Copyright © 2011-2019 Cree, Inc. All rights reserved. The information in this document is subject to change without notice. Cree®is a registered trademark and the Cree logo is a trademark of Cree, Inc.

8

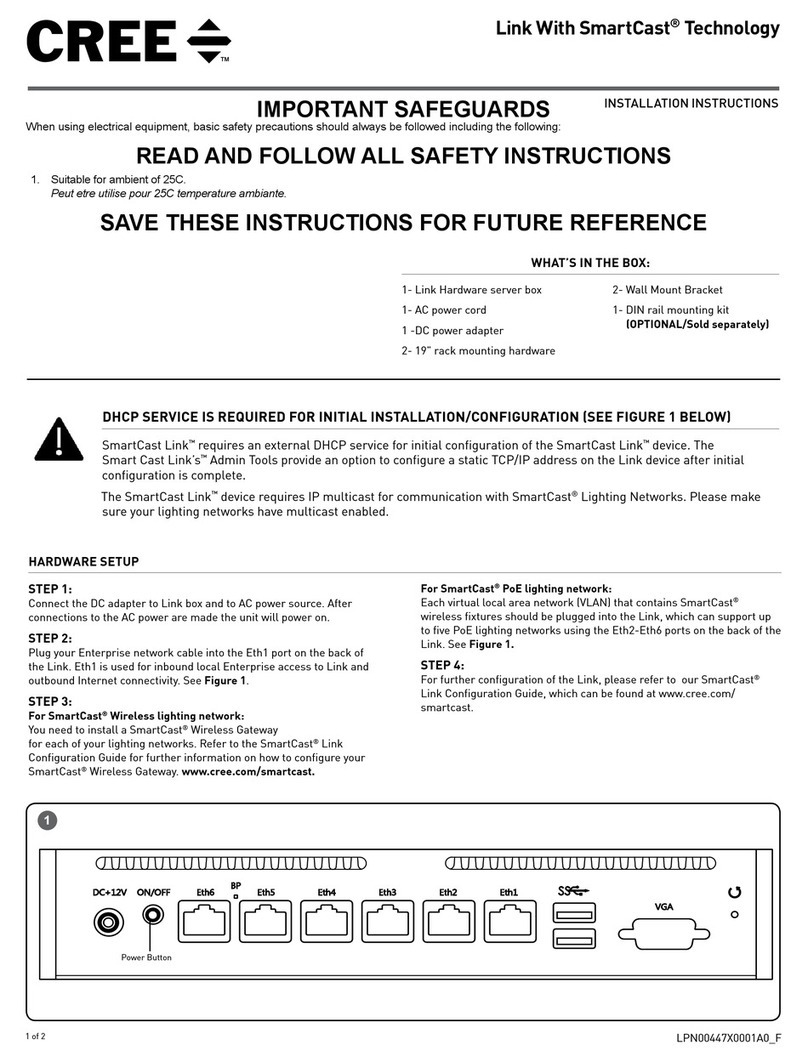

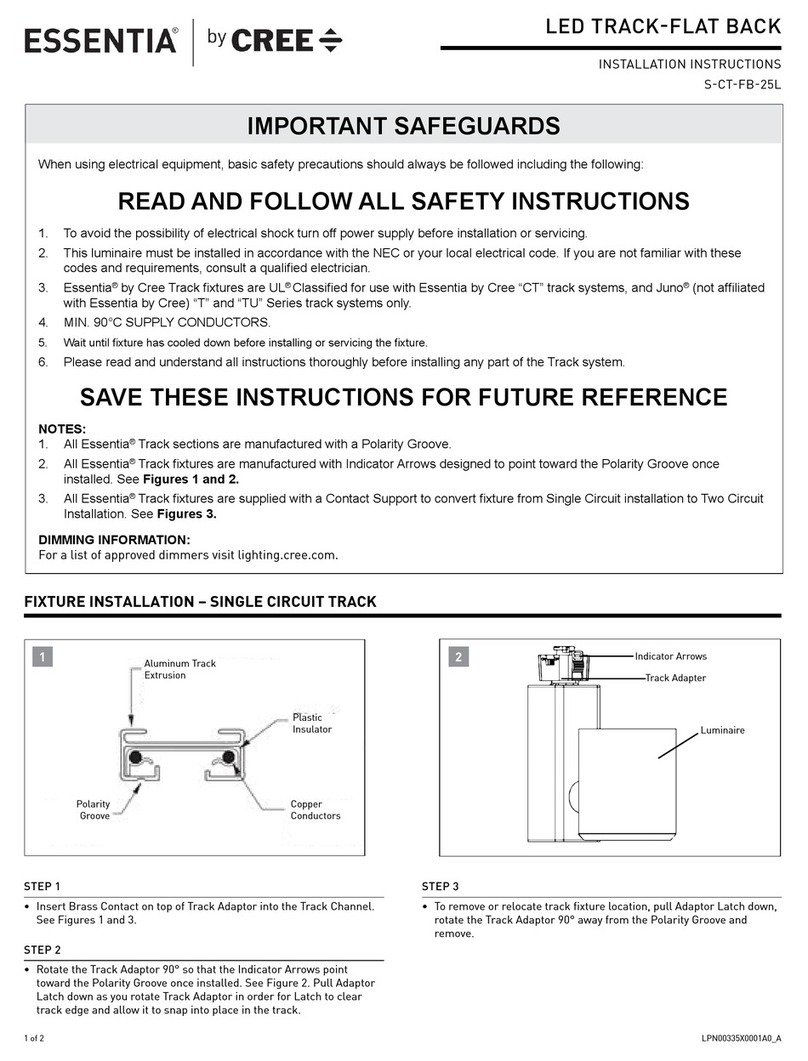

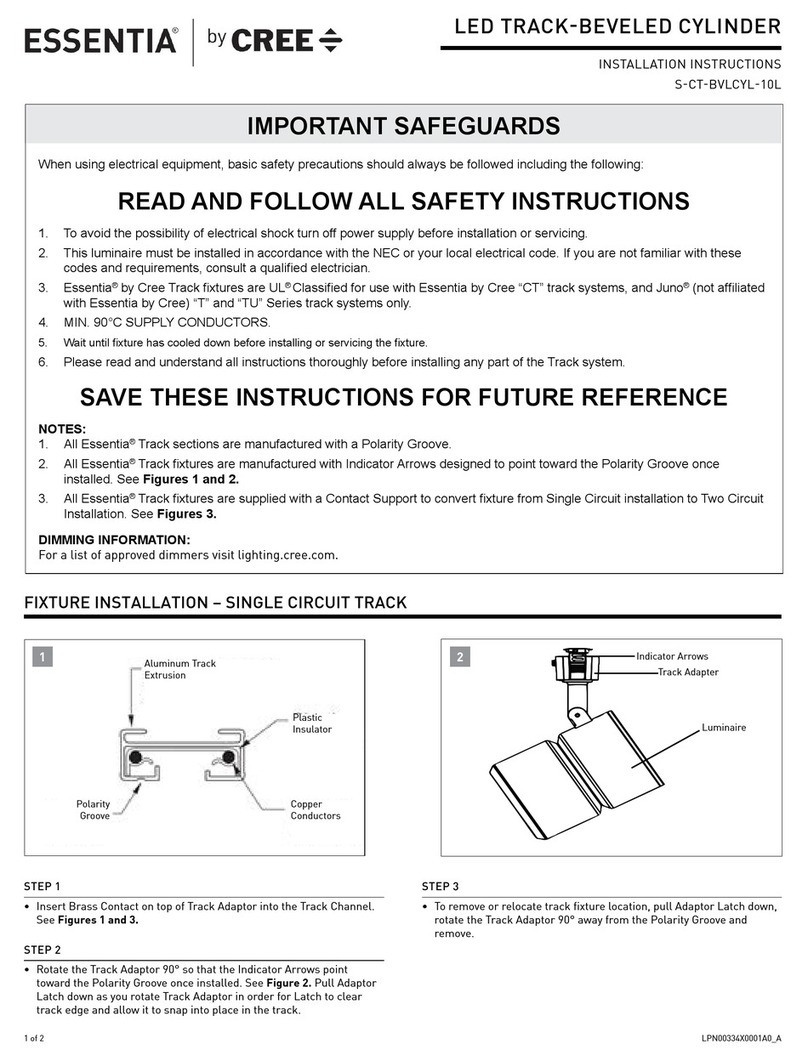

HIGH‑BRIGHTNESS LED SOLDERING & HANDLING

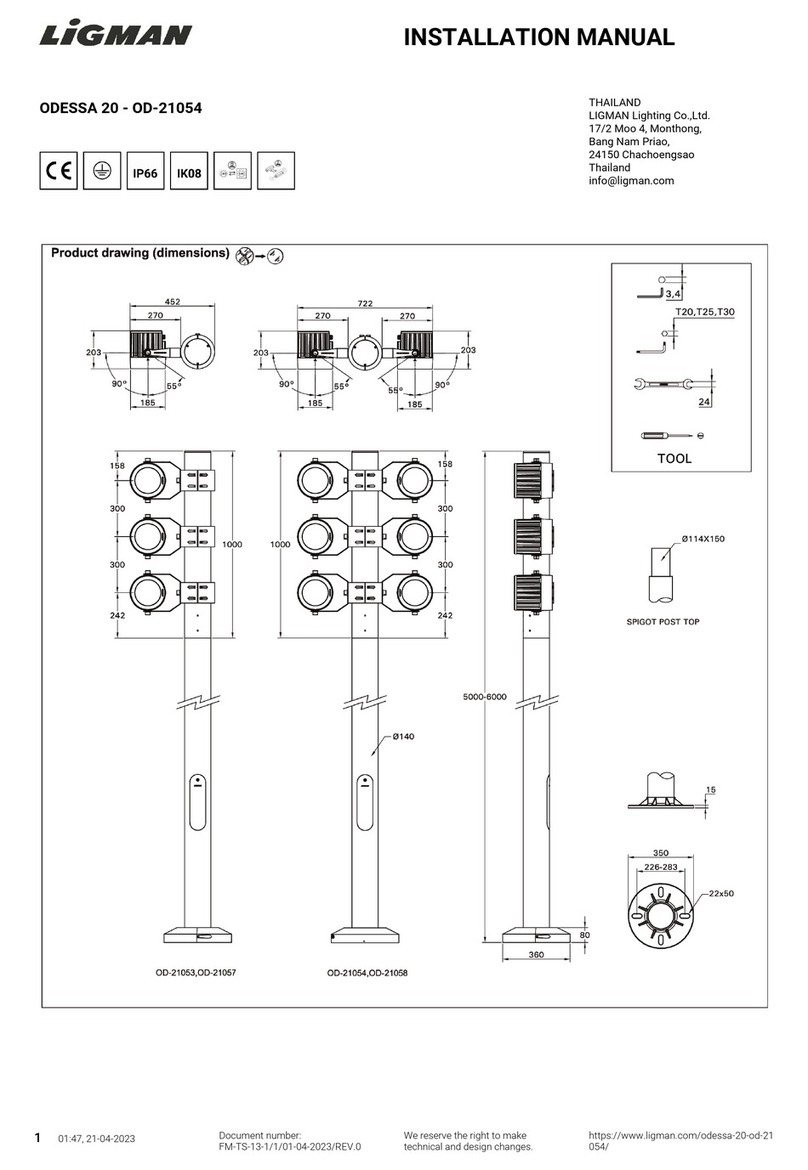

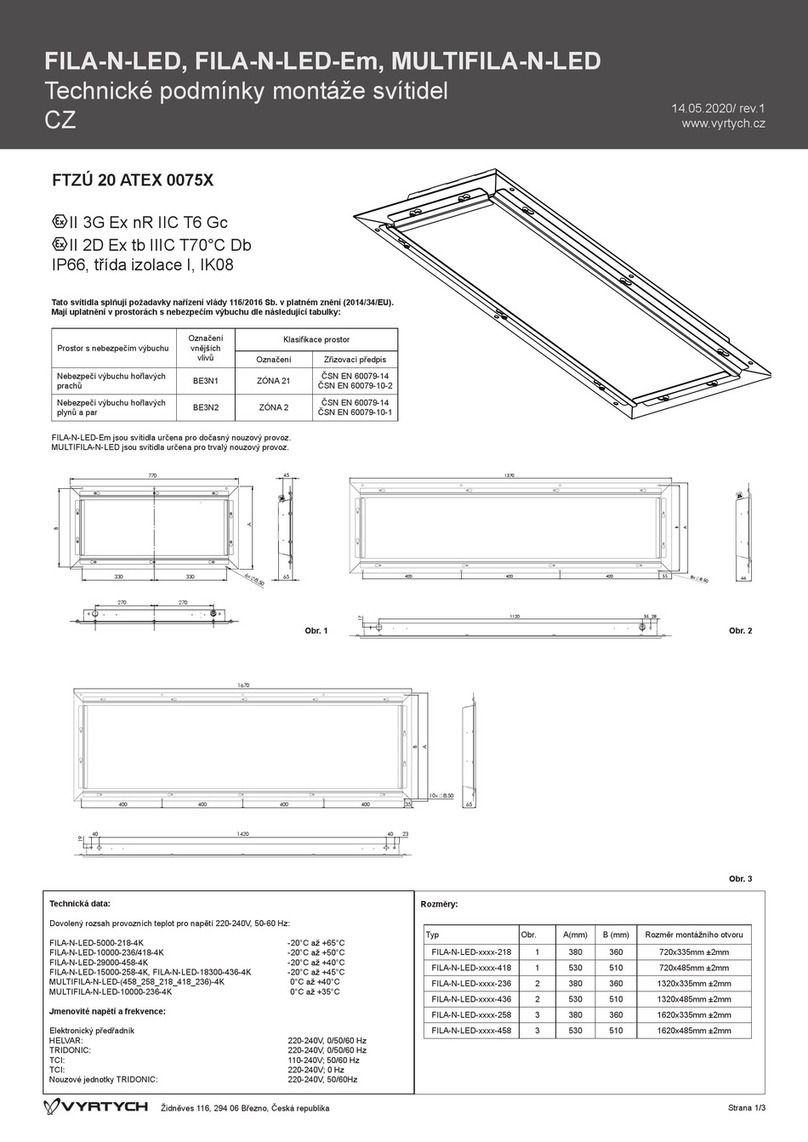

LU6 series recommended solder-pad design for heat dissipation:

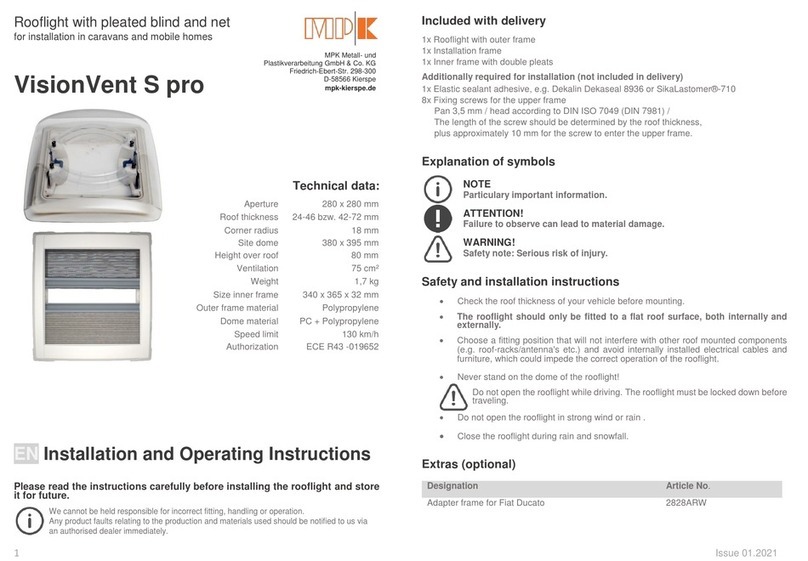

Small‑top SMD LM3 series recommended solder-pad design for heat dissipation:

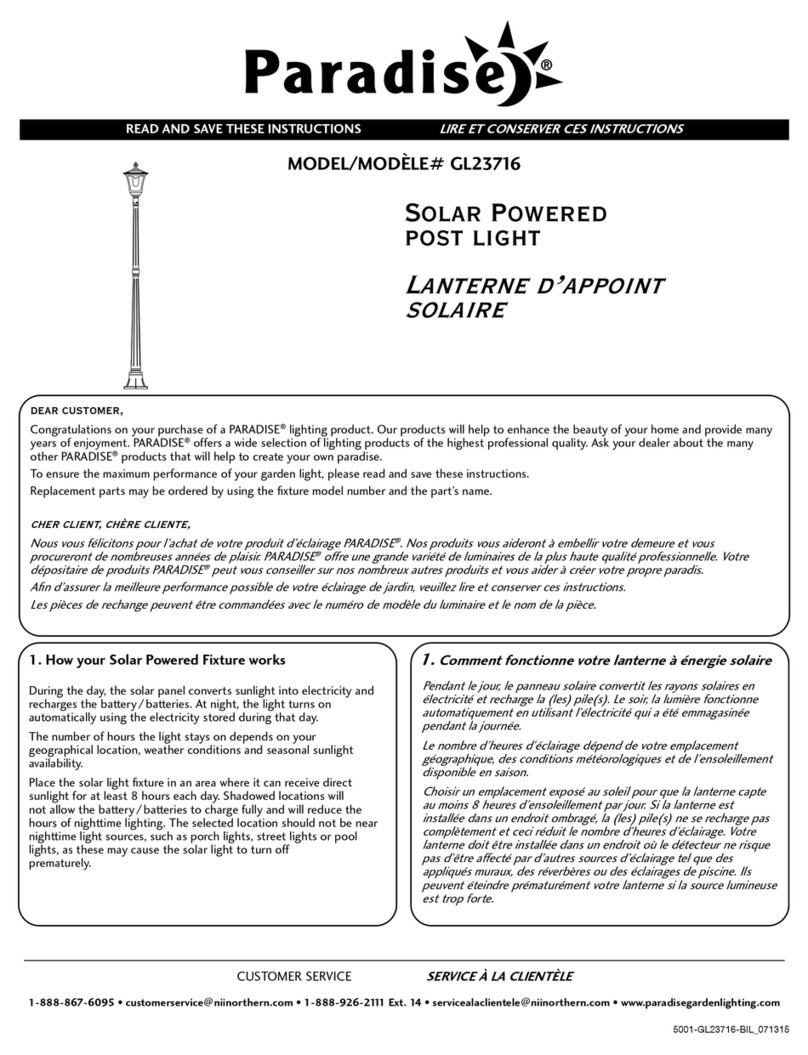

Mini side 0.8‑mm SMD LS8 series recommended solder-pad design for heat dissipation:

Note

Metal area at 1, 2, 3 should not

be less than 16 mm2each for

sufcientheatdissipation.

6/13

1.6

0.5

2.0

4

5

3

2

8.4

6

A

1

6.6

2.0

2.4

3.0

LU6 series recommended solder pad design for heat dissipation:

4.7

1.65 1.4

0.8

0.35

9.4

9.5

4.0

1.8

4

5

3

2

61

Small Top SMD LM3 series recommended solder pad design for heat dissipation:

Mini side 0.8mm SMD LS8 series recommended solder pad design for heat dissipation:

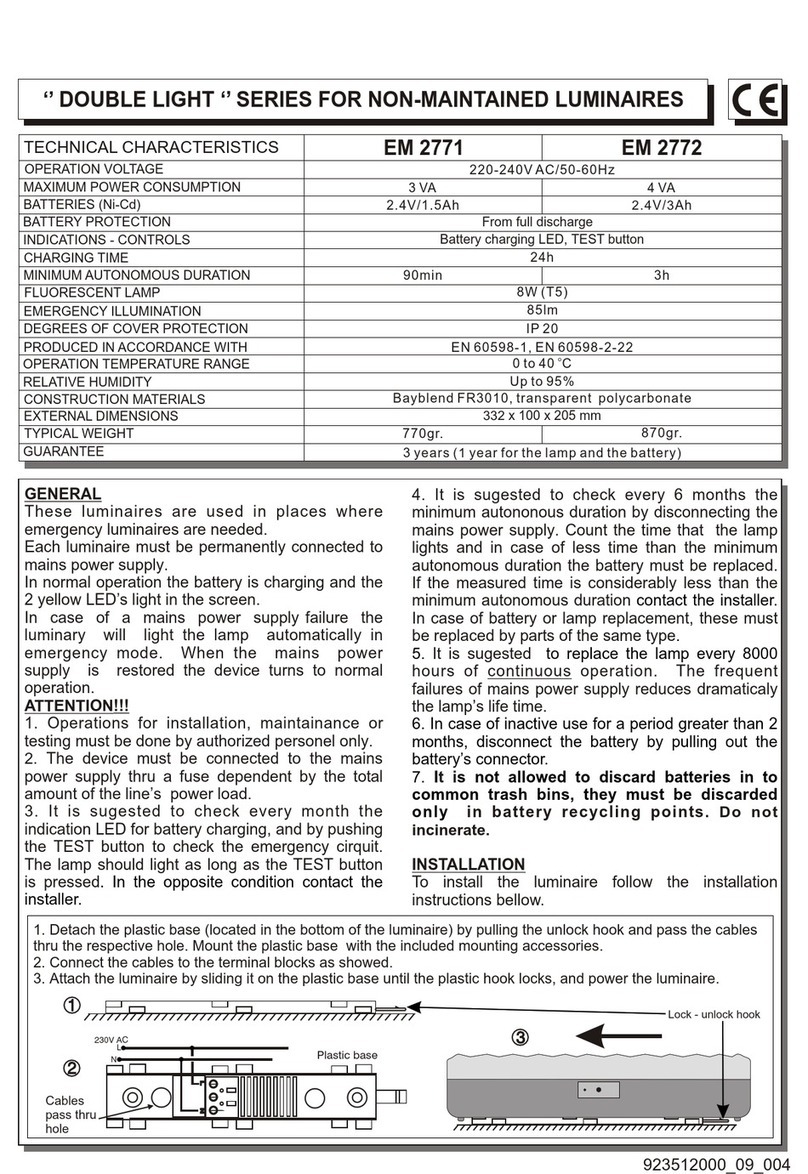

LA6 series recommended solder pad design for heat dissipation:

Note:

Metal area at 1, 2, 3 should not

be less than 40mm2

each for

sufficient heat dissipation.

1.3

4.0

9.3

1.3

2.2

1.55

4.4

1.0

0.9

1.4

3.8

1.0

Note:

Metal area at 1, 2, 3 should not

be less than 16mm2

each for

sufficient heat dissipation.

6/13

1.6

0.5

2.0

4

5

3

2

8.4

6

A

1

6.6

2.0

2.4

3.0

LU6 series recommended solder pad design for heat dissipation:

4.7

1.65 1.4

0.8

0.35

9.4

9.5

4.0

1.8

4

5

3

2

61

Small Top SMD LM3 series recommended solder pad design for heat dissipation:

Mini side 0.8mm SMD LS8 series recommended solder pad design for heat dissipation:

LA6 series recommended solder pad design for heat dissipation:

Note:

Metal area at 1, 2, 3 should not

be less than 40mm2

each for

sufficient heat dissipation.

1.3

4.0

9.3

1.3

2.2

1.55

4.4

1.0

0.9

1.4

3.8

1.0

Note:

Metal area at 1, 2, 3 should not

be less than 16mm2

each for

sufficient heat dissipation.

6/13

1.6

0.5

2.0

4

5

3

2

8.4

6

A

1

6.6

2.0

2.4

3.0

LU6 series recommended solder pad design for heat dissipation:

4.7

1.65 1.4

0.8

0.35

9.4

9.5

4.0

1.8

4

5

3

2

61

Small Top SMD LM3 series recommended solder pad design for heat dissipation:

Mini side 0.8mm SMD LS8 series recommended solder pad design for heat dissipation:

LA6 series recommended solder pad design for heat dissipation:

Note:

Metal area at 1, 2, 3 should not

be less than 40mm2

each for

sufficient heat dissipation.

1.3

4.0

9.3

1.3

2.2

1.55

4.4

1.0

0.9

1.4

3.8

1.0

Note:

Metal area at 1, 2, 3 should not

be less than 16mm2

each for

sufficient heat dissipation.

6/13

1.6

0.5

2.0

4

5

3

2

8.4

6

A

1

6.6

2.0

2.4

3.0

LU6 series recommended solder pad design for heat dissipation:

4.7

1.65 1.4

0.8

0.35

9.4

9.5

4.0

1.8

4

5

3

2

61

Small Top SMD LM3 series recommended solder pad design for heat dissipation:

Mini side 0.8mm SMD LS8 series recommended solder pad design for heat dissipation:

LA6 series recommended solder pad design for heat dissipation:

Note:

Metal area at 1, 2, 3 should not

be less than 40mm2

each for

sufficient heat dissipation.

1.3

4.0

9.3

1.3

2.2

1.55

4.4

1.0

0.9

1.4

3.8

1.0

Note:

Metal area at 1, 2, 3 should not

be less than 16mm2

each for

sufficient heat dissipation.

6/13

1.6

0.5

2.0

4

5

3

2

8.4

6

A

1

6.6

2.0

2.4

3.0

LU6 series recommended solder pad design for heat dissipation:

4.7

1.65 1.4

0.8

0.35

9.4

9.5

4.0

1.8

4

5

3

2

61

Small Top SMD LM3 series recommended solder pad design for heat dissipation:

Mini side 0.8mm SMD LS8 series recommended solder pad design for heat dissipation:

LA6 series recommended solder pad design for heat dissipation:

Note:

Metal area at 1, 2, 3 should not

be less than 40mm2

each for

sufficient heat dissipation.

1.3

4.0

9.3

1.3

2.2

1.55

4.4

1.0

0.9

1.4

3.8

1.0

Note:

Metal area at 1, 2, 3 should not

be less than 16mm2

each for

sufficient heat dissipation.

6/13

1.6

0.5

2.0

4

5

3

2

8.4

6

A

1

6.6

2.0

2.4

3.0

LU6 series recommended solder pad design for heat dissipation:

4.7

1.65 1.4

0.8

0.35

9.4

9.5

4.0

1.8

4

5

3

2

61

Small Top SMD LM3 series recommended solder pad design for heat dissipation:

Mini side 0.8mm SMD LS8 series recommended solder pad design for heat dissipation:

LA6 series recommended solder pad design for heat dissipation:

Note:

Metal area at 1, 2, 3 should not

be less than 40mm2

each for

sufficient heat dissipation.

1.3

4.0

9.3

1.3

2.2

1.55

4.4

1.0

0.9

1.4

3.8

1.0

Note:

Metal area at 1, 2, 3 should not

be less than 16mm2

each for

sufficient heat dissipation.