TFC-JR 0321 5

• GROUND FAULT CIRCUIT INTERRUPTER: This unit is provided with a

Ground Fault Circuit Interrupter (GFCI) built into the power cord plug to

prevent electrocution. This device provides additional protection from the

risk of electric shock. DO NOT RUN THE UNIT WITHOUT THIS DEVICE!!

If replacement of the plug or cord becomes necessary, use only identical

replacement parts that include GFCI protection.

• Do not abuse the cords. Never use the cord to carry the tool or pull the plug

from an outlet. Keep cord away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged cords increase the risk of

electric shock.

• WARNING: The cords, wires, and/or cables supplied with this product may

contain chemicals, including lead or lead compounds, known to the State of

California to cause cancer and birth defects or other reproductive harm. Always

wash hands thoroughly after handling the unit.

• Avoid body contact with grounded surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body

is grounded.

• EXTENSION CORDS: Use only extension cords that are intended for outdoor

use. These extension cords are identied by a marking “Acceptable for use with

outdoor appliances; store indoors while not in use.” Use only 3-wire extension

cords that have 3-prong grounding-type plugs and 3-pole cord connectors

that accept the plug from the product. Use only extension cords having an

electrical rating not less than the rating of the product. Do not use damaged

extension cords. Always disconnect the extension cord from the receptacle

before disconnecting the product from the extension cord.

OVERVIEW

Buildup of organic slime (algae, bacteria colonies, insects and other organic

materials) together with scale, hard water deposits, sand, dirt, etc. can seriously

reduce the heat exchange efciency of cooling towers. The cooling tower ll

should be cleaned to return the tower to optimal operational condition. The TFC-JR

is capable of applying Scalebreak®-GEL that clings to the vertical surfaces of the

tower ll. After a sufcient dwell time, the Scalebreak®-GEL breaks down the scale.

This allows the mechanical action of the oscillating turbo nozzle to rinse the tower

ll clean.

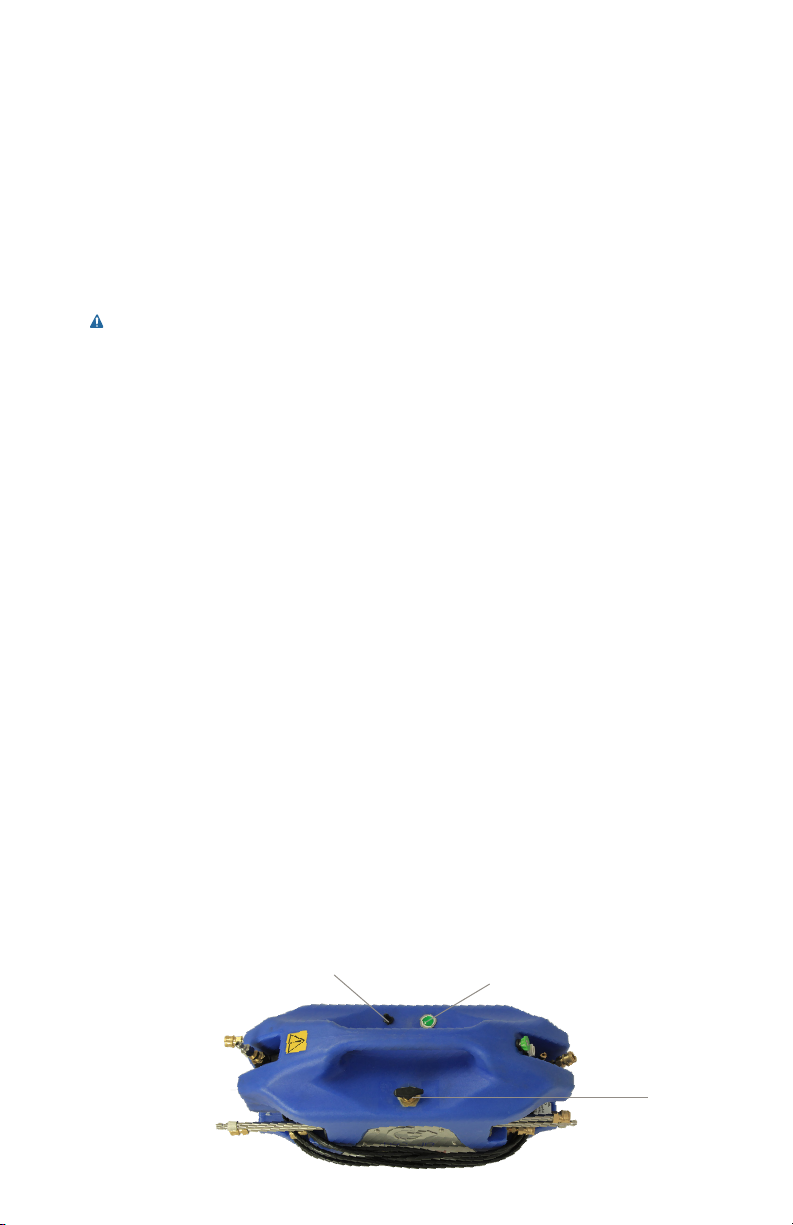

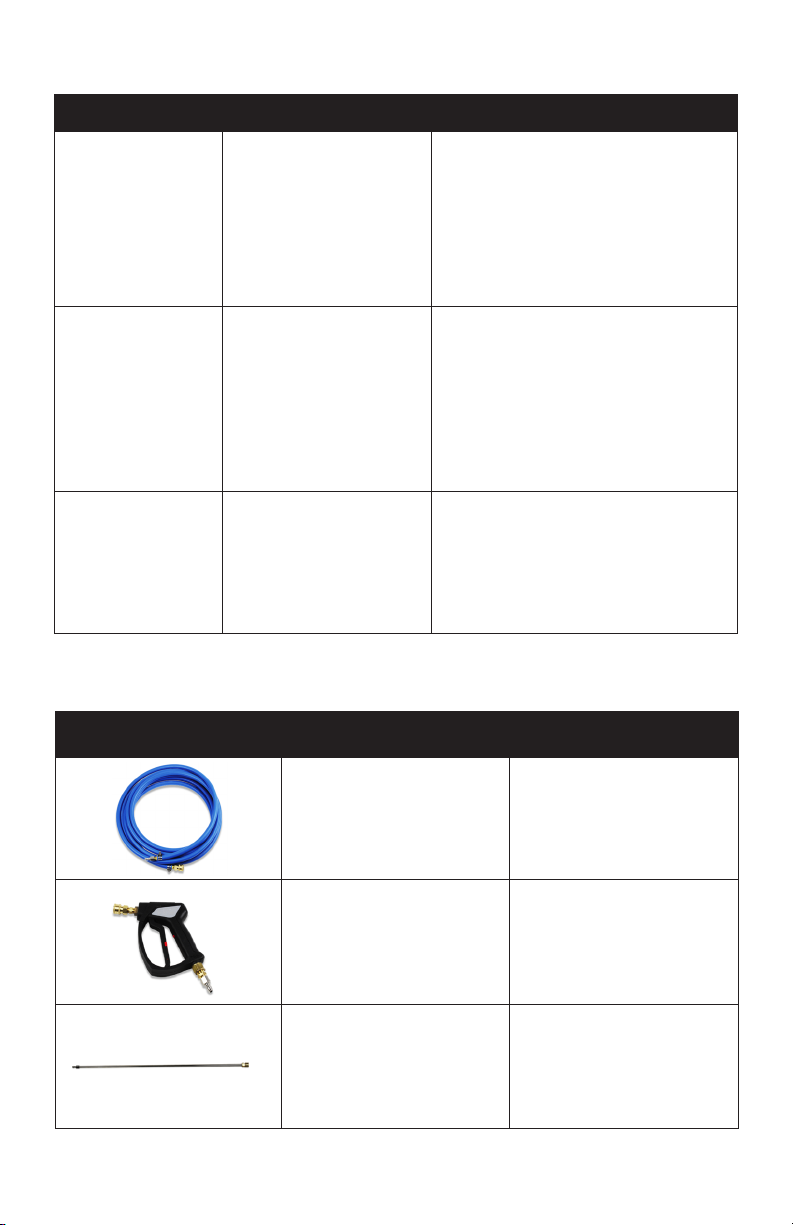

IDENTIFYING MAIN COMPONENTS

Light

Power Switch

Inlet Selector