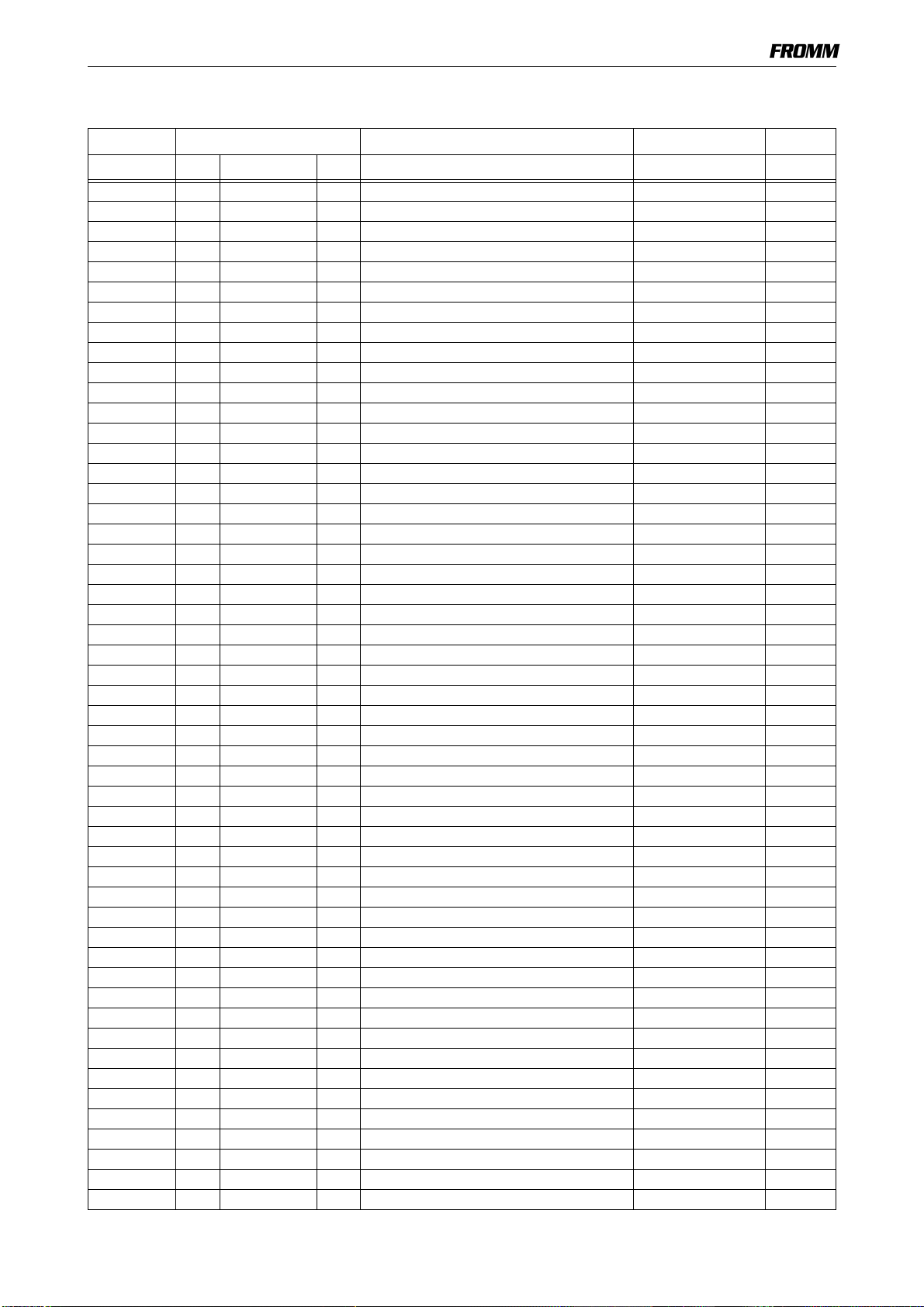

[ ] = Group * = Wearing parts

23

43253301.een.fm

16 SPARE PARTS LIST 43.2533.01

43.2533.01 P329/19/1.06-1.35 P329.0001.01 13.05.14

Item-No. in group Pcs. Description Dimension Field

N1.1196 3 SCREW M4 X 16 D6

N1.1305 6 SCREW M4 X 7.8 C2+

N1.1553 P35.0146 1 HEXAGON SCREW M4 X 8 B12

N1.1910 2 FLAT HEAD SCREW M4 X 12 B10

N1.1911 2 FLAT HEAD SCREW M4 X 8 A3

N1.1927 P32.0219 1 FLAT HEAD SCREW M4 X 60 D19

N1.1928 1 FLAT HEAD SCREW M4 X 16 B6

N1.1934 1 FLAT HEAD SCREW M4 X 50 B6

N1.1934 P32.0219 2 FLAT HEAD SCREW M4 X 50 D19

N1.1943 2 FLAT HEAD SCREW M4 X 40 B6

N1.1966 P32.0219 1 SCREW M4 X 70 C19

N1.1972 P32.0219 1 SCREW M4 X 80 D19

N1.1973 1 FLAT HEAD SCREW M4 X 10 A6

N1.2188 P32.0205 3 COUNTERSUNK SCREW M4 X 16 D13

N1.2189 P32.0208 3 COUNTERSUNK SCREW M4 X 20 D14

N1.2222 2 COUNTERSUNK SCREW M4 X 10 C1

N1.6305 P32.0219 1 SPACER WASHER 6 X 18 X 0.5 B24

N1.6331 P32.0219 3 SPACER WASHER 6 X 12 X 0.5 C18+

N1.6386 P32.0219 1 SPACER WASHER 9 X 15 X 0.50 D17

N1.6504 18 SAFETY WASHER M4 B4+

N1.6504 P32.0219 5 SAFETY WASHER M4 D20+

N1.6504 P35.0146 1 SAFETY WASHER M4 B12

N1.7207 P32.0219 1 PT-SCREW 3 X 40 C20

N1.7211 P32.0219 8 PT-SCREW 3 X 20 C19+

N1.7222 P32.0219 1 PT-SCREW 2.2 X 5 B21

N2.1118 P32.0219 2 SECURITY RING 6 B9+

N2.1121 1 SECURITY RING 5 B12

N2.1121 P32.0219 4 SECURITY RING 5 C11+

N2.1606 P32.0219 1 SPRING RING SW6 C19

N2.1610 P32.0208 1 SPRING RING SB44 C14

N2.2110 P32.0218 1 PARALLEL PIN 4 m6 X 10 D8

N2.2119 P32.0222 1 PARALLEL PIN 4 m6 X 18 D4

N2.2124 1 PARALLEL PIN 4 m6 X 40 C2

N2.2126 P32.0207 1 PARALLEL PIN 5 m6 X 26 B15

N2.2142 P32.0206 1 PARALLEL PIN 4 m6 X 28 C16

N2.2145 P32.0205 3 PARALLEL PIN 4 h6 X 18 C14

N2.2147 P32.0218 2 PARALLEL PIN 3 m6 X 10 C2

N2.2180 P32.0208 1 PARALLEL PIN 4 m6 X 16 C16

N2.2187 P32.0218 1 PARALLEL PIN 3 m6 X 6 C9

N2.2190 P32.0219 1 PARALLEL PIN 6 h6 X 18 C18

N2.2193 1 PARALLEL PIN 3 m6 X 32 C12

N2.2443 P32.0203 1 DOWEL PIN 4 X 15 A8

N2.3364 P32.0219 1 FEATHER KEY 2 X 2 X 6 C7

N2.4902 2 HAMMER HEAD BOLT 1.85 X 4.76 A6

N2.4902 P32.0221 2 HAMMER HEAD BOLT 1.85 X 4.76 A6

N2.5157 P32.0219 2 PRESSURE SPRING 0.6 X 4.8 X 20/15.5 B8

N2.5178 2 PRESSURE SPRING 0.32X2.82X20.5/20.5 C12

N2.5237 1 PRESSURE SPRING 0.8 X 4.8 X 25/18.5 C11

N2.5296 P32.0208 1 PRESSURE SPRING 0.5 X 4 X 24/16.5 C16

N21.2140 P32.0219 1 PARALLEL PIN 2 m6 X 16 D7

N21.2144 P32.0219 1 PARALLEL PIN 3 h6 X 30 B16