Labels

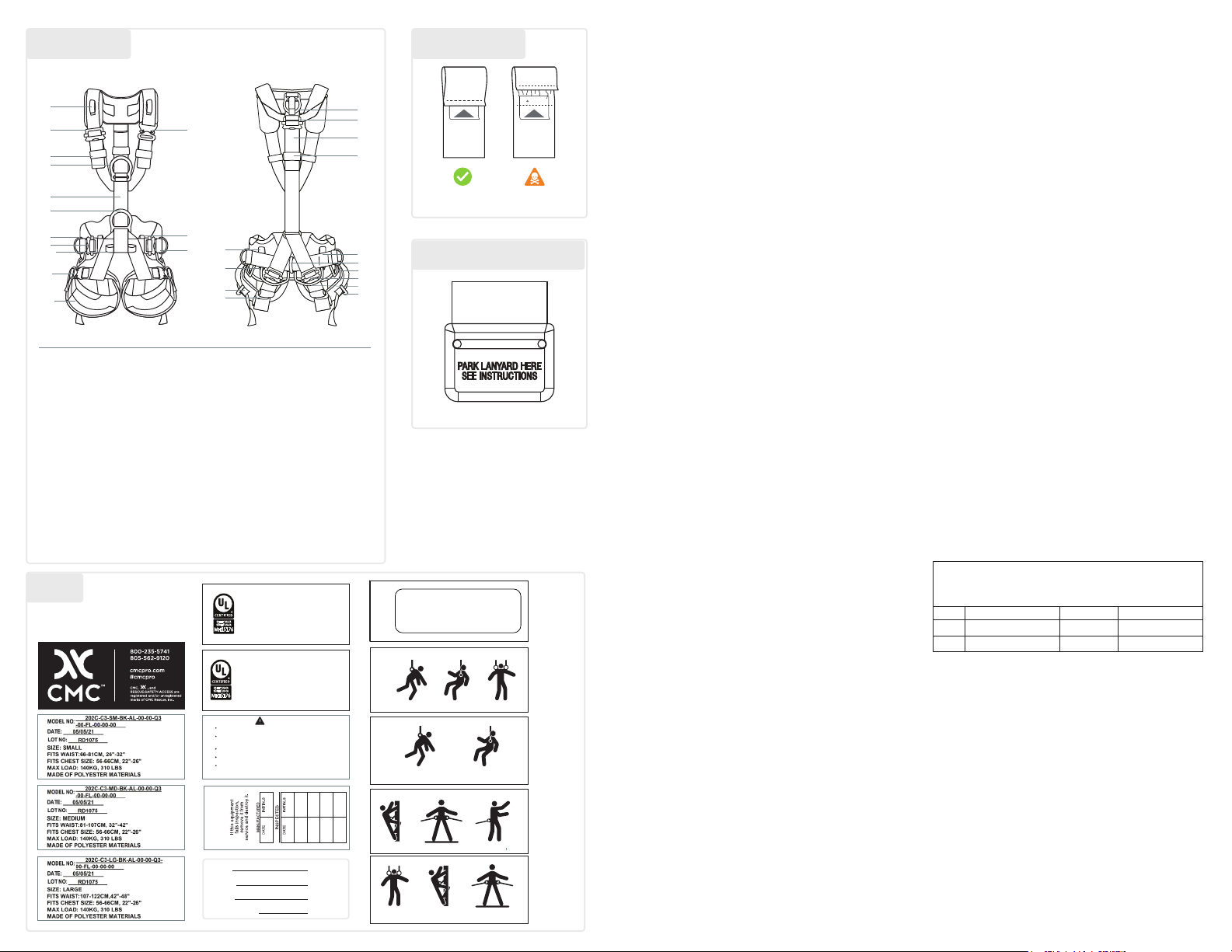

Nomenclature

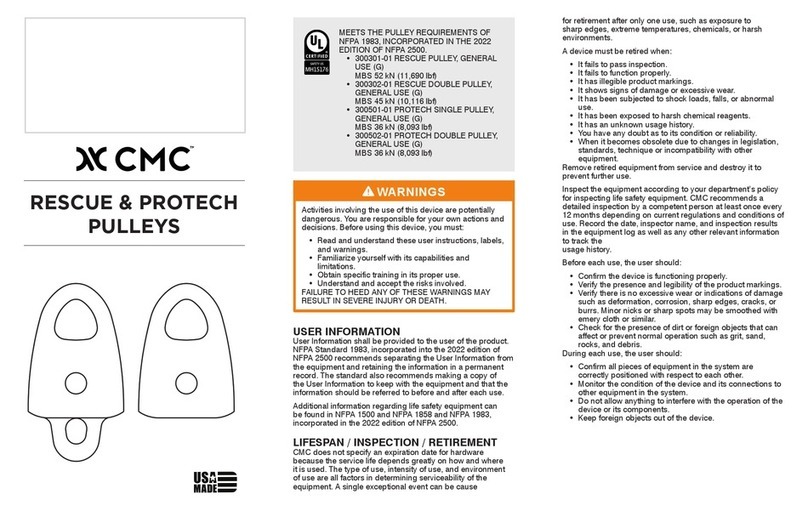

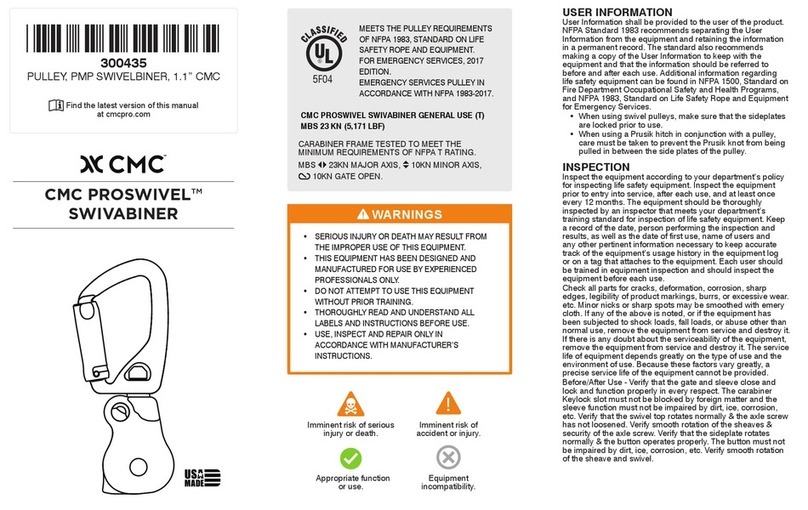

USER INFORMATION

User Information shall be provided to the user of the product. NFPA Standard

1983, incorporated into the 2022 edition of NFPA 2500 recommends

separating the User Information from the equipment and retaining the

information in a permanent record. The standard also recommends making

a copy of the User Information to keep with the equipment and that the

information should be referred to before and after each use.

Additional information regarding life safety equipment can be found in NFPA

1500 and NFPA 1858 and NFPA 1983, incorporated in the 2022 edition

of NFPA 2500 and the ANSI Z359 and CSA Z259 series of Fall Protection

standards.

LIFESPAN / INSPECTION / RETIREMENT

The equipment has a lifespan of 10 years from the date of manufacture shown

on the product label. The type of use, intensity of use, and environment of

use are all factors in determining serviceability of the equipment. A single

exceptional event can be cause for retirement after only one use, such

as exposure to sharp edges, extreme temperatures, chemicals, or harsh

environments. Any concerns about its safe use is cause for retirement.

Remove retired equipment from service and destroy it to prevent further use.

A device must be retired when it fails to pass inspection; it fails to function

properly; it has illegible product labels or markings; it shows signs of damage

or excessive wear; it has been subjected to shock loads, falls, or abnormal

use; it has been exposed to harsh chemical reagents; it has an unknown

usage history; you have any doubt as to its condition or reliability; or when

it becomes obsolete due to changes in legislation, standards, technique or

incompatibility with other equipment.

Inspect the equipment according to your department’s policy for inspecting

life safety equipment. CMC recommends a detailed inspection by a

competent person at least once every 12 months depending on current

regulations and conditions of use. Record the date, inspector name,

and inspection results in the equipment log as well as any other relevant

information to track the usage history.

When inspecting the equipment, conrm it is functioning properly and verify

the presence and legibility of labels and markings. Check soft components

for cuts, worn or frayed areas, broken bers, soft or hard spots, discoloration,

or melted bers. Check the stitching for pulled threads, abrasion, or breaks.

Check hardware for excessive wear or indications of damage such as

deformation, corrosion, sharp edges, cracks, or burrs. Minor nicks or sharp

spots may be smoothed with emery cloth or similar. Check for the presence

of dirt or foreign objects that can affect or prevent normal operation Conrm

all pieces of equipment in the system are correctly positioned with respect to

each other and monitor the condition of the equipment and its connections.

Do not allow anything to interfere with the proper operation of the equipment.

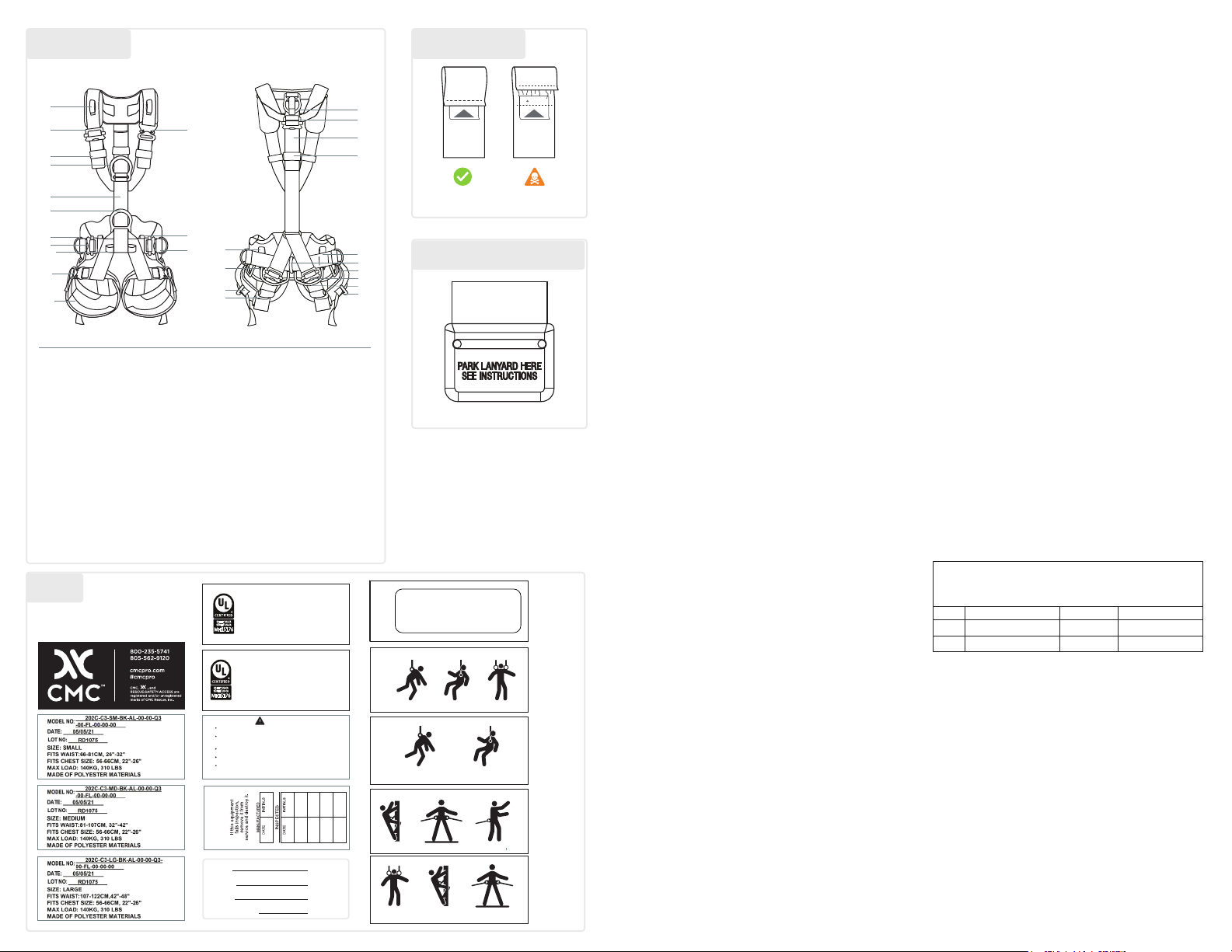

Visual Indicator: Prior to donning the harness, inspect the visual indicator

located in proximity of the dorsal attachment point. If the visual indicator is

damaged or shows signs of deployment, remove the harness from service.

LIMITATIONS AND PROPER USE

The ATOM Harness is designed for optimum performance, dependability,

and comfort in rescue and work positioning applications. Its low-prole

construction and supportive architecture provides excellent mobility on rope

and on the ground. When using the ATOM Harness, follow best practices

for avoiding high impact falls. Always keep the safety line (belay) above the

wearer and keep the slack in the safety line to a minimum. To ensure the

safety and comfort of your ATOM Harness, make sure it is properly sized and

adjusted per the instructions below. Depending on the conguration of the

harness, not all attachment elements outlined in this user guide apply.

CMC warns against using the equipment around moving machinery and

electrical hazards.

Rescue: NFPA 1983, incorporated into the 2022 edition of NFPA 2500

provides specications for a rescue harness. All front and back D-ring

connection points are dynamically and statically tested, and independently

certied to this standard.

Rope Access Work: A harness selected for rope access work needs

comfort and support very similar to a rescue harness, which is not available

in a harness designed solely for fall arrest applications. Depending on the

applicable regulations, fall protection may also be required.

Fall Protection: Harnesses designed for fall protection must meet the

requirements of ANSI Z359.11 and CSA Z259.10. All attachment points are

independently certied to these standards. When using this equipment the

user shall have a rescue plan and the means at hand to implement it when

using the harness for fall arrest.

To prevent roll out when using carabiners to attach to an attachment

point, use only locking models. If using manual locking carabiners, verify

that they are locked before use. It is the users responsibility to verify

equipment compatibility with components and sub-systems before use.

Consult with the current edition of ANSI/ASSP Z359.11 / CSA Z259.10 and

applicable state or provincial regulations governing occupational safety. The

user should consider all component extensions and allow clearance for an

arrest to take place a safe distance away from the ground or structure. A

harness stretch factor of up to 18 inches (46 cm) should be factored in while

calculating fall clearance.

PUTTING ON YOUR HARNESS

• Loosen all the harness straps for easy donning, including waist belt, leg

loops, and shoulder strap (disconnect quick-connect buckles if present).

• Hold shoulder straps to the side and step through the waist belt, putting

each foot into the proper leg loop.

• Position the waist belt and ventral attachment point above the waistline.

• Tighten the waist belt by pulling both sides simultaneously until the waist

is snug, and the front D-ring is centered.

• Position the dorsal attachment point level with shoulder blades and

adjust back strap.

• Position the sternal attachment point as high as possible and adjust

shoulder straps on each side.

• Tighten the rear leg straps, this is especially important when using the

dorsal point.

• Position the leg loops with padding along back and side of legs.

• Tighten leg loops, leaving about a nger width of space between the leg

loops and the legs.

• Before use, conrm all straps are tight, stow excess web in elastic

keepers and apply load to the sternal attachment point and conrm

position of all D-rings.

A suspension test should be carried out in a safe place prior to putting the

harness in service. A suspension test will verify that the harness is the correct

size, has sufcient adjustment and is of an acceptable comfort level for the

intended use.

WARNING: Make sure the straps are snug. This increases the comfort

when sitting in the harness and helps prevent the quick-connect buckles

from disconnecting. When wearing the harness, double-check the

buckles, adjusters, and t of the harness immediately prior to relying on

it for support.

LANYARD PARKING ELEMENT

If using a fall arrest lanyard or Y-lanyard, connect the lanyard snaphook to

the parking element located on the shoulders of the harness when not in use

(unless otherwise connected to an anchorage point). The lanyard parking

element of the harness is intended to disengage in the event that the lanyard

is hung up or tangled during a fall or during normal use creating a hazard.

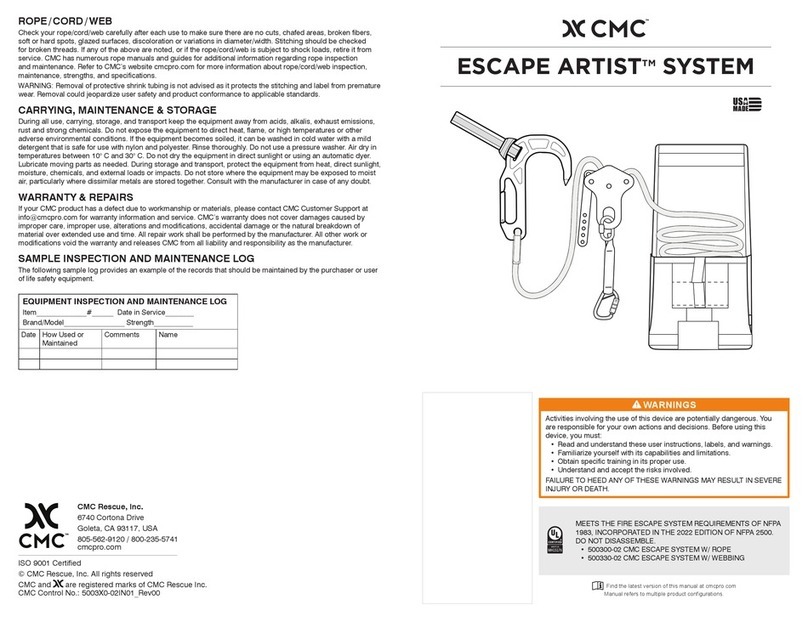

CARRYING, MAINTENANCE & STORAGE

During use, carrying, storage, and transport keep the equipment away

from acids, alkalis, exhaust emissions, rust and strong chemicals. Do not

expose the equipment to direct heat, ame, or high temperatures or other

adverse environmental conditions. If the equipment becomes soiled, it can

be washed in cold water with a mild detergent that is safe for use with nylon

and polyester. Rinse thoroughly. Do not use a pressure washer. Air dry in

temperatures between 10° C and 30° C. Do not dry the equipment in direct

sunlight or using an automatic dyer. Lubricate moving parts as needed.

During storage and transport, protect the equipment from heat, direct

sunlight, moisture, chemicals, and external loads or impacts. Do not store

where equipment may be exposed to moist air, particularly where dissimilar

metals are stored together. Consult with manufacturer in case of any doubt.

WARRANTY & REPAIRS

If your CMC product has a defect due to workmanship or materials,

information and service. CMC’s warranty does not cover damages caused

by improper care, improper use, alterations and modications, accidental

damage or the natural breakdown of material over extended use and time.

All repair work shall be performed by the manufacturer. All other work or

modications void the warranty and releases CMC from all liability and

responsibility as the manufacturer.

SAMPLE INSPECTION AND MAINTENANCE LOG

The following sample log provides an example of the records that should be

maintained by the purchaser or user of life safety equipment.

EQUIPMENT INSPECTION AND MAINTENANCE LOG

Item______________#______ Date in Service________

Brand/Model_________________ Strength___________

Date How Used or Maintained Comments Name

ANNEX A - NORMATIVE

Note: The following information from the ANSI/ASSP Z359.11 standard

is required to be included in the instruction manual for the end user. The

manufacturer of this equipment may impose more stringent restrictions

on the use of the products they manufacture; see the manufacturer’s

instructions.

1. It is essential that the users of this type of equipment receive proper

training and instruction including detailed procedures for the safe

use of such equipment in their work application. ANSI/ASSP Z359.2,

Minimum Requirements for a Comprehensive Managed Fall Protection

Program, establishes guidelines and requirements for an employer’s

managed fall protection program including policies, duties and

training; fall protection procedures; eliminating and controlling fall

hazards; rescue procedures; incident investigations; and evaluating

program effectiveness.

2. Correct t of a full body harness (FBH) is essential to proper

performance. Users must be trained to select the size and maintain the

t of their FBH.

3. Users must follow manufacturer’s instructions for proper t and sizing,

paying particular attention to ensure that buckles are connected and

aligned correctly, leg straps and shoulder straps are kept snug at all

times, chest straps are located in the middle chest area and leg straps

are positioned and snug to avoid contact with the genitalia should a

fall occur.

4. FBHs which meet ANSI/ASSP Z359.11 are intended to be used with

other components of a personal fall arrest system that limit maximum

arrest forces to 1800 pounds (8kN) or less 5. Suspension intolerance,

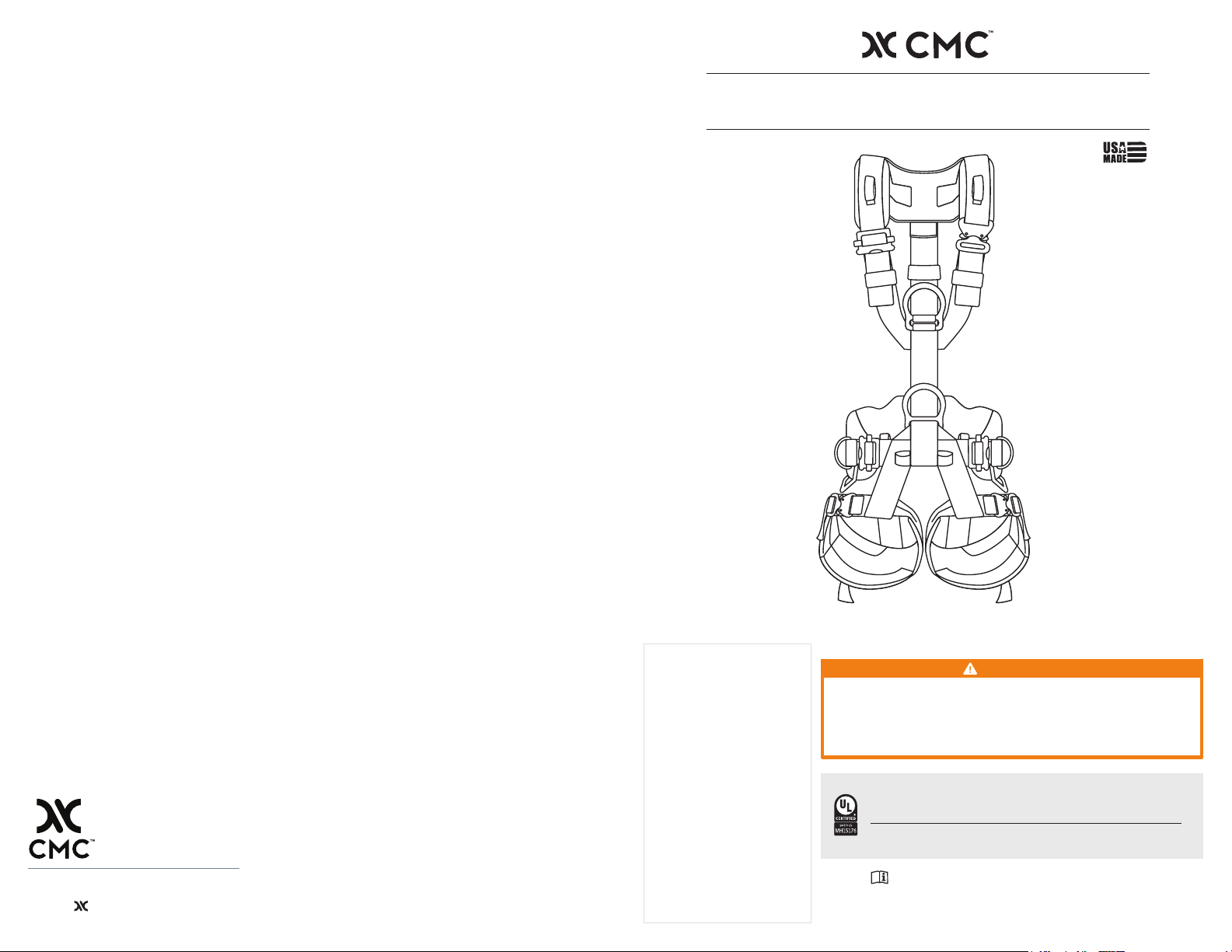

Visual Indicator

WARNING

!

Lanyard Parking Element

1 Lanyard parking element

2 Shoulder strap adjustment buckle

3 Quick-release shoulder strap

adjustment buckle

(varies by model)

4 Elastic keepers for straps (multiple

locations)

5 Sternal attachment point

(“A” label)

6 Chest ascender location (ascender kit

sold separately)

7 Ventral attachment point

8 Side work-positioning attachment points

(varies by model)

9 Adjustment buckles for waist straps

10 Work seat connection loops

(work seat sold separately)

11 Quick-release leg strap adjustment

buckles

(varies by model)

12 Leg loops

13 Dorsal attachment point

14 Adjustment buckle for rear strap

15 Visual indicator

16 Tool carrier attachment point

(tool carrier sold separately)

17 Rear travel restraint point

18 Gear loops

(10 kg max, varies by model)

19 Adjustment buckles for leg loop link

strap

20 Tool loops (10 kg max)

21 Accessory attachment points

(10 kg max)

1

2

4

5

6

7

8

9

10

11

12

3

21

4

13

14

15

4

21

21

4

4

16

17

18

19

20

20

000120_Rev02

3.625” (92.075MM)

1.5” (38.1MM)

0.1806” (4.48724MM)

0.5315” (13.5MM)

0.1806” (4.48724MM)

3.625” (92.075MM)

1.5” (38.1MM)

THIS DRAWING AND ALL INFORMATION HEREIN IS THE PROPERTY OF CMC RESCUE, INC.

ANY COPYING, REPRODUCTION OR UNAUTHORIZED USE WITHOUT WRITTEN CONSENT IS FORBIDDEN.

LABEL, COVER

DESCRIPTIONREV. DATE INITIALS

INITIAL RELEASE00 03/02/18 CMC

NOTES:

1. WHITE SATIN POLY - TEAR RESISTANT

2. 100% BLACK PRINT

3. PART NUMBER TO BE HIDDEN WHEN SEWN IN

CMC RESCUE

6740 CORTONA DR. GOLETA, CA

PART#: 000120

DATE: 02/11/2020DRAWN BY: CMC

DRAWING SCALED @ 100%

TEMPLATE UPDATE01 02/11/20 JR

P65 WARNING ADDED TO THE BACK OF LABEL02 12/02/20 AH

WARNING: Cancer and Reproductive Harm

www.P65Warning.ca.gov

PROJECT INFO.

ITEM INFO.

COLOR

ALL STRUCTURE FEATURES & CALL OUTS DO NOT PRINT.

ADD. INFO

Overall Size :

Finished / Folded Size :

Item Type :

Additional Info. / Instructions:

Material / Construction:

Date:

Customer Name:

SML Requester:

Project #: Art Request #:

Fonts:

Notes:

File Name:

Customer Item Code :

Artist Name:

Date Started:

COPY SAFE

DIELINE

FOLD LINE

SEW LINE DIMENSIONS

New Proof Needed

Date : Signature :

This artwork/proof is being submitted for your approval. Please check this layout for design, spelling, and color.

(The colors on this proof do not necessarily represent the exact shade of printing ink on your chosen substrate.)

SML will not be responsible for errors, omissions, etc. Overlooked by the customer, after signed approval by customer.

Production will begin only after this proof has been approved/signed and faxed or e-mailed to your sml representative.

Approved

Approved w/ Change

ATTENTION

NE PAS ENLEVER CETTE ÉTIQUETTE!

000273F 00

VOUS POURRIEZ ÊTRE TUÉ OU GRAVEMENT BLESSÉ SI VOUS LISEZ PAS ET

NE COMPRENEZ PAS CETTE ÉTIQUETTE AVANT D’UTILISER CET ÉQUIPEMENT.

UNE FORMATION ET DES CONNAISSANCES SPÉCIALES SONT NÉCESSAIRES

POUR UTLISER CET ÉQUIPEMENT DE SÉCURITÉ DE LA VIE.

VOUS DEVEZ LIRE ET COMPRENDRE TOUTES LES INSTRUCTIONS DU

FABRICANT AVANT UTILISATION.

N’UTILISEZ ET INSPECTEZ CET ÉQUIPEMENT DE SÉCURITÉ DE LA

VIE SEULEMENT SELON LES INSTRUCTIONS DU FABRICANT.

SERIOUS INJURY OR DEATH MAY RESULT FROM THE

IMPROPER USE OF THIS EQUIPMENT.

THIS EQUIPMENT HAS BEEN DESIGNED AND

MANUFACTURED FOR USE BYEXPERIENCED

PROFESSIONALS ONLY.

DO NOT ATTEMPT TO USE THIS EQUIPMENT WITHOUT

PRIOR TRAINING.

THOROUGHLY READ AND UNDERSTAND ALL LABELS AND

INSTRUCTIONS BEFORE USE.

USE, INSPECT AND REPAIRONLY IN ACCORDANCE WITH

MANUFACTURER’S

INSTRUCTIONS.

WARNING

DO NOT REMOVE THIS LABEL!

BLACK

XXXXX

XXXXX

XXXXX

XXXXX

XX" X XX"

3.625" X 1.50"

PRINTED LABEL

ALDO ANGELES

ROBERTA GUILLORY

CMC-000273F

1257341394B

CMC_000273F_PL_41394B

CMC

03_05_201903_13_2019

1.50 in

3.625 in

3 mm 3 mm

3 mm3 mm

12.7MM

0.5”

000273F - FRENCH

BACK

1.50 in

3.625 in

3 mm 3 mm

3 mm3 mm

12.7MM

0.5”

000273F - ENGLISH

FRONT

PROJECT INFO.

ITEM INFO.

COLOR

ALL STRUCTURE FEATURES & CALL OUTS DO NOT PRINT.

ADD. INFO

Overall Size :

Finished / Folded Size :

Item Type :

Additional Info. / Instructions:

Material / Construction:

Date:

Customer Name:

SML Requester:

Project #: Art Request #:

Fonts:

Notes:

File Name:

Customer Item Code :

Artist Name:

Date Started:

COPY SAFE

DIELINE

FOLD LINE

SEW LINE DIMENSIONS

New Proof Needed

Date : Signature :

This artwork/proof is being submitted for your approval. Please check this layout for design, spelling, and color.

(The colors on this proof do not necessarily represent the exact shade of printing ink on your chosen substrate.)

SML will not be responsible for errors, omissions, etc. Overlooked by the customer, after signed approval by customer.

Production will begin only after this proof has been approved/signed and faxed or e-mailed to your sml representative.

Approved

Approved w/ Change

000295‐ FRENCH

FABRIQUÉ AUX ÉTATS ‐UNIS DE

COMPOSANTS AMÉRICANS ET

ÉTRANGERS PAR

CMC RESCUE, INC.

6740 CORTONA DRIVE

GOLETA, CA 93117 USA

CMCPRO.COM

000295F 00

NOM:

AGENCE:

TÉLÉPHONE:

MISE EN SERVICE:

000295‐ ENGLISH

BACK

FRONT

NAME:

AGENCY:

PHONE:

DATE IN SERVICE:

MANUFACTURED IN USA

OF US AND FOREIGN

COMPONENTS

BY CMC RESCUE, INC.

6740 CORTONA DRIVE

GOLETA, CA 93117

CMCPRO.COM

BLACK

XXXXX

XXXXX

XXXXX

XXXXX

XX" X XX"

3.625" X 1.50"

PRINTED LABEL

ALDO ANGELES

ROBERTA GUILLORY

CMC-000295F

1257441395B

CMC-000295F_PL_41395B

CMC

03_05_201903_13_2019

1.50 in

3.625 in

3 mm 3 mm

3 mm3 mm

1.50 in

3.625 in

3 mm 3 mm

3 mm3 mm

CONFORME AU HARNAIS DE SÉCURITÉ VIE

EXIGENCES DE NFPA1983, INCORPORÉES DANS

L'ÉDITION 2022 DE NFPA2500, CLASSE III.

CE HARNAIS N’EST PAS RÉSISTANT AUX FLAMMES !

NE PAS ENLEVER CETTE ÉTIQUETTE!

HARNAIS INTÉGRAL, ÉGALEMENT CLASSIFIÉ AVEC

ANSI/ASSE Z359.11-2021 ETAUSSI AVEC CSA

Z259.10-2018.

MEETS THE LIFE SAFETY HARNESS

REQUIREMENTS OF NFPA1983, INCORPORATED

IN THE 2022 EDITION OF NFPA2500, CLASS III.

THIS HARNESS IS NOT FLAME RESISTANT!

DO NOT REMOVE THIS LABEL!

FULL BODY HARNESS INACCORDANCE WITH:

ANSI / ASSP Z359.11-2021 AND CSA Z259.10-2018

THIS DRAWING AND ALL INFORMATION HEREIN IS THE PROPERTY OF CMC RESCUE, INC.

ANY COPYING, REPRODUCTION OR UNAUTHORIZED USE WITHOUT WRITTEN CONSENT IS FORBIDDEN.

LABEL, ANSI Z359.11-2021 ATTACHMENTS

3.625 IN (92 MM)

1.5 IN (38 MM)

DESCRIPTIONREV. DATE INITIALS

INITIAL RELEASE00 10/19/2022 BK

CMC RESCUE

6740 CORTONA DR. GOLETA, CA

PART#: 000141

000141_Rev00

DATE: 10/19/2022DRAWN BY: BK

DRAWING SCALED @ 100%

ANSI Z359.11-2021

DORSAL STERNAL SHOULDER

FRONTAL WAIST REAR WAIST

NOTES:

1. PRINT ON CMC LABEL STOCK PN 000270 OR PN 000956-BERRY USING BLACK TRANSFER RIBBON CMC PN 000959

2. ALTERNATIVELY, PRINT ON MINIWAWA (SML) WHITE SATIN POLY WOVEN LABEL STOCK

3. PART NUMBER TO BE HIDDEN WHEN SEWN IN

0.866"

0.044"

THIS IS AN UNRELEASED DRAFT COPY, WILL BE RELEASED PER CMC PROCESS AFTER

UL APPROVAL, AND MAY BE REVISED WHILE STILL SHOWING REV 02

THIS DRAWING AND ALL INFORMATION HEREIN IS THE PROPERTY OF CMC RESCUE, INC.

ANY COPYING, REPRODUCTION OR UNAUTHORIZED USE WITHOUT WRITTEN CONSENT IS FORBIDDEN.

LABEL, CSA Z259.11-18 ATTACHMENTS

3.625 IN (92 MM)

1.5 IN (38 MM)

DESCRIPTIONREV. DATE INITIALS

INITIAL RELEASE00 10/19/2022 BK

CMC RESCUE

6740 CORTONA DR. GOLETA, CA

PART#: 000142

000142_Rev00

DATE: 10/19/2022DRAWN BY: BK

DRAWING SCALED @ 100%

CSA Z259.10-18

CLASS A - FALL ARREST

CLASSE A - ANTICUTE

CLASS D - SUSPENSION AND CONTROLLED DESCENT

CLASSE D - SUSPENSION ET DESCENTE CONTRÔLÉE

CLASS E - LIMITED ACCESS

CLASSE E - ACCÈS LIMITÉ

CLASS L - LADDER CLIMBING

CLASSE L - ACENSIONAUX ÉCHELLE

CLASS P - WORK-POSITIONING

CLASSE P - MAINTIEN EN

POSITION DU TRAVAIL

NOTES:

1. PRINT ON CMC LABEL STOCK PN 000270 OR PN 000956-BERRY USING BLACK TRANSFER RIBBON CMC PN 000959

2. ALTERNATIVELY, PRINT ON MINIWAWA (SML) WHITE SATIN POLY WOVEN LABEL STOCK

3. PART NUMBER TO BE HIDDEN WHEN SEWN IN

CSA Z259.10-18

THIS IS AN UNRELEASED DRAFT COPY, WILL BE RELEASED PER CMC PROCESS AFTER

UL APPROVAL, AND MAY BE REVISED WHILE STILL SHOWING REV 02

0.925"

0.050"

000143_Rev00

ANSI Z359.11-2021

ANSI Z359 Recognizes the use of this

harness only within the capacity range of:

130-310 lbs.

THIS DRAWING AND ALL INFORMATION HEREIN IS THE PROPERTY OF CMC RESCUE, INC.

ANY COPYING, REPRODUCTION OR UNAUTHORIZED USE WITHOUT WRITTEN CONSENT IS FORBIDDEN.

LABEL, CSA Z259.11-18 ATTACHMENTS

3.625 IN (92 MM)

1.5 IN (38 MM)

DESCRIPTIONREV. DATE INITIALS

INITIAL RELEASE00 10/19/2022 BK

CMC RESCUE

6740 CORTONA DR. GOLETA, CA

PART#: 000142

000142_Rev00

DATE: 10/19/2022DRAWN BY: BK

DRAWING SCALED @ 100%

CSA Z259.10-18

CLASS A - FALL ARREST

CLASSE A - ANTICUTE

CLASS D - SUSPENSION AND CONTROLLED DESCENT

CLASSE D - SUSPENSION ET DESCENTE CONTRÔLÉE

CLASS E - LIMITED ACCESS

CLASSE E - ACCÈS LIMITÉ

CLASS L - LADDER CLIMBING

CLASSE L - ACENSIONAUX ÉCHELLE

CLASS P - WORK-POSITIONING

CLASSE P - MAINTIEN EN

POSITION DU TRAVAIL

NOTES:

1. PRINT ON CMC LABEL STOCK PN 000270 OR PN 000956-BERRY USING BLACK TRANSFER RIBBON CMC PN 000959

2. ALTERNATIVELY, PRINT ON MINIWAWA (SML) WHITE SATIN POLY WOVEN LABEL STOCK

3. PART NUMBER TO BE HIDDEN WHEN SEWN IN

CSA Z259.10-18

THIS IS AN UNRELEASED DRAFT COPY, WILL BE RELEASED PER CMC PROCESS AFTER

UL APPROVAL, AND MAY BE REVISED WHILE STILL SHOWING REV 02

0.925"

0.050"

THIS DRAWING AND ALL INFORMATION HEREIN IS THE PROPERTY OF CMC RESCUE, INC.

ANY COPYING, REPRODUCTION OR UNAUTHORIZED USE WITHOUT WRITTEN CONSENT IS FORBIDDEN.

LABEL, ANSI Z359.11-2021 ATTACHMENTS

3.625 IN (92 MM)

1.5 IN (38 MM)

DESCRIPTIONREV. DATE INITIALS

INITIAL RELEASE00 10/19/2022 BK

CMC RESCUE

6740 CORTONA DR. GOLETA, CA

PART#: 000141

000141_Rev00

DATE: 10/19/2022DRAWN BY: BK

DRAWING SCALED @ 100%

ANSI Z359.11-2021

ANSI Z359.11-2021

FRONTAL WAIST REAR WAIST

NOTES:

1. PRINT ON CMC LABEL STOCK PN 000270 OR PN 000956-BERRY USING BLACK TRANSFER RIBBON CMC PN 000959

2. ALTERNATIVELY, PRINT ON MINIWAWA (SML) WHITE SATIN POLY WOVEN LABEL STOCK

3. PART NUMBER TO BE HIDDEN WHEN SEWN IN

0.866"

0.044"

THIS IS AN UNRELEASED DRAFT COPY, WILL BE RELEASED PER CMC PROCESS AFTER

UL APPROVAL, AND MAY BE REVISED WHILE STILL SHOWING REV 02