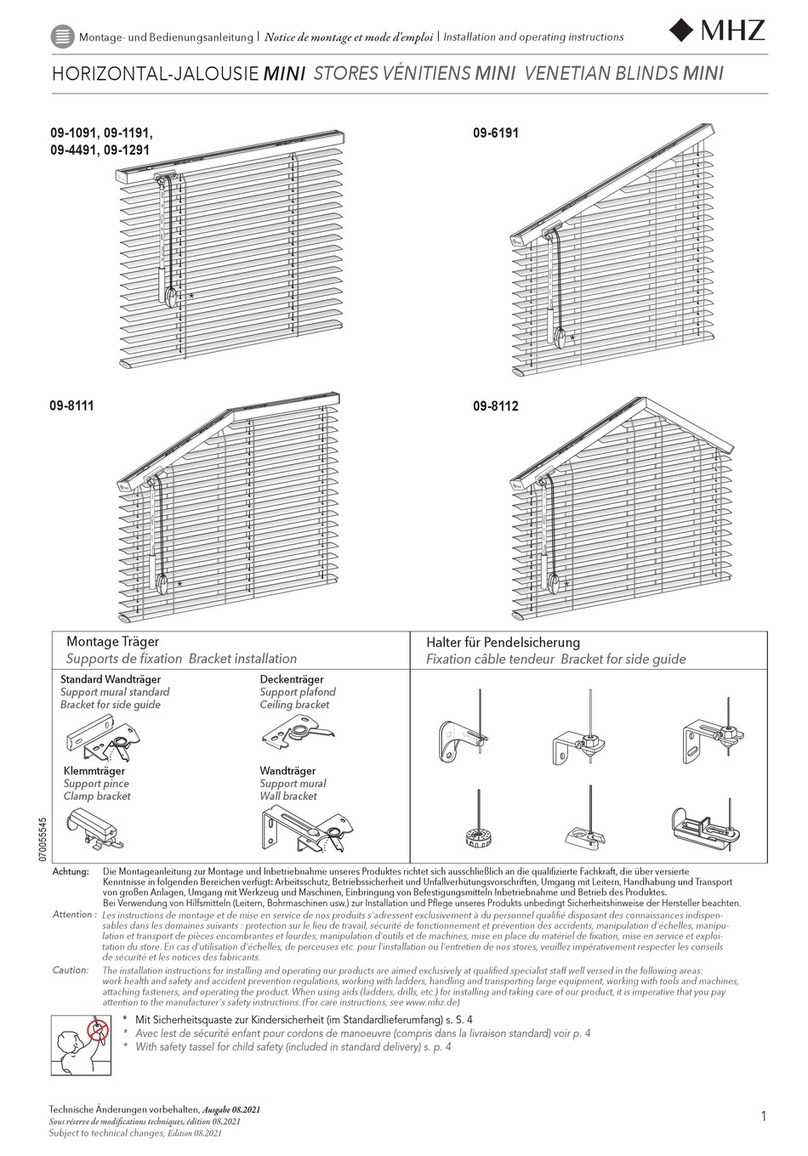

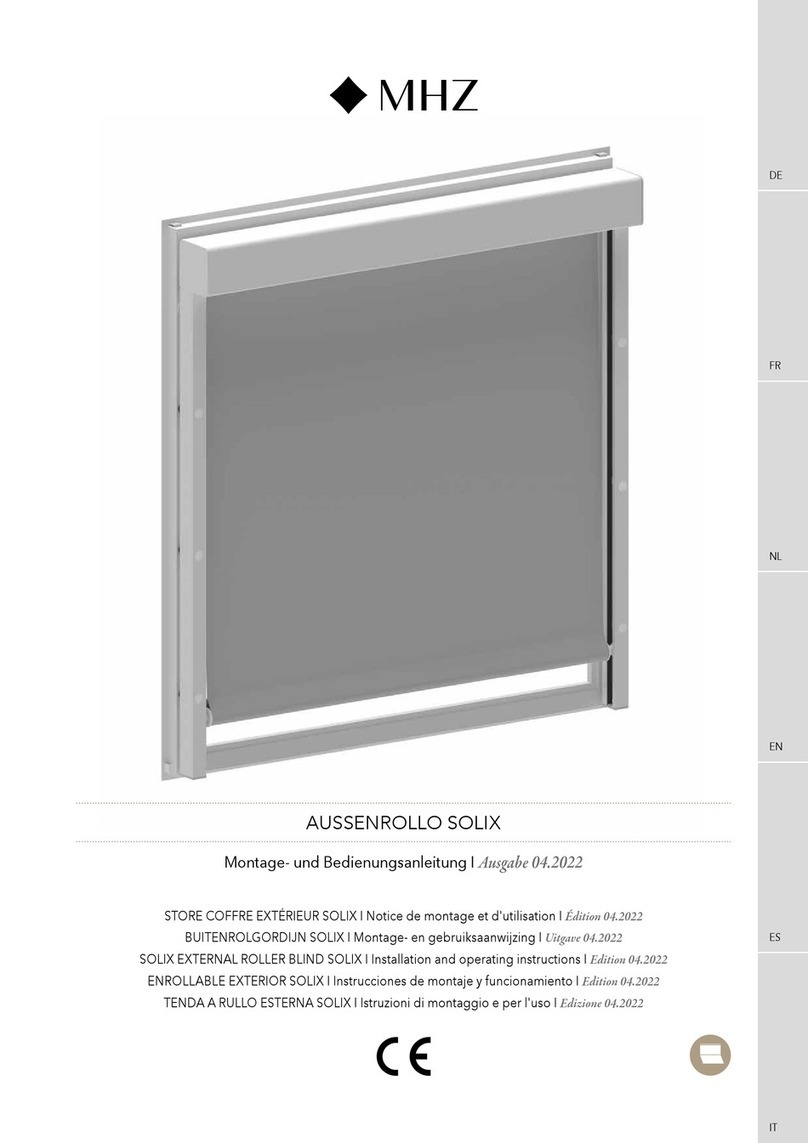

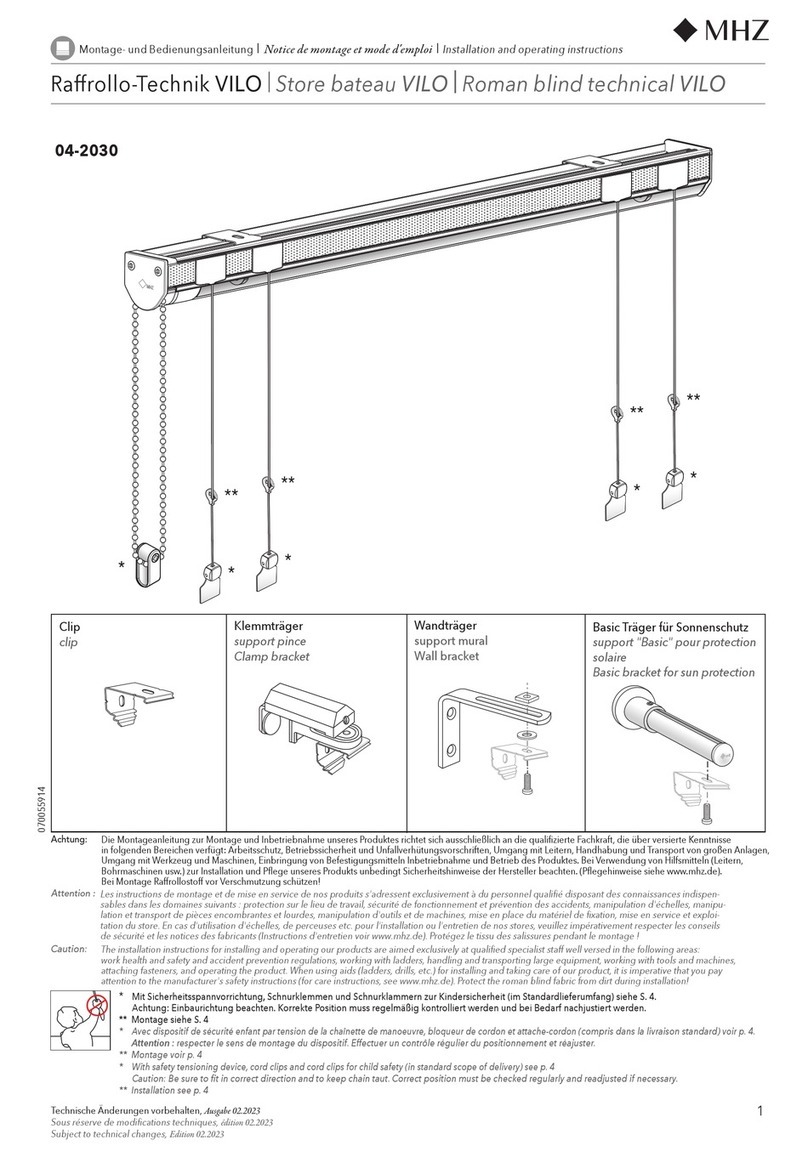

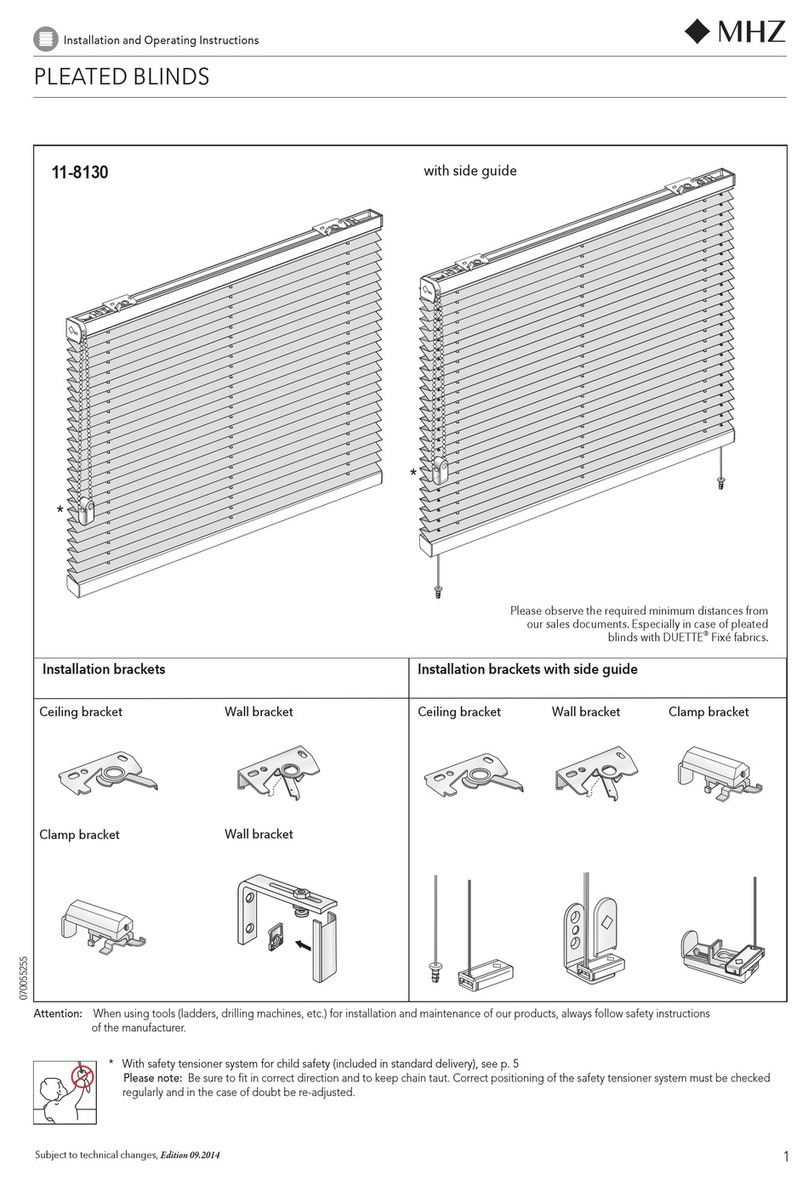

MHZ s-enro SE 72/1 User manual

Metal blind s_enro SE 72/1, SE 72/2

Installation instructions I Edition 03.2022

Page 2 Subject to technical changes I Edition 03/2022

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Table of contents

Safety information for the installation 3 - 6

Installation instructions 7 - 21

Record of delivery 23

Page

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Page 3Subject to technical changes I Edition 03/2022

1. Reading the installation and operating instructions

The installation and operating instructions must be read prior

to installation and then duly followed. Any failure to do so absolves

the manufacturer of any liability.

1.1. Safety and warning notes for the installation instructions

Safety notes can be found throughout the text. They are marked

with various symbols and text:

Important safety note:

Notes that are important for the functioning of the product and can

result in serious injury or death if they are not observed are marked

with this warning triangle.

Important safety note:

Notes that are important for the functioning of the product and

that represent a risk of electrocution that can result in serious injury

or death if they are not observed are marked with this warning

triangle.

2. Qualications

These installation instructions are aimed exclusively at qualied

installers with extensive knowledge in the following areas:

n Health and safety at work and accident prevention regulations

n Working with ladders and scaffolding

n Handling and transporting long, heavy components

n Working with tools and machines

n Attaching fasteners

n Assessing the building fabric

n Commissioning and operating the product

In the absence of any of these qualications, a specialist

installation company must be employed to install the product.

Electrical work:

The permanent electrical installation must be carried out by a

qualied electrician in accordance with statutory and local regula-

tions (VDE 100). The enclosed installation instructions for the electri-

cal devices supplied with the product must be followed.

The unit is to be protected with an upstream

FI circuit breaker in accordance with VDE regulations.

3. Goods receipt

The delivery must be inspected immediately upon receipt for any

damage sustained in transit. In addition, the contents of the ship-

ment must be checked against the delivery note.

4. Transport

The permissible axle loads and the permissible total weight of

the means of transport must not be exceeded. Loading can affect

the vehicle’s handling.

The goods being transported are to be tied down and properly

secured. The metal blind packaging must be kept dry.

Wet packaging may disintegrate, causing accidents. Packaging

opened for the purpose of inspecting incoming goods must be

properly taped up again for further transportation.

After unloading, the metal blind should be transported to the

installation site right-side-up and in the proper installation posi-

tion, so that it will not have to be manoeuvred later in tight spaces.

Attention must be paid to the note on the box indicating position

and side.

5. Lifting with ropes

If the unit needs to be lifted to a higher position using ropes,

the metal blind should be

n taken out of the packaging,

n fastened to the hoisting ropes in such a way that it cannot

slip off

n and lifted smoothly in a horizontal position.

The same applies to taking down the metal blind.

6. Installation

Prior to installation, check the load-carrying capacity of the

sub-construction.

It is important to check the structural properties of the glass facade

construction prior to installation. In addition, ensure that the

fastening screws are screwed directly into the supporting structure

and that, in the event of wind, there is no connection to the glazing

bead, as this could result in stress cracks. If this is not feasible, the

installation must not be performed.

If there is any doubt, the manufacturer of the glass facade construc-

tion must be consulted.

Important safety information for the installation

!

!

!

!

!

!

!

Page 4 Subject to technical changes I Edition 03/2022

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Caution:

Supplied without ttings (accessories).

The installer must select ttings that are suitable for the particular

sub-construction.

The installer is solely liable for ensuring that the ttings are suitable

for the respective brickwork and that the installation work is per-

formed properly. The respective installation notes from the manu-

facturer of the glass facade construction must be adhered to!

7. Fasteners

The metal blind fulls the requirements of the wind resistance

class specied in the CE conformity mark (see operating instruc-

tions). When installed, these requirements are only met if:

n The metal blind is installed using the type and number of

brackets recommended by the manufacturer

n The metal blind is suitably mounted to the sub-construction

n The wind resistance class to be achieved depends on the

installation substructure and unit width

n The conditions to be complied with to ensure that the perfor

mance specications are fullled are based on static loads and

do not take account of any dynamic effect of repeatedly

applied loads (turbulence) to which the metal blind and frame

are exposed during actual use. The static pressure can there

fore not be used to determine how to anchor the metal blinds

to the building.

Maximum permissible wind speed at which the unit can be used

Resistance to wind load

The wind classes dened by DIN EN 13659 do not permit any con-

clusions to be drawn on usability (extending/retracting, intermedi-

ate positions, etc.) under actual wind loads. The manufacturer must

therefore dene the maximum speed above which the metal blind

must be retracted taking into consideration the installation situation

and the blind clearance. This wind speed must be stated in the tech-

nical documentation (e.g. operating instructions). The conditions to

be complied with to ensure that the performance specications are

fullled are based on static loads and do not take account of any

dynamic effect of repeatedly applied loads (turbulence) to which

the metal blind and frame are exposed during actual use. The static

pressure can therefore not be used to determine how to anchor the

metal blinds to the building.

The substructure/distance to the facade/height/corner situation

also has an inuence on the maximum possible wind speed and

is not taken into account in the standard (DIN EN 1932:2013-09

External blinds and shutters – Resistance to wind loads – Method

of testing and performance criteria) although these factors have a

signicant impact on the product’s resistance to wind loads.

Note regarding applicability

The wind speeds used in the following table only apply with win-

dows closed and not in corner situations. Similarly, the positioning

and number of wind monitors used are of vital importance in se-

lecting the appropriate wind speed for the building in question. In

particular, the building’s geometry and location must be taken into

consideration. For this reason, it is essential to consult the specialist

planner in such situations.

Maximum wind speed at which the unit can be used in m/s

Note:

Please note that the specications on the maximum wind speed at

which the unit can be used relate to installation as intended directly

on the facade. In the case of installation options deviating from the

above, please contact MHZ for the necessary specications.

Important safety information for the installation

!

Unit width (mm)

Unit

height

(mm)

1000

1500 2000 2500

1000 16 16 16 12

1500 16 16 16 12

2000 16 16 16 12

2500 16 16 16 12

3000 16 16 14 10

3500 14 14 14 10

* The wind resistance class depends on the application width.

The declared performance applies only to the product.

After installation, the installation base may result in a lower

performance.

Wind resistance class:

Class 3 up to max. 11,9 m/s or up to max. 43 km/h

Class 4 up to max. 16,1 m/s or up to max. 58 km/h

MHZ Hachtel GmbH & Co. KG

Sindelfinger Straße 21, D-70771 Leinfelden-Echterdingen

Germany

2021

LE-013/2

EN 13659:2004+A1:2008

s_enro SE 72/1, SE 72/2, Modell 48-1182

CE product marking

External installations on buildings

and other structures

Wind resistance *:

Units up to 2000 mm width = Class 4

Units up to 2500 mm width = Class 3

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Page 5 Subject to technical changes I Edition 03/2022

!

!

!

!

!

!

8. Climbing aids

Climbing aids must not be attached to or leant against the

metal blind. They must be steady and provide adequate grip. Use

only climbing aids with a sufciently high load-bearing capacity.

Only approved climbing aids (ladders) may be used.

9. Fall protection equipment

There is a risk of falling when working at height.

Appropriate fall protection equipment must be used.

10. Electrical connection

The metal blind may only be connected if the

electric drive’s specications match the electricity source (see oper-

ating instructions).

The installation notes included with the electrical components must

be followed.

The unit is to be protected with an upstream

FI circuit breaker in accordance with VDE regulations.

Only cables and connectors with a minimum protection class

of IP 54 should be used to supply power.

11. Intended use

Metal blinds should only be used for the purpose dened for

them in the operating instructions.

Changes, such as attachments and modications, not intended by

the manufacturer may only be carried out with the manufacturer’s

written consent.

Applying additional loads to the metal blind by attaching objects

can result in it becoming damaged or falling down and is therefore

not permitted.

12. Unsupervised operation

When working within the metal blind’s range of motion, the

automatic control must be turned off. There is a risk of crushing or

falling.

In addition, it must be ensured that the unit cannot be unintention-

ally manually operated. For this purpose, the power supply must

be cut, e.g. take out the fuse or disconnect the plug coupling on

the motor.

If the metal blinds are operated by several users, a priority locking

system (externally controlled circuit breaker) must be used, which

makes any retraction and extension of the metal blind impossible.

!

13. Trial run

The rst time the unit is extended, no one is permitted to be

in the metal blind’s range of motion or underneath it. A visual check

must be made of the fasteners and brackets after the unit has been

extended for the rst time.

For trial runs never use automatic controls or switches from which

the operator has no view of the metal blind (there is a risk of it start-

ing to move unintentionally). The use of a test cable to connect the

motor is recommended.

The installation and adjustment instructions included with the metal

blind from the manufacturers of the motor, switch and control must

be followed.

14. Crush and shear zones, plus sharp-edged parts

To avoid injuries, the end positions of the drive must be adjust-

ed in line with the on-site conditions, where applicable.

There are crush and shear zones between the drop bar, case

covers and around the side guide rails. Caution! Risk of injury!

Limbs and clothing can potentially get caught up, crushed or pulled

in by the unit!

If the metal blind is being tted at a height of less than 2.5 metres

above accessible thoroughfares, the metal blind may only be oper-

ated by a push-button switch within sight of the moving parts.

Electrical controls, radio drives with lock switches, lock switches, etc.

are not permissible in this case.

Any long parts taken off, e.g. covers or guide rails, may have

sharp edges (caution – risk of injury/cuts).

!

!

!

!

Important safety information for the installation

Page 6 Subject to technical changes I Edition 03/2022

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

15. Handover

All operating instructions, as well as the installation and adjust-

ment instructions issued by the motor, switch and control manufac-

turers, are to be handed over to the user with appropriate training.

The safety information and information on use relating to the metal

blind must be explained in full. Failure to follow the instructions or

any incorrect operation can cause accidents and damage to the

metal blind.

All instructions are to be kept by the customer for future reference

and must be passed on to the new owner if the metal blind is sold.

Based on knowledge of the particular conditions at the site and

the nished installation, the installation company will tell the user

whether the wind resistance class specied by the manufacturer

has been achieved in the installed condition. If not, the installation

company must document the wind resistance class actually

achieved.

Recommendation:

If you are the installer, have the metal blind’s correct installation and

set-up,the time of installation and details of the acceptance meet-

ing, including that you explained the safety information, conrmed

in writing. The MHZ record of delivery can be used for this purpose

(see p. 23).

Important safety information for the installation

!

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Page 7Subject to technical changes I Edition 03/2022

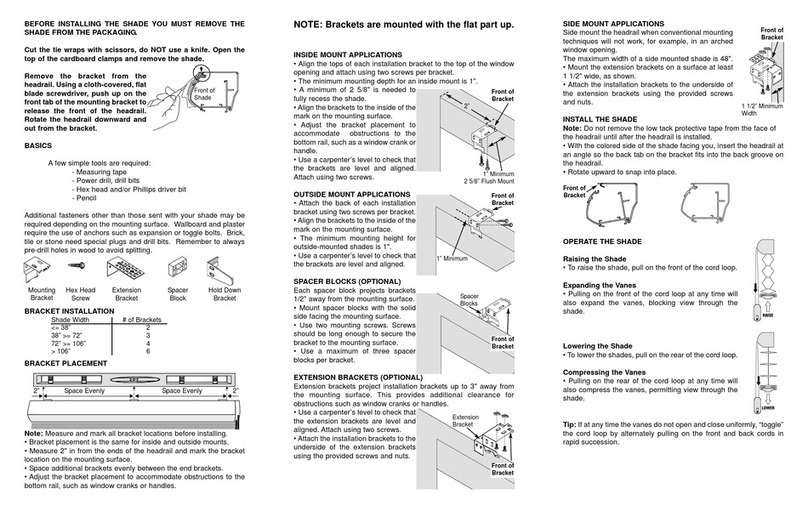

Inspect the delivery for any damage

sustained in transit right away. The

contents of the shipment must be

checked against the specications in

the delivery note.

Caution: Supplied without ttings.

The installer must choose ttings suita-

ble for the installation substructure.

Inspection of the sub-construction:

It is important to check the strutural

properties of the

glass facade con-

struction

prior to installation.

In addition, ensure that the fastening

screws are screwed directly into the

supporting structure and that, in the

event of wind, there is no connection

to the glazing bead, as this could result

in stress cracks.

If there is any doubt, the manufacturer

of the glass facade construction must

be consulted.

Operating note:

A metal blind provides sun protection

– it is not a shield for all forms of weath-

er. If there is a strong wind, ice or snow,

it must be retracted.

If the metal blind is equipped with an

automatic control (e.g. wind and sun

sensor), this must be switched off over

the winter (risk of freezing).

Give the user of the metal blind the

accompanying operating instructions

and explain to them in detail all the

information on metal blind use and

safety.

MHZ metal blinds are largely mainte-

nance-free. If any faults do arise, notify

your specialist retailer.

Installation aids:

- Drill

- Spirit leve

- Allen keys size 3, 4 and 5mm

- Ring spanners A/F 10 and 13

- Tape measure

- Safety knife

- Adjustment cables for elero drives

(item no. 99-1085)

The drive settings are not applied at

the factory. Please refer to the instal-

lation

and operating instructions provided by

the motor manufacturer for the setting

options.

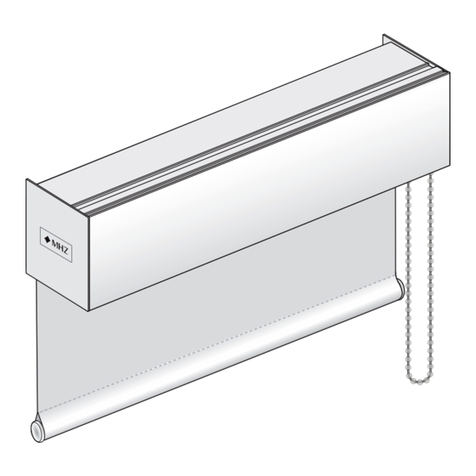

1. Sword-shaped bracket

2. Side plate

3. Guide rail 45x37

4. Wall bracket

5. Metal blind

6. Deection tube

7. Drop bar with guide slider

8. Cover

9. End cover

10. Hirschmann plug coupling

with holder

7

98

2

34

56

1

10

Page 8 Subject to technical changes I Edition 03/2022

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Technische Daten

Unit width:

From 800mm to 2500mm

Unit height:

From 650mm to 2501mm

Cover:

Width: 227mm

Height: 285mm

Unit width:

From 800mm to 2500mm

Unit height:

From 2501mm to 3500mm

Cover:

Width: 267mm

Height: 330mm

SE 72/1 SE 72/2

Unit height max. 2500 mm

Unit height max. 3500 mm

Unit width

Unit width

Grid width

Grid width

Light measurement between

the sword holders

Light measurement between

the sword holders

Light measurement between

the sword holders

Light measurement between

the sword holders

Grid width

Grid width

Unit width

Unit width

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Page 9 Subject to technical changes I Edition 03/2022

1. Installation of sword-shaped bracket

Position the sword-shaped brackets (1)

Installation example uses on-site threaded bolts.

The metal blind is supplied without ttings.

The sword-shaped brackets must be exactly aligned

vertically and horizontally.

Permissible dimensional tolerance for the clear unit width

between the sword-shaped brackets: +/-2mm

Clear system width

!

1

Page 10 Subject to technical changes I Edition 03/2022

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

2. Montage hintere Abdeckung

Before installing the rear cover (12), you must push the on-

site cable through the cable grommet.

Then push the cable grommet (13) and cable into the recess

in the cover (see detail drawing).

Install the cover and then connect the Stak 3 Hirschmann

coupling. Cable length approx. 40cm.

From the outside, fasten the rear cover (12) to the saddle

at the back (11) of the left and right sword-shaped bracket

(1) with 2 x M5x8 hex bolts and ø5.3 U-washers (14) in each

case.

approx. 40 cm

12

11

1

111412

13

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Page 11Subject to technical changes I Edition 03/2022

Clear guide rail dimension =

system width - 102 mm

Permissible dimensional deviation

+/ - 2 mm

The wall brackets must be pre-mounted prior to installation

of the guide rail 45x37 (3) on the sword-shaped bracket.

Use an M6x25 threaded pin, ø6.4 U-washer and M6 hexagon

nut (15) to bolt the wall brackets (4) to the M6 square nuts

(16) already located in the guide rail (see detail drawing).

Pay attention to measurement X and the distance be-

tween the wall brackets (see also the table).

Measurement X = max. 150mm

Secure the cable in the cable clamp pre-mounted on the side

plate.

Once completed, the guide rails 45x37 (3) are fastened

to the sword-shaped brackets using 1 x M6x12 hex bolt, ø6.4

U-washer and ø6 spring washer (17) inserted through the

drill holes on the mounting bracket (18) in each case.

The guide rails must be exactly aligned vertically and

parallel to one another.

max. 1500 mm

X

max. 1500 mm

3. Installation of guide rail 45x37 on sword-shaped bracket

15

3

16

!

18

Unit heightNumber of wall brackets

per guide rail

Up to 2500mm 2

From 2501 to 3500mm 3

4

17

!

3

Cable clamp

Page 12 Subject to technical changes I Edition 03/2022

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

4. Installation of side plates with blind tube

Push the side plates (2) with blind tube (19) from the front

into the grooves of the support bars (20).

Motor installed on right

Check whether the installed position of the side plates with

blind tube is correct:

- At the side plates, the slots open at the top must

point upwards (see detail drawing)

- The motor cable outlet must point vertically downwards

Motor installed on left

Check whether the installed position of the side plates with

blind tube is correct:

- At the side plates, the slots open at the top must

point upwards (see detail drawing)

- The motor cable outlet must point vertically downwards

2

19

20

Illustration

without blind

Illustration

without blind

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Page 13Subject to technical changes I Edition 03/2022

21 1

150

150

210

210

150x150 side plate Up to 2500mm unit height

210x210 side plate From 2501mm unit height

upwards

INFORMATION: The procedure for installation of the

210x210mm side plates (with stailess-

steel adapter plates) is identical to the

150x150mm side plates shown in the

instructions

Next, x each of the side plates to the sword-shaped

brackets (1) using 4 x M6 hex bolts (21).

150x150 side plate: M6x12 hex bolts

210x210 side plate: M6x10* hex bolts

*The bolts used to install the 210x210 side plates need to be

shorter, otherwise they will collide with the end cover.

Fasten the motor cable in the second cable clamp

pre-mounted on the side plate to avoid a stripe on the blind.

Connect the adjustment cable.

Use the adjustment cable to move the blind into a position

where the drop bar is at around 45° at the back and cannot

fall forwards and down when the stretch lm (22) is removed.

Cable clamp

22

Page 14 Subject to technical changes I Edition 03/2022

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

5. Removal of stretch lm packaging from the blind tube

You must take the utmost care when removing the stretch

lm.

n Never use a box knife to cut the lm.

n Cut with the safety knife supplied (23) to avoid damaging

the blind.

n It is best to make the cut at the drop bar.

n Remove the lm from the blind carefully (do not rip it or

pull it away with force).

n Remove the yellow adhesive tapes (24) and the foam piec

es carefully.

Example of a safety knife

23

24

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Page 15 Subject to technical changes I Edition 03/2022

6. Procedure for blind

Slowly insert the blind into the guide rail on the left

and right (approx. 10cm).

!When it is being inserted, make sure the blind does not

move to either side. It must be inserted into the guide rails in

a central position.

5 mm 5 mm

Insertion

groove,

drop bar

adapter

Insertion

groove,

drop bar

adapter

Blind with

drop bar

Page 16 Subject to technical changes I Edition 03/2022

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

7. Installation of deection tube

Position each mounting bracket for the deection tube

assembly (25) on the sword-shaped bracket (1) using 1 x

M6x12 hex bolt, ø6 spring washer and ø6.4 U-washer (17).

Make sure that the lateral tip of the mounting bracket for the

deection tube (25) snaps into the recess in the mounting

bracket for the guide rail (18) (see detail drawing).

Check that the roller blind tube is in a horizontal position.

Adjust as necessary using the M6x30 threaded pin (27) locat-

ed in the end position side plate (26).

25

2518

17

1

Allen key size 3

26

27

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Page 17Subject to technical changes I Edition 03/2022

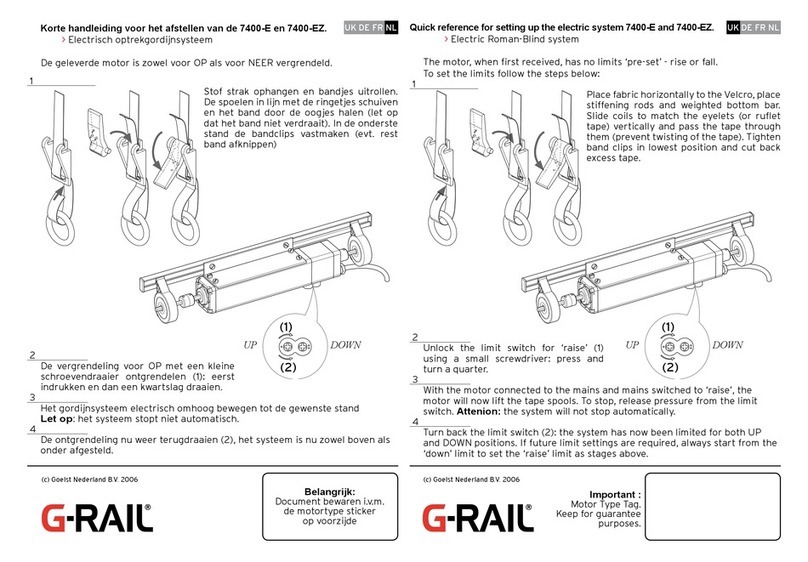

8. End position adjustment

Top end position adjusted to torque with strain relief, bottom

end position adjusted freely

Please follow the programming procedure in full and in the

order stated here.

nMove the blind and the installation cable into a central

position.

nPress the UP pand DOWN buttons qsimultaneously to

set the drive to its factory setting.

The motor signals that this has happened by initiating an

UP/DOWN movement.

nPress the UP button p: the drive moves approx. 20–50cm,

stops briey, then continues to move.

Use the UP button pto move the blind as far as the upper

stop (deection tube).

The drive now switches off based on torque.

Keep the UP button ppressed and, from this position,

press the DOWN button too quntil the drive stops auto

matically when moving downwards.

The top end position incl. strain relief function is set for

the blind.

nPress the DOWN button qagain.

Move it to just before the bottom end position (bottom

edge of the drop bar approx. 15mm above the piping

clip).

You can use the UP/DOWN buttons pqto make any

corrections.

From the specied end position, press the UP button p

until the drive stops.

The bottom end position is now set.

nThe end position adjustment is hereby complete.

The adjustment mode ends after the two end positions

have been set.

nSecond trial run

nDoes the blind move and wind without any problems?

Please check!

nRaise/retract the blind.

Note:

You can reprogram the end positions by repeating points 1

and 2 to restore the motor to its factory setting.

Top end position

Bottom end position

15 mm

Page 18 Subject to technical changes I Edition 03/2022

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Fasten the plug coupling holder (28) to the sword-shaped

bracket (1) with 2 x M6x10 cylinder screws and ø6.4 U-wash-

ers (29).

Fit the Hirschmann plug coupling (30) together and fasten it

to the plug coupling holder (28) using the cable ties (31).

3130

28 29

9. Installation of plug coupling holde

28

1

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

Page 19 Subject to technical changes I Edition 03/2022

10. Installation of front cover

The front saddle for fastening must be installed prior to

installation of the front cover.

Attach the front saddle (32) to each sword-shaped

bracket using 5 x M5x8 cylinder screws (33).

Screw the front cover (34) to the left and right front saddle

using 4 x M5x8 cylinder screws and ø5.3 U-washers (35).

Finally, fasten an end cover (9) to the left and right of the

bracing using 4 x M4x6 cylinder screws and ø4.3 U-washers

(36).

33

36

35

34

32

9

Page 20 Subject to technical changes I Edition 03/2022

Installation instructions for metal blind s_enro SE 72/1, SE 72/2

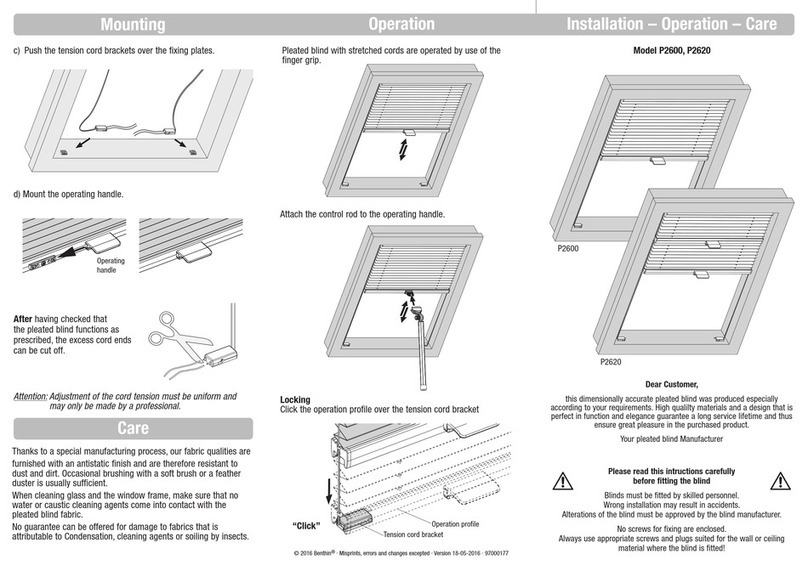

11. Multi-unit systems

The procedure for the installation of multi-unit systems is

essentially identical to the installation of a single-unit system.

When pre-assembling the wall brackets on the guide rails,

the wall brackets for the outer guide rails (3a) are mounted

singly (4a) and the wall brackets for the inner or adjacent

guide rails (3b) are mounted in double (4b).

3a

3a

3b 3b

4b

4a

Grid width

Grid width

Unit width

Unit width

Grid

width

Grid

width

4a

This manual suits for next models

1

Other MHZ Window Blind manuals

Popular Window Blind manuals by other brands

Victoria M

Victoria M SYSTEM VS 2 Original instructions

Diaz

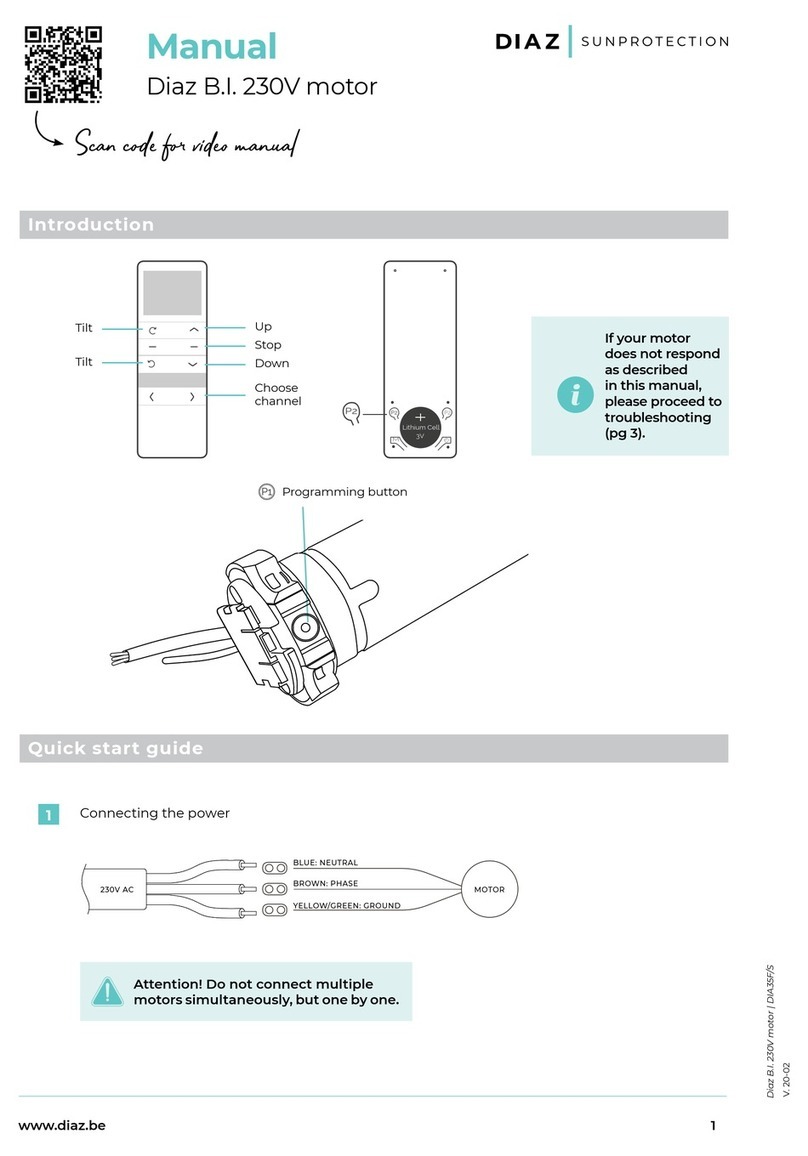

Diaz Diaz B.I. 230V quick start guide

John Lewis

John Lewis Corded roman blind kit manual

Roomy

Roomy Thermo-Rollo Assembly instructions

Gale Pacific

Gale Pacific Coolaroo SOLAR MOTORISED 490904 Assembly & operating instructions

Renson

Renson Fixscreen Minimal installation instructions