USER INFORMATION

User Information shall be provided to the user of the product. NFPA Standard 1983, incorporated

into the 2022 edition of NFPA 2500 recommends separating the User Information from the equipment

and retaining the information in a permanent record. The standard also recommends making a copy

of the User Information to keep with the equipment and that the information should be referred to

before and after each use.

Additional information regarding life safety equipment can be found in NFPA 1500 and NFPA 1858

and NFPA 1983, incorporated in the 2022 edition of NFPA 2500 and the ANSI Z359 series of Fall

Protection standards.

LIFESPAN / INSPECTION / RETIREMENT

CMC does not specify an expiration date for hardware because the service life depends greatly on

how and where it is used. The type of use, intensity of use, and environment of use are all factors in

determining serviceability of the equipment. A single exceptional event can be cause for retirement

after only one use, such as exposure to sharp edges, extreme temperatures, chemicals, or harsh

environments.

A device must be retired when:

• It fails to pass inspection.

• It fails to function properly.

• It has illegible product markings.

• It shows signs of damage or excessive wear.

• It has been subjected to shock loads, falls, or abnormal use.

• It has been exposed to harsh chemical reagents.

• It has an unknown usage history.

• You have any doubt as to its condition or reliability.

• When it becomes obsolete due to changes in legislation, standards, technique or incompatibility

with other equipment.

Remove retired equipment from service and destroy it to prevent further use.

Inspect the equipment according to your department’s policy for inspecting life safety equipment.

CMC recommends a detailed inspection by a competent person at least once every 12 months

depending on current regulations and conditions of use. Record the date, inspector name, and

inspection results in the equipment log as well as any other relevant information to track the

usage history.

Before each use, the user should:

• Conrm the device is functioning properly.

• Verify the presence and legibility of the product markings.

• Verify there is no excessive wear or indications of damage such as deformation, corrosion, sharp

edges, cracks, or burrs. Minor nicks or sharp spots may be smoothed with emery cloth or similar.

• Check for the presence of dirt or foreign objects that can affect or prevent normal operation such

as grit, sand, rocks, and debris.

During each use, the user should:

• Conrm all pieces of equipment in the system are correctly positioned with respect to each other.

• Monitor the condition of the device and its connections to other equipment in the system.

• Do not allow anything to interfere with the operation of the device or its components.

• Keep foreign objects out of the device.

LIMITATIONS AND PROPER USE

All carabiners are designed to specic performance criteria. Be aware of load limitations, manner

used, and proper technique. Do not overload a carabiner. Carabiners can fail under improper use

conditions such as cross loading, gate open loading, loading other than major axis, applying a shear

or torsional load to the carabiner, etc. If you are not sure of proper application or technique, seek

proper training in carabiner use and technical rope application.

To remove the keeper pin (for models so equipped), use the supplied hex wrench to remove the

set screw, then pull the pin completely from the carabiner frame. To reinstall, insert the keeper pin

through the hole in the gate side of the frame, then ensure the pin is fully seated in the blind hole in

the spine side of the frame. Reinstall the set screw, taking care not to overtighten or strip the threads

or head. Use a thread locker to ensure the set screw does not back out during use.

Auto-Lock: (1)Push gate down (2)Twist gate to unlock (3)Push Gate in to open

(4)Release Gate to Lock (5)Conrm Gate Locking

Screw-Lock: (1)Unscrew gate to unlock (2)Push gate in to open (3)Screw gate to close

(4)Conrm gate locking

Manual-Lock: (1)Push gate down (2)Twist gate to unlock (3)Push gate in to open

(4) Push gate down and release to lock (5)Conrm gate locking

Do not use if gate fails to lock or open properly.

COMPATIBILITY

300273-01 XL AUTO RED, ANSI, GENERAL USE (G) are connecting components in accordance

with ANSI Z359.12-2019 Section 5.3.1, used to connect two or more pieces of equipment together

in Personal Fall Arrest Systems. Ensure compatibility with other components in the fall protection

system.

MATERIALS

• Principal Material: Aluminum alloy, anodized.

CARRYING, MAINTENANCE & STORAGE

During all use, carrying, storage and transport keep the equipment away from acids, alkalis, rust and

strong chemicals. Do not expose the equipment to direct heat, ame or high temperatures.

Clean equipment using clean fresh water to remove any dust or debris. Do not use a pressure

washer for cleaning. If the equipment gets wet, remove excess moisture and allow to air dry at

temperatures between 10° C and 30° C. Lubricate moving parts as needed.

During storage and transport, protect the equipment from heat, direct sunlight, moisture, chemicals,

and external loads or impacts. Do not store where the equipment may be exposed to moist air,

particularly where dissimilar metals are stored together.

WARRANTY & REPAIRS

If your CMC product has a defect due to workmanship or materials, please contact CMC Customer

CMC’s warranty does not cover damages caused by improper care, improper use, alterations and

modications, accidental damage or the natural breakdown of material over extended use and time.

The equipment should not be modied in any way or altered to allow attachment of additional parts

without the manufacturer’s written recommendation. If original components are modied or removed

from the product, its safety aspects may be restricted.

All repair work shall be performed by the manufacturer. All other work or modications void the

warranty and releases CMC from all liability and responsibility as the manufacturer.

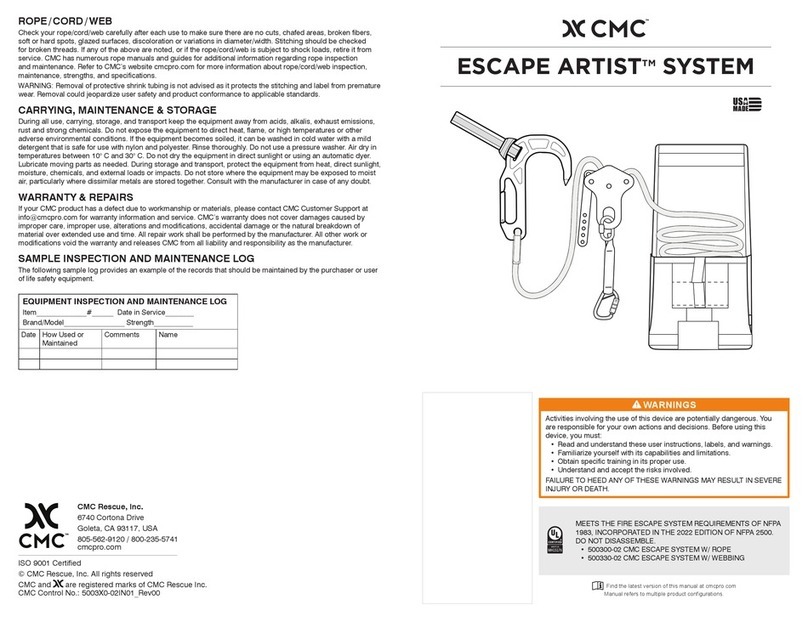

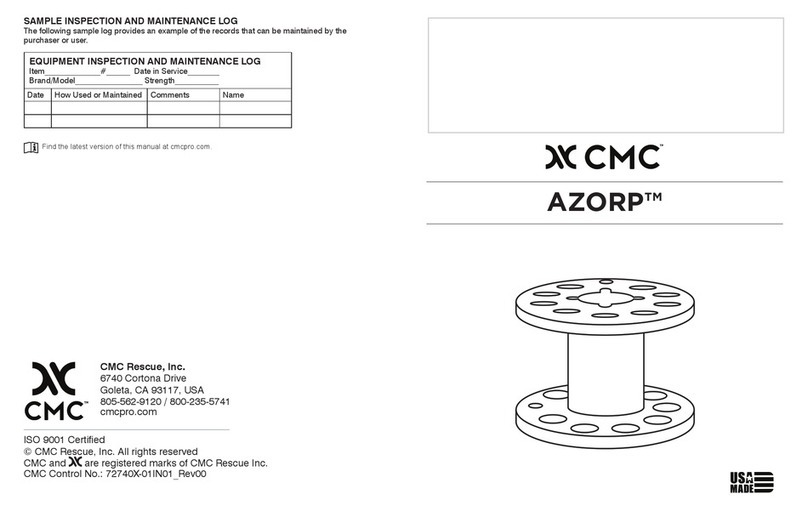

SAMPLE INSPECTION AND MAINTENANCE LOG

The following sample log provides an example of the records that can be maintained by the

purchaser or user.

EQUIPMENT INSPECTION AND MAINTENANCE LOG

Item______________#______ Date in Service________

Brand/Model_________________ Strength___________

Date How Used or

Maintained

Comments Name