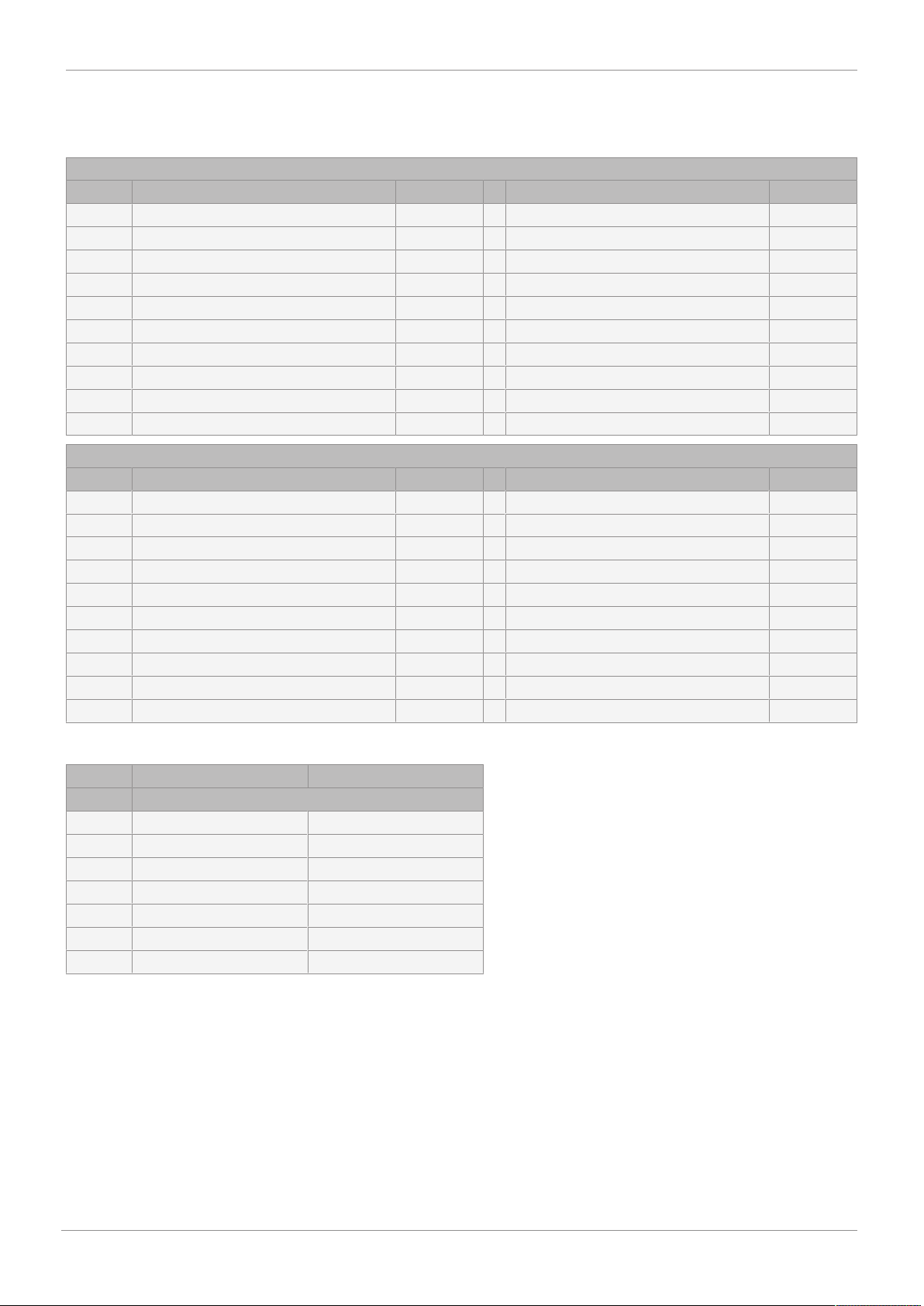

8 Continuation of Actuator version Code

Actuator, pneumatic, single acting, clockwise rota-

tion, spring closing,

SC0220U 6F07/10 S22

SU22KD

Actuator GEMÜ 9415

GEMÜ actuator, pneumatic, size 0, piston diameter

50 mm

0

GEMÜ actuator, pneumatic, size 1, piston diameter

70 mm

1

9 Actuator particulars Code

Gen. industrial version,

body alu, anodising layer 25-35µm, end caps alu,

powder coated,

shaft C steel + ENP, bolts A2

0

10 Ball config./port position Code

2/2-way body

R ball (control ball)

for 0°- 90° control range

linear control characteristic between port position

and percentage flow rate

R

Multi-port version

L-port, standard end position "Open", connection 2

and 3 open,

L-port, standard end position "Closed", connection

1 and 3 open

L

10 Continuation of Ball config./port position Code

T-port, standard end position "Open", connection 1,

2 and 3 open,

T-port, standard end position "Closed", connection

1 and 3 open

T

T-port, end position "Open", connection 1 and 3

open,

T-port, end position "Closed", connection 1 and 2

open

2

T-port, end position "Open", connection 1 and 2

open,

T-port, end position "Closed", connection 2 and 3

open

3

T-port, end position "Open", connection 2 and 3

open,

T-port, end position "Closed", connection 1, 2 and 3

open

4

L-port, end position "Open", connection 1 and 3

open,

L-port, end position "Closed", connection 1 open

6

11 Type of design Code

Without

Insert in PE 1187

12 CONEXO Code

without

Integrated RFID chip for electronic identification

and traceability

C

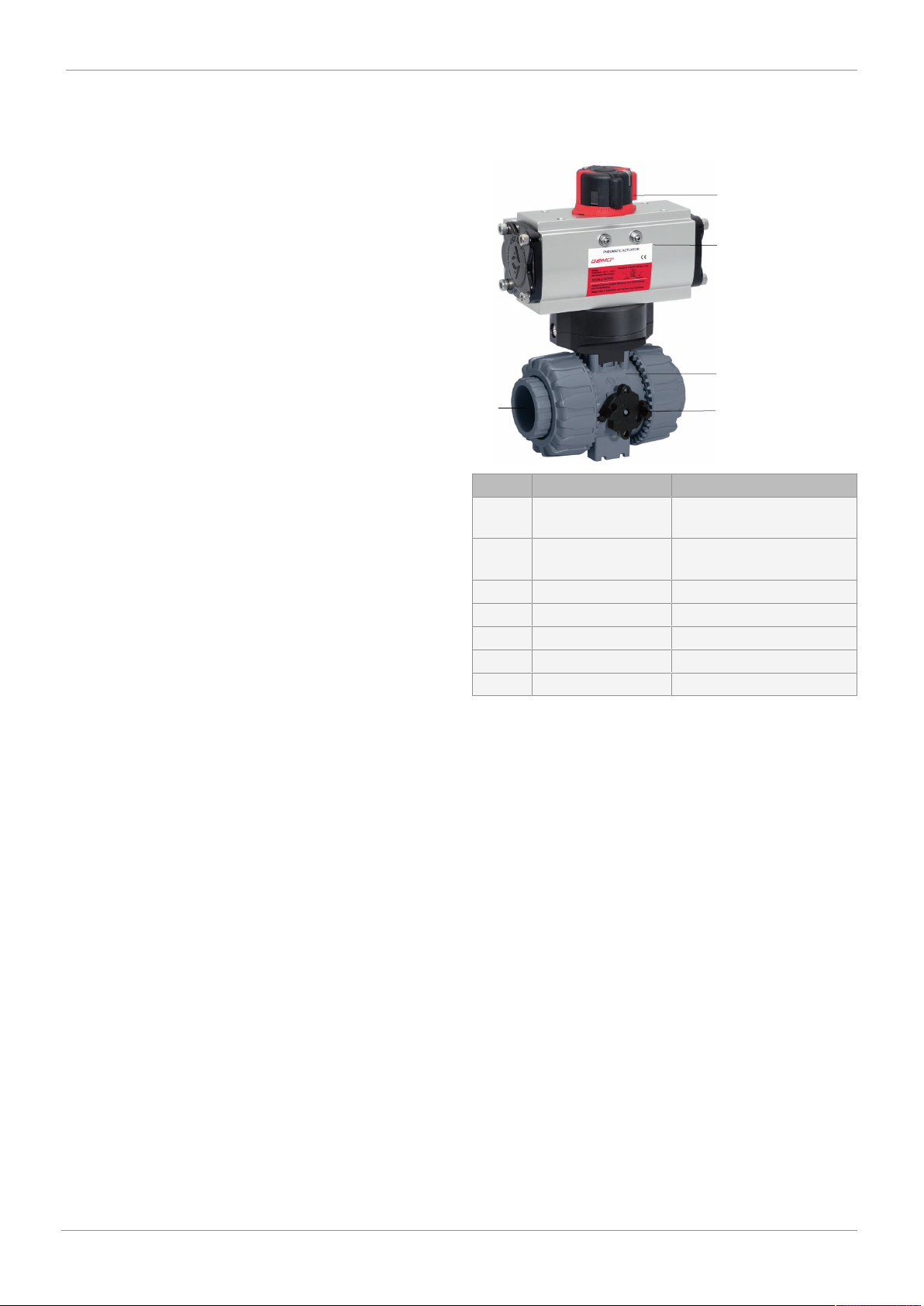

Order example

Order option Code Description

1 Type 710 Ball valve, plastic, pneumatically operated

2 DN 15 DN 15

3 Body configuration M Multi-port version

4 Connection type 33 Union end with inch insert - BS (socket)

5 Ball valve material 1 PVC-U, grey

6 Seal material 14 EPDM

7 Control function 3 Double acting (DA)

8 Actuator version BU02AN Actuator, pneumatic, double acting, clockwise rotation,

ADA0020U F03/05 S09

9 Actuator particulars 0 Gen. industrial version,

body alu, anodising layer 25-35µm, end caps alu, powder coated,

shaft C steel + ENP, bolts A2

10 Ball config./port position L L-port, standard end position "Open", connection 2 and 3 open,

L-port, standard end position "Closed", connection 1 and 3 open

11 Type of design Without

12 CONEXO without

7 Order data

www.gemu-group.com 9 / 44 GEMÜ 710