- 1

TABLE OF CONTENTS

1 GENERAL.................................................................................................................... 2

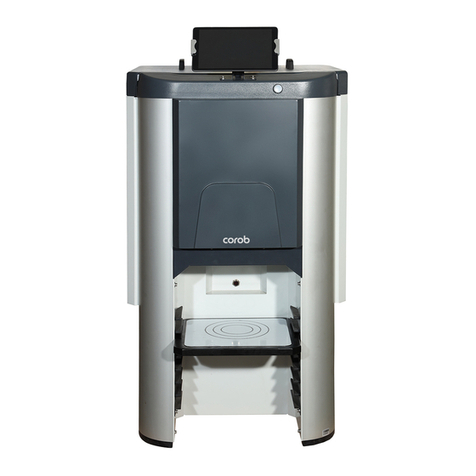

1.1 COROBTM D300 parts.......................................................................................... 2

1.2 The control system of COROBTM D300 .................................................................... 4

1.3 Technical information .......................................................................................... 8

2 MACHINE INSTALLATION ........................................................................................ 10

2.1 Installation site requirements ............................................................................. 10

2.2 Installation ...................................................................................................... 10

2.3 Mounting monitor cables .................................................................................... 13

2.4 Mounting the keyboard and the mouse cable ....................................................... 14

3 MAINTENANCE INSTRUCTIONS ............................................................................... 15

3.1 Removing the front casing.................................................................................. 15

3.2 Removing the can table during service................................................................. 15

3.3 Tilting the dispensing module.............................................................................. 16

3.4 Changing the solenoid rail assembly .................................................................... 17

3.5 Adjusting the valve solenoid ............................................................................... 18

3.6 Changing the puncher blade (optional)................................................................. 19

3.7 Maintenance of the hydraulic lift unit ................................................................... 20

3.7.1 Changing the hydraulic lift unit.................................................................. 20

3.7.2 Venting.................................................................................................. 23

3.7.3 Adding oil............................................................................................... 24

3.8 Replacing a pump ............................................................................................. 25

3.8.1 Removing a pump ................................................................................... 26

3.8.2 Installing a pump .................................................................................... 27

3.9 Replacing a canister .......................................................................................... 28

3.9.1 Removing a canister from the machine....................................................... 29

3.9.2 Installing a canister ................................................................................. 30

3.10 Replacing a sensor .......................................................................................... 32

How to check the functioning of the IR sensors: ................................................... 33

3.11 Replacing the processor and the connector board ................................................ 33

3.12 Replacing a motor ........................................................................................... 34

3.12.1 The dispensing motor............................................................................. 34

3.12.2 The stirring motors ................................................................................ 37

4 SERVICE OPERATIONS ............................................................................................. 39

5 ESSENTIAL ERROR CODES........................................................................................ 40

Error code 8000: Photocell. No can on the can table. ............................................ 40

Error code 8002: OFFLINE button pressed. .......................................................... 40

Error code 8102: E7 error ................................................................................. 40

Error code 8104: Busy error. Machine is busy. ..................................................... 40

Error code 8197: CRC error on data receive. ....................................................... 41

Error code 8199: No reply from the machine. ...................................................... 41

Error code 8501: Error: Cap closed during dispensing ........................................... 41

6 ELECTRICAL DIAGRAM ............................................................................................. 42

7 KOECDRIVER............................................................................................................ 45

7.1 Tests............................................................................................................... 45

7.1.1 Serial test .............................................................................................. 45

7.1.2 Encoder and zero sensor test .................................................................... 45

7.1.3 Cup sensor test....................................................................................... 45

7.1.4 Can sensor test....................................................................................... 45

7.1.5 Stirring tests........................................................................................... 46

7.2 Configuration settings........................................................................................ 46

7.3 Purge, init and dispense commands..................................................................... 47