946 Controller Instruction Manual pg. 3

7.2 Installing Hot Cathode Sensors.......................................................................... 67

7.2.1 Over Pressure Conditions .......................................................................................................... 67

7.2.2 Locating a Hot Cathode Sensor ................................................................................................. 67

7.2.3 Preventing Contamination in a Hot Cathode Sensor .................................................................. 67

7.2.4 Orienting a Hot Cathode Sensor ................................................................................................ 68

7.2.5 Connecting a Hot Cathode Sensor to the Vacuum System ........................................................ 68

7.2.6 Connecting a Hot Cathode Sensor to the 946 Controller ........................................................... 68

7.3 Installing Convection Pirani, Convectron, or Pirani Sensors ............................... 69

7.3.1 Over Pressure Conditions .......................................................................................................... 69

7.3.2 Locating the Sensor ................................................................................................................... 70

7.3.3 Preventing Contamination in a Pirani Sensor ............................................................................. 70

7.3.4 Orienting the Series 317Convection Pirani or Convectron Sensor ............................................. 70

7.3.5 Orienting the Series 345 Pirani Sensor ...................................................................................... 70

7.3.6 Connecting Convection Pirani, Convectron, or Pirani Sensors .................................................. 70

7.3.7 Preparing the 317 Sensor for Bakeout ....................................................................................... 71

7.4 Installing Capacitance Manometers - MKS Baratron .......................................... 72

7.4.1 Installing a Capacitance Manometer .......................................................................................... 72

7.4.2 Connecting a Capacitance Manometer ...................................................................................... 72

7.5 Series 902B Piezo ............................................................................................. 73

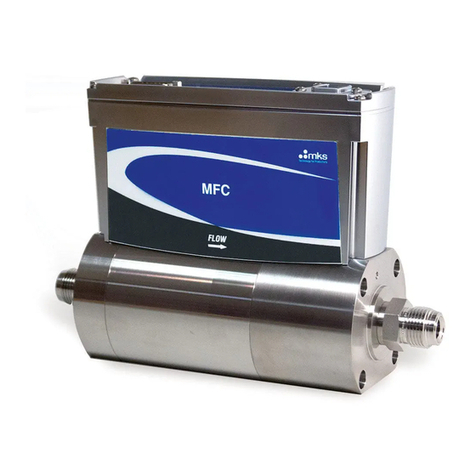

7.6 Installing Mass Flow Controllers ........................................................................ 73

7.6.1 Environmental requirements ...................................................................................................... 73

7.6.2 Interface Cables ......................................................................................................................... 73

7.6.3 Setup .......................................................................................................................................... 74

7.6.4 Gas Line Connections ................................................................................................................ 74

7.7 Installing a Pressure Control Valve .................................................................... 74

7.7.1 Installing an Upstream Solenoid Valve ....................................................................................... 74

7.7.2 Installing a Downstream MKS 153 or T3B Throttle Valve ........................................................... 75

8Connecting Relay and Analog Outputs ..................................................... 77

8.1 Connecting 946 Relay Outputs ...................................................................................... 77

8.1.1 Pin Out for the 946 Relay Output ............................................................................................... 77

8.1.2 Proper Setting of a Relay ........................................................................................................... 78

8.1.3 Relay Inductive Loads and Arc Suppression .............................................................................. 79

8.2 Connecting the 946 Analog Output .................................................................... 79

8.3 Buffered Analog Output ..................................................................................... 80

8.4 Logarithmic/Linear and Combination Analog Output .......................................... 91

8.4.1 Logarithmic/Linear Analog Output .............................................................................................. 91

8.4.2 Combination Analog Output ....................................................................................................... 91

8.4.3 Logarithmic/Linear Analog Output when the Sensor Power is Turned OFF ............................... 93

9RS232/485 Serial Communication Commands ......................................... 94

9.1 Serial Communication Wiring Diagram .............................................................. 94

9.2 Communication Protocols .................................................................................. 94

9.3 Pressure Reading Commands ........................................................................... 95

9.4 Relay and Control Setting Commands ............................................................... 96

9.5 Capacitance Manometer Control Commands .................................................... 97

9.6 Convection Pirani, Convectron and Pirani Control Commands .......................... 97

9.7 Cold Cathode Control Commands ..................................................................... 98

9.8 Hot Cathode Control Commands ....................................................................... 99

9.9 MFC Control Commands ................................................................................. 100

9.10 Pressure (Valve) Control Commands............................................................... 100

9.11 PID Recipe Setting Commands ....................................................................... 101

9.12 Ratio Recipe Setting Commands ..................................................................... 102

9.13 PID/Ratio Control Activation Command ........................................................... 102