DENALI

///////////////////////////////////////////////

LAH.00.10000.B

Instruction Rev00

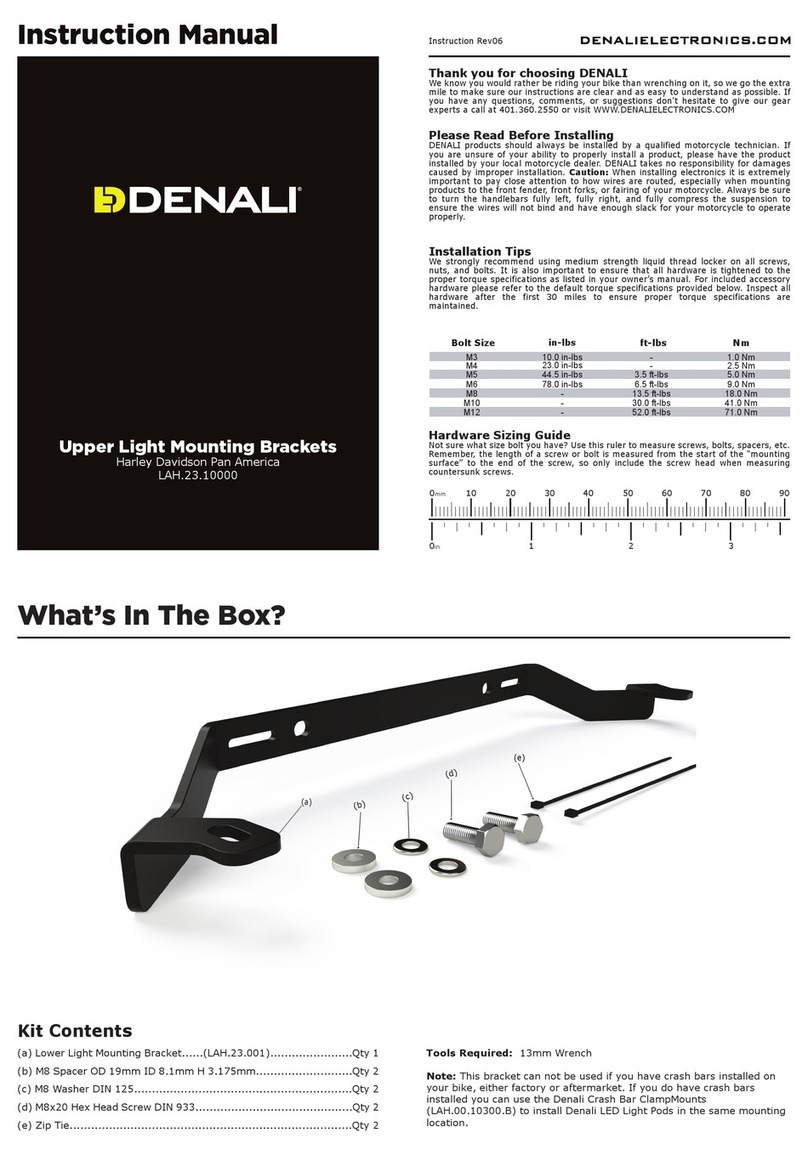

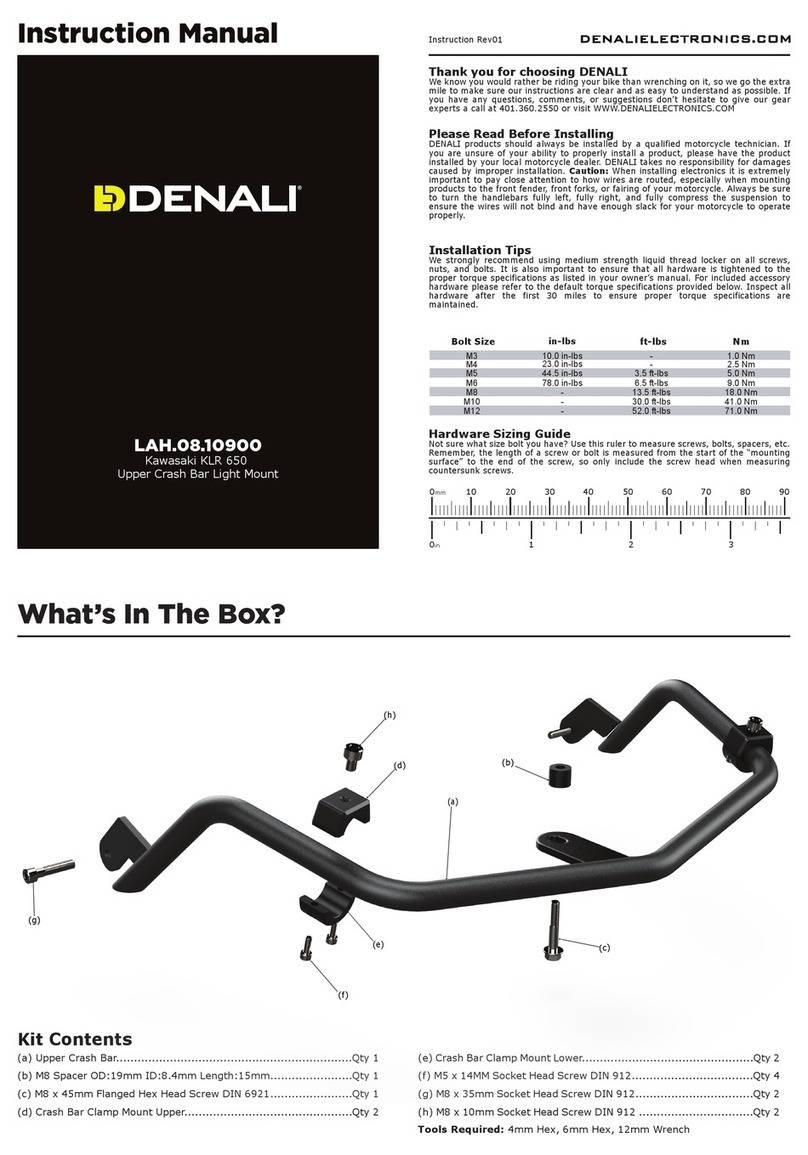

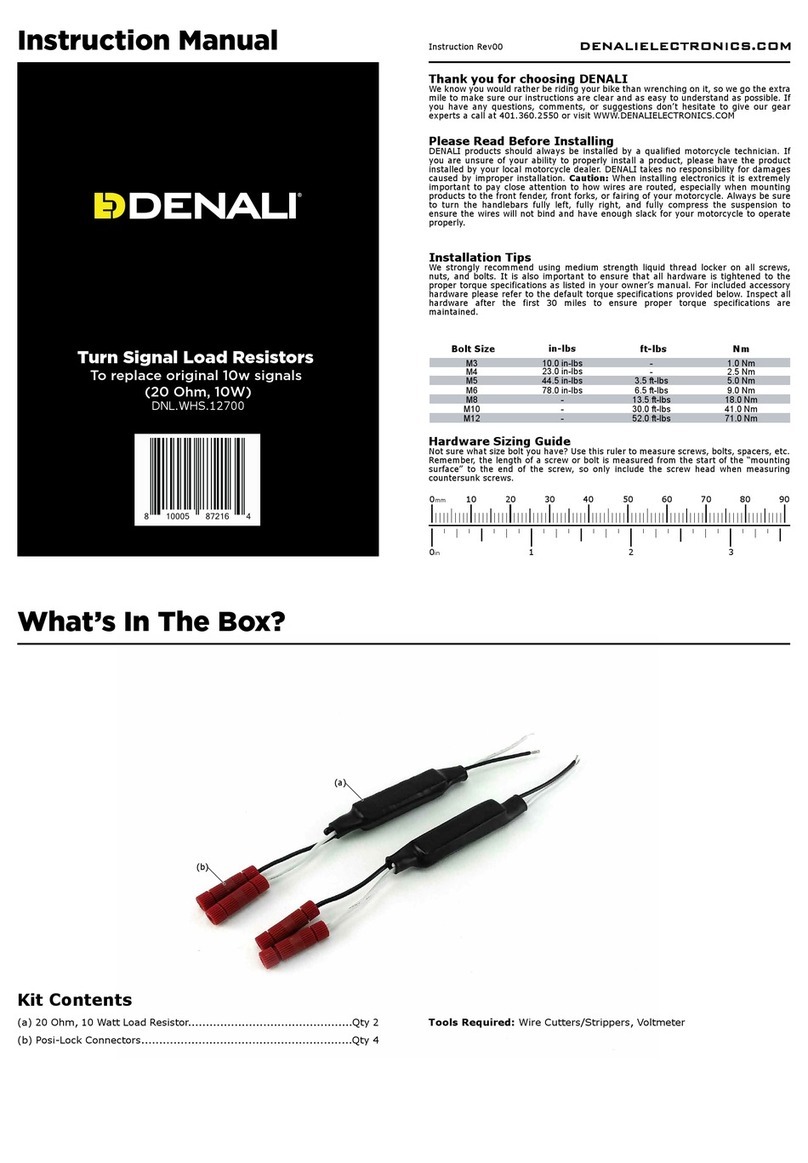

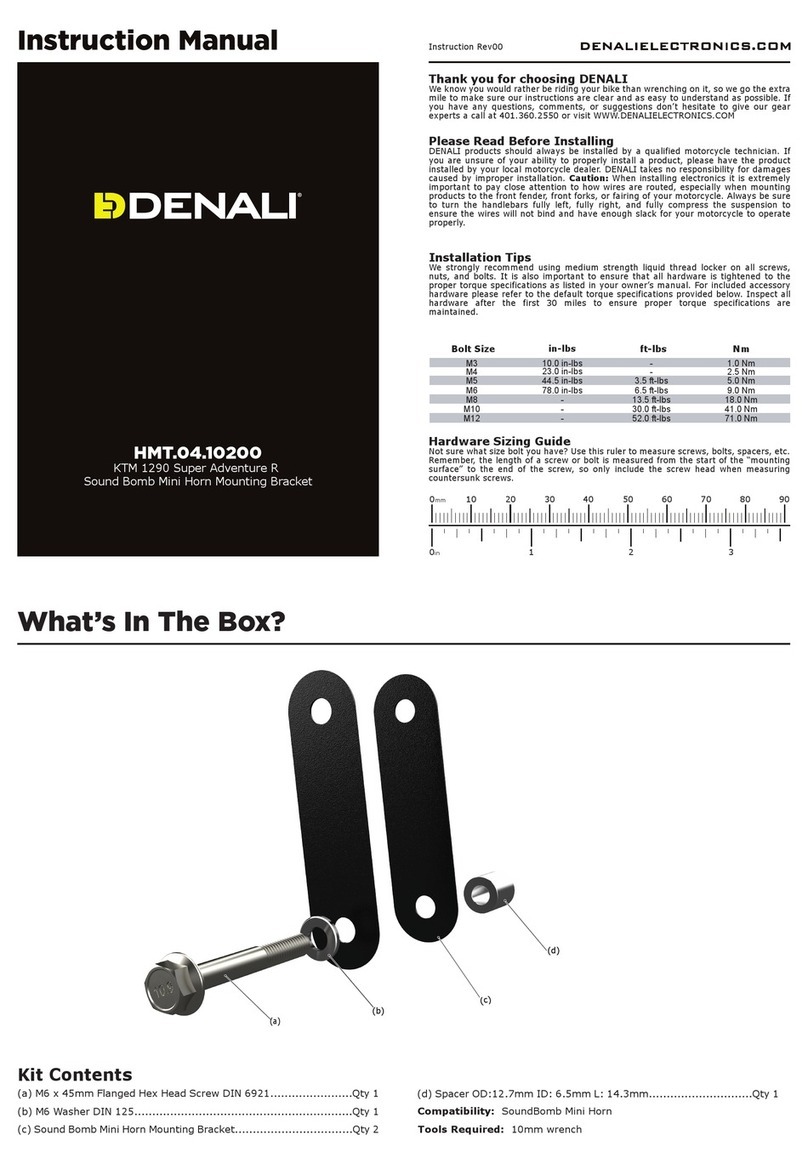

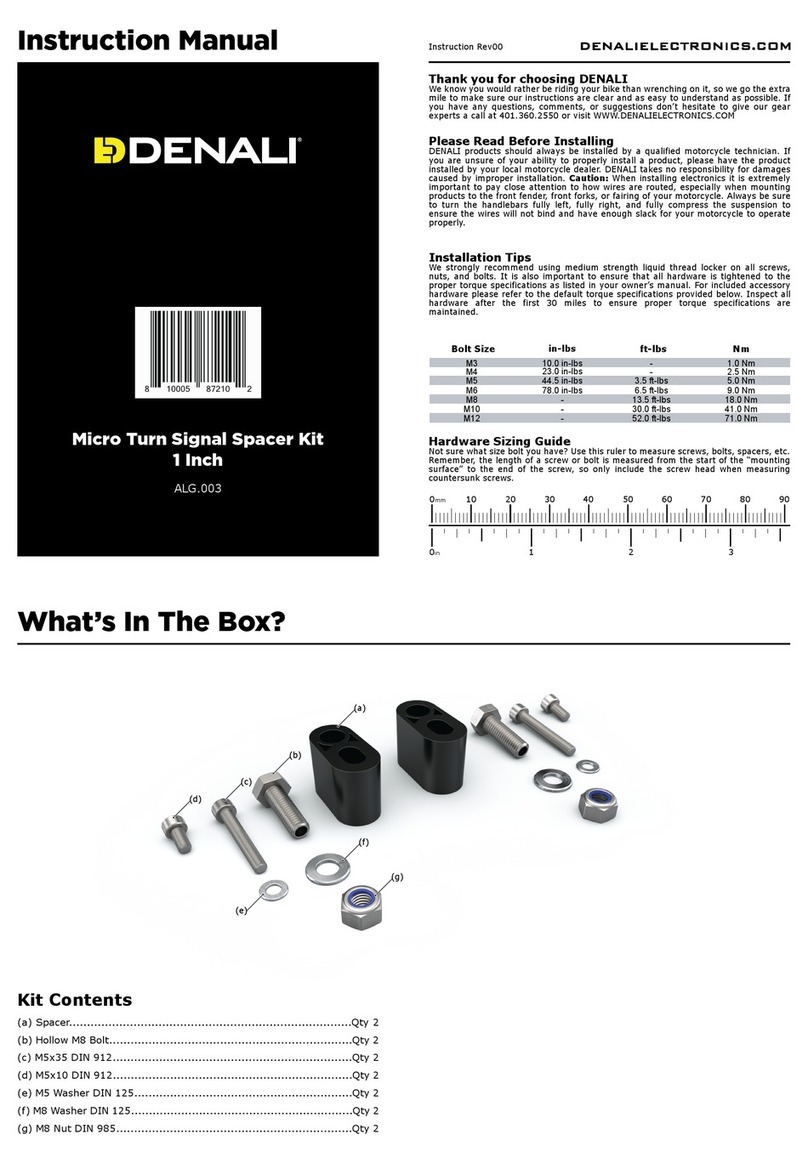

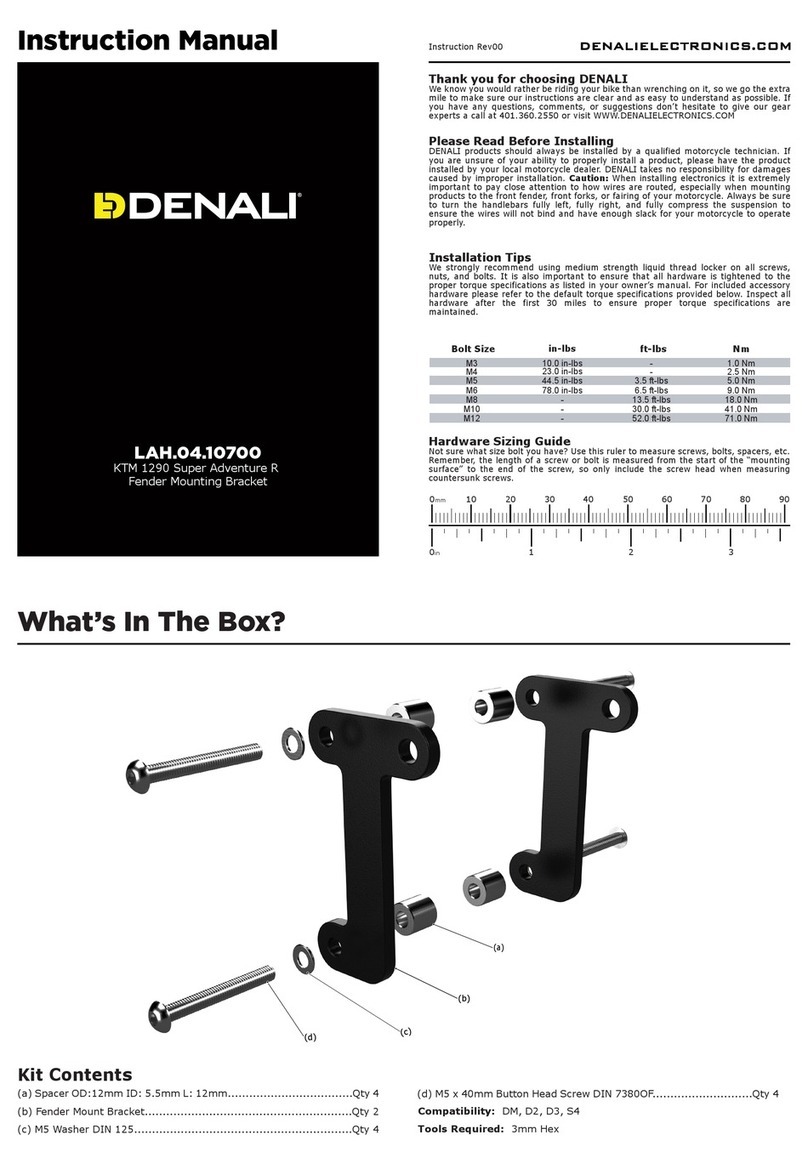

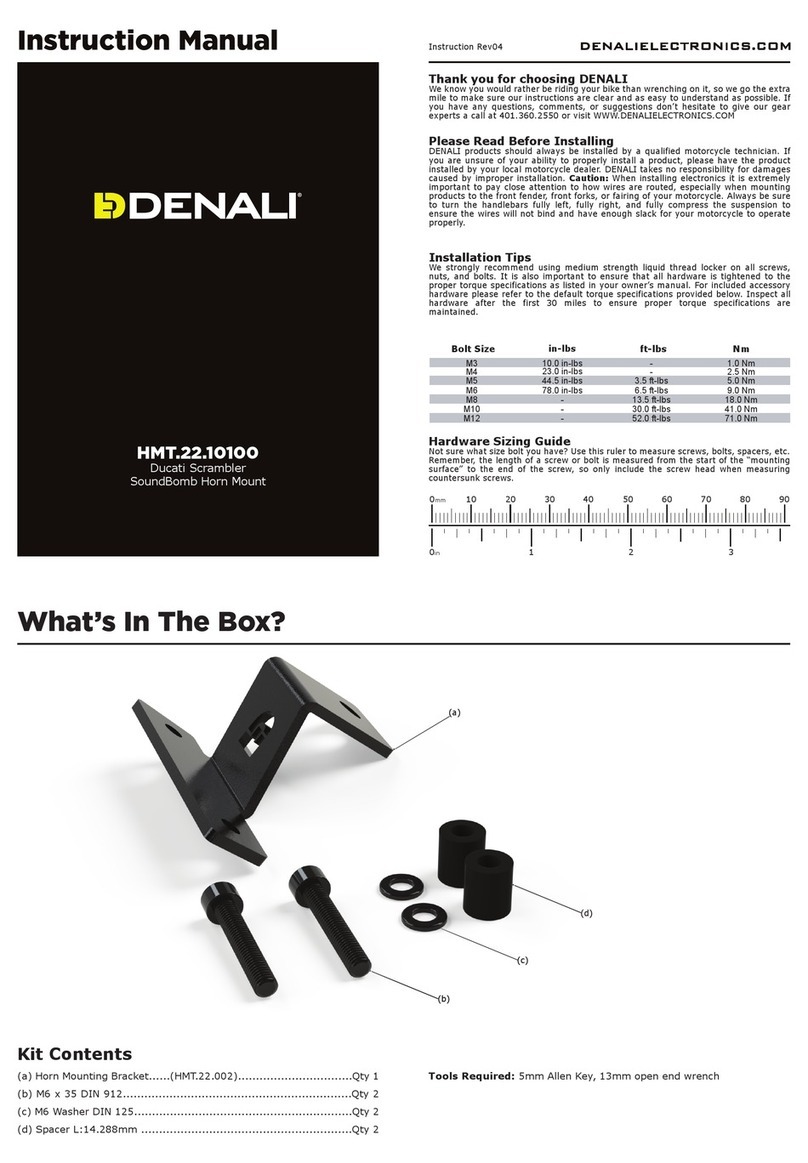

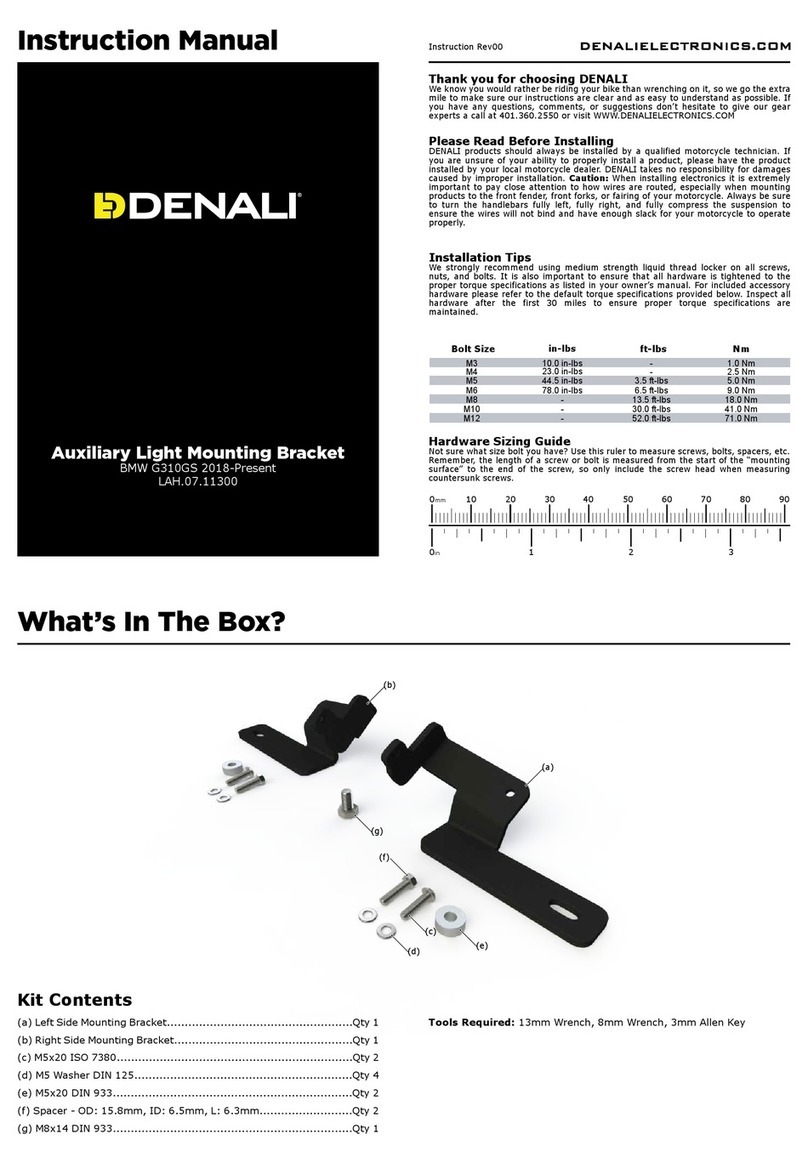

Kit Contents Tools Required

(a) Bracket..............................Qty 2

(b) OD:13mm ID:6mm L:22mm....Qty 2

(c) OD:13mm ID:6mm L:14mm....Qty 2

(d) M8 to M5 Bushing.....................Qty 2

(e) M8 to M6 Bushing.....................Qty 2

(f) M5x60 ISO 7380.................Qty 2

(g) M5x50 ISO 7380.................Qty 2

(h) M5x30 ISO 7380.................Qty 2

(i) M6x60 ISO 7380........................Qty 2

(j) M6x50 ISO 7380........................Qty 2

(k) M6x30 ISO 7380........................Qty 2

(l) M8x12 DIN 7984.........................Qty 2

• 5mm Allen Key

• 4mm Allen Key

• 3mm Allen Key

• 13mm Wrench

• 10mm Wrench

0mm 10 20 30 40 50 60 70 80 90

Thank you for choosing DENALI

We know you would rather be riding your bike than wrenching on it, so we go the extra

mile to make sure our instructions are clear and as easy to understand as possible. If

you have any questions, comments, or suggestions don’t hesitate to give our gear

experts a call at 401.360.2550 or visit DenaliElectronics.com

Please Read Before Installing

DENALI products should always be installed by a qualified motorcycle technician. If

you are unsure of your ability to properly install a product, please have the product

installed by your local motorcycle dealer. DENALI takes no responsibility for damages

caused by improper installation. Caution: When installing electronics is it extremely

important to pay close attention to how wires are routed, especially when mounting

products to the front fender, front forks, or fairing of your motorcycle. Always be sure

to turn the handlebars fully left, fully right, and fully compress the suspension to

ensure the wires will not bind and have enough slack for your motorcycle to operate

properly.

Installation Tips

We strongly recommend using medium strength liquid thread locker on all screws,

nuts, and bolts. It is also important to ensure that all hardware is tightened to the

proper torque specifications as listed in your owner’s manual. For included accessory

hardware please refer to the default torque specifications provided below. Inspect all

hardware after the first 30 miles to ensure proper torque specifications are

maintained.

Hardware Sizing Guide

Not sure what size bolt you have? Use this ruler to measure screws, bolts, spacers, etc.

Remember, the length of a screw or bolt is measured from the start of the “mounting

surface” to the end of the screw, so only include the screw head when measuring

countersunk screws.

M5 44.5 in-lbs 3.5 ft-lbs 5.0 Nm

M6 78.0 in-lbs 6.5 ft-lbs 9.0 Nm

M10 - 30.0 ft-lbs 41.0 Nm

M12 - 52.0 ft-lbs 71.0 Nm

ft-lbs NmBolt Size

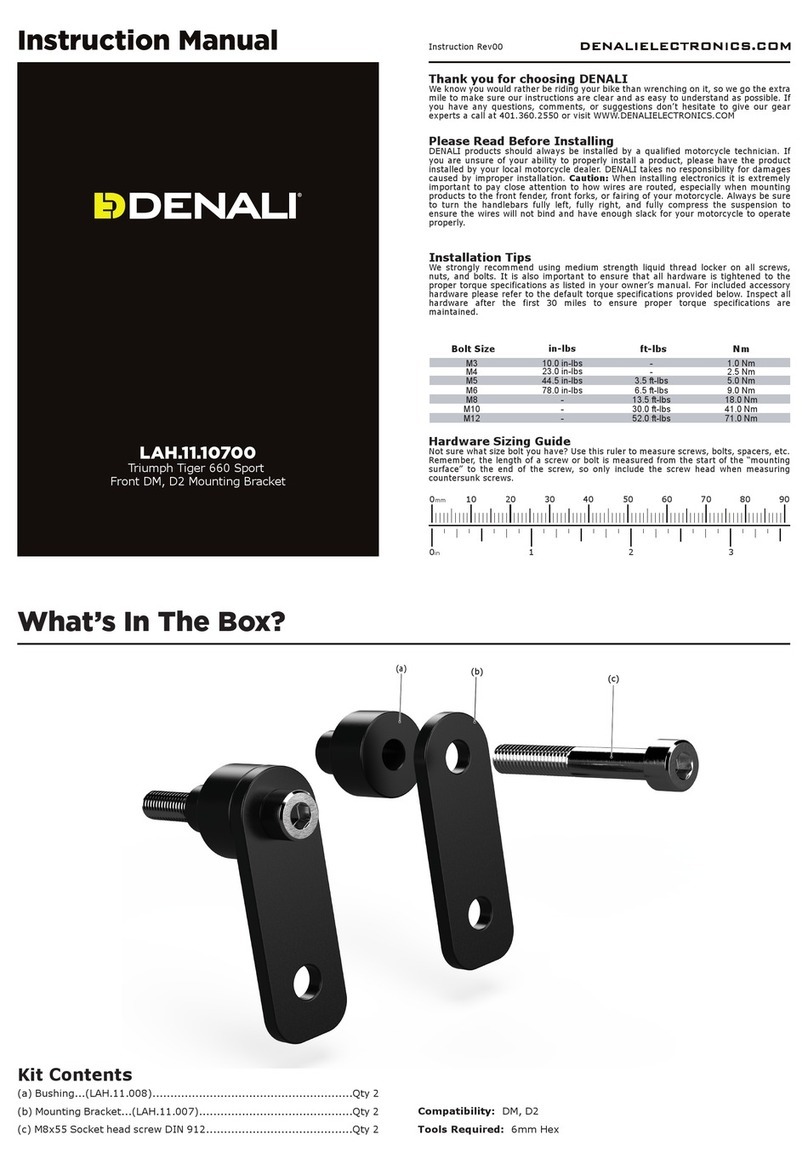

Universal Pivot Mount

M5, M6 & M8 Mounting Points

Illustration not to scale

0in 1 2 3

a

b

c

e

d

f

ghi

j

k

l

Figure 1