MHZ R 03 User manual

Operation Manual

ROLLO R_03 with electric motor

Subject to technical changes I

Edition 02.2018

3

Operation Manual

Rollo R_03 with electric motor

1. Important basic information

1.1 About this Operation Manual

This Operation Manual describes and explains the products and how to use them safely.

Adherence to the Operation Manual constitutes part of proper use and contributes signi cantly

to avoiding danger, maintaining the products' reliability and optimising the length of their service

life. The Operation Manual must be available at the place where the products are in use.

Everybody who works with or does work on the products must have read and understood this

Operation Manual.

The contents of the technical documents have been developed with great care and knowledge.

Please report any inconsistencies or errors to the manufacturer. The Operation Manual is subject

to changes.

1.2 Manufacturer

MHZ Hachtel GmbH & Co. KG

Sindel nger Str. 21 · 70771 Leinfelden-Echterdingen

Tel. +49 711 9751 0

∙

1.3 Copyright

The content of the Operation Manual is the intellectual property of the manufacturer and is

protected by copyright.

The manufacturer reserves the right to forward, reproduce, distribute or edit the Operation Manu-

al or parts thereof, as well as to exploit, use or disclose the Operation Manual.

Rights to trade marks, names and logos of the manufacturers of sub-contracted or third party

parts or materials are the property of the respective developer / license holder.

1.4 Loss/Replacement

This Operation Manual is a safety-relevant component of the products and if lost must be

replaced without delay. When you order a replacement copy, the manufacturer may charge a

nominal fee.

1.5 Legal Notices

The manufacturer disclaims any liability, warranty or guarantee that exceeds the statutory

minimum rights, unless otherwise agreed in the respective agreement.

In the event of any modi cation of the products not of approved by the manufacturer, any use of

impermissible materials and/or any application that goes beyond the intended use, the owner/

operator loses any right to claim against the manufacturer.

1.6 Additional applicable documents

Not relevant.

1.7 Items included

•1 x Rollo R_03, dimensions and speci cation as per delivery documents

•1 x Operation Manual

1.7.1 Items optionally included

•Accessories as per delivery documents

1.8 Text display conventions

Body copy for the depiction of information.

•Itemization / assignment to the operator

System reaction

1.9 Conventions for important information

1.10 Symbol conventions

The following symbols are used in this Operation Manual and/or on the products.

The symbols used have the following meaning:

Additional safety and occupational health signs according to the Technical Rules for Workplaces

ASR A1.3

1.10.1Warning signs according to DIN EN ISO 7010

1.10.2Safety signs according to DIN EN ISO 7010

1.10.3Prohibitions

2. Safety

2.1 Basic safety precautions

The products have been designed and made in accordance with the applicable EU directives.

The technology used, in particular for safety and personal safety, corresponds to the state of the

art at the time of construction. In the event of improper application or misuse of the products, the

risk of injury or damage can, nevertheless, not be ruled out. For operator and tter/installer it is

important to read this Operation Manual prior to any operation of the products.

2.1.1 Conduct in case of emergency

Not relevant.

2.1.2 Personnel requirement, duty to take due care

This roller blind must be operated only by people who have knowledge of this Operation Manual

and in particular of the safety section and warning notices. Children or people who are not capa-

ble to properly assess the consequences and effects of their actions are prohibited from operating

the product.

2.2 Hazard-specific safety precautions

2.2.1 Electric power (versions with mains connection only)

Only original fuses with the speci ed voltage may be used!

If faults arise in the electrical power supply, switch off the roller blind straight away!

Components on which inspection, maintenance and repair work is performed, must be in the off

position / volt free (electricity switched off). Check that the electricity is switched off!

The roller blind's electrics must be inspected/checked regularly.

Defects, such as loose connections or scorched cables, must be renewed immediately.

2.3 Responsibilities

2.3.1 Responsibilities of the manufacturer

The manufacturer must:

•ensure that the products conform to Directive 2006/42/EC and to all other relevant directives.

•con rm conformity with relevant directives in the form a declaration of conformity.

•enclose this declaration or a copy of its contents with the technical documents that are ap-

pended as a safety-relevant item of the roller blind.

•retain the technical documentation for at least ten years after the last product made is

shipped/commissioned.

2.3.2 Responsibilities of the operator

The operator must:

•ensure an operating environment compliant with regulations.

•keep the product in good, safe condition.

•keep this Operation Manual safe.

Operation without

relevant qualifi cation

prohibited!

WARNING!

Indicates a possible danger.

If the situation is not avoided, fatal or serious injury can result!

CAUTION!

Indicates a possible danger.

If not avoided, this danger could cause moderate or minor injuries!

ATTENTION!

Indicates a possibly hazardous situation,

If it is not avoided, the product or something near it may get damaged!

CAUTION!

Indicates possibly important information.

If it is followed, the product can be used effi ciently and for a long time.

Warning of dangerous

electric voltage.

(W012)

Generic warning.

(W001)

Warning of a danger of

falling.

(W008)

Warning of a danger of

obstacles on fl oor.

(W007)

General mandatory action

sign.

(M001)

Disconnect before carrying

out maintenance or repair.

(M021)

WARNING!

Hazard through electrical shock due to incorrect installation!

Work on electrical systems or equipment may only be performed by

qualifi ed electricians or other appropriately trained persons under the

supervision of an electrician and must performed in accordance with all

relevant electrical regulations!

Subject to technical changes I

Edition 02.2018

4

Operation Manual

Rollo R_03 with electric motor

2.4 Intended use

2.4.1 Scope of application

The products are installed for decorative, screening or light management purposes.

The product is installed inside on and around windows.

The products are available with different operating versions.

2.4.2 Improper use

Improper uses are not foreseeable.

2.4.3 Operation conditions

As per the technical data. The products must be used only in dry surroundings that can be heated,

and not in any explosive atmospheres.

2.5 Improper use

Improper uses are e.g.:

•Use of low-quality spare parts.

•Objects and obstructions in the products' path of travel.

•Operation in an unsuitable environment.

The operator bears sole responsibility for any damage or losses resulting from this and the

manufacturer/vendor shall not be liable in any way.

2.6 Modifications

In the event of any unauthorised conversions or alterations of the products, any manufacturer

liability or warranty shall lapse.

No additional loads may be placed on the product!

2.7 Residual risks / hazards and protective measures

Risks or hazards, that cannot be controlled through design or safety measures must be clearly

marked through signs and/or instructions.

Risks and hazards listed below can be minimised by the personnel's knowledge and awareness.

3. Technical data

3.1 General

3.2 Electric/electromechanical specifications

3.3 Emissions (electrically powered versions only)

3.4 Safety signs/labels

In accordance with Directive 2006/42/EC, Appendix 1, 1.7.1

The following pictograms and warning texts have been put on the roller blind (varies by version).

Any signs/labels that are damaged or have been removed must be replaced!

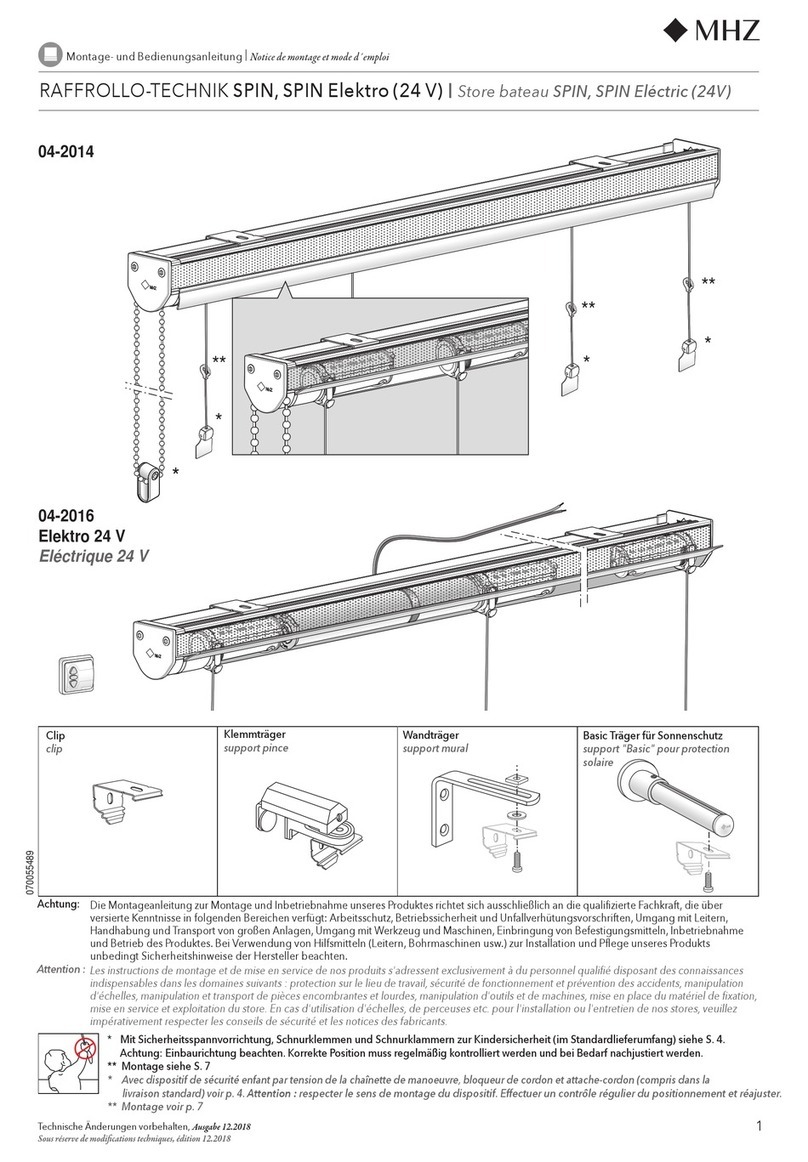

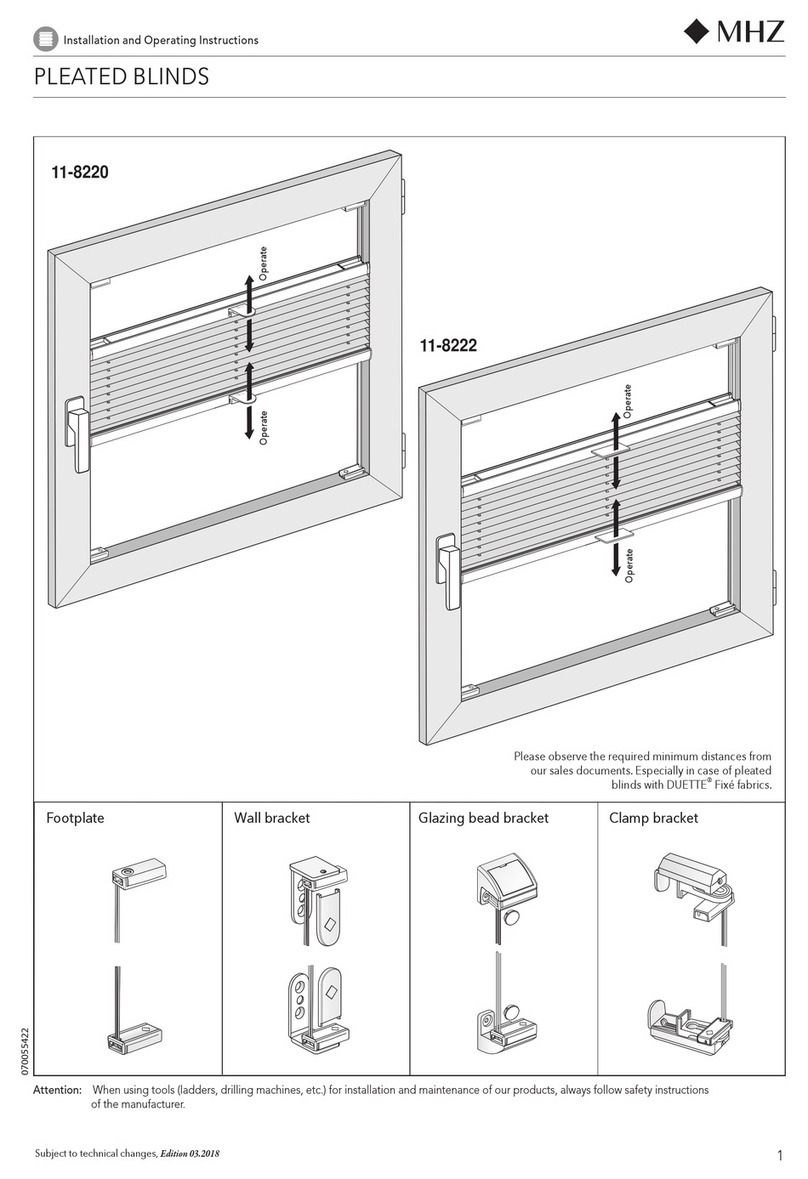

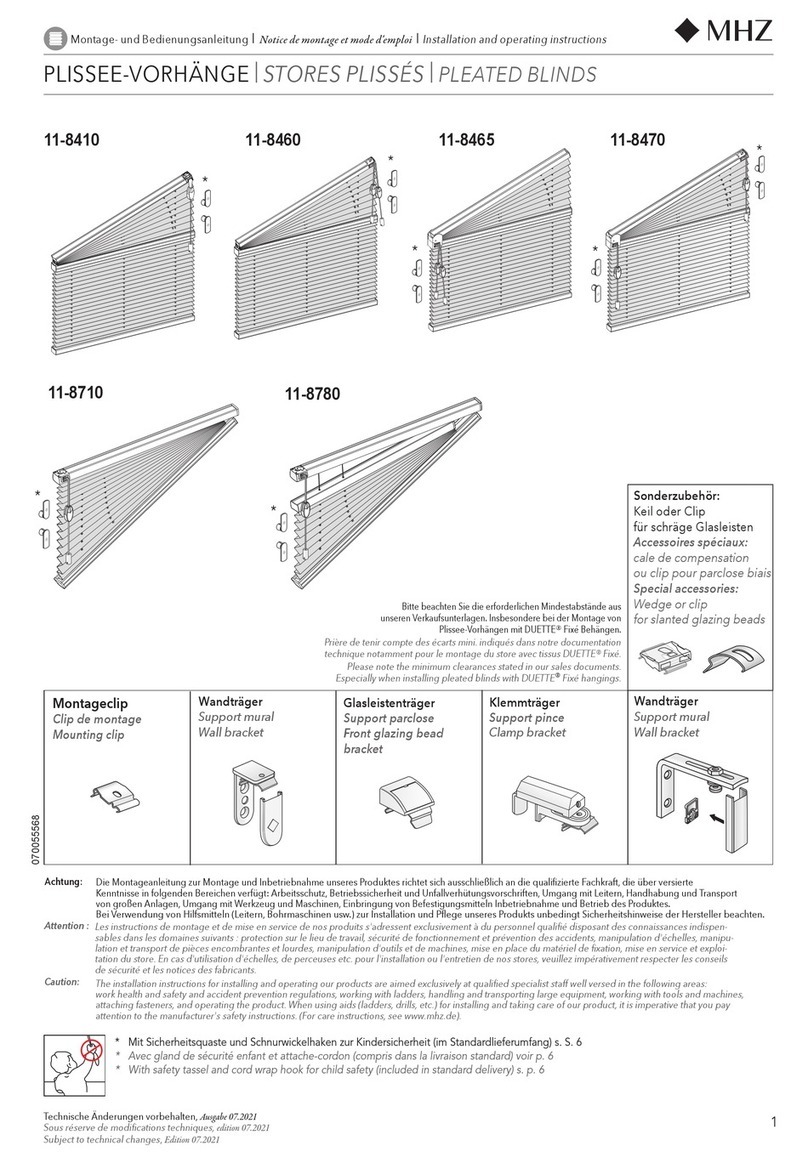

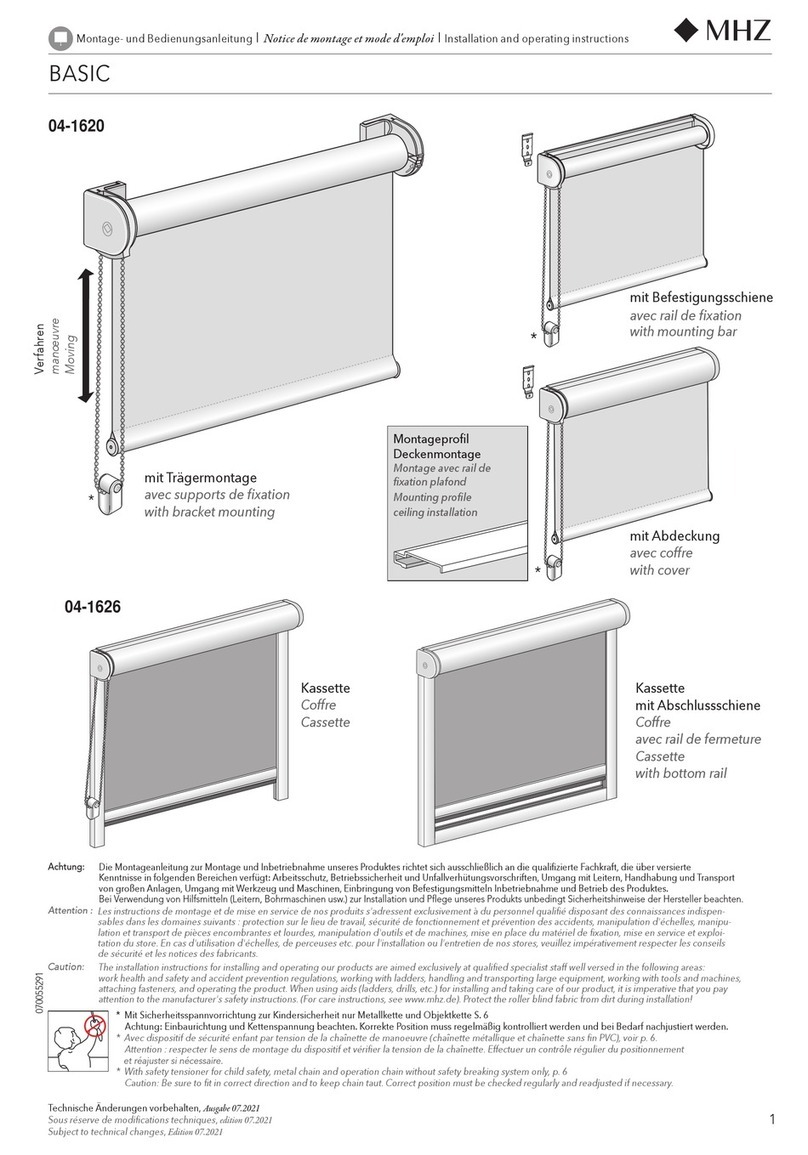

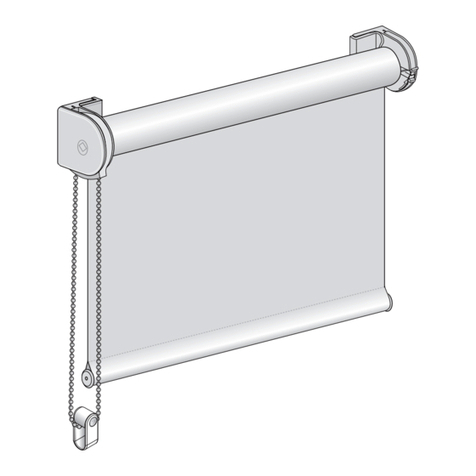

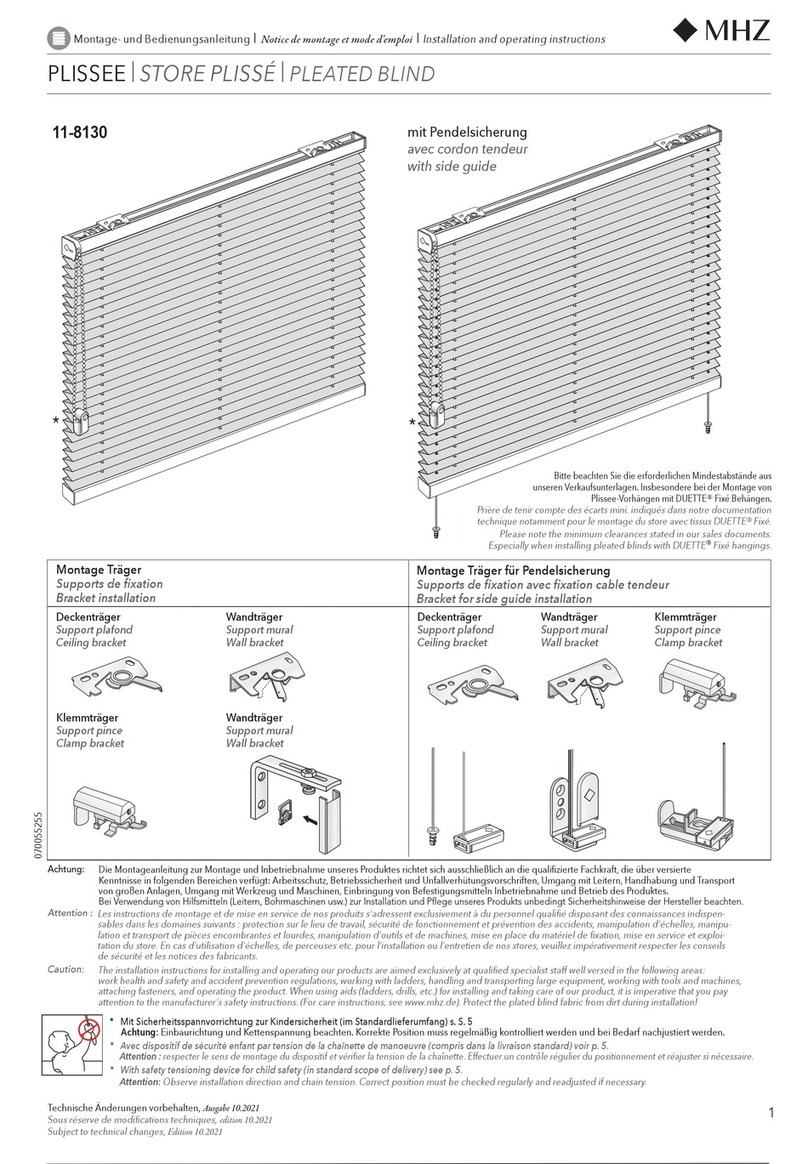

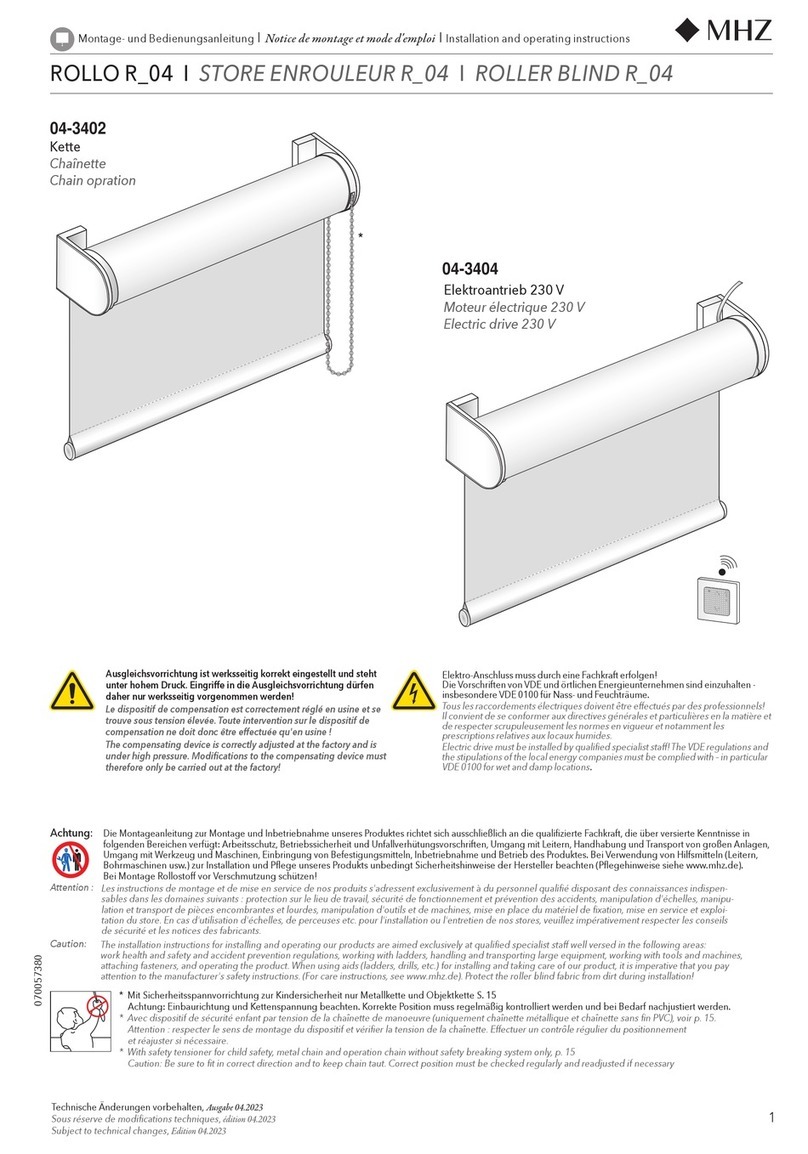

4. Structure and Function

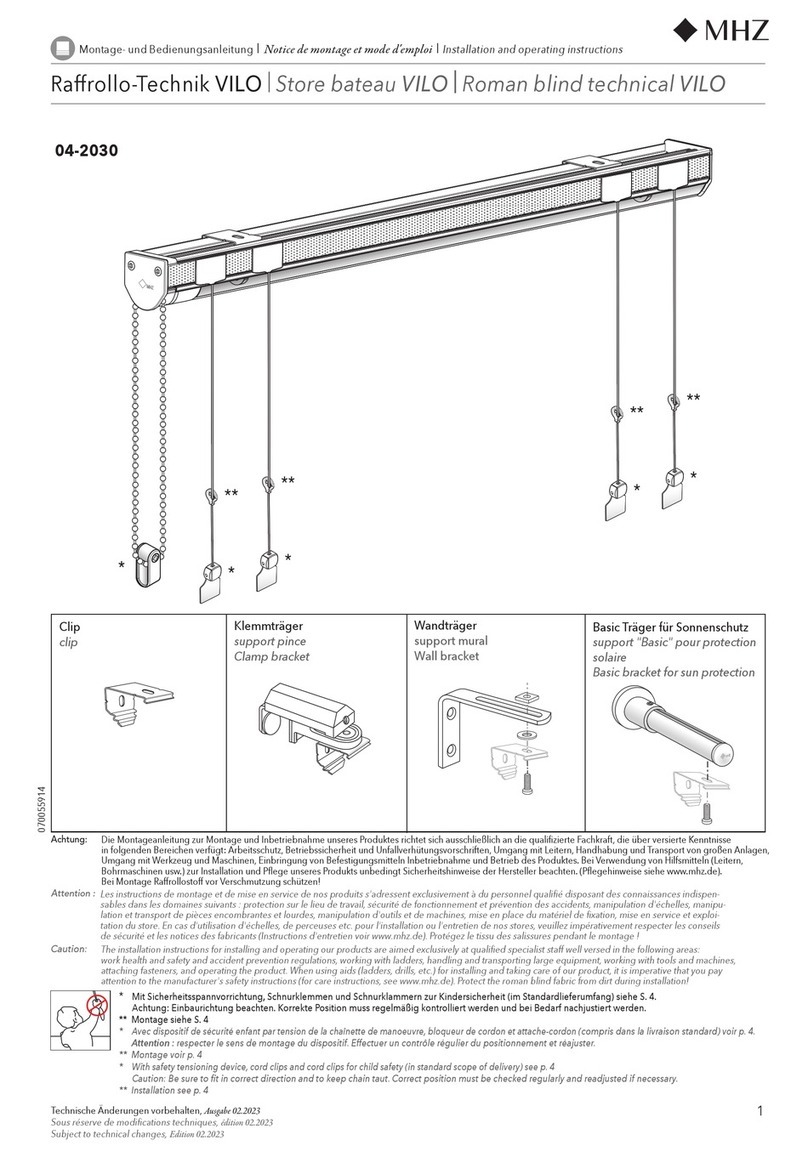

4.1 Graphic Depiction

8

Basic bracket

Clamp

Tube with fabric

Weighted rod, inlying

External weighted rod,

rectangular

External weighted rod, round

Side guide

Cable

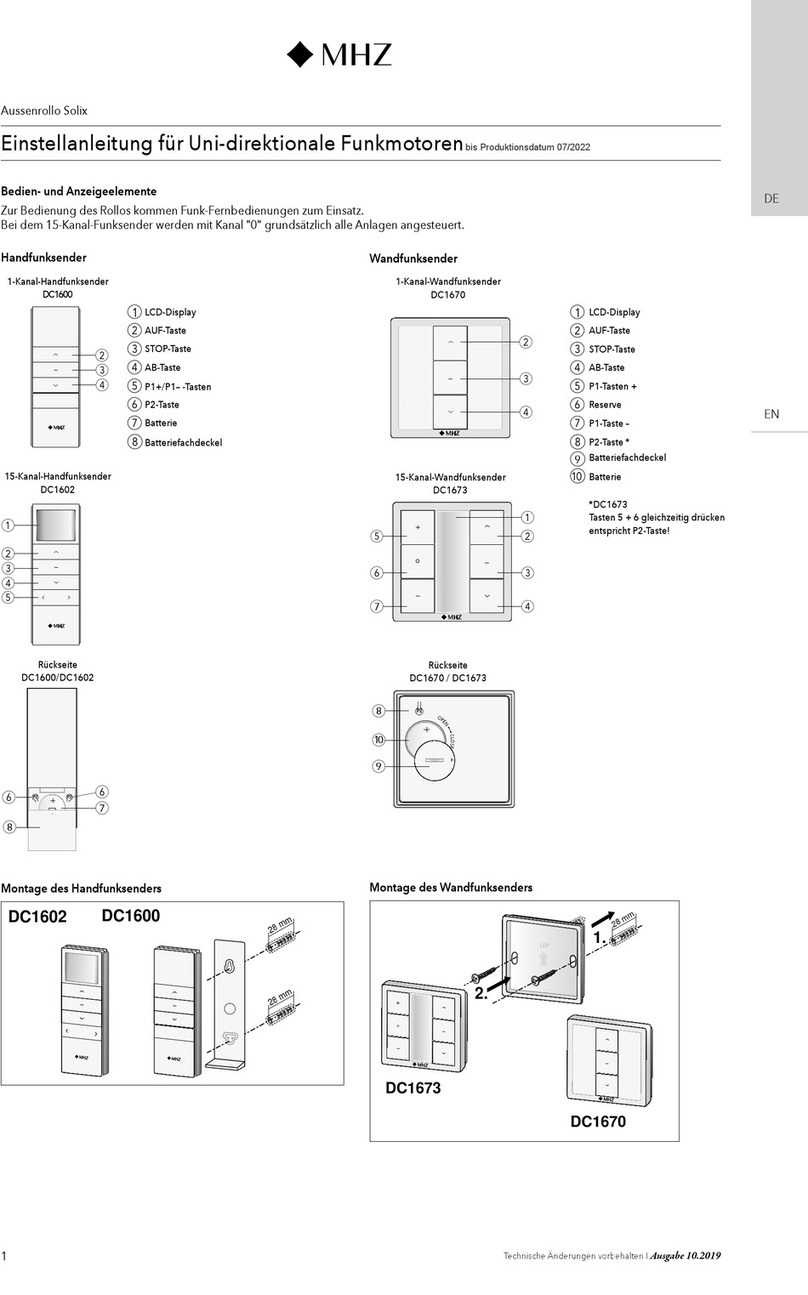

4.2 Functional description

The products are installed for decorative or light management purposes on or around windows.

The movement of some products is electrically powered. The product is automatically stopped

at the top and bottom end of its path of travel. Factory staff programme the end positions on the

product in its delivery condition (electrically powered versions only).

4.3 Safety Concept

The products are intrinsically safe and following correct installation can be safely used by the

operator until normal wear ends their service life.

The electrically powered drive system is of a size and design that when used properly there are

adequate safeguards against any risks to humans or animals (electrically powered versions only).

4.4 Notes on the battery-operated radio-controlled drive unit

•Protect products / radio-controlled drive unit from knocks during transportation, storage and

installation.

•Use only the charger approved by MHZ!

•The rechargeable battery is shipped partially charged.

•Prior to rst use, the battery must be fully charged (takes c. 6 hours).

•In subsequent operation, the time required to charge the battery when fully discharged is c.

3 hours.

•In order to preserve the battery's charge capacity, it should be recharged every 6 months.

•The red LED on the charger lights up when the charger is plugged in and indicates the charg-

ing activity. As soon as the green LED comes on, the battery is fully charged.

•Number of movement cycles per battery charge: c. 300, depending on product weight and

size (1 movement cycle equates to one up and down movement).

•Battery and radio-controlled drive unit are tted as a single item inside the product housing.

Defective batteries cannot be replaced alone.

•Remote control range in enclosed buildings: c. 35 m.

•The setting of the end positions is retained even when the battery has discharged.

•Radio-controlled drive and control system components are not compatible with other manu-

facturers' products.

•Minimum drive system distance from radio equipment: 20 cm.

4.5 Notes on the electric drive unit with mains connection

•Any suitable roller blind switch can be installed as the control element.

Determining its technical suitability and installing the switch are tasks that must be done by an

electrician!

4.6 Operator stations

Not relevant.

Continuous sound pressure level [dB(A)]:

* The value can vary depending on the installation

< 70*

EMC: within permissible limits pursuant to Directive 2014/30/EU

Performance data, protection type and protection class as per type plate / delivery documents

Hazard through electric power by touching live parts

(versions with mains connection only)!

Terminal box and any other electrical modules to be opened only by an electrician and after

switching off the mains power.

Hazard resulting from wear and tear breakage!

To avoid any breakages with hazardous consequences all load-bearing and mechanical moving

components must be routinely checked for the appearance of wear and tear or signs of damage.

Damaged / worn out components must be replaced immediately!

Pictogram Explanatory text

Caution!

Dangerous electrical voltage!

The drive unit does not contain

any repairable parts and may

not be opened!

Size [mm]

20

20

Mounting

Near the connecting

terminals

(versions with mains

connection only)

In the separable joints

area

Dimensions W x H in [mm]:

Weight [kg]:

Drive type:

Temperature for storage and operation [°C]:

Relative humidity [%]

as per delivery documents

±0 to +40

50 to 80 (not condensing)

Subject to technical changes I

Edition 02.2018

5

Operation Manual

Rollo R_03 with electric motor

5. Transport, storage and set-up conditions

5.1 Special safety precautions for transport

5.2 Local requirements

5.2.1 Ambient conditions

The products must be installed only in dry surroundings that can be heated, and not in any

explosive atmospheres. The degree of electromagnetic compatibility of the electrically powered

products conforms to Directive 2014/30/EU in terms both of resistance to and emission of any

interference. These products must not be used in surroundings with higher than normal levels of

interference or that contain highly sensitive equipment!

6. Installation and fi rst entry into service

6.1 Installation

6.1.1 Unpacking instructions

•All packaging parts are to be opened, loosened and removed carefully, so that the equipment

is not damaged.

•Take care that the product is not knocked or dropped!

•Remove group packaging, cardboard, foils and transport aids and separate according to the

material groups and recycle or dispose of in an environmentally compatible way in accordance

with local regulations.

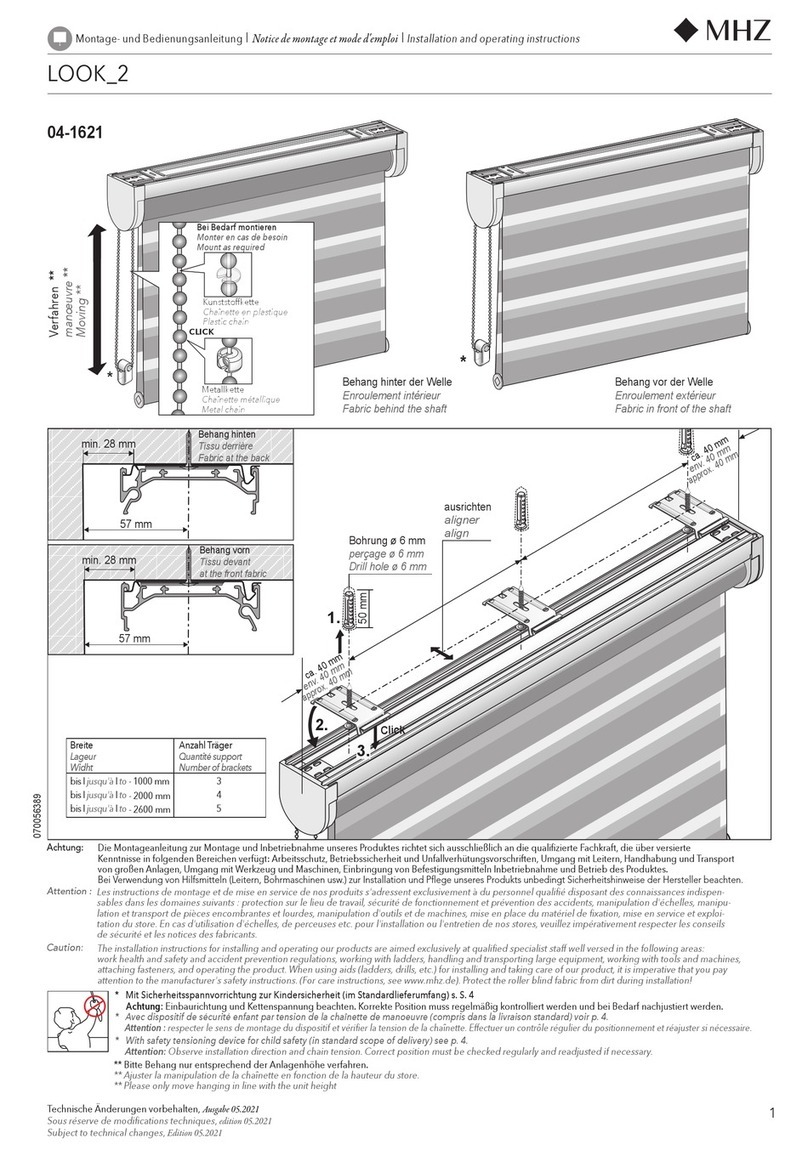

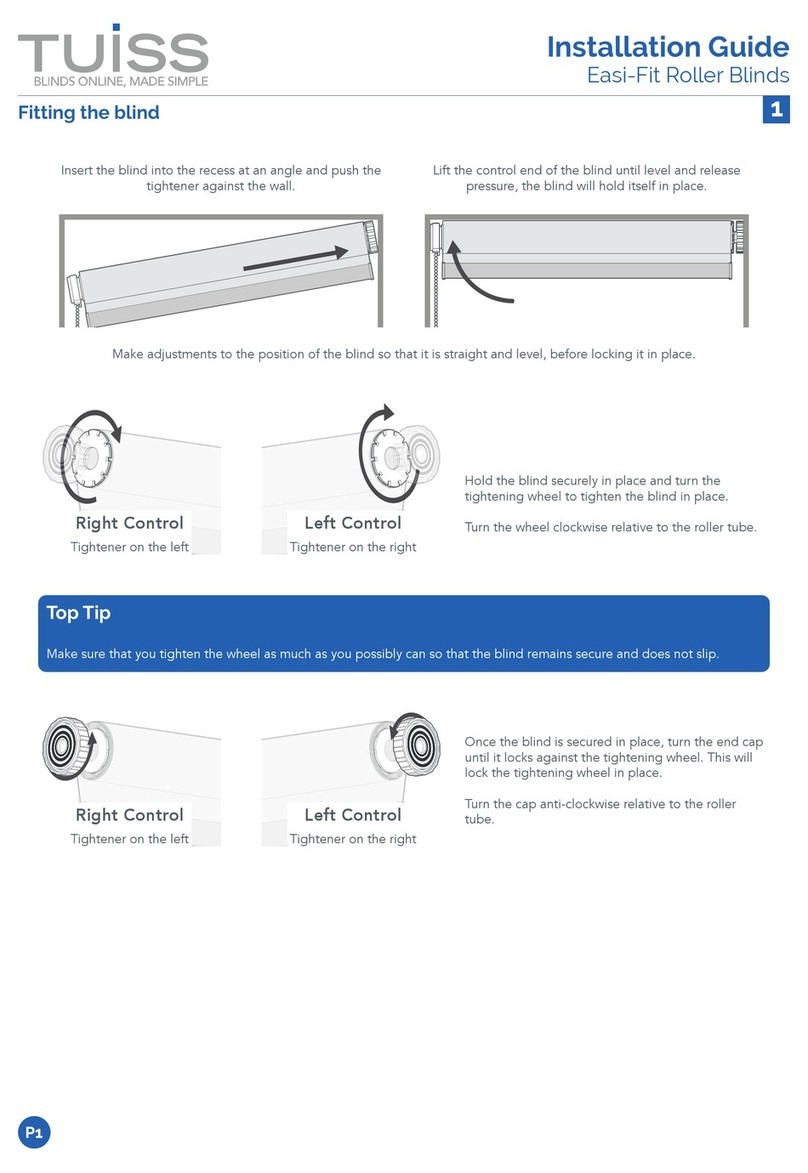

6.1.2 Installation work description

•The product is xed to the ceiling or wall or tted within a recess.

•The installer must independently assess the composition of the substrate and select the appro-

priately sized fasteners (screws, dowels etc.).

•Check the selected drill hole locations with a detector to ensure that there are no electrical

conduits!

•Align and rmly t the prescribed number of support brackets to wall/ceiling/recess.

•Fit the roller blind as per the installation instructions.

•During installation protect the motor cable from getting damaged (versions with mains

connection only).

•Check that the motor cable has been laid safely and with no damage (versions with mains

connection only).

•Check that the roller blind is rmly attached to wall/ceiling/recess.

6.2 Connections (versions with mains connection only)

6.2.1 Electrics connection (versions with mains connection only)

•Plug mains cable with device and mains plug into mains socket

•The installation of any 230-volt components without a mains plug must be done only by an

electrician.

6.3 First entry into service

7. Operation

8. Disruption and defect identifi cation

8.1 Identify the defect

Operation of the roller blind is not possible.

8.2 Repair

•The battery is not suf ciently charged (versions with battery-powered radio-controlled drive

only)

⇒Using the charger, charge the battery.

•The power supply has been lost (versions with mains power connection only)

⇒Check the fuses and, if necessary, fl ip the fuse.

•The drive unit has become overloaded/overheated (electrically powered versions only)

⇒Prior to trying to start the drive again, let it cool down for 15 minutes.

•The blind has got caught, jammed or gone askew at the side.

⇒Recti cation/replacement by specialist rm.

8.3 Service address

The service address is as shown in the information in Section 1.2 'Manufacturer'.

9. Upkeep and Maintenance

Regular maintenance constitutes part of using the roller blind properly and is an absolute

prerequisite for its ef cient and safe operation.

9.1 Service address

The service address is as shown in the information in Section 1.2 'Manufacturer'.

9.2 Spare parts and consumable supplies

Using original spare parts and only consumables approved by the manufacturer constitutes part

of using the product properly.

9.3 Inspection and maintenance work, maintenance intervals

9.3.1 Routine upkeep work

•Clean blind fabric: follow cleaning and care instructions in the 'Textiles Information' brochure.

•Check all connections and mechanical assemblies for wear and tear and integrity.

CAUTION!

Risk of injury through uncontrolled load movement!

Protect product from slipping or tipping over during all loading and

transportation.

Do not store or set product down upright.

CAUTION!

Danger of falling from ladders!

If the product is being fi tted in a high position, a secure ladder must be used!

Only use the ladder on an even and load-bearing surface! Pay attention to the

maximum load-bearing weight!

The ladder must not be leaned up against the product!

If the ladder is not properly set up or loaded, it can fall over!

WARNING!

Hazard through the use of unsuitable materials and techniques!

The products may be installed only by experienced specialist fi rms/fi tters.

During installation, the product must be secured against falling down.

The product must be installed only in dry internal rooms. Any penetration of

moisture must be avoided!

CAUTION!

Operation of the product is dependent on the control elements that are being

used with it (electrically powered versions only).

Typical controls for this purpose are buttons or wireless transmitters with

self-explanatory symbols that enable intuitive operation.

Operation as per the control elements' documentation and/or

as instructed by the fi tter installing the product.

CAUTION!

Hazards caused by the operation of a defective product!

The operation of a non-compliant product can lead to injuries to people or

animals and/or to damage!

If you notice anything unusual happening or any unusual noises during

operation, immediately stop using the product and contact the responsible

specialist fi rm.

CAUTION!

Hazard through improper operation!

During operation, do not reach into product openings!

When operating the roller blind manually, its movement must be monitored.

When it is being operated automatically, it must be ensured as far as possible

that there are no people or objects in the products' path of travel.

Do not apply any loads to the product, no not lean any objects up against the

product!

Do not pull on the product, do not try to hold the product!

CAUTION!

The roller blind is commissioned by the specialist fi rm at the operating

company's premises. The product is handed over in full working order.

The specialist fi rm will instruct the operator during commissioning in how the

product works, how it is operated and on the safety precautions.

WARNING!

Hazard through the use of unsuitable materials and techniques!

Any repairs to the roller blind may be carried out only by trained personnel

that have been instructed in the prevailing safety and accident prevention

regulations.

The roller blind must not be opened - it does not contain any parts that the

layman could repair.

Turn off the electricity and fuses prior to performing repair work

(versions with mains connection only).

Repairs and upkeep/maintenance work that is not performed accordingly will

result in the loss of conformity with the 2006/42/EC Directive!

CAUTION!

Danger of tripping through incorrect installation!

All of the product's supply or connecting lines must run along side walls or

ceiling.

WARNING!

Hazard through electrical shock due to incorrect installation!

The installation of any 230-volt components without a mains plug must be

done only by an electrician or a duly instructed person under the guidance and

supervision of an electrician and must be done in accordance with all electrical

regulations.

The power supply may be turned on only after complete installation and the

closing of all covers!

All lines and materials used must suit the intended purpose in every aspect of

their specifi cation.

Subject to technical changes I

Edition 02.2018

6

Operation Manual

Rollo R_03 with electric motor

10. Taking the blind down

10.1Special safety precautions for removing the blind

10.1.1Description of the removal process

•Switch off power supply (versions with mains connection only)

•Check that blind has no power (versions with mains connection only)

•By pulling the Hirschmann coupling, disconnect cable connection (versions with mains

connection only)

•Take down the roller blind as per the installation instructions.

•Throughout the complete process of removing it, secure the roller blind from falling down!

10.2Disposal/Recycling

11. Declaration of Conformity

EC Declaration of Conformity pursuant to Directive 2006/42/EC,

Appendix II 1.A

The manufacturer:

•MHZ Hachtel GmbH & Co. KG

Sindel nger Straße 21

70771 Leinfelden-Echterdingen

declares that the following product:

•ROLLO R_03

in all available versions

conforms in each instance to the relevant directives:

•Machinery Directive 2006/42/EC (all versions)

•EMC Directive 2014/30/EU (electrically powered versions only)

•Radio Equipment Directive 2014/53/EU (electrically powered versions only)

The product adheres to the protection objectives of Low Voltage Directive 2014/35/EC

(versions with mains connection only).

Harmonised standards applied:

•EN 13120:2009+A1:2014/AC:2015 Internal blinds - Performance requirements including

safety (all versions)

•EN 60335-2-97:2006/A12:2015

Household and similar electrical appliances - Safety -

Part 2-97: Particular requirements for roller shutters, awnings, Venetian blinds and similar

products. (IEC 60335-2-97:2002 (modified) + A1:2004 (modified))

(electrically powered versions only)

Person authorised to prepare technical documents:

•MHZ Hachtel GmbH & Co. KG

Heftensteige 1

97996 Niederstetten

Leinfelden-Echterdingen, 30 November 2017

Jochen Hachtel

Managing Director

WARNING!

Hazard through the use of unsuitable materials and techniques!

Work on electrical systems or equipment may only be performed by qualifi ed

electricians or other appropriately instructed persons under the supervision

of an electrician and must be performed in accordance with all electrical

regulations (versions with mains connection only).

The roller blind may be taken down only by experienced specialist fi rms/

fi tters.

As it is being removed, the blind must be secured against falling down.

CAUTION!

Hazard through falling!

Any people or animals present could be injured by the roller blind or parts of

it falling down!

When loosening the fi xings, ensure that the roller blind is always adequately

secured.

Danger of falling from ladders!

If the blind is fi tted in a high position, a secure ladder must be used! Only use

the ladder on an even and load-bearing surface! Pay attention to the maximum

load-bearing weight!

The ladder must not be leaned up against the product!

If the ladder is not properly set up or loaded, it can fall over!

ATTENTION!

Risk of environmental pollution / wasting resources!

Materials are to be separated according to material groups

and recycled accordingly!

Separate collection of electric and electronic components

as per the 2002/96/EG Directive!

Observe local recycling regulations!

Germany

MHZ Hachtel GmbH & Co. KG Postfach 80 05 20 D-70505 Stuttgart Tel. 0711/97 51-0 Fax 0711/ 97 51-4 11 50 www.mhz.de

Austria

MHZ Hachtel & Co. Ges.m.b.H. Laxenburger Str. 244 A-1230 Vienna Tel. 0810 95 10 05 Fax 0800 12 12 40 www.mhz.at

BENELUX

MHZ Hachtel S.à.r.l. 27, rue de Steinfort L-8366 Hagen Tel. + 352 31 14 21 Fax +352 31 23 28 www.mhz.lu

Switzerland

MHZ Hachtel + Co. AG Eichstrasse 10 CH-8107 Buchs/Zurich Tel. 0848 47 13 13 Fax 0800 55 40 04 www.mhz.ch

France

ATES-Groupe MHZ 1 B, rue Pégase - CS 70071 F-67841 Entzheim Tel. 03.88.10.16.20 Fax 03.88.10.16.46 www.ates-mhz.com

exterior Venetian blinds, awnings and shading systems, insect screens

Panel blinds, roller blinds, vertical blinds, Roman blinds, pleated blinds, Venetian blinds, curtain rods, curtain rails,

MHZ COMPLETE RANGE IMade-to-measure solutions

We would be pleased to advise you:

07-0056-664 / 02.2018 - FA

Other manuals for R 03

2

Table of contents

Other MHZ Window Blind manuals

Popular Window Blind manuals by other brands

paramondo

paramondo 1000016155 Assembly instructions

Hyman

Hyman Radiance 1108117 manual

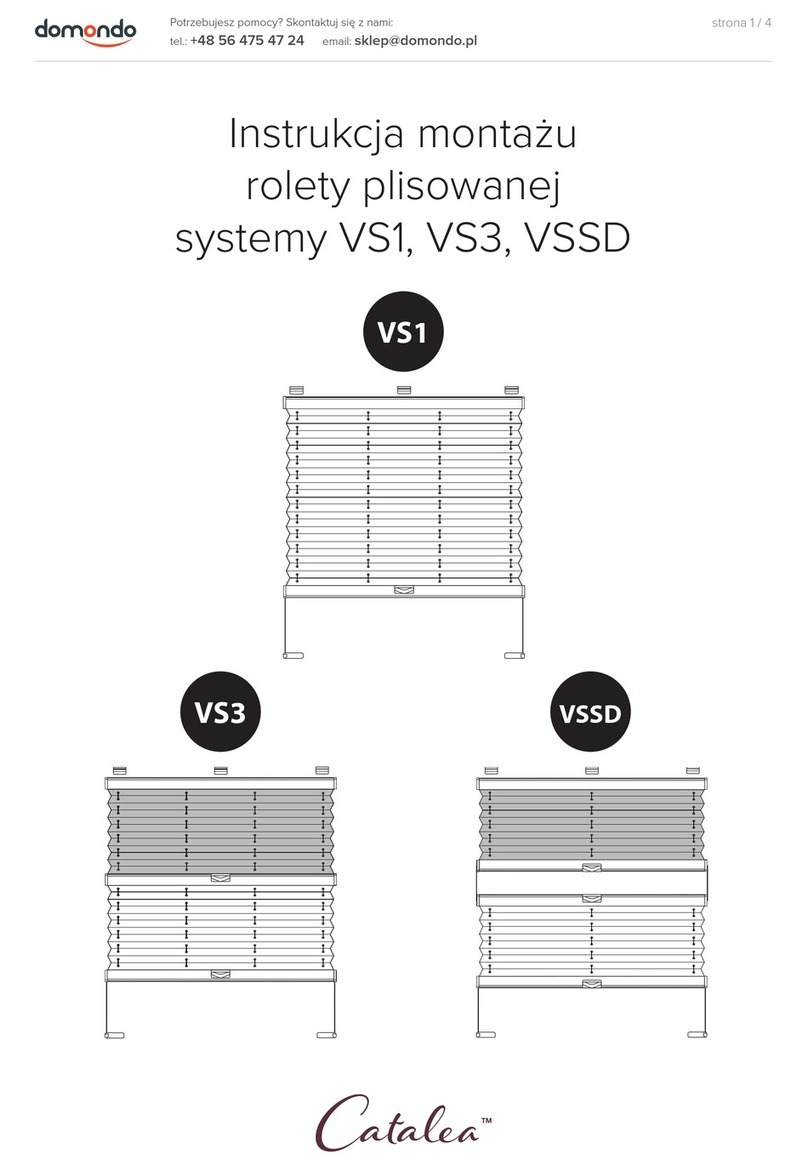

Catalea

Catalea VS1 installation instructions

Benthin

Benthin RS01 Guide

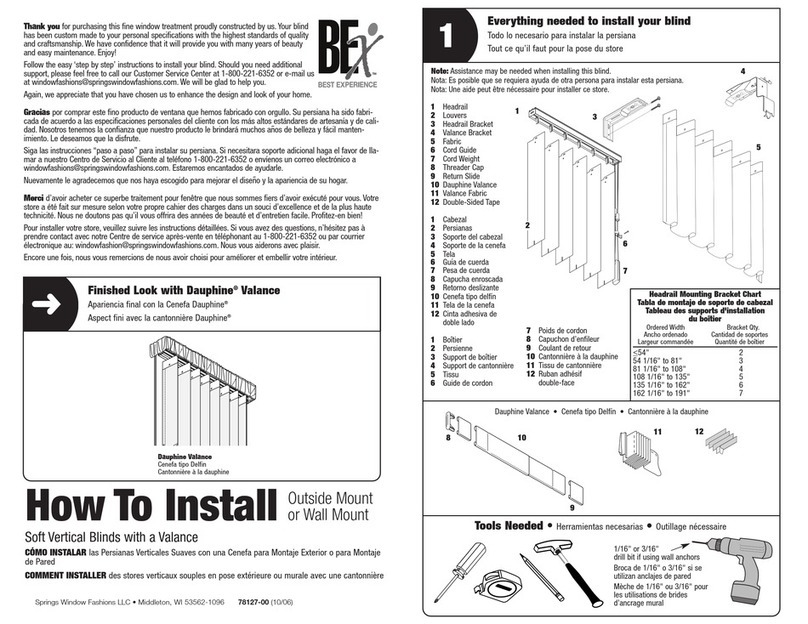

BEST EXPERIENCE

BEST EXPERIENCE Springs Window Fashions Soft Vertical Blinds with a... How to install

LEHA

LEHA DUPLEX Installation and instruction manual

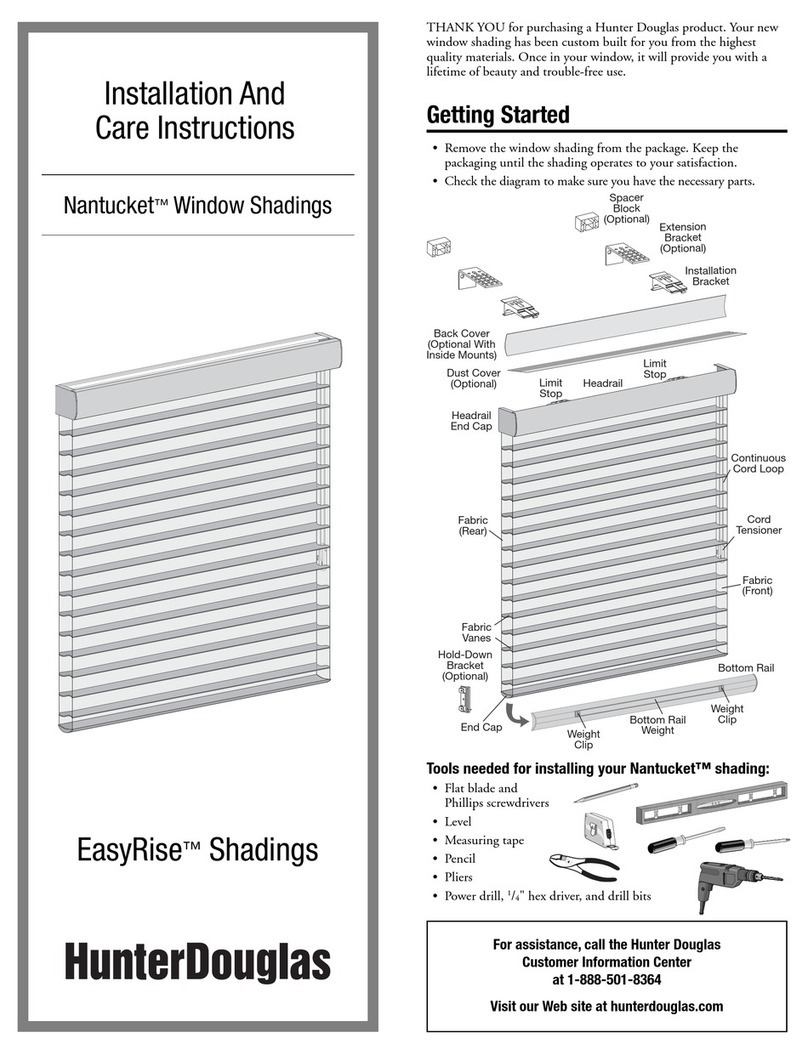

HunterDouglas

HunterDouglas LiteRise Installation operation care

Silent Gliss

Silent Gliss DUETTE Care Instructions

HunterDouglas

HunterDouglas Nantucket EasyRise INSTALLATION AND CARE INSTRUCTIONS

HunterDouglas

HunterDouglas LiteRise INSTALLATION AND CARE INSTRUCTIONS

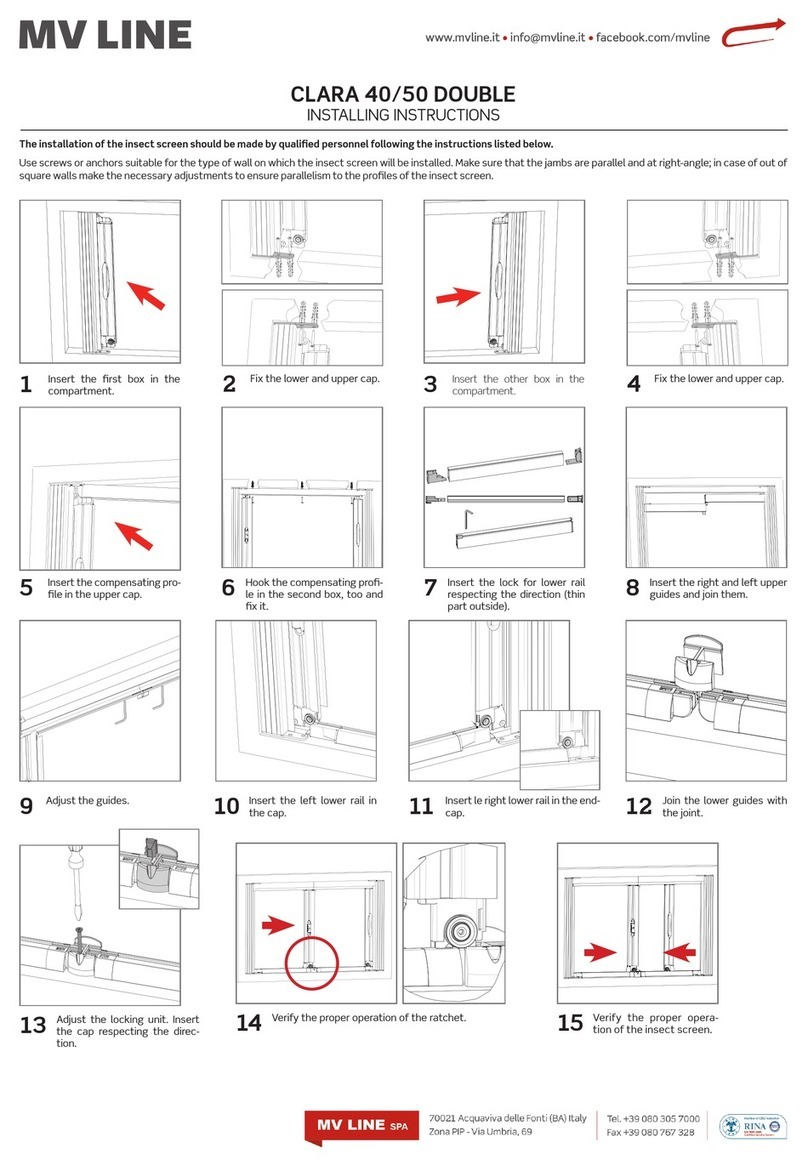

MV LINE

MV LINE CLARA 40 DOUBLE Installing instructions

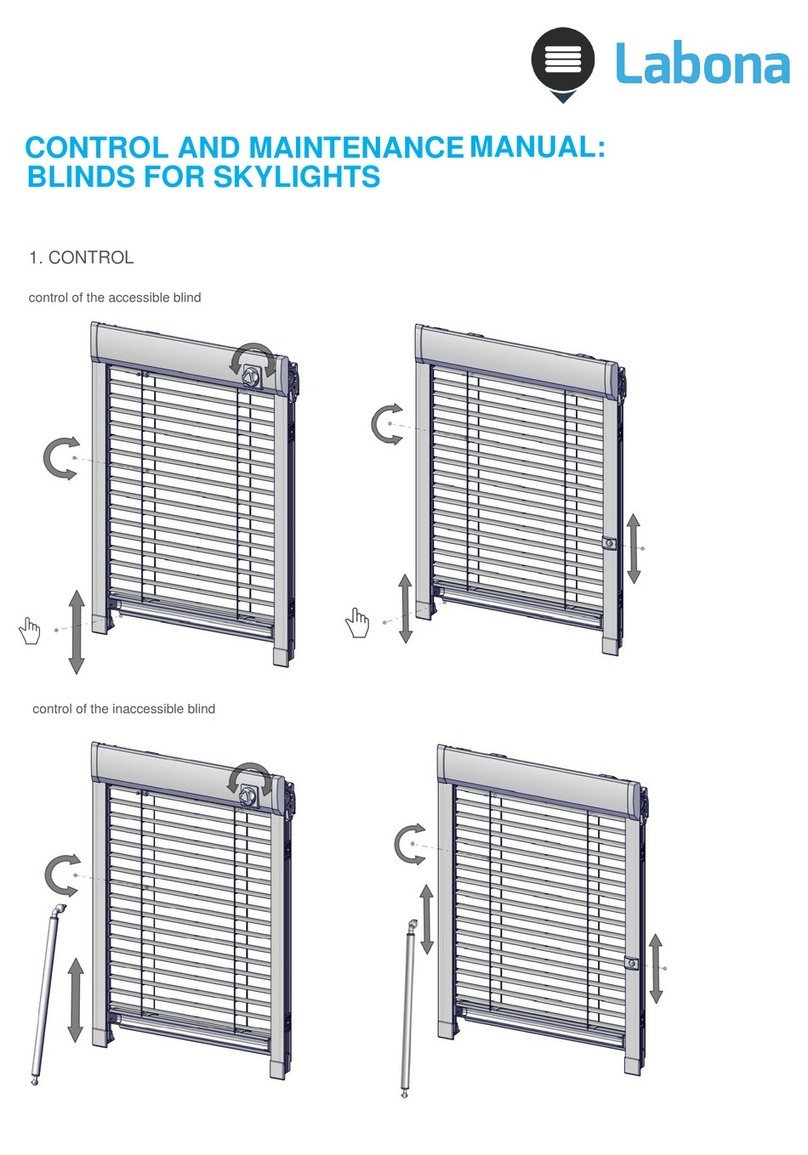

Labona

Labona V-LITE CONTROL AND MAINTENANCE MANUAL