CONTENTS 0-3

COROB™ TATOCOLOR

CONTENTS

1INTRODUCTION ................................................................................................... 1-1

1.1 Purpose and use of this manual.........................................................................1-1

1.2 Conventionally used graphics............................................................................1-1

2GENERAL INFORMATION...................................................................................... 2-1

2.1 General safety warnings...................................................................................2-1

2.2 Residual risks .................................................................................................2-2

2.3 Position of labels.............................................................................................2-4

2.4 Identifying information and reference standards ..................................................2-5

2.5 Warranty .......................................................................................................2-6

2.6 Definitions .....................................................................................................2-7

2.6.1 Operator - Machine interaction .................................................................2-7

2.6.2 Personnel qualifications ...........................................................................2-7

2.7 Fire extinguishing means to be used ..................................................................2-7

2.8 Declaration of conformity .................................................................................2-7

3FEATURES ............................................................................................................ 3-1

3.1 General description .........................................................................................3-1

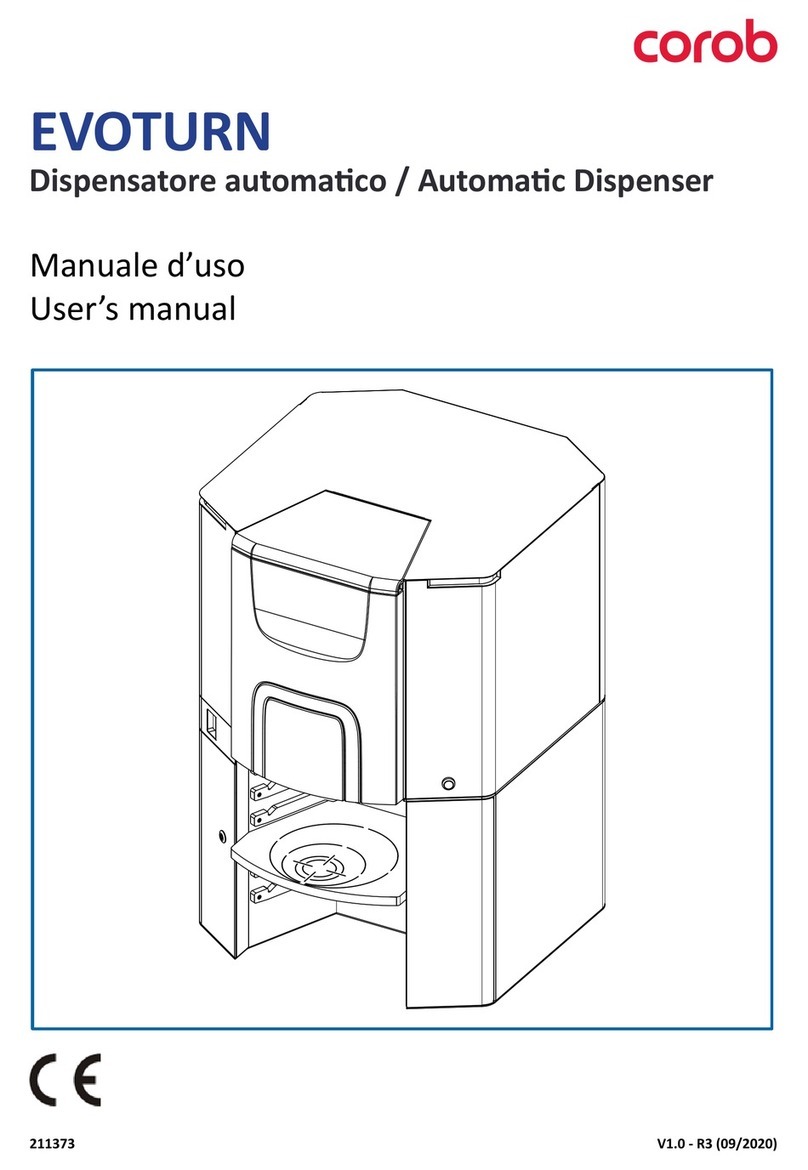

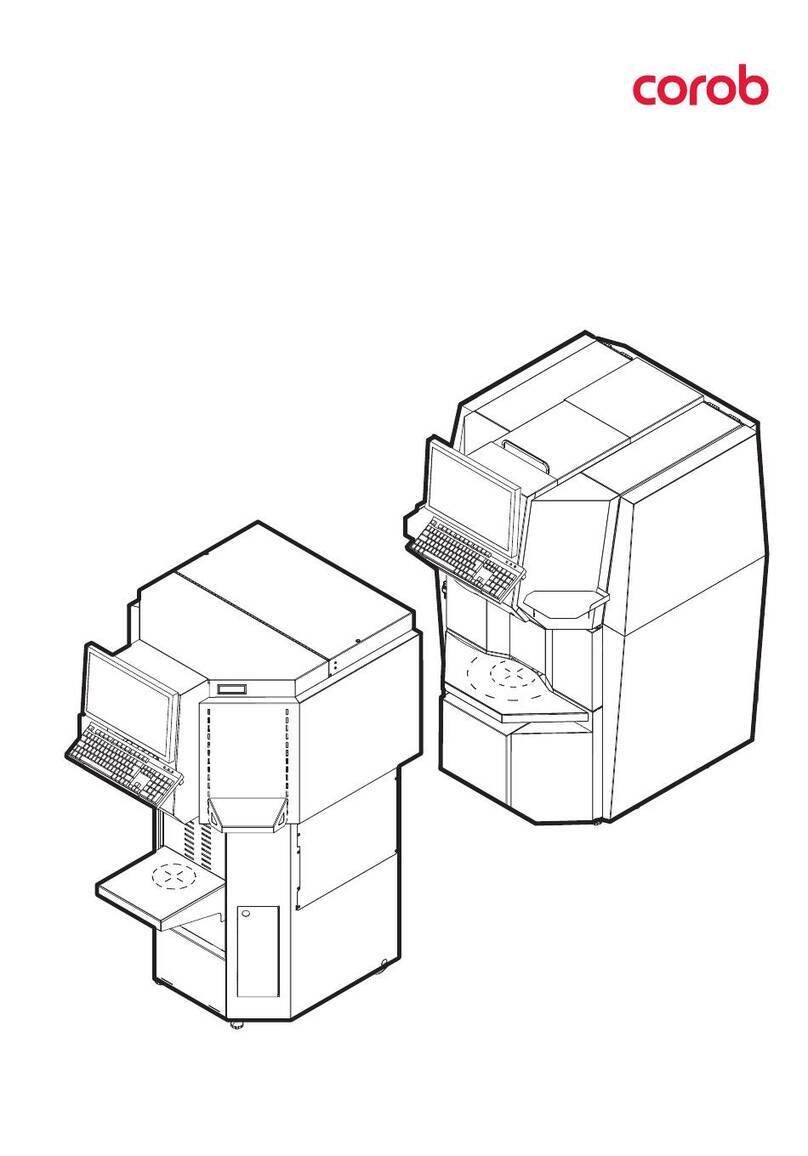

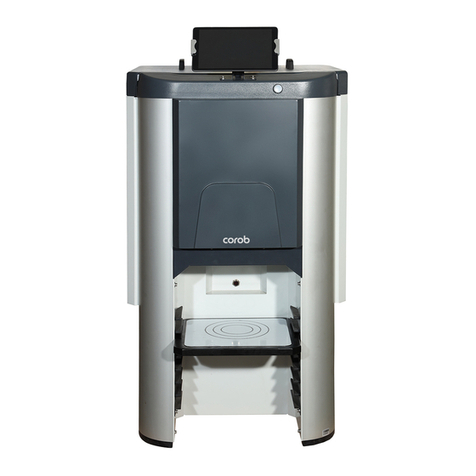

3.1.1 COROB™ TATOCOLOR TB ........................................................................3-1

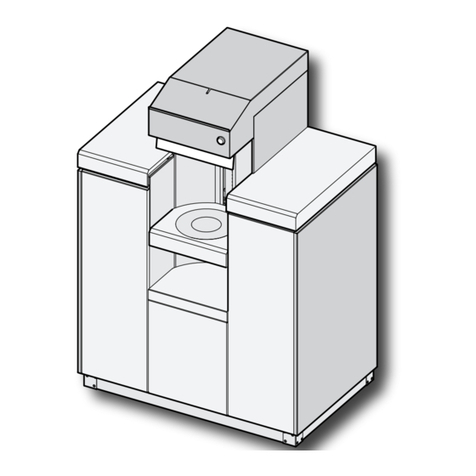

3.1.2 COROB™ TATOCOLOR TA ........................................................................3-2

3.2 Description of groups.......................................................................................3-2

3.2.1 Canister section .....................................................................................3-2

3.2.2 Dispensing section..................................................................................3-3

3.2.3 Shelf for can positioning ..........................................................................3-4

3.2.4 Humidifier cap........................................................................................3-5

3.2.5 Punch & plugger - TATOCOLOR TA only......................................................3-6

3.3 Technical specifications....................................................................................3-7

3.4 Performance and characteristics of the machine...................................................3-8

3.5 Cans to be handled..........................................................................................3-8

3.5.1 COROB™ TATOCOLOR TB ........................................................................3-9

3.5.2 COROB™ TATOCOLOR TA ........................................................................3-9

3.6 Minimum computer requirements ......................................................................3-9

3.7 Intended and improper use...............................................................................3-9

3.8 Safety devices .............................................................................................. 3-10

4SHIPPING, HANDLING AND UNPACKING ............................................................. 4-1

4.1 General warnings............................................................................................4-1

4.2 Moving and handling the packed machine...........................................................4-1

4.3 Environment conditions of the installation site.....................................................4-1

4.4 Unpacking and placement.................................................................................4-2

4.5 Moving and handling the unpacked machine........................................................4-5

4.6 Storage .........................................................................................................4-5

4.7 Product disposal and recycling ..........................................................................4-6

5INSTALLATION (by qualified personnel).............................................................. 5-1

5.1 General warnings............................................................................................5-1

5.2 Conditions for proper installation.......................................................................5-1

5.3 Installing accessories.......................................................................................5-1

5.3.1 Mounting the support plate for the computer ..............................................5-1

5.4 Canister filling and first machine startup.............................................................5-2

5.4.1 Purge procedure.....................................................................................5-2

5.4.2 Colorant recirculation procedure ...............................................................5-3

5.5 Connecting the computer and installing the software............................................5-3

5.5.1 Installing the keyboard (only model TB, with sheet metal panels)..................5-5

5.5.2 Machine configuration through the management program................................5-5

5.6 Moistening the cap sponge ...............................................................................5-5