19

4.4 How to x and adjust the mechanical limit switches

• Unlock the operator;

• Rotate the wing to the position of complete opening, position the mechanical limit switch on the stop with the straight arm and fasten it

with the provided screws (Pic. 10). If necessary, you can mount a second mechanical limit switch for the closing stop. In this case follow

the above directions by moving the door in the desired closed position and x it with the screws provided in detention;

• Repeat the previous step for a possible second door;

• Secure the protective cover on the straight arm with the screws provided (Pic. 10).

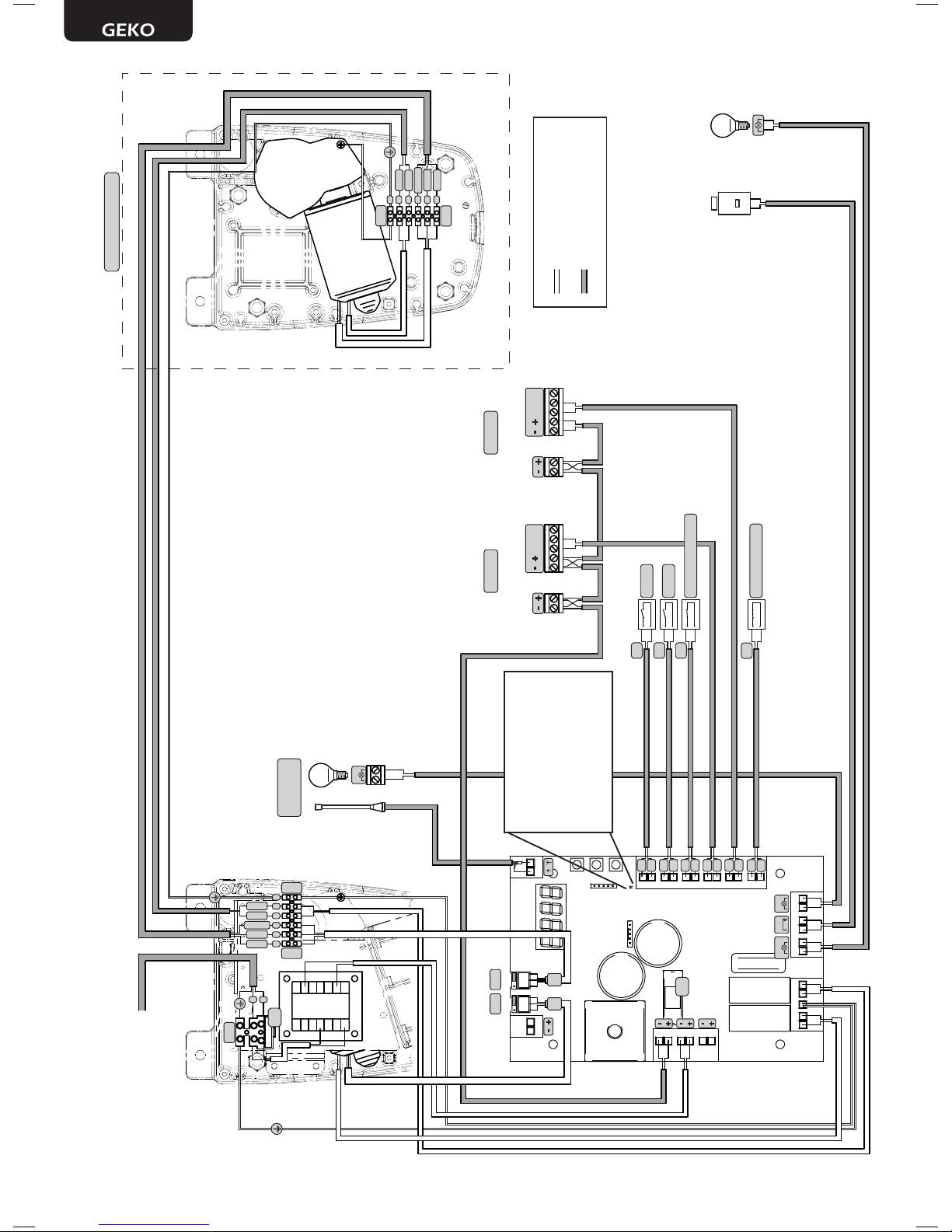

5 ELECTRICAL CONNECTIONS

Execute the wiring following the directions of table 1 and diagrams on page 20.

WARNING To ensure an appropriate level of electrical safety always keep the 230V power supply cables apart (minimum 4mm in the

open or 1 mm through insulation) from low voltage cables (motors power supply, controls, electric locks, aerial and auxiliary circuits

power supply), and fasten the latter with appropriate clamps near the terminal boards.

WARNING Connect to the power supply 230 V ~± 10% 50 Hz through a multi pole switch or a different device that can ensure multi pole

disconnection from the power supply, with a contact opening of 3 mm.

WARNING To connect the encoder to the control panel, use only a dedicated cable 3x0,22mm2.

Table 1 “terminal board connections”

1-2 +24 V power supply output for auxiliary devices 200mA

3-4 22 V ~ transformer power supply input

5-6 24 V battery power supply or photovoltaic accumulator Green Energy input (follow carefully polarity indications).

7-8 Operator 1 output

9Connection of motors metallic parts

10-11 Operator 2 output (if present)

12-13 24 V max 15 W output for open gate x warning light (if P052=0), ashing (if P052=1) or courtesy light (if

P052>1)

14-15

14 (-) “Boost” output for electric-lock, max 1 x art. 110 (if P062=0), 24V pulse output, max 5W (if P062=1), step

by step (if P062=2), electro-brake output for not self-locking operators (if P062=3), output for electric-lock

power supply via external relay (if P062=4), output for electro-magnets power supply for barriers (if P062=5)

or temporized output (if P062>5).

15 (+)

16-17 24 V Flashing light output max 15W art. Lumy/24A/S

18-19 18 - N.C. Input 6 STOP. In case of intervention, it stops the movement of both motors during any

operation. If unused, short circuit.

If the installation requires different commands

and / or additional to the standard, you can

congure each input to the required rate.

Refer to Chapter

“Advanced Programming”.

19 - Com

20-21

20 - N.C. Input 5 PHOTO 2. When enabled (see parameter P051 in the table), activation of PHOTO

2 provokes: an inversion of direction (during closing), the arrest of the movement (during

opening), prevent the start (gate closed). If unused, short circuit.

21 - Com

22-23

22 - N.C. Input 4 PHOTO 1. When enabled (see parameter P050 in the table), activation of PHOTO

1 provokes: an inversion of direction (during closing), the arrest of the movement (during

opening), prevent the start (gate closed). If unused, short circuit.

23 - Com

24-25 24 - N.C. Input 3 SAFETY. If activated, it causes the inversion. See P055 and P056 on the parame-

ters table. If unused, short circuit.

25 - Com

26-27 26 - N.O. Input 2 PED. If activated, it opens motor nr. 1 only.

27 - Com

28-29 28 - N.O. Input 1 START. In case of intervention it provokes: the operator opening or closing. It may

operate as “inversion” mode (P049=0) or “step by step” mode (P049=1).

29 - Com

30 Aerial signal input

31 Ground aerial input

32-33 32 (+) DE@NET mains input (unused at the moment)

33 (-)

CON 1 230 V ~ ±10% (50/60 Hz) power supply input

CON 2 Connection of encoder to operator 2 (1-2-3)

CON 3 Connection of power supply to operator 2 + ground (4-5-6)

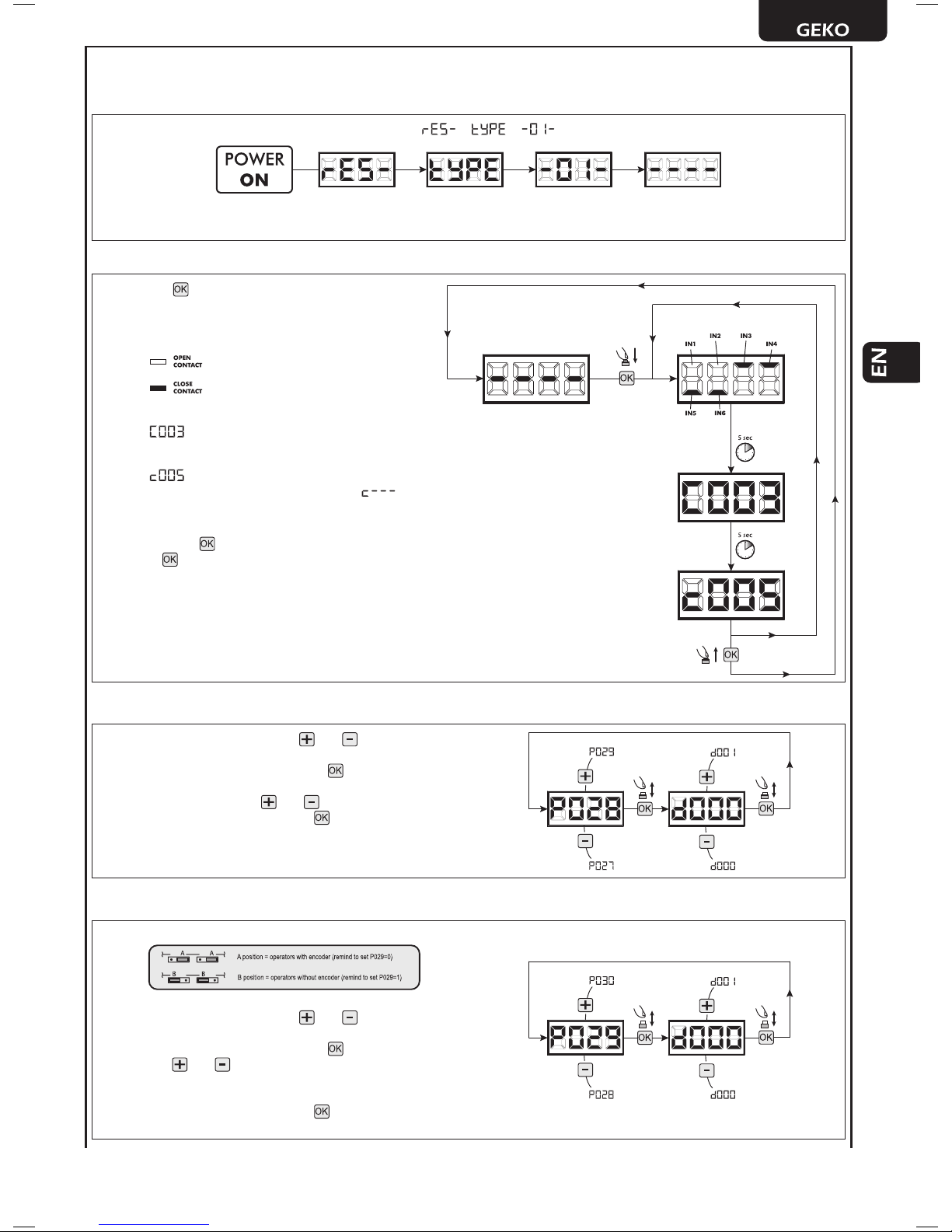

J5 J9 Encoder selection Jumper:

•A position = operators with encoder (remind to set P029=0)

•B position = operators without encoder (remind to set P029=1)

AB AB