RAM PRO XL 0321

4

• WARNING To reduce the risk of electrocution, keep all connections dry and

off the ground. Do not handle the unit or electrical plug with wet hands.

• When unplugging the power cord, grasp the plug – not the cord.

• Unplug the power cord when servicing the unit or leaving the machine

unattended.

• Do not roll the machine over the power cord, pull the cord, close a door on the

cord or pull the cord around sharp corners. Keep the cord away from

hot surfaces.

• Do not use the machine if it has a damaged cord or plug.

Operational Precautions

• Maximum water pressure; 100 p.s.i.

• Water pressure relief – If water pressure exceeds 100 p.s.i., water will vent

under chassis.

• Do not use in an environment or on objects that are above 175°F (79°C).

• Do not use with ammable or explosive uids such as gasoline, fuel oil,

kerosene, etc. Do not use in explosive atmospheres.

• Keep clear of moving shaft. Make sure the shaft will not catch on anything

while in use.

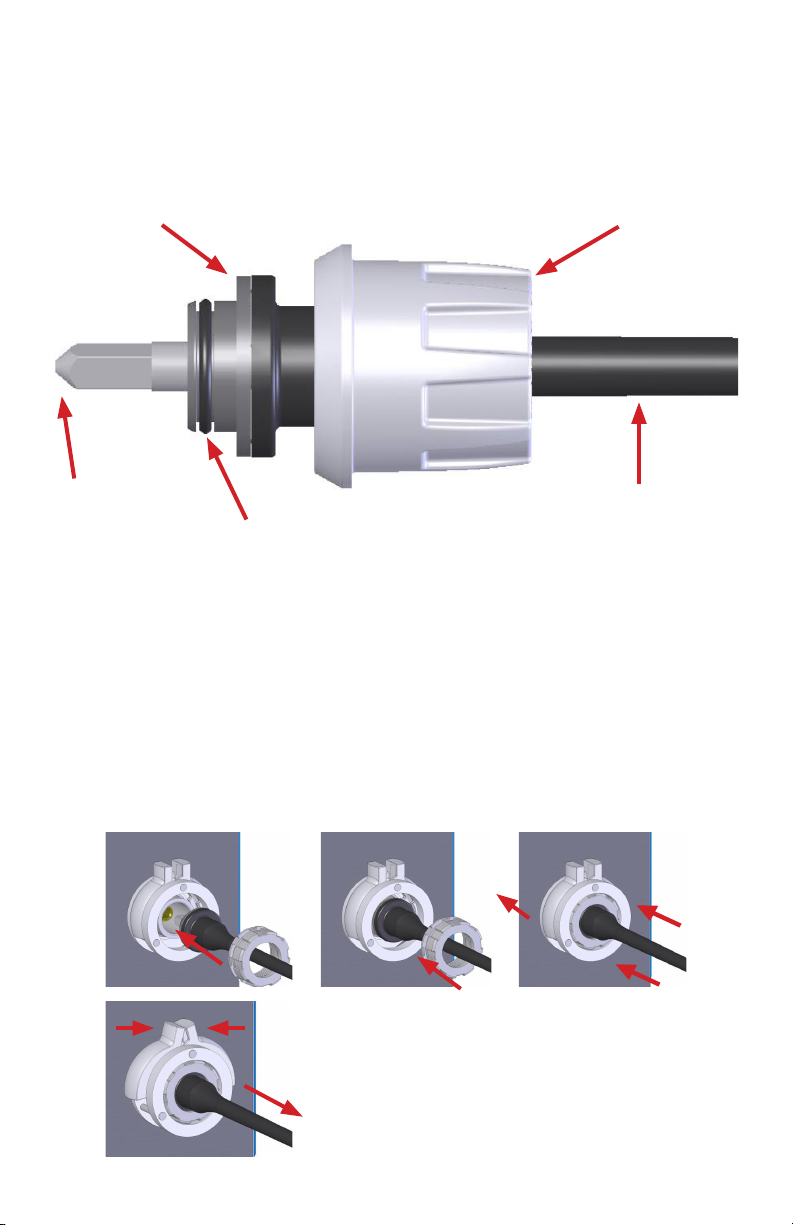

• Check exible shaft for weak or worn condition before each use. Make certain

that all connections are tight and secure.

• If the machine does not operate properly or is damaged contact Goodway

Customer Service.

• Disconnect the plug from the power source and turn off water supply

before disconnecting hoses, ttings, or exible shaft and before making any

adjustments or changing accessories. Such preventive safety measures reduce

the risk of starting the unit accidentally.

• Check for misalignment or binding of moving parts, breakage of parts,

and any other condition which may affect the tool’s operation. If damaged,

have the tool serviced before using. Many accidents are caused by poorly

maintained tools.

• If servicing this unit, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to

follow maintenance instructions may create a risk of electric shock or injury.

• Be sure to select the proper size exible shaft and tool for the job. Do not force

the tool. Use the correct tool for the application.

• WARNING Use only Goodway-approved chemicals in the dispenser-

incompatible chemicals can cause damage or unwanted reactions.

• INSPECT CHEMICAL CAP AND DISPENSER FOR DAMAGE AND WEAR—if any

cracks are detected or if cap thread diameter is less than 4.25 in., CAP and

DISPENSER MUST BE REPLACED.

• DANGER!! DO NOT OPERATE THE UNIT WITH COVER(S) REMOVED - WHEN

MOVING PARTS AND ELECTRICAL CONNECTIONS ARE EXPOSED!!!