1.1 Purpose and use of this manual ................................................................................................................................. 5

1.1.1 Convenonallyusedgraphics...........................................................................................................................5

1.2 Denions .................................................................................................................................................................. 5

................................................................................................................................................................ 6

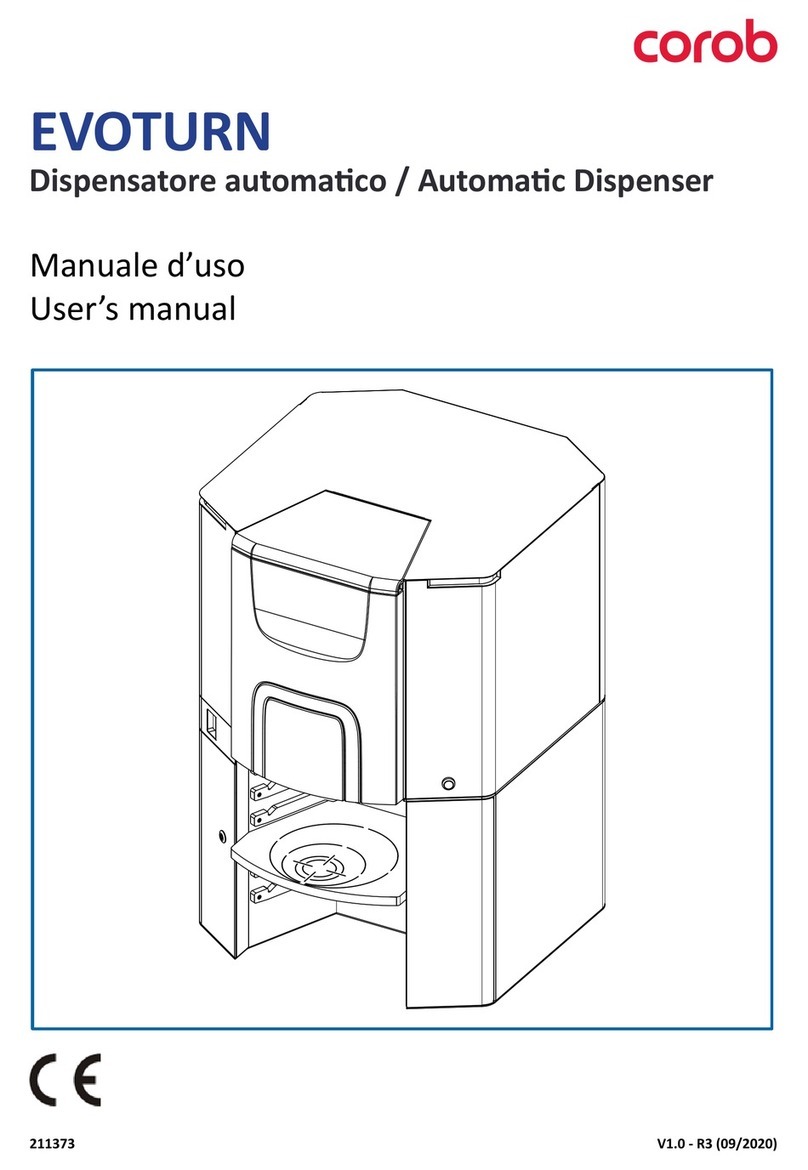

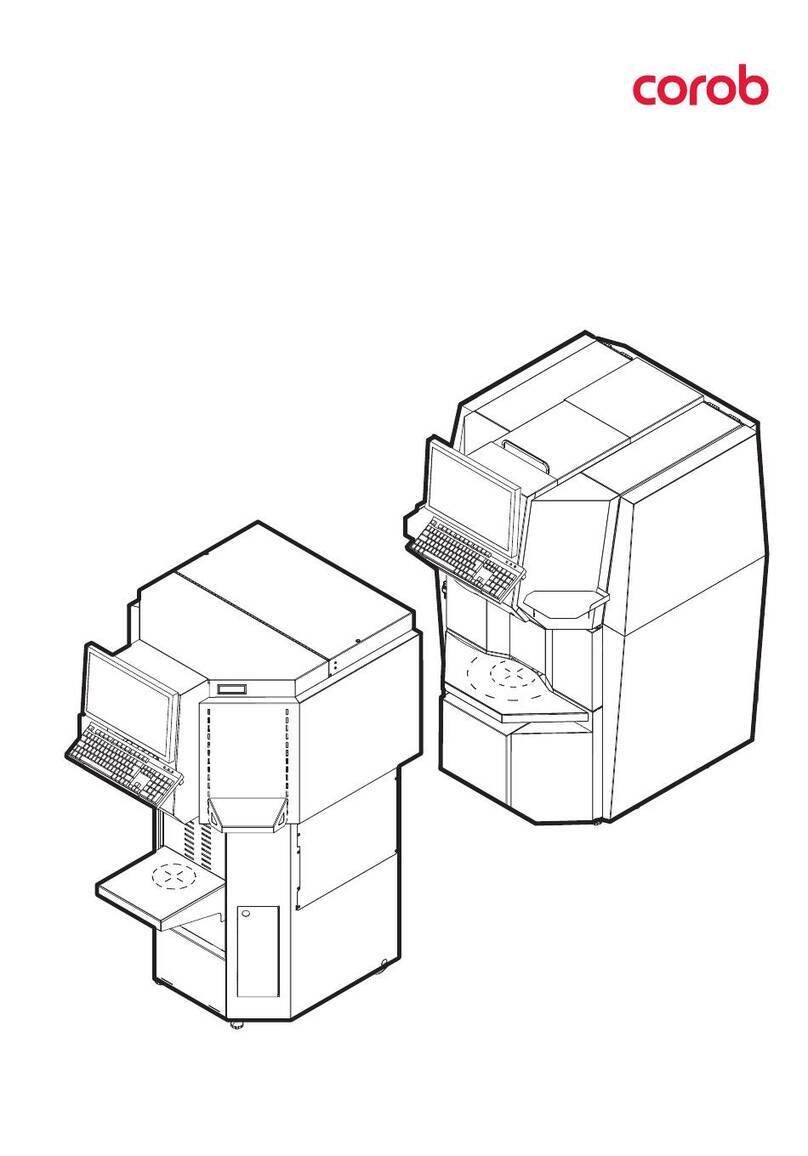

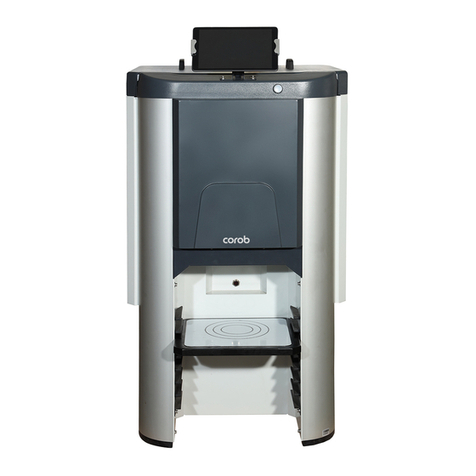

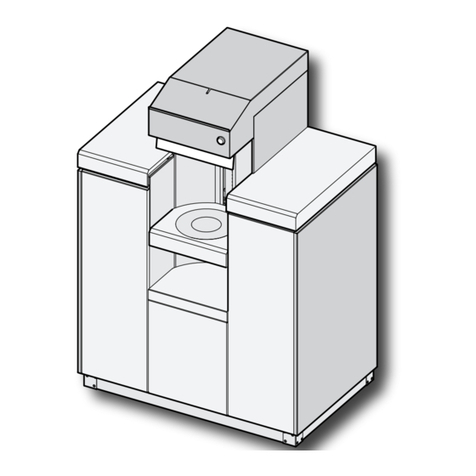

2.1 Descripon of the machine ........................................................................................................................................ 6

2.2 Descripon of unit ..................................................................................................................................................... 7

2.3 Usable cans ................................................................................................................................................................ 8

2.4 Intended use ..................... ......................................................................................................................................... 8

2.5 Idenfying informaon ........ ...................................................................................................................................... 8

3.1 Safety warnings and unauthorized use ....................................................................................................................... 9

3.2 Warning on the use of colorants ............................................................................................................................... 10

3.3 Residual risks ............................................................................................................................................................ 11

3.4 Posion of labels ...................................................................................................................................................... 12

3.5 Requirement of the installaon site ......................................................................................................................... 13

3.6 Safety device ............................................................................................................................................................ 13

.............................................................................................................. 14

4.1 General warnings ...................................................................................................................................................... 14

4.2 Unpacking and placement ........................................................................................................................................ 14

4.2.1Removingturntablelockhardware................................................................................................................. 16

4.2.3Standardmaterialsupplied............................................................................................................................... 17

4.3 Storage ............... ...................................................................................................................................................... 17

............................................................................................................................................................... 18

5.1 General warnings ..................................................................................................................................................... 18

5.2 Management computer ........................................................................................................................................... 18

5.3 Control devices ........................................................................................................................................................ 19

5.4 Electrical connecon and start-up ........................................................................................................................... 20

5.5 Inializaon ............................................................................................................................................................. 20

5.6 Use of the o-line buon ......................................................................................................................................... 21

5.7 Shut-down ................................................................................................................................................................ 21

6.1 General warnings ..................................................................................................................................................... 22

6.2 At the beginning of the working day ......................................................................................................................... 22

6.3 Running the machine ............................................................................................................................................... 22

6.3.1Runningthemachine....................................................................................................................................... 22

6.3.2 Loading of cans ................................................................................................................................................ 23

6.3.3 Use of the Bung Hole Locator .......................................................................................................................... 23

6.3.4 Dispensing ...... ................................................................................................................................................. 23

6.4 Automac process ................ ................................................................................................................................... 24

6.5 Relling the canister ......... ....................................................................................................................................... 24

6.6 Troubleshoong ......... .............................................................................................................................................. 27

................................................................................................................................... 28

7.1 General warnings ..................................................................................................................................................... 28

7.2 Maintenance table ................................................................................................................................................... 28

7.3 Products to be used ................................................................................................................................................. 28

7.4 External cleaning ...................................................................................................................................................... 28

7.5 Relling the liquid of the cleaning brush .................................................................................................................. 29

8.1 Technical data .......................................................................................................................................................... 30

8.2 Dimensions . ............................................................................................................................................................. 31

8.3 Declaraon of conformity......................................................................................................................................... 31

8.4 Warranty .................................................................................................................................................................. 31

FLEX 200