ISO 9001 Certied

© CMC Rescue, Inc. All rights reserved

CMC and are registered marks of CMC

Rescue Inc.

CMC Control No.: 300391-01IN01_Rev01

CMC Rescue, Inc.

6740 Cortona Drive

Goleta, CA 93117, USA

805-562-9120 / 800-235-5741

cmcpro.com

The Kootenay sheave is equipped with two ball bearings for

efciency. The sheave can be locked for use as a high strength

tie-off using the included screw. The Kootenay is compact

while having the capability to pass knots. It has two extra holes

that can be used for hoist lines, in addition to the standard tag

line holes. See below for additional product-specic guidance.

• To prevent roll-out, use only locking carabiners. Do not

allow ropes or objects to rub or twist the sleeve because

this could unlock it. Vibration can also unlock a sleeve.

Sleeves must be locked to achieve full strength.

• Check that the sheave is in good condition and freely

rotates. Conrm security of the axle screw.

• Do not let an object in between the sideplates and never

rig your system so that the pulley is forced against

something that could break or open the sideplate.

• Sideplates must be closed and both must be attached to

the anchor. Connecting to only one sideplate is forbidden.

Pulleys must be free to align with the load, any restraint

is dangerous.

• When using the pulley as a highline carriage or a knot-

pass pulley, ensure that the sheave is unlocked and

allows freewheeling.

• High Strength Tie-Off: For use as a High-Strength Tie-Off,

ensure that the sheave is locked off by securing (hand

tight) the locking bolt in one of the sheave holes. (The

locking bolt can be secured in the axle assembly when

not in use). Wrap the rope multiple times (at least 3, but

not so many that the rope rolls over itself) around the

sheave. The running end of the rope should be anchored

using a separate carabiner to an anchor located behind

the pulley or to the standing part of the rope. This use

requires advanced special training. The rope must never

contact a sharp edge. There are many hazards associated

with applying high forces on a rope

• Edge Roller: The Kootenay Ultra Pulley may also be used

as an edge roller. When using it as an edge roller make

sure that the sheave is unlocked and is freewheeling.

Also make sure that the pulley is secured in a manner to

prevent it from falling over the edge.

• The additional holes allow complete separation of tag

lines and hoist/reeve lines. Independent holes for hoist

lines and the resulting separation from the reeving line

help prevent spinning of the load below the highline. The

extra holes also make rigging easier and help prevent

carabiners from interfering with each other.

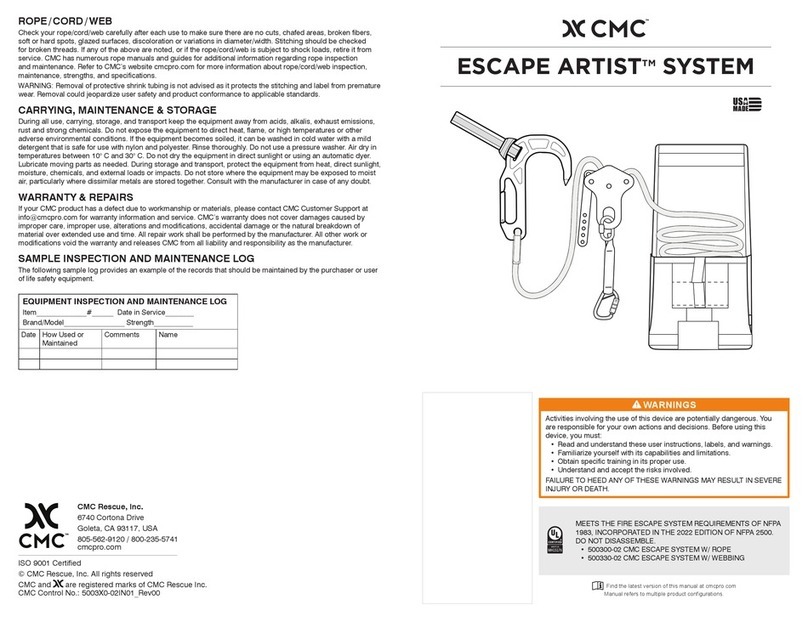

CARRYING, MAINTENANCE & STORAGE

During all use, carrying, storage and transport keep the

equipment away from acids, alkalis, rust and strong

chemicals. Do not expose the equipment to direct heat, ame

or high temperatures. Clean equipment using clean fresh

water to remove any dust or debris. Do not use a pressure

washer for cleaning. If the equipment gets wet, remove

excess moisture and allow to air dry at temperatures between

10° C and 30° C. Lubricate moving parts as needed. During

storage and transport, protect the equipment from heat, direct

sunlight, moisture, chemicals, and external loads or impacts.

Do not store where the equipment may be exposed to moist

air, particularly where dissimilar metals are stored together.

WARRANTY & REPAIRS

If your CMC product has a defect due to workmanship or

materials, please contact CMC Customer Support at info@

cmcpro.com for warranty information and service. CMC’s

warranty does not cover damages caused by improper

care, improper use, alterations and modications, accidental

damage or the natural breakdown of material over extended

use and time. The equipment should not be modied in

any way or altered to allow attachment of additional parts

without the manufacturer’s written recommendation. If original

components are modied or removed from the product, its

safety aspects may be restricted. All repair work shall be

performed by the manufacturer. All other work or modications

void the warranty and releases CMC from all liability and

responsibility as the manufacturer.

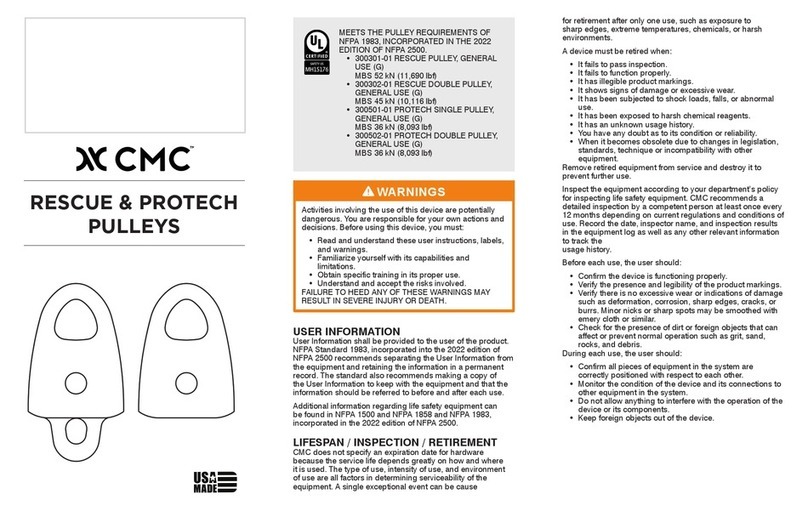

SAMPLE INSPECTION AND

MAINTENANCE LOG

The following sample log provides an example of the records

that can be maintained by the purchaser or user.

EQUIPMENT INSPECTION AND

MAINTENANCE LOG

Item______________#______ Date in Service________

Brand/Model_________________ Strength___________

Date How Used or Maintained Comments Name

Find the latest version of this manual at cmcpro.com.