL DEVICE HAS PASSED THE MANNER OF FUNCTION AND

HOLDING LOAD TESTS USING THE FOLLOWING ROPE:

• CMC PROSERIES ESCAPE LINE, CMC PN 292015, MFG TEUFELBERGER FIBER ROPE

CORP, Ø 7.5 MM

THIS DESCENT CONTROL DEVICE HAS PASSED THE MANNER OF FUNCTION AND

HOLDING LOAD TESTS USING THE FOLLOWING ESCAPE WEBBING:

• CMC FIRE ESCAPE WEB, CMC PN 200517-01, MFG CMC RESCUE, PERIMETER 30.0MM

LIMITATIONS AND PROPER USE

The Escape Artist is designed to be used as an Escape Descent Control Device and is only certified for use with 7.5

mm escape line and CMC FR Escape Web. Use only locking carabiners with the Escape Artist to prevent roll out.

Verify that carabiners gates are closed and locked prior to use.

Threading the rope/web: The escape rope/web must be pre-rigged into the Escape Artist so that it is ready for

use when needed. A diagram for reeving the rope through the device is permanently marked on the side plate. It is

essential to the function of the Escape Artist that the rope/web be correctly reeved.

Practice is Essential: Safe use of the Escape Artist requires familiarity with its operation and basic rappel skills.

CMC strongly recommends training from a competent instructor and practice in both descending with the Escape

Artist and in exiting windows. Always use a backup belay when training.

Exiting the Structure: The Escape Artist is designed to allow both hands to be used to exit a window or other

opening in the structure. A safe descent requires a moderate amount of pre-planning with time to set a secure

anchor, remove any edge material that may damage the escape rope/web, and to make sure the connector,

Escape Artist, and any other equipment clears the edge without damage or hanging up. Fully engaging the handle

will provide for maximum payout capability prior to exiting the structure.

Descending: Start by loading the system with your body weight. One hand must grasp the untensioned (running)

end of the rope/web (similar to rappelling with a Figure 8 device), while the other hand grasps the control lever.

Slowly squeeze the control lever towards the connector hole to initiate your descent. Control the rate of descent by

varying the amount of grip applied to the running end of the rope/web, as well as varying the amount of pressure

on the control lever. To stop descending, release the lever and tighten the grasp on the free end of the rope. Fully

squeezing the control lever will cause a rapid descent. The control lever must be released to stop the descent.

ESCAPE ARTIST SYSTEM - ROPE

SYSTEM COMPONENTS

• CMC Escape Artist (300913)

• Flash.2 Escape Anchor (300983-02) or Flash.G Escape Anchor (300973-01)

• CMC 7.5mm ProSeries Escape Line (292015) with CMC factory sewn termination

• CMC Fire Escape Tether Assembly (203500-01)

USING THE ESCAPE SYSTEM WITH ROPE

For proper deployment of the Escape Artist System, refer to the included User Information for the Escape Artist,

Flash Escape Anchor, ProTech Carabiner and 7.5mm ProSeries Escape Line.

The system can be connected to the user’s belt or harness using the included tether, or the tether can be removed

and the Escape Artist can be connected directly to the belt or harness using just the ProTech Carabiner. When

re-packing the system into the supplied CMC Escape Bag or Lumbar Pack, stuff the rope into the main pouch to

minimize twisting during deployment. Also make sure that the Flash Escape Anchor and Escape Artist are properly

stowed in their respective holders and will deploy freely.

If storing the Escape Artist System directly in the bunker pants pocket or using a different external bag than the

supplied CMC Escape Bag or Lumbar Pack, ensure that the rope is properly stuffed and the hardware is packed

such that it will deploy freely.

To view a video with more information and detailed instructions on properly packing the Escape Artist System,

please visit cmcpro.com.

ESCAPE ARTIST SYSTEM - WEB

SYSTEM COMPONENTS

• CMC Escape Artist (300913-01)

• Flash.2 Escape Anchor (300983-02) or Flash.G Escape Anchor (300973-01)

• Fire Escape Web (200517-01) with CMC factory sewn termination

• CMC Fire Escape Tether Assembly (203500-01)

USING THE ESCAPE SYSTEM WITH WEB

For proper deployment of the Escape Artist System, refer to the included User Information for the Escape Artist,

Flash Escape Anchor, ProTech Carabiner and Fire Escape Web.

The system can be connected to the user’s belt or harness using the included tether, or the tether can be removed

and the Escape Artist can be connected directly to the belt or harness using just the ProTech Carabiner.

When re-packing the system into the supplied CMC Escape Bag or Lumbar Pack, stuff the web into the main

pouch to minimize twisting during deployment. Also make sure that the Flash Escape Anchor and Escape Artist are

properly stowed in their respective holders and will deploy freely.

If storing the Escape Artist System directly in the bunker pants pocket or using a different external bag than the

supplied CMC Escape Bag or Lumbar Pack, ensure that the web is properly stuffed and the hardware is packed

such that it will deploy freely.

To view a video with more information and detailed instructions on properly packing the Escape Artist System,

please visit cmcpro.com.