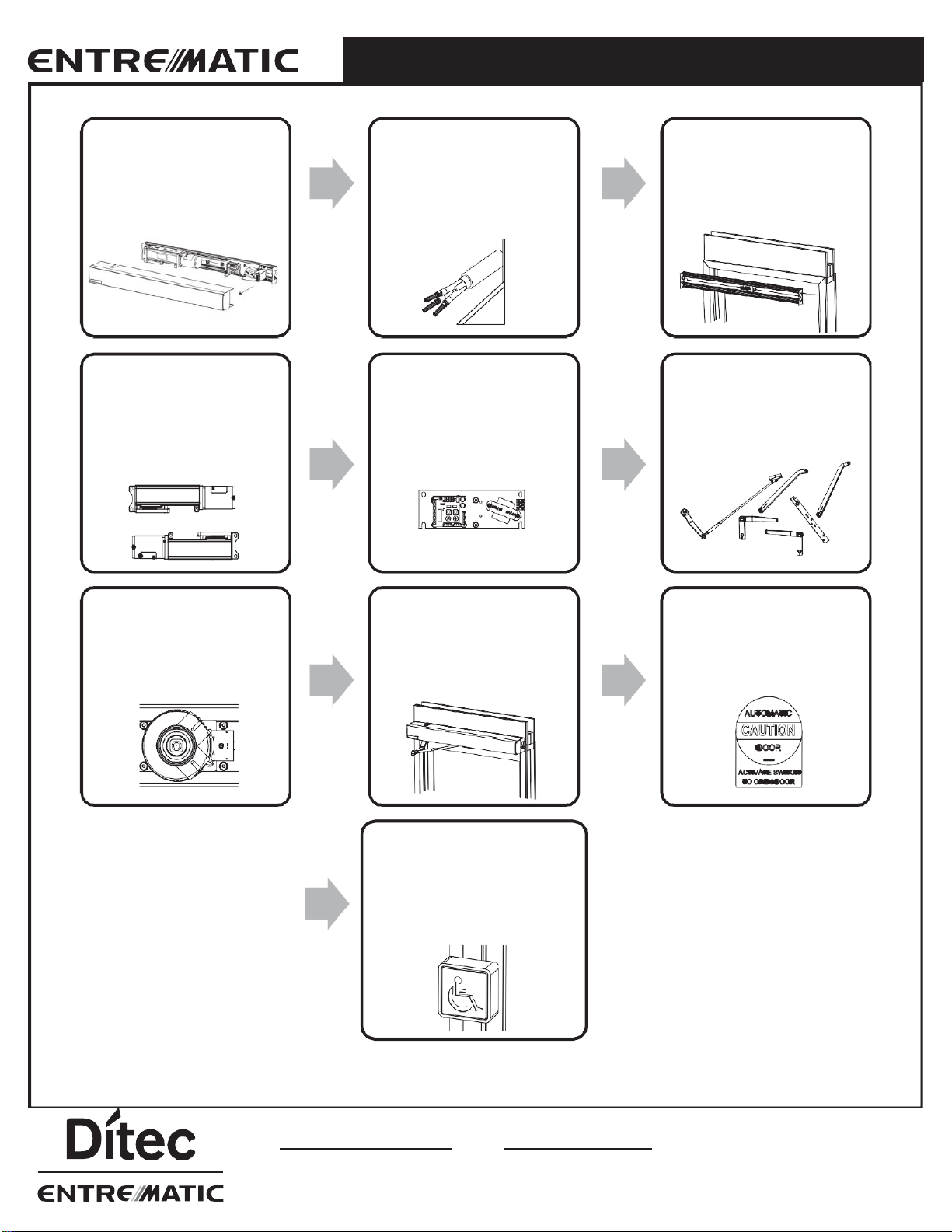

1.2 General Information

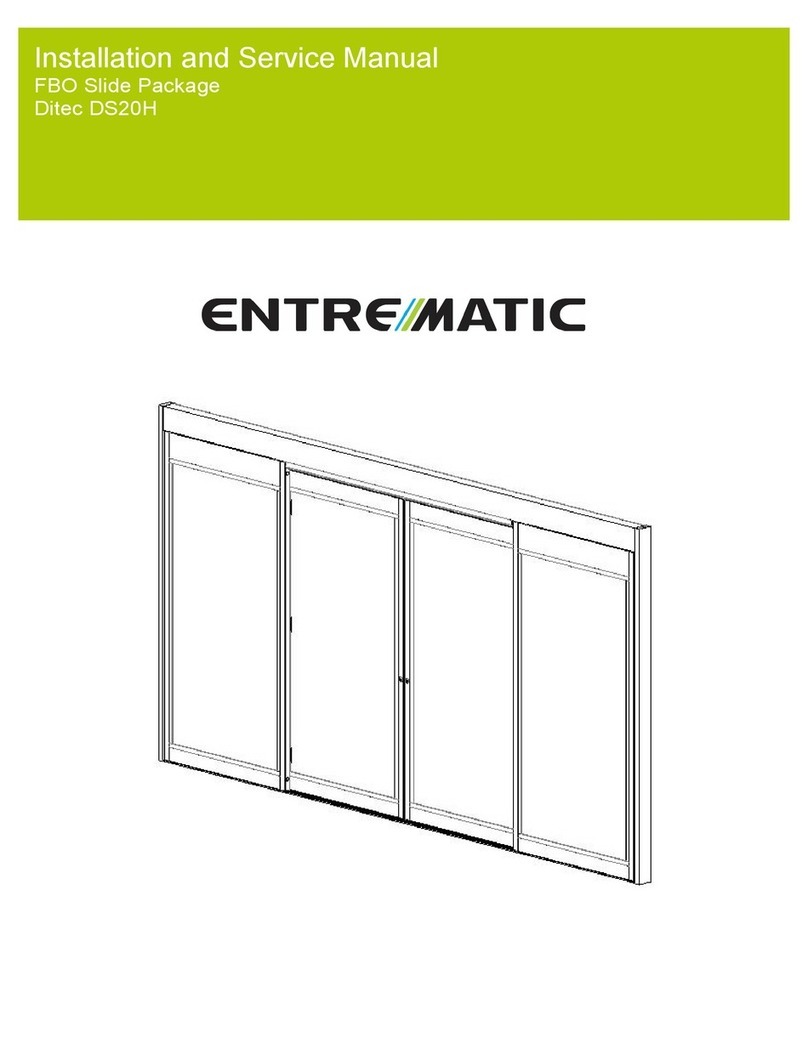

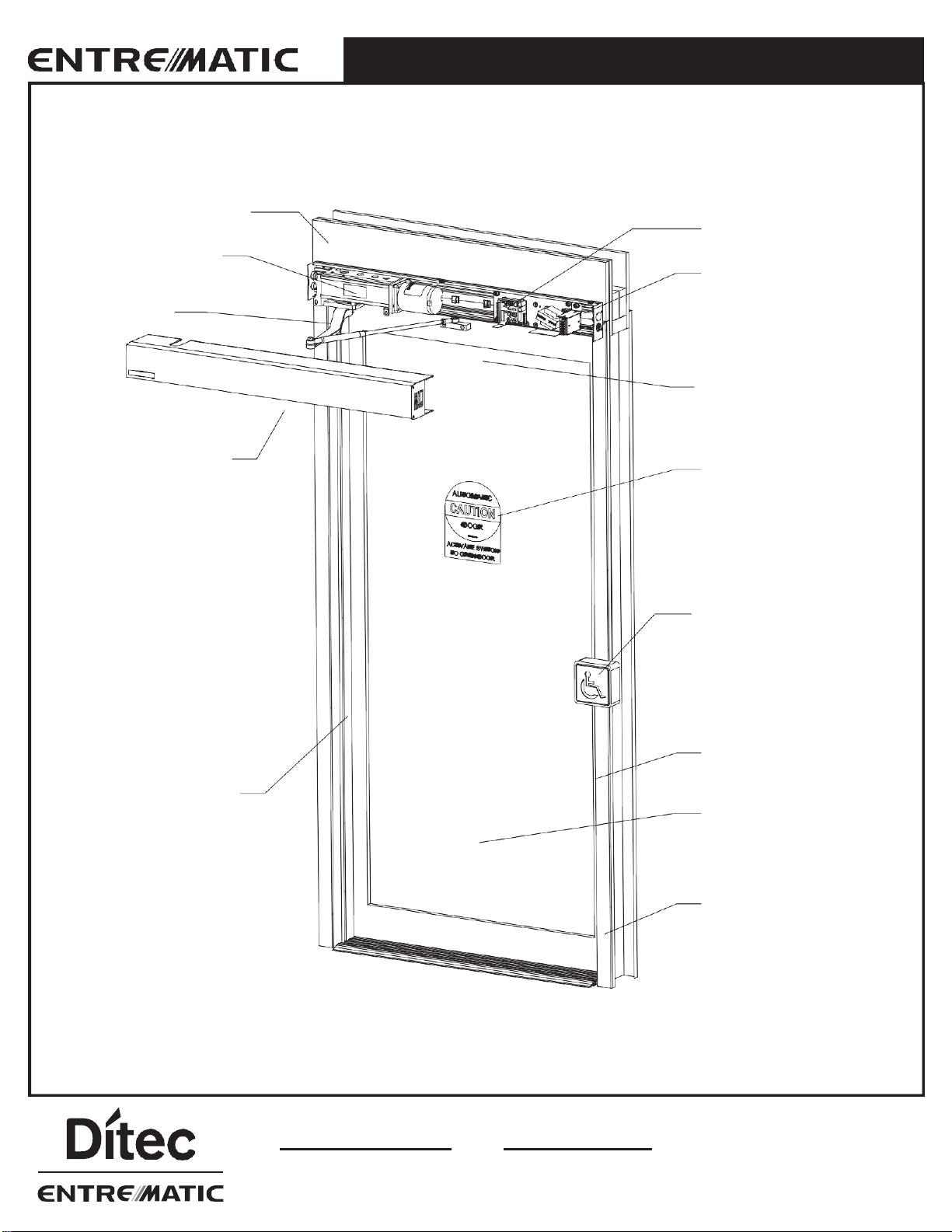

The HA8-LP Operator is a complete swinging door solution for push, pull, surface applied installations. The header contains

the Driving system (Motor), Torque production (Gearbox), and a Control system to interlink the two.

The HA8-LP Operator ensures all-around safety. It can be combined with the full range of safety units, such as presence

and motion sensors. It is easy to install for both new construction and retrofit applications.

•All wiring must conform to standard wiring practice in accordance with national and local wiring codes.

•Door must swing freely through the entire opening and closing cycle before beginning of installation.

Typically, doors are hung on hinges 5” (127mm) maximum width or 3/4” (19mm) offset pivots.

•An incorrectly installed or improperly adjusted door operator can cause property damage or personal injury.

These instructions should be followed to avoid the possibility of misapplication or maladjustment.

•All dimensions are given in inches (millimeters), unless otherwisenoted.

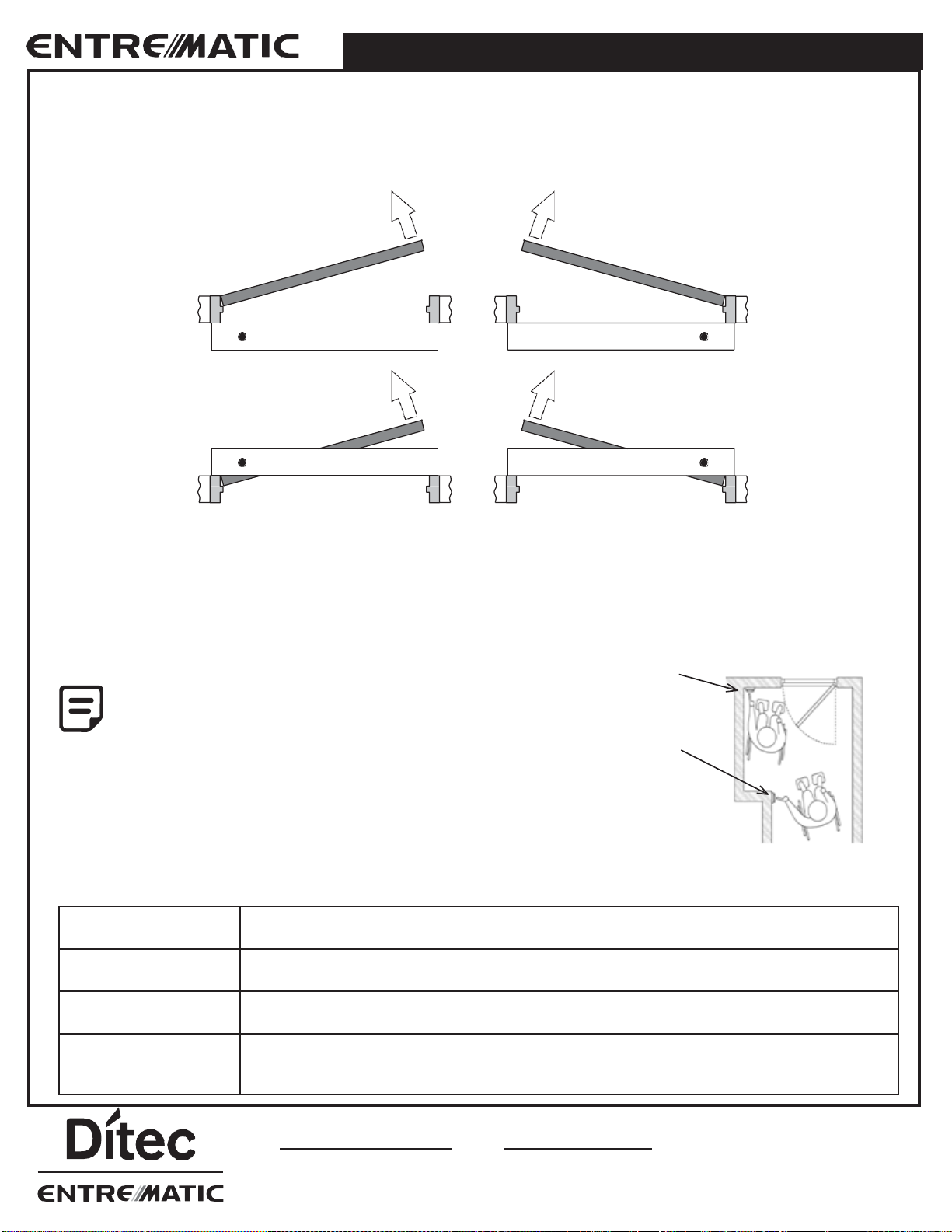

Door/Frame Preparation

•Before installation, verify door frame is properly reinforced and is well anchored in the wall.

•Concealed electrical conduit, and concealed switch or sensor wires should be pulled to the frame before proceeding.

Suggested Fasteners for Frame

•#14 x 2-3/4” (70mm) long sheet metal screws.

Suggested Fasteners for Door

•#12, #14, Wood screws, Sheet Metal screws, Self-tapping screws of varying lengths depending on applications.

The fastener components listed above are merely suggestions. A technician should use their best

discretion to determine what components they’ll need to complete thejob.

Do Not use Drywall Screws or Hollow Wall Anchors to mount the Back Plate / Header.

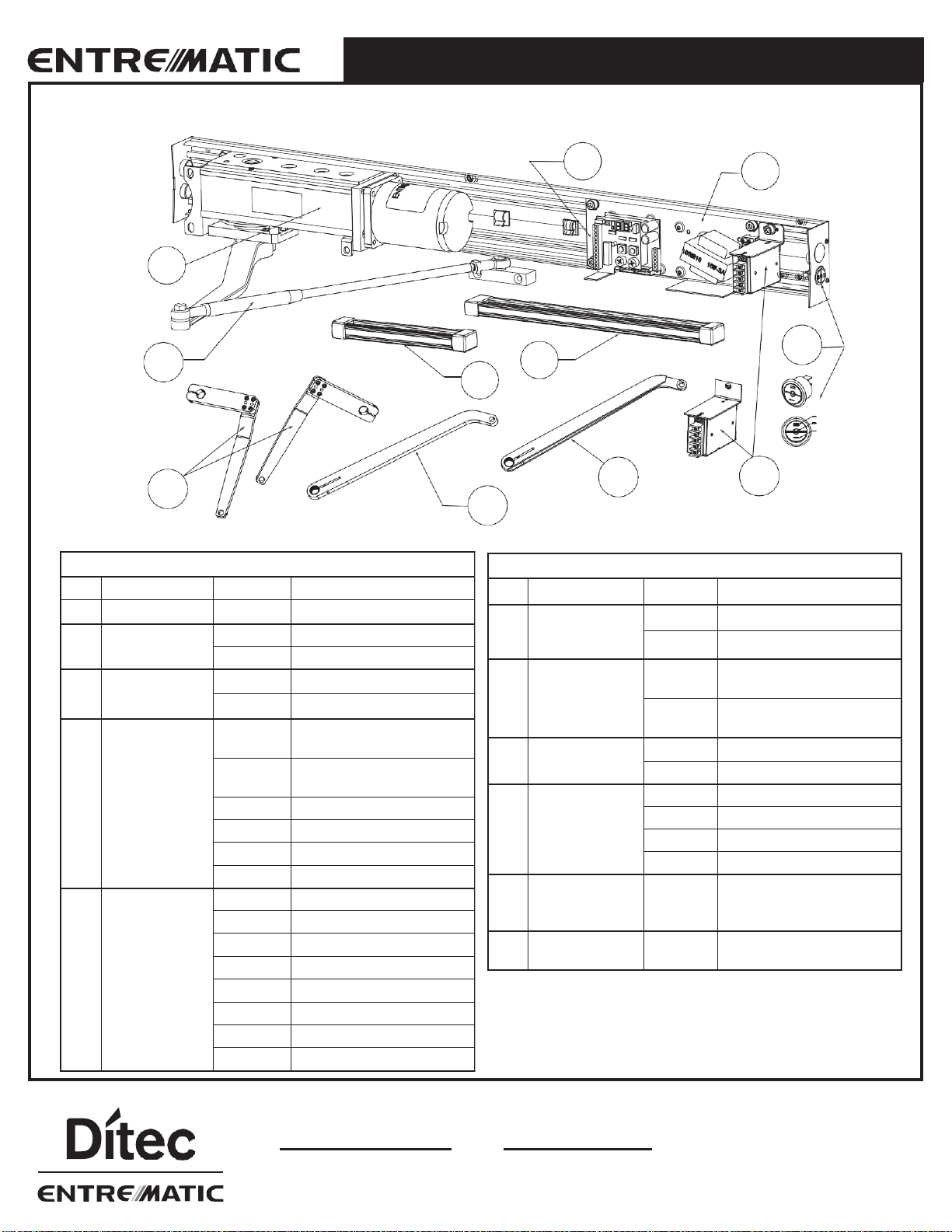

Shipping inspection

Verify that the order was shipped complete and correct, including model number, door handing, color, and header width.

•If any of the above items are not correct, do not attempt to install until all conditions are correct

•Report any incorrect items to the general contractorimmediately.

NO CLAIMSFOR SHORTAGES WILL BE ALLOWED UNLESSREPORTED

WITHIN 24HOURSOF RECEIPTOFSHIPMENT.

Safety Precautions

•Do not climb or put weight on any door or headerparts

•Do not let children play with the operator or the electricalboard

•Keep remote controls away from children

•Keep all power off to the unit, when performing any work ormaintenance

Toavoid bodily injury, material damage and malfunction of the product, the instructions contained in this manual must be

strictly observed during installation, adjustment, repairs and service etc. Training is needed to carry out these tasks safely.

Only Entrematic-trained technicians should be allowed to carry out theseoperations.