PERIODIC MAINTENANCE AND CONTROL

1-9

1.3.2 Troubleshooting

A sufficient compressed air supply and the use of the tool’s specific strap should be guaranteed before

each tool repair.

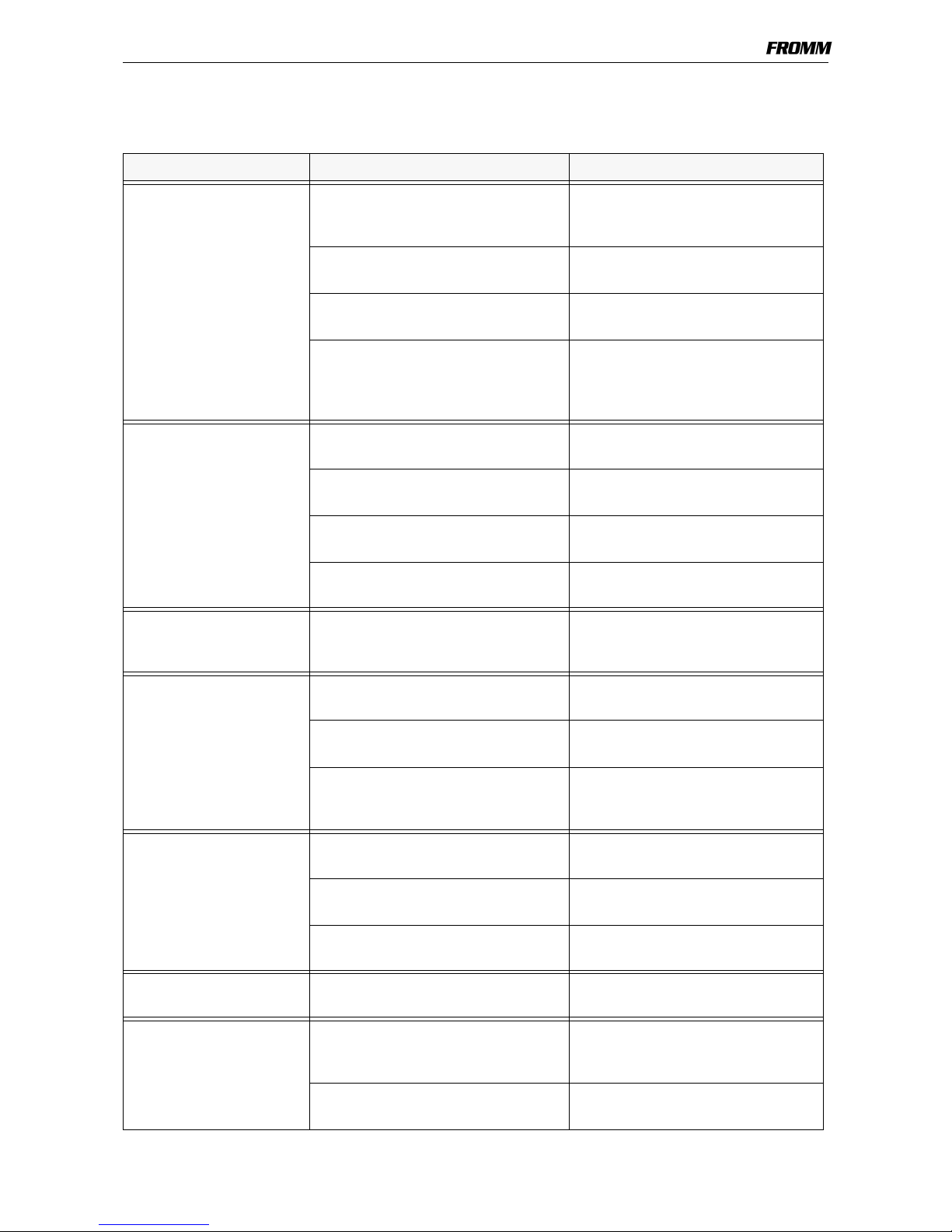

SYMPTOM CAUSE REMEDY

Tool doesn’t tension,

Tensioning motor runs

The tensioning wheel is packed with

strap residue or is worn and mills on

the strap

Clean tensioning wheel with

compressed air or replace it

Wrong tensioning wheel or tensioning

wheel is assembled reversed

Correct assembling or use the correct

tensioning wheel.

Grippers are dirty, worn or wrongly

assembled

Replace grippers, clean them with

compressed air or assemble correctly

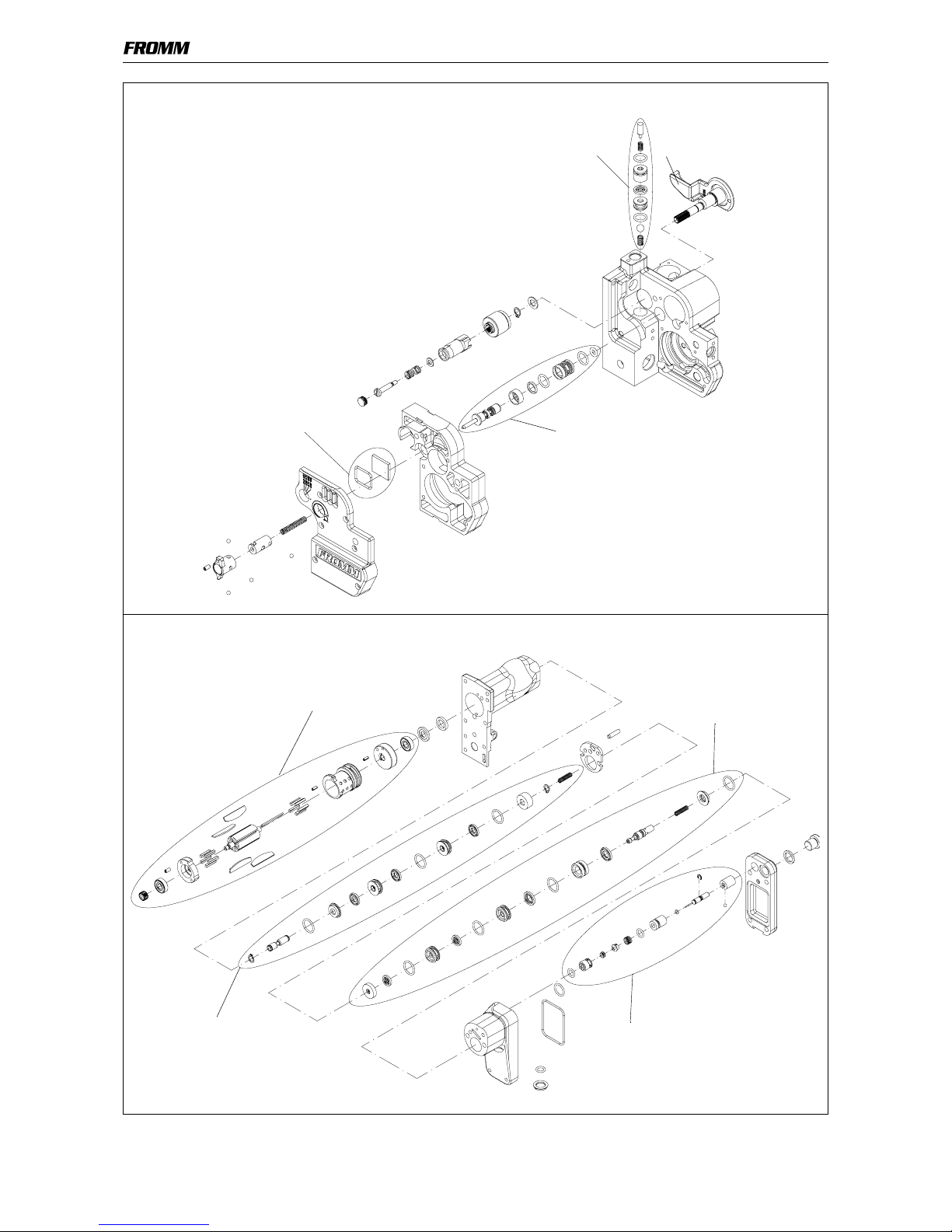

Gearing parts from the tensioning gear

are defective

Loose pinion P32.1123 on tensioning

motor

Check tensioning gear and replace

defect parts

Tensioning motor doesn’t

run

Tensioning motor defective Check component parts and replace

damaged ones

Tensioning gear defective Check component parts and replace

damaged ones

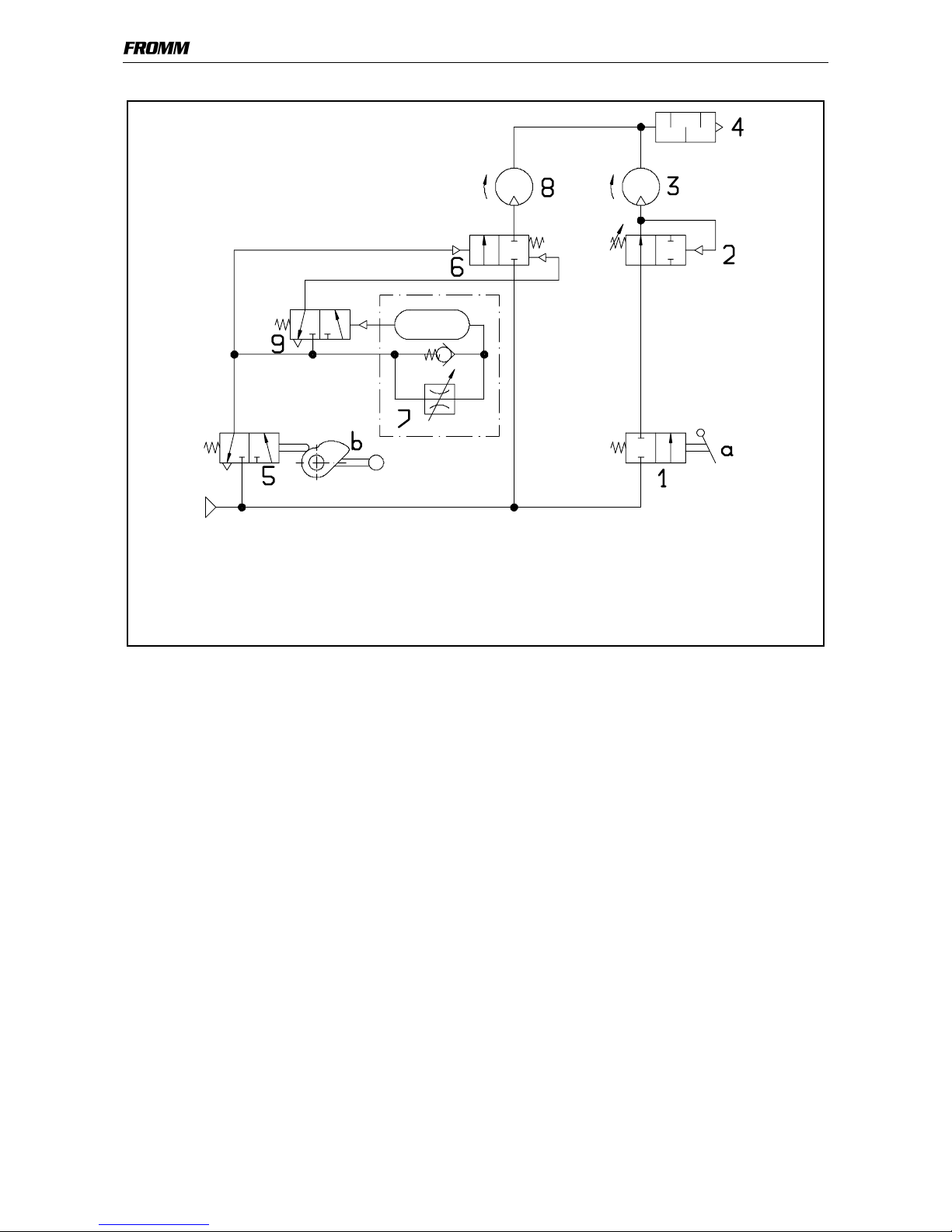

Pneumatic control system is defective Check component parts and replace

damaged ones

Needle free wheeling assembled

reversed

Assemble correctly

Tensioning wheel turns

back immediately after the

tensioning cycle

Defective needle free wheeling

N3.4509

Check and replace if necessary

Tool doesn’t weld,

welding motor runs

Welding gripper is dirty or worn Clean and check welding gripper and

replace damaged one

Welding stop gripper is dirty or worn Clean and check welding stop gripper

and replace damaged one

Pinion P32.1023 lose at the motor or

welding eccentric, resp. The journal at

the welding eccentric is broken off.

Check component parts and replace

damaged ones

Welding motor doesn’t run Welding motor defective Check component parts and replace

damaged ones

Welding mechanism defective Check component parts and replace

damaged ones

Pneumatic control system is defective Check component parts and replace

damaged ones

Gear noise Tensioning or welding gear is worn Check component parts and replace

damaged ones

Welding motor does not

stop

Turn off valve or welding motor valve

jam, resp. the welding time valve is

blocked.

Check and clean parts, exchange

damaged parts

Diameter of the air supply hose is too

small.

Install air supply hose with a minimum

inner diameter of 9mm (3/8")