1

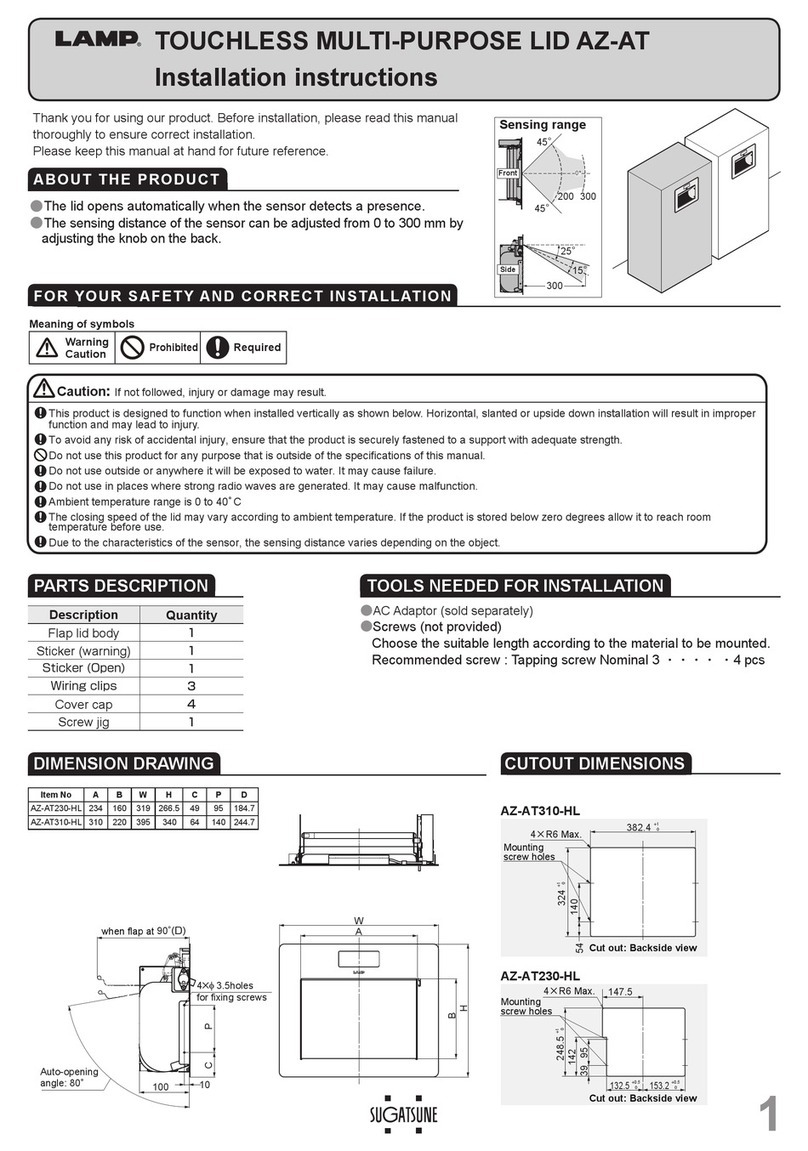

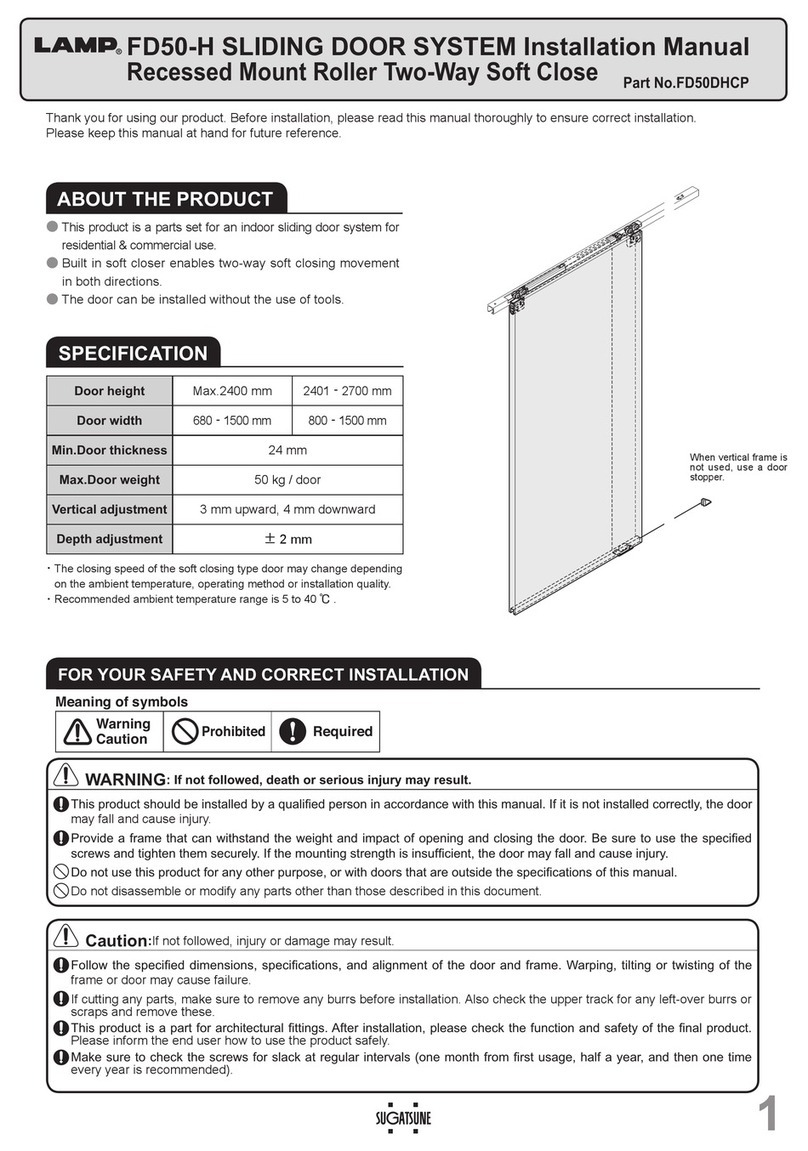

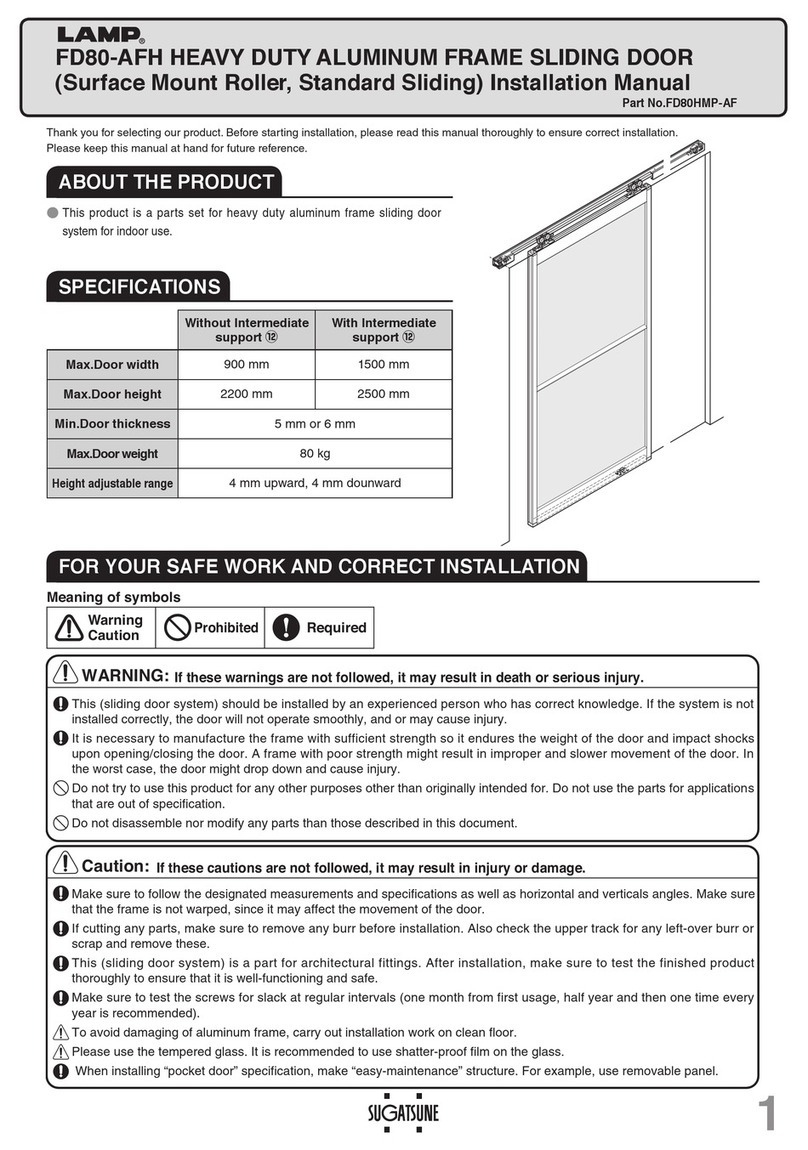

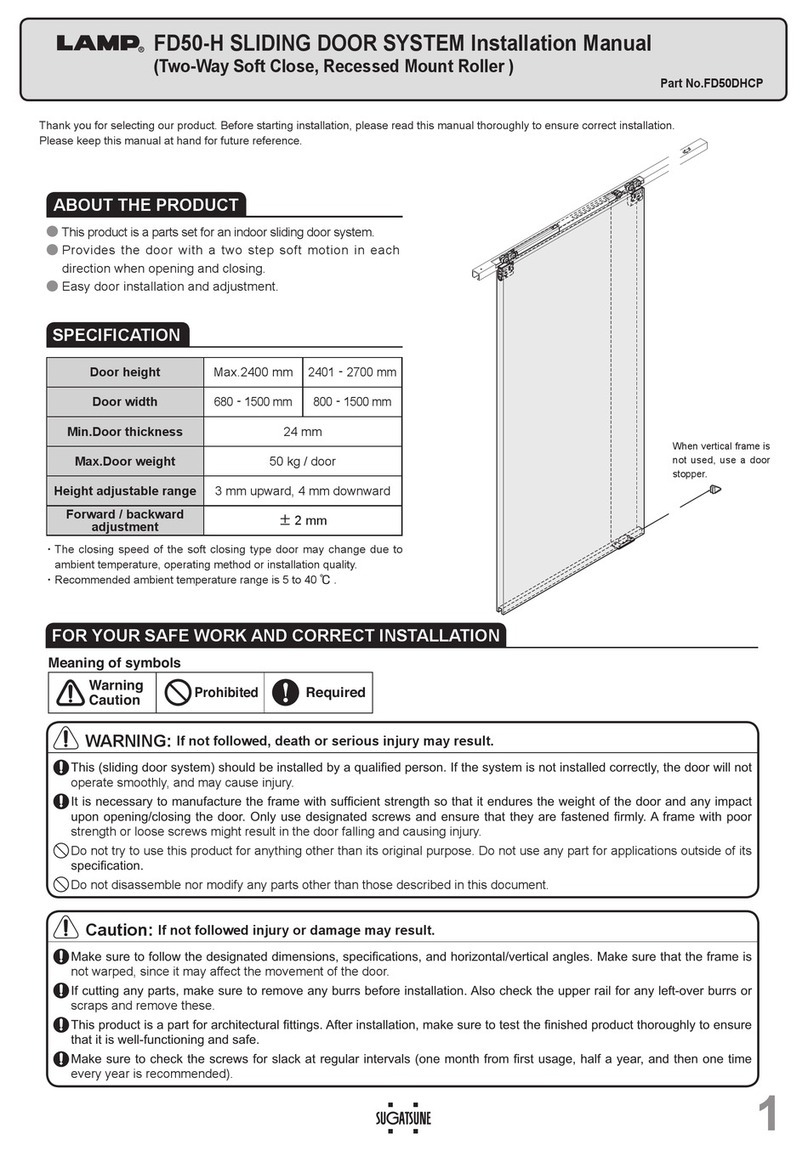

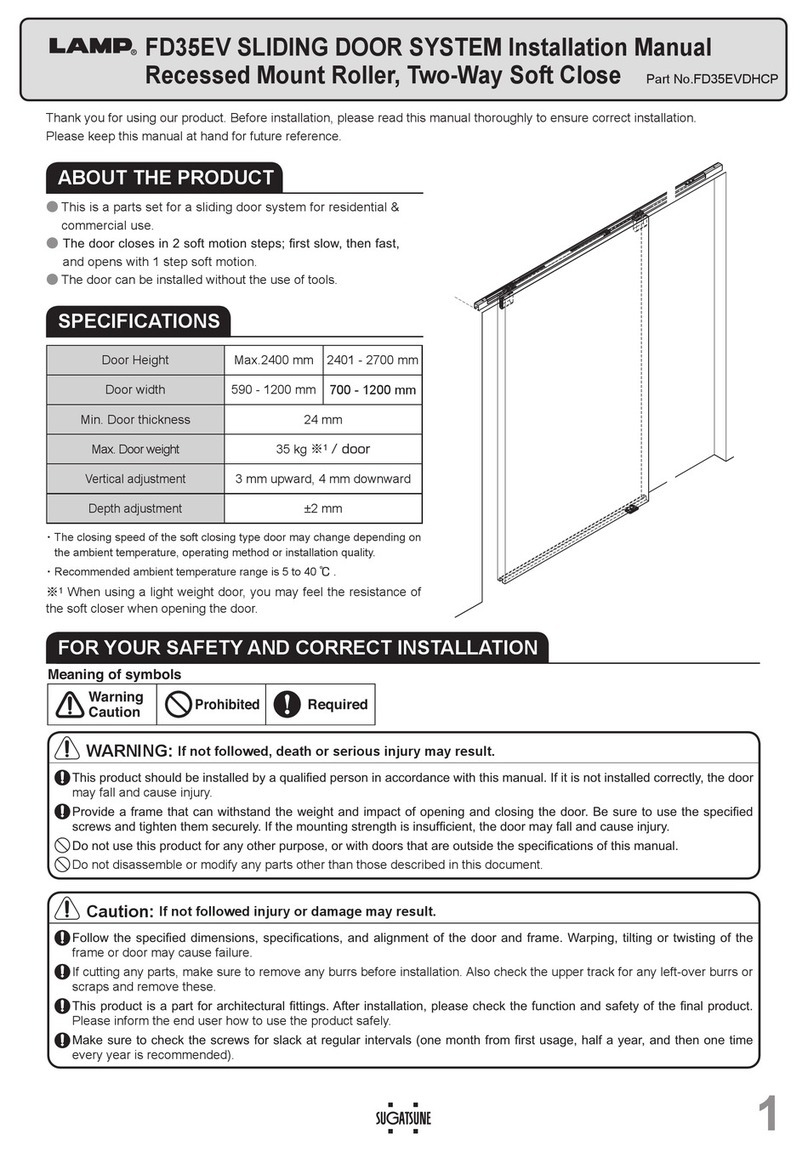

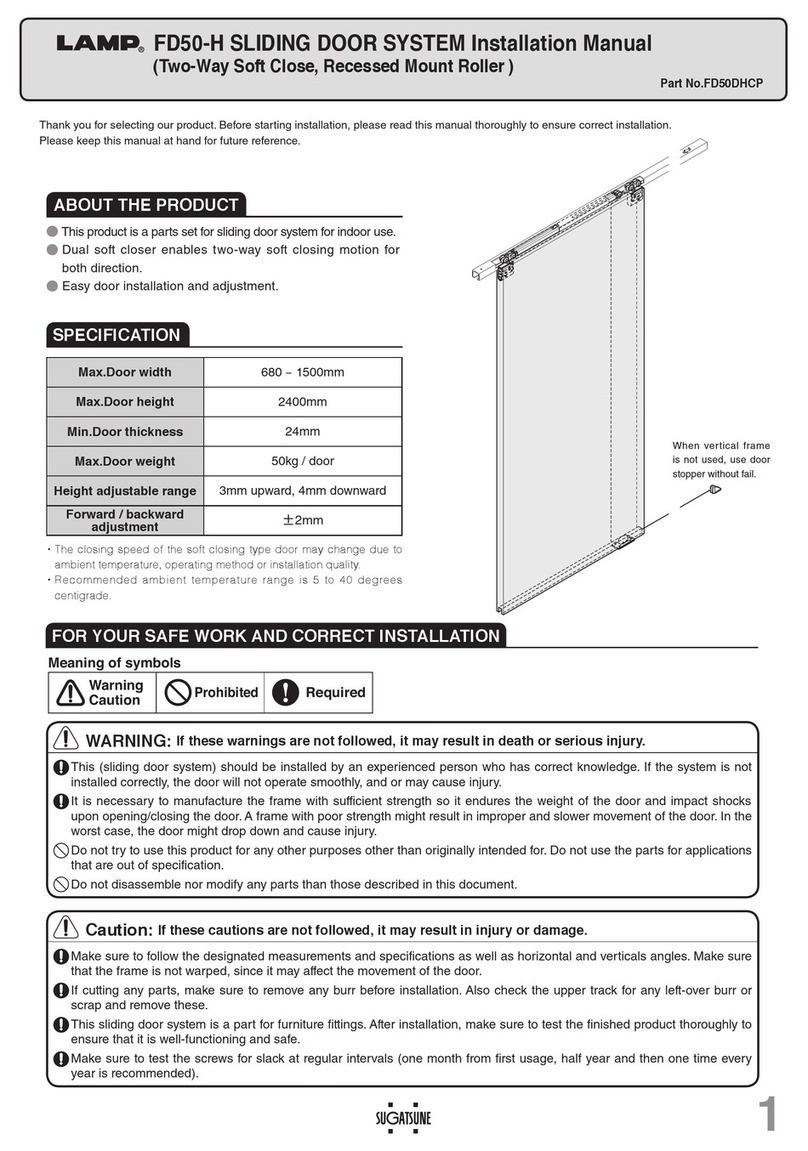

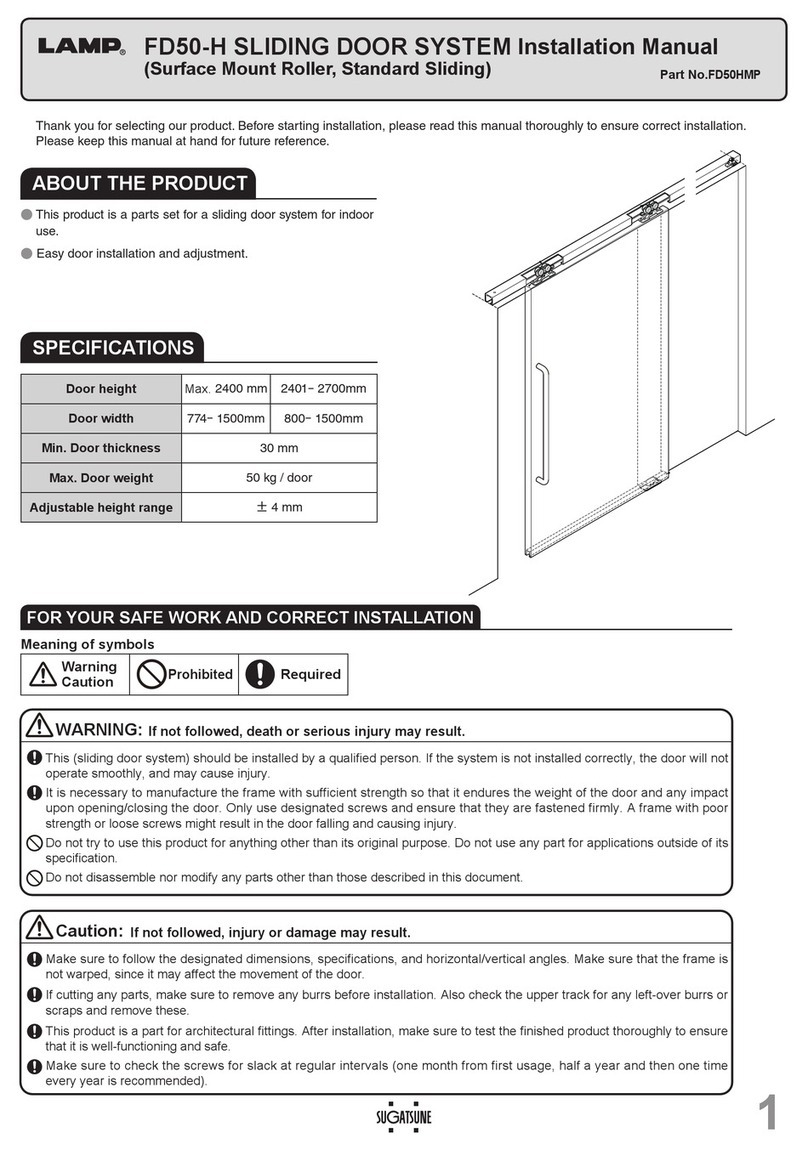

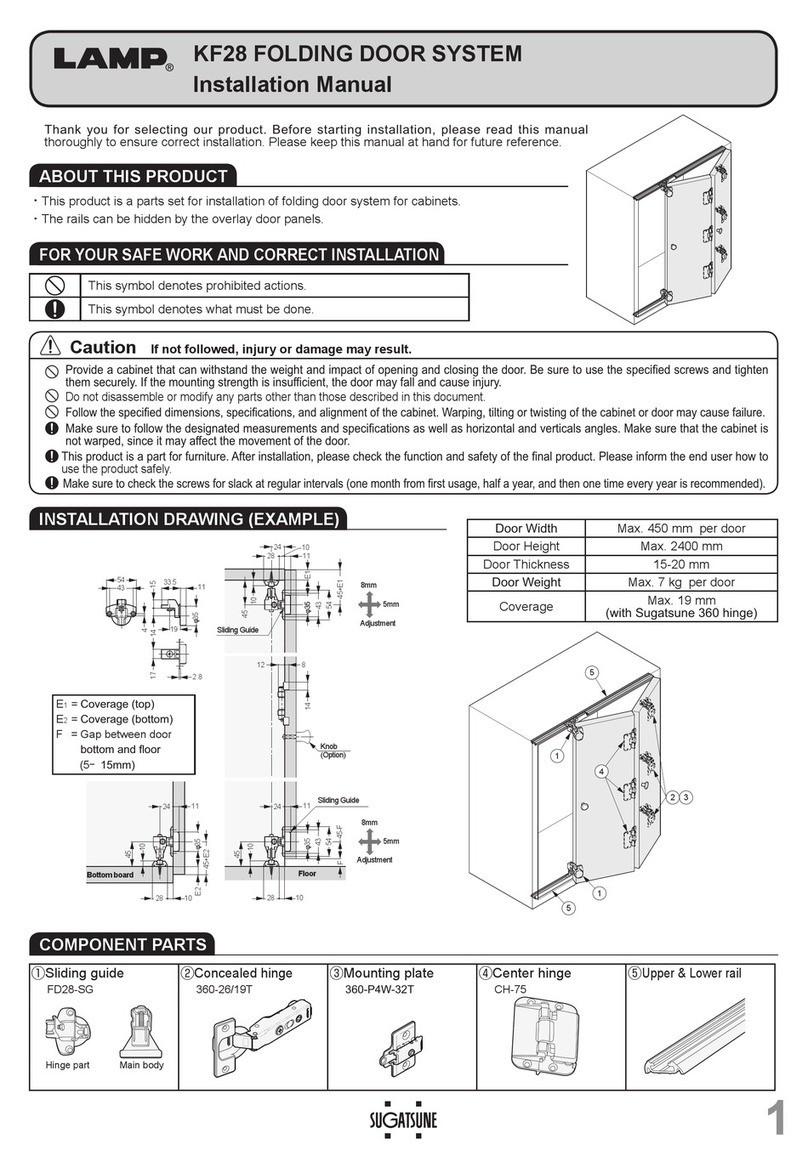

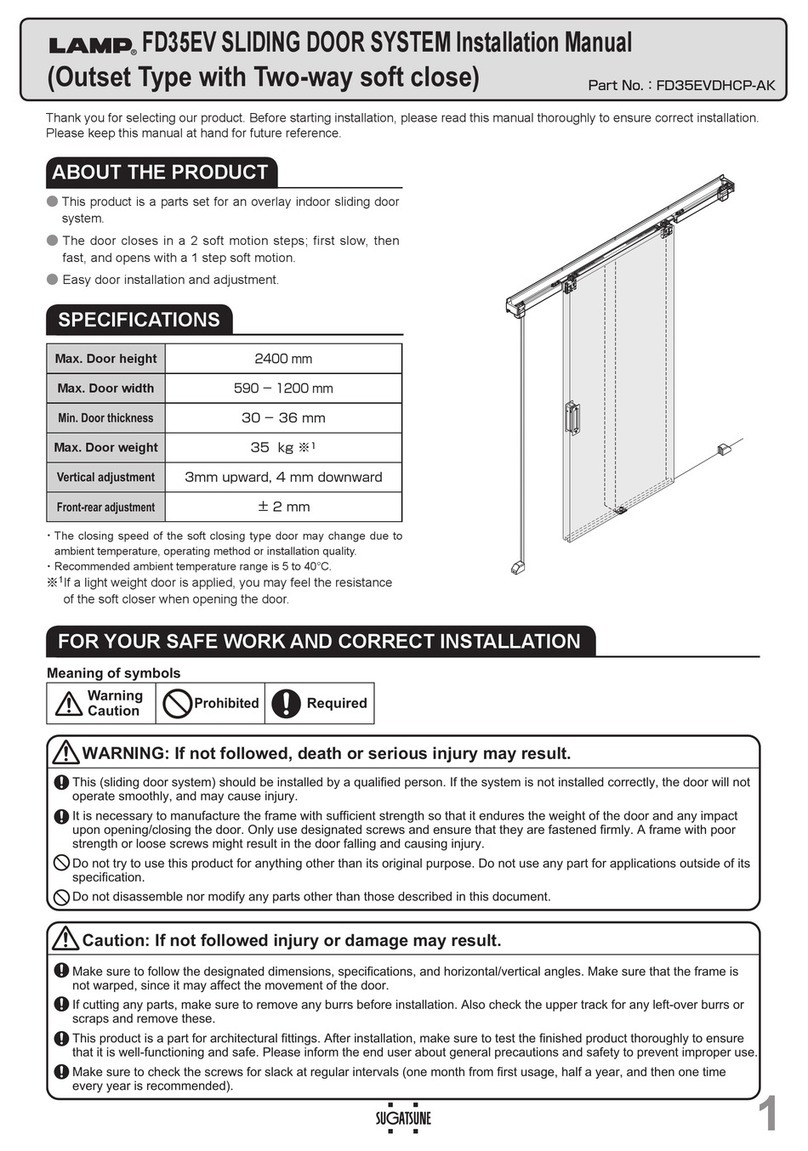

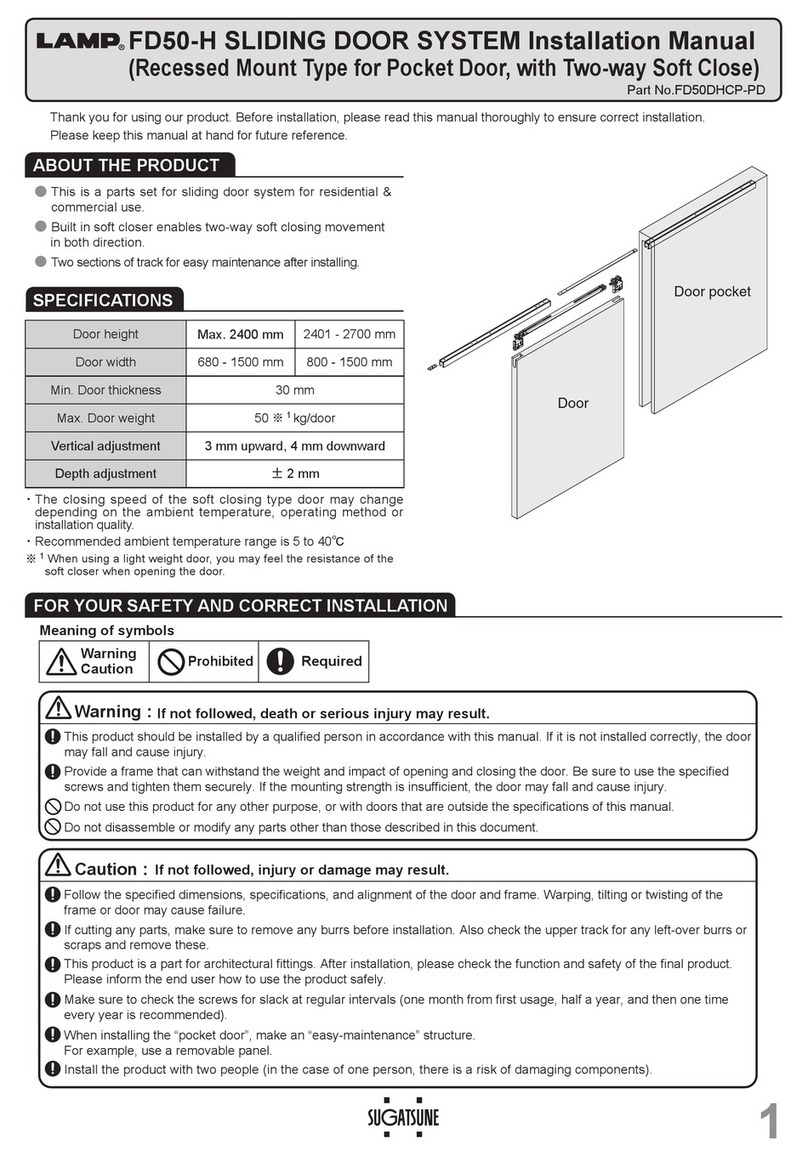

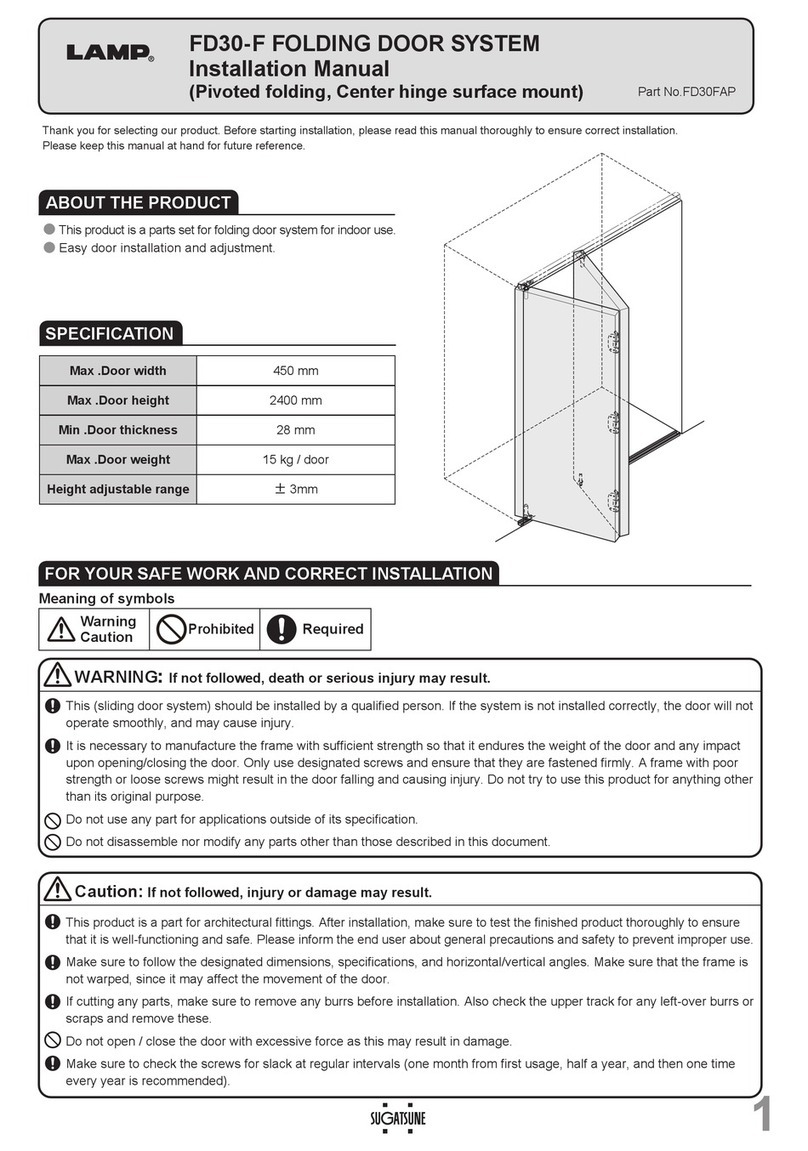

SPECIFICATIONS

FOR YOUR SAFETY AND CORRECT INSTALLATION

Max. Door height 2400 mm

Door width 590 -1000 mm

Min. Door thickness 30 mm

Max. Door weight 30 kg/door ※1

Vertical adjustment 4 mm upward

3 mm downward

Depth adjustment

±2 mm

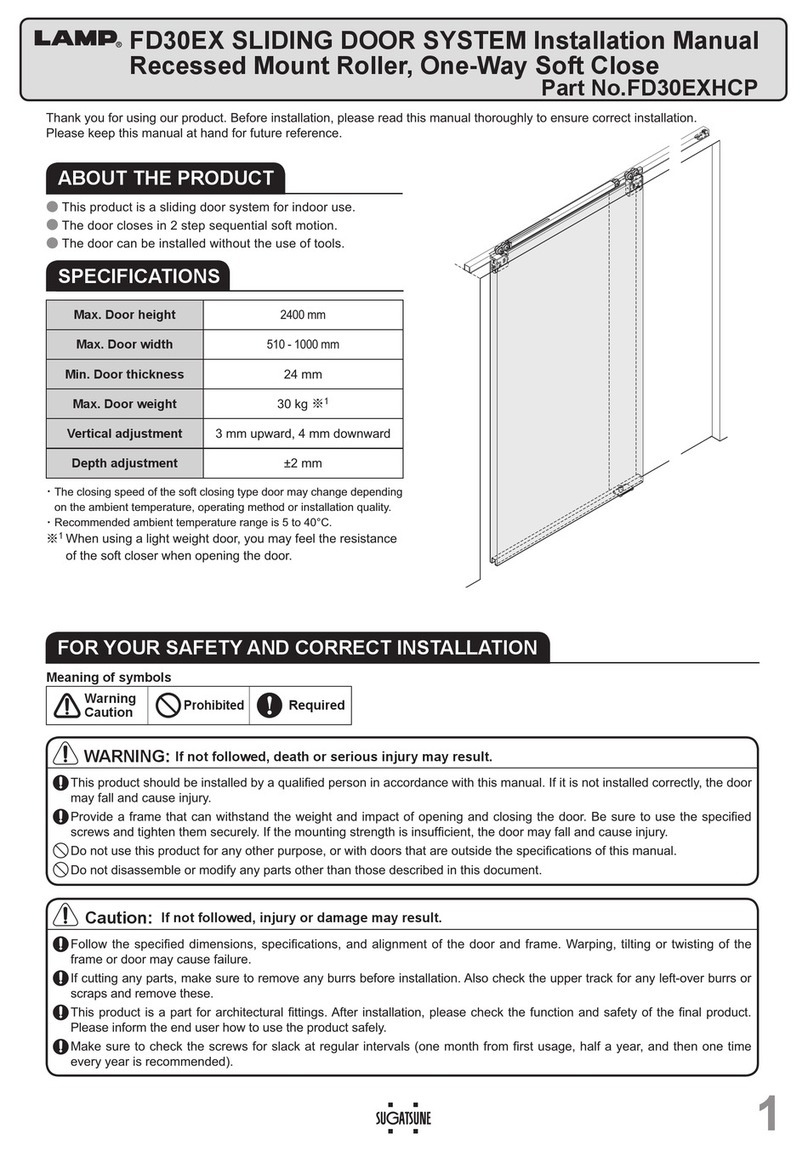

Door

Door pocket

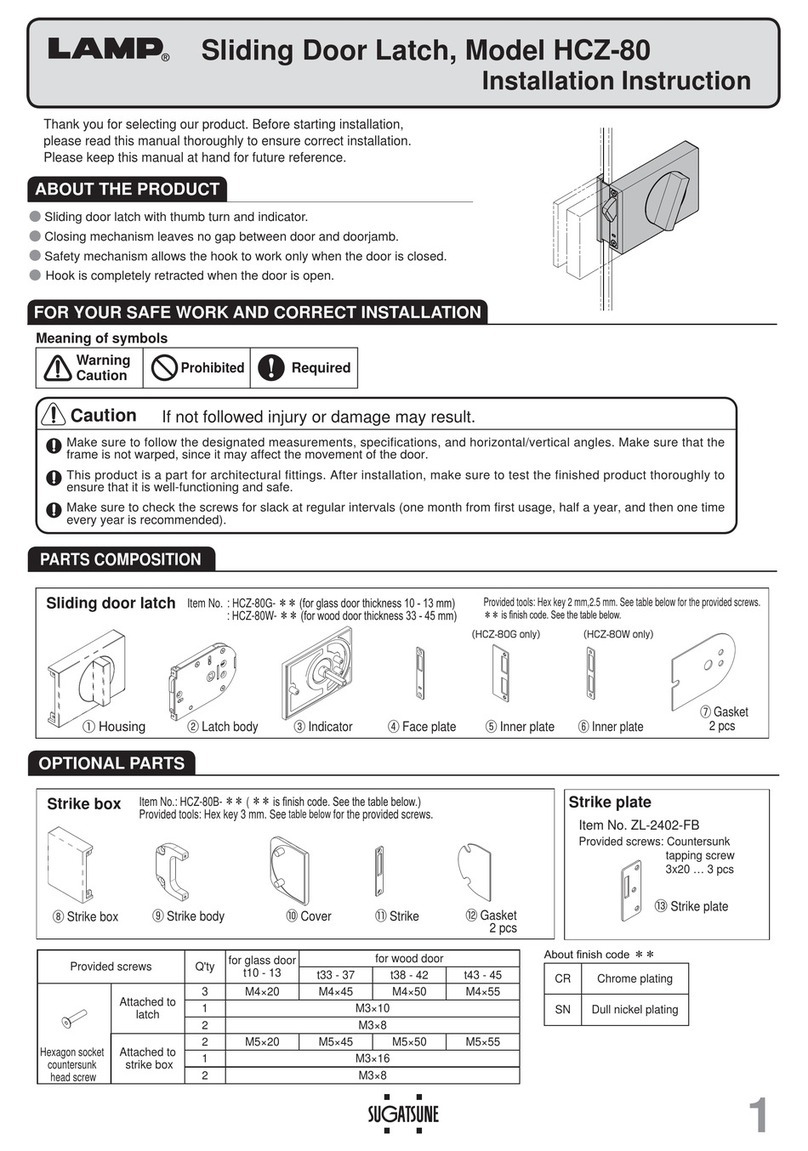

FD30EX SLIDING DOOR SYSTEM Installation Manual

(Ceiling Mount Type for Pocket Door, with Dual Soft Close)

Part No.FD30EXDHCP-PD

Thank you for using our product. Before installation, please read this manual thoroughly to ensure correct installation.

Please keep this manual at hand for future reference.

ABOUT THE PRODUCT

●

This is a parts set for a sliding door system for indoor use.

●

7KHGRRUFORVHVLQVRIWPRWLRQVWHSV¿UVWVORZWKHQIDVWand

opens with a 1 step soft motion.

●

Two sections of track for easy maintenance after installing.

・

The closing speed of the soft closing type door may change

depending on the ambient temperature, operating method or

installation quality.

・

Recommended ambient temperature range is 5 to 40 degrees

centigrade.

※1When using a light weight door, you may feel the resistance of

the soft closer when opening the door.

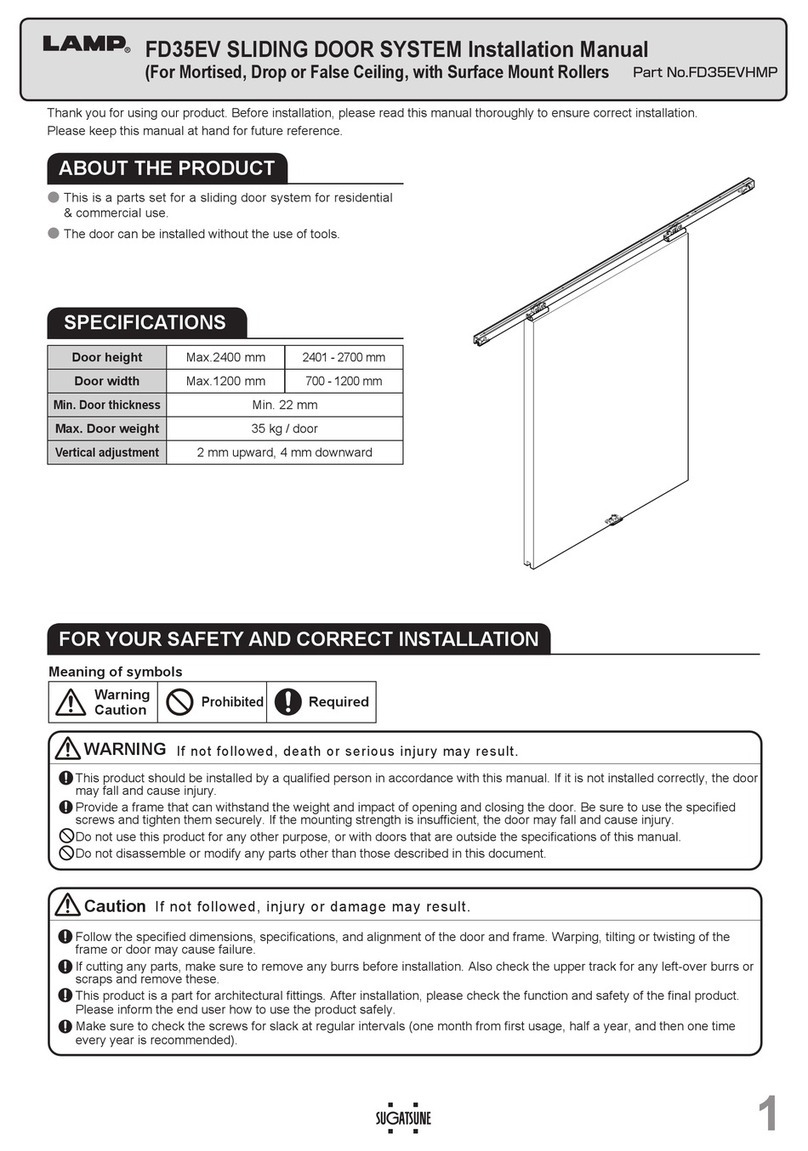

WARNING:If not followed, death or serious injury may result.

Caution: If not followed injury or damage may result.

Prohibited

Warning

Caution Required

Meaning of symbols

This product should be installed by a qualified person in accordance with this manual. If it is not installed correctly, the door

may fall and cause injury.

Provide a frame that can withstand the weight and impact of opening and closing the door. Be sure to use the specified screws

and tighten them securely. If the mounting strength is insufficient, the door may fall and cause injury.

Do not use this product for any other purpose, or with doors that are outside the specifications of this manual.

Do not disassemble or modify any parts other than those described in this document.

Follow the specified dimensions, specifications, and alignment of the door and frame. Warping, tilting or twisting of the frame

or door may cause failure.

If cutting any parts, make sure to remove any burrs before installation. Also check the upper track for any left-over burrs or

scraps and remove these.

This product is a part for architectural fittings. After installation, please check the function and safety of the final product.

Please inform the end user how to use the product safely.

Make sure to check the screws for slack at regular intervals (one month from first usage, half a year, and then one time every

year is recommended).

When installing the “pocket door”, make an “easy-maintenance” structure. For example, use a removable panel.

Install the product with two people (in the case of one person, there is a risk of damaging components).