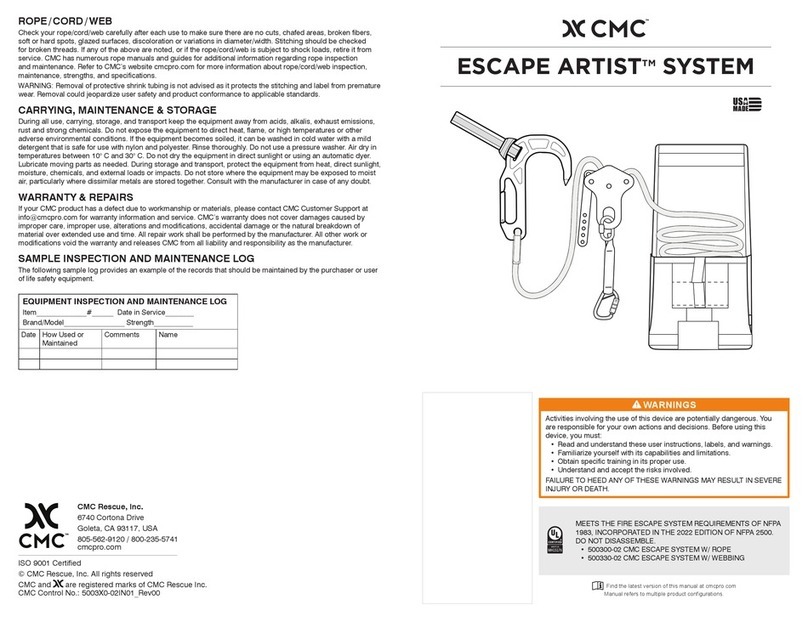

CARRYING, MAINTENANCE & STORAGE

Clean and dry this equipment after each use to remove any

dust, debris and moisture. During use, carrying and storage

keep the equipment away from acids, alkalis, rust and strong

chemicals. Do not expose the equipment to ame or high

temperatures. Store in a cool, dry location. Do not store where

the equipment may be exposed to moist air, particularly where

dissimilar metals are stored together.

REPAIR

All repair work shall be performed by the manufacturer. All

other work or modications void the warranty and releases

CMC from all liability and responsibility as the manufacturer.

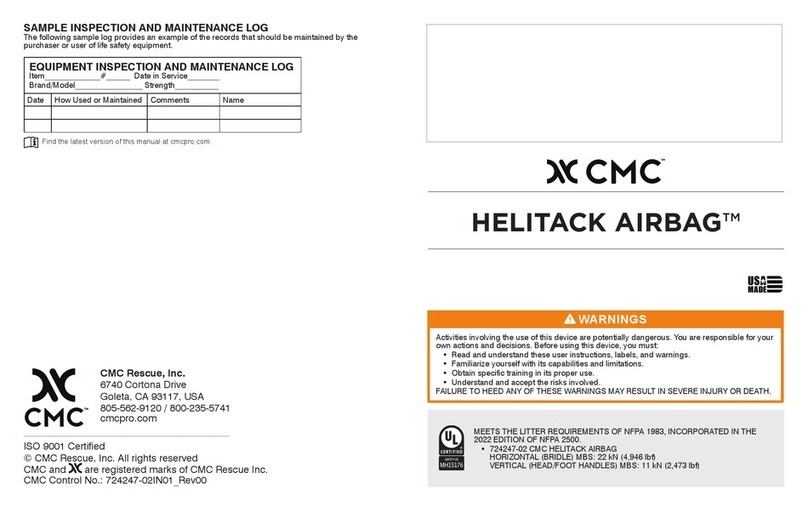

SAMPLE LOG

The sample log suggests records that should be maintained

by the purchaser or user of life safety equipment.

Equipment Inspection and Maintenance Log

Item______________#______ Date in Service________

Brand/Model_________________ Strength___________

Date How Used or Maintained Comments Name

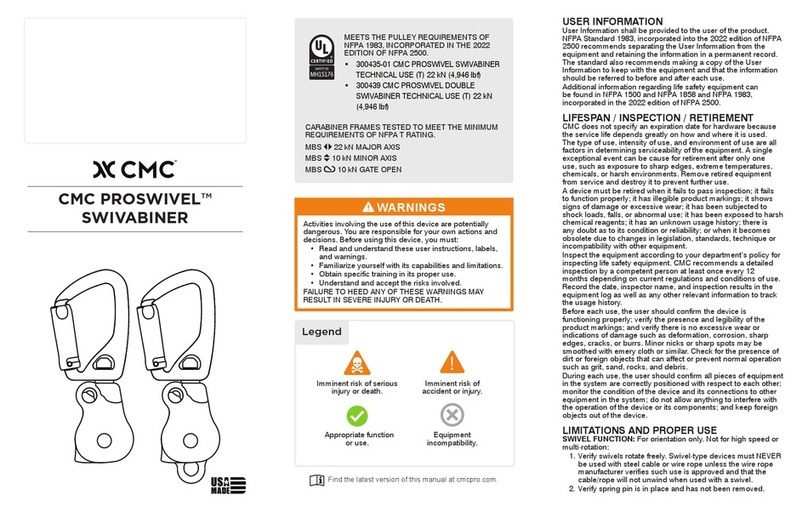

USES

SWIVEL FUNCTION: For orientation only. Not for high speed

or multi-rotation:

1. Verify swivels rotate freely. Swivel-type devices must

NEVER be used with steel cable or wire rope unless the

wire rope manufacturer veries such use is approved

and that the cable/rope will not unwind when used with

a swivel.

2. Verify spring pin is in place and has not been removed.

3. Ensure swivel axle has not loosened by checking axle

head with your ngers and making sure swivel top does

not move up or down.

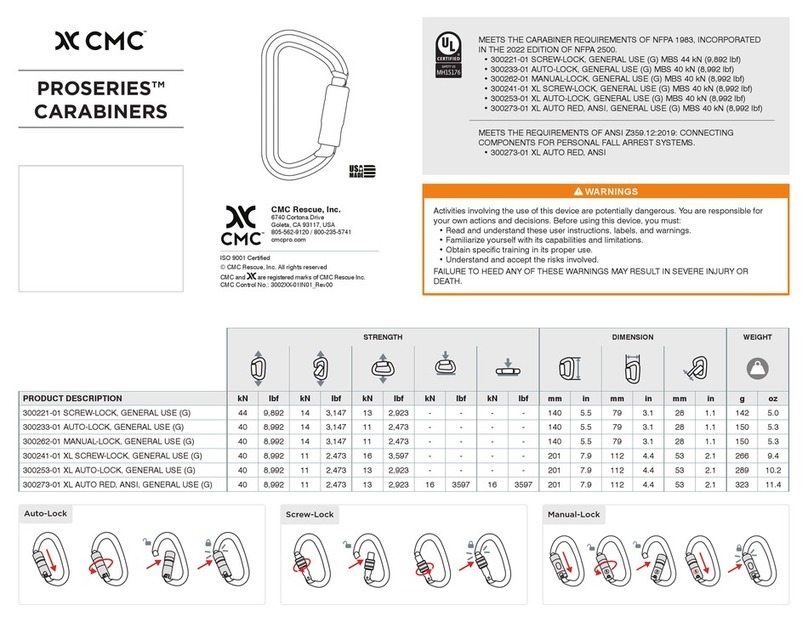

MANDATORY CARABINER LOCKING PROCEDURE:

Serious accidents have resulted from unlocked carabiners.

Dirt, ice, etc. can jam a sleeve. Never assume auto-lock

carabiners lock on closing always conrm! You must

understand how the sleeve works and know what it looks like

when it is locked and unlocked. You must do the following

every time you clip a locking carabiner:

1. Visually conrm the carabiner is locked.

2. Push in on the gate/sleeve to conrm by touch that it is

locked.

Do not allow ropes or objects to rub or twist the sleeve

because this could unlock it. Vibration can also unlock a

sleeve. Regularly check that the carabiner is locked and

positioned properly and always do so if items contact it or

anything unusual occurs. Sleeves must be locked to achieve

full strength.

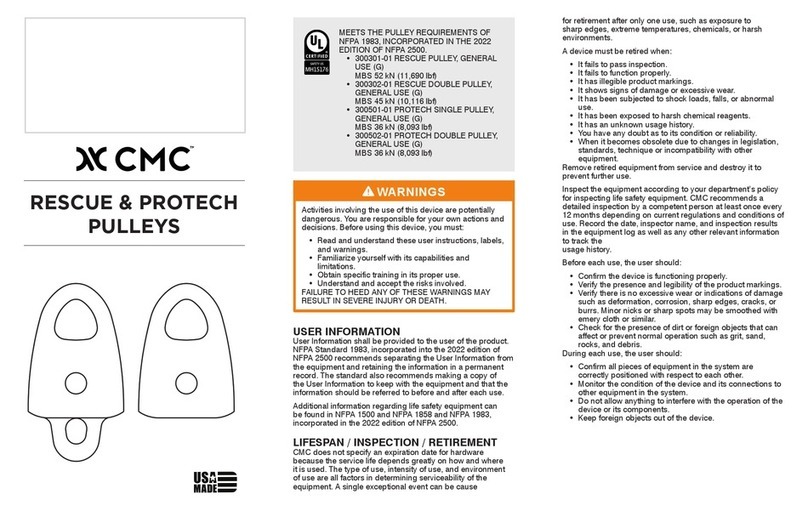

MANDATORY PULLEY LOCKING PROCEDURE: The

sideplate must be closed and locked with the button fully

extended, or strength will be greatly reduced and the rope

may fall out with catastrophic results. See g. 2. You must

understand how the sideplate & locking button work & must

faithfully do the following every time you use it:

1. Visually conrm the sideplate is fully closed and the

locking button is fully extended.

2. Test the sideplate by attempting to rotate it to conrm by

touch that it is locked.

Do not allow anything to contact the button in use. Regularly

check that the sideplate is locked and the pulley is positioned

properly. If the pulley cannot be kept in sight, use a

conventional pulley.

WARNINGS: Strength - In a single pulley, half the load is

on one side of the rope and half is on the other. The total

load on the pulley is thus 2x the mass that is being raised or

lowered. In a double pulley the total load is 4x the load on the

4 individual ropes. This is illustrated on the pulley. Breaking

Strength & Working Load are based on this equal loading.

If the sideplate is not fully locked by the button, the strength

will be severely reduced, to about 10kN, but also, the rope

may fall out. Pulleys must be free to align with the load, any

restraint is dangerous.

PRUSIK USE - CAUTION! Prusiks must always have an

experienced person tending them. Never allow a jammed

Prusik to be pulled in between the sideplates. This can bend

or break the pulley and allow the rope to fall out!

BREAKAGE HAZARD

DANGER! NEVER APPLY A BENDING FORCE!

Due to leverage, even a small amount of weight can cause

catastrophic breakage. Never use when bending could occur!

Do not let an object in between the sideplates and never rig

your system so that the pulley is forced against something that

could break or open the sideplate, allowing the rope to fall out.

See g. 1.

The Omni-Block SwivaBiner must only be used in a straight

pull. It must NEVER be subjected to a bending force. Only

loading shown in the gure with the checkmark is allowed.

See g. 3.

1

2

3

ISO 9001 Certied

©2021 CMC Rescue, Inc. All rights reserved

CMC and are registered marks of CMC Rescue Inc.

CMC Control No.: 300435IN01_Rev00

CMC Rescue, Inc.

6740 Cortona Drive

Goleta, CA 93117, USA

805-562-9120 / 800-235-5741

cmcpro.com