Coalesse SW 1 User manual

Other Coalesse Indoor Furnishing manuals

Coalesse

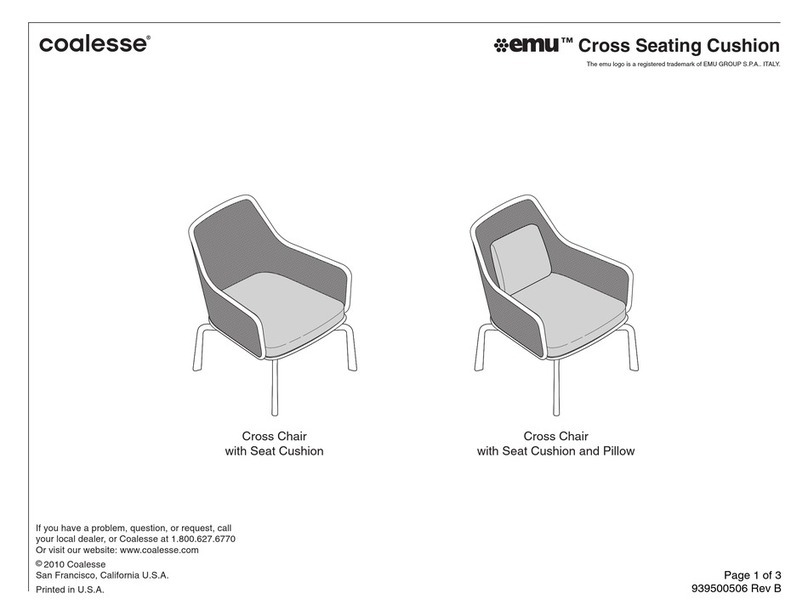

Coalesse emu Heaven Seating & Table Cushion User manual

Coalesse

Coalesse SW 1 Operating instructions

Coalesse

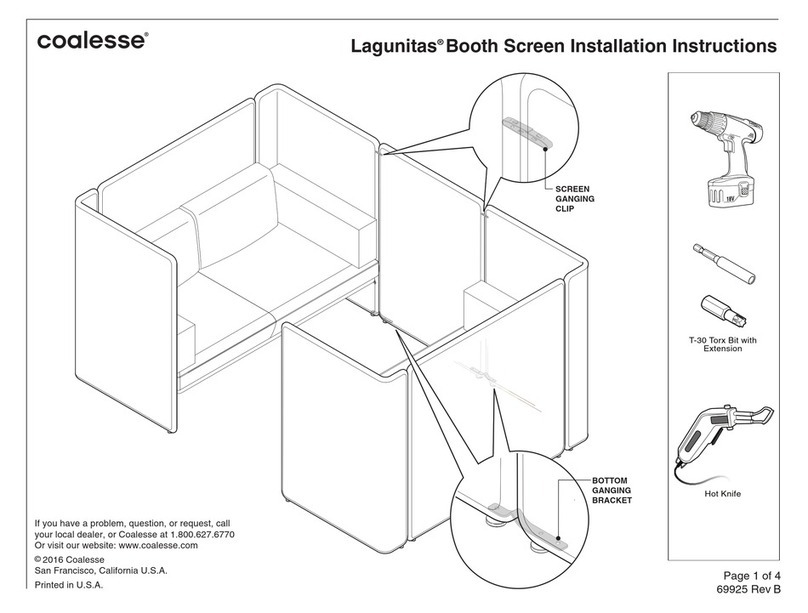

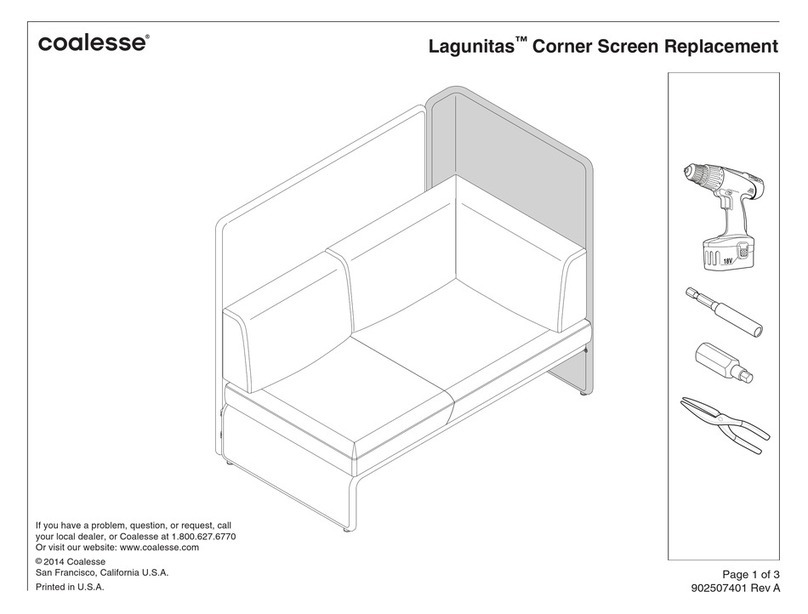

Coalesse Lagunitas User manual

Coalesse

Coalesse E-table 2 User manual

Coalesse

Coalesse Montara650 4-Leg Chair Operating instructions

Coalesse

Coalesse Denizen Round Operating and safety instructions

Coalesse

Coalesse EMU Re-trouve MIDBACK User manual

Coalesse

Coalesse Potrero 415 Light Table User manual

Coalesse

Coalesse LessThanFive User manual

Coalesse

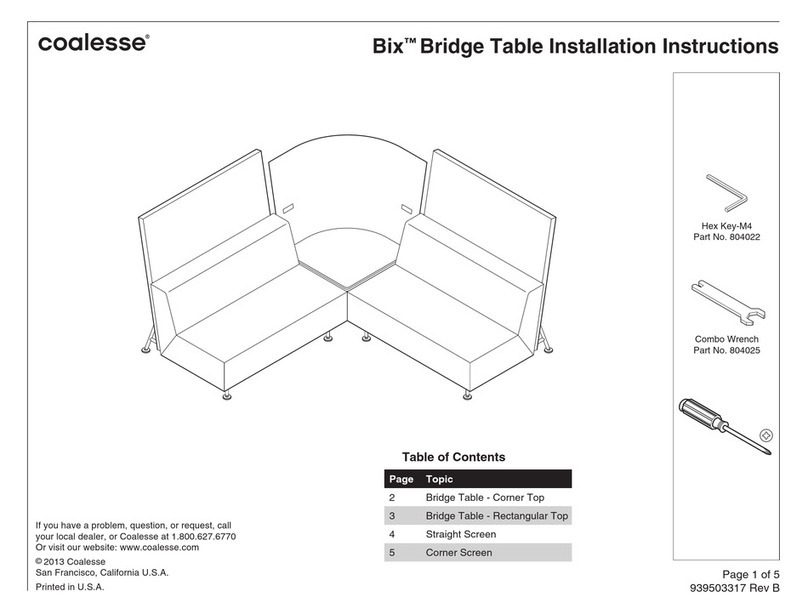

Coalesse Bix Bridge Table User manual

Coalesse

Coalesse Emu Ivy User manual

Coalesse

Coalesse Topo User manual

Coalesse

Coalesse Emu User manual

Coalesse

Coalesse Lagunitas Arm, Corner & Straight Back... Use and care manual

Coalesse

Coalesse Lox 4-Star Base Chair Reference guide

Coalesse

Coalesse Chord Use and care manual

Coalesse

Coalesse Massaud User manual

Coalesse

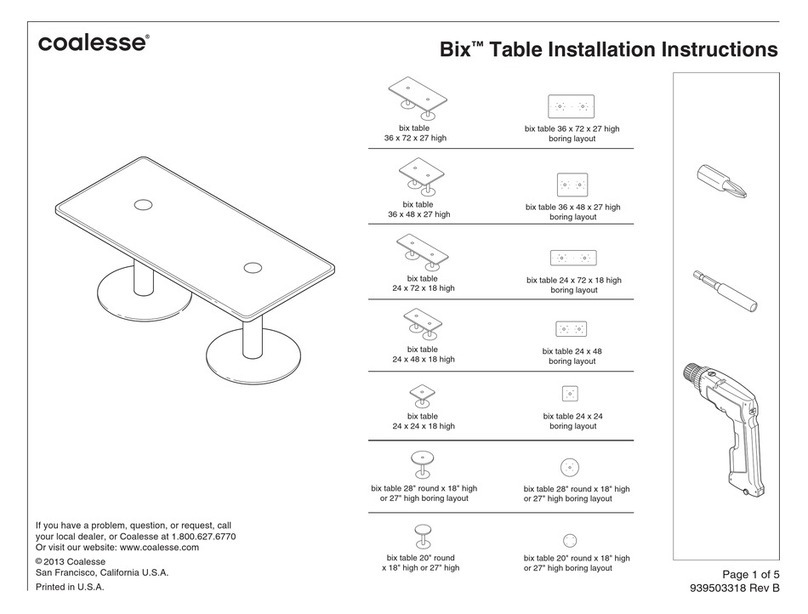

Coalesse Bix Table User manual

Coalesse

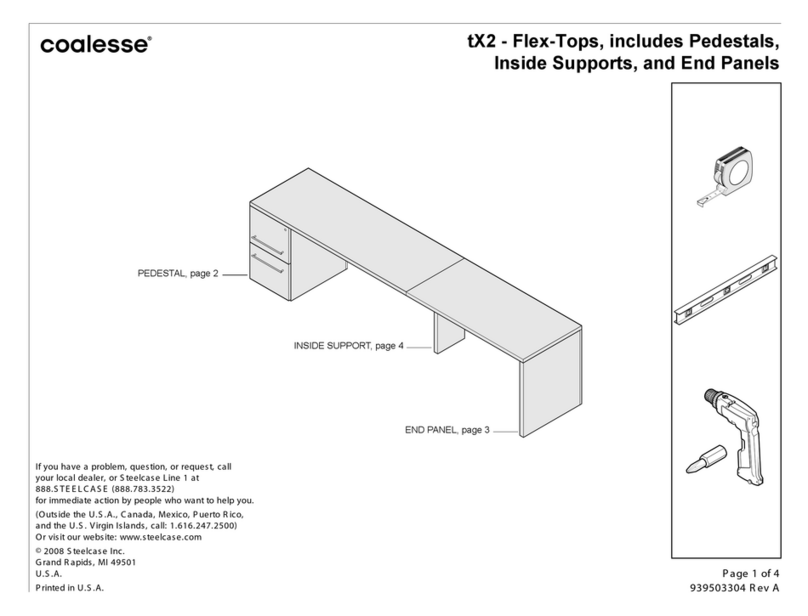

Coalesse tX2 User manual

Coalesse

Coalesse Denizen User manual

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual